A Vibrating Rotary Jet Drill Bit

A vibratory drill bit technology, which is applied in vibration drilling, drill bits, liquid/gas jet drilling, etc., can solve the problems of short service life of the drill bit, hindering the advancement of the drill bit, and large wear of the drill bit, so as to prolong the service life and increase the size of the drill bit. The effect of jet breaking rock area and repairing hole wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

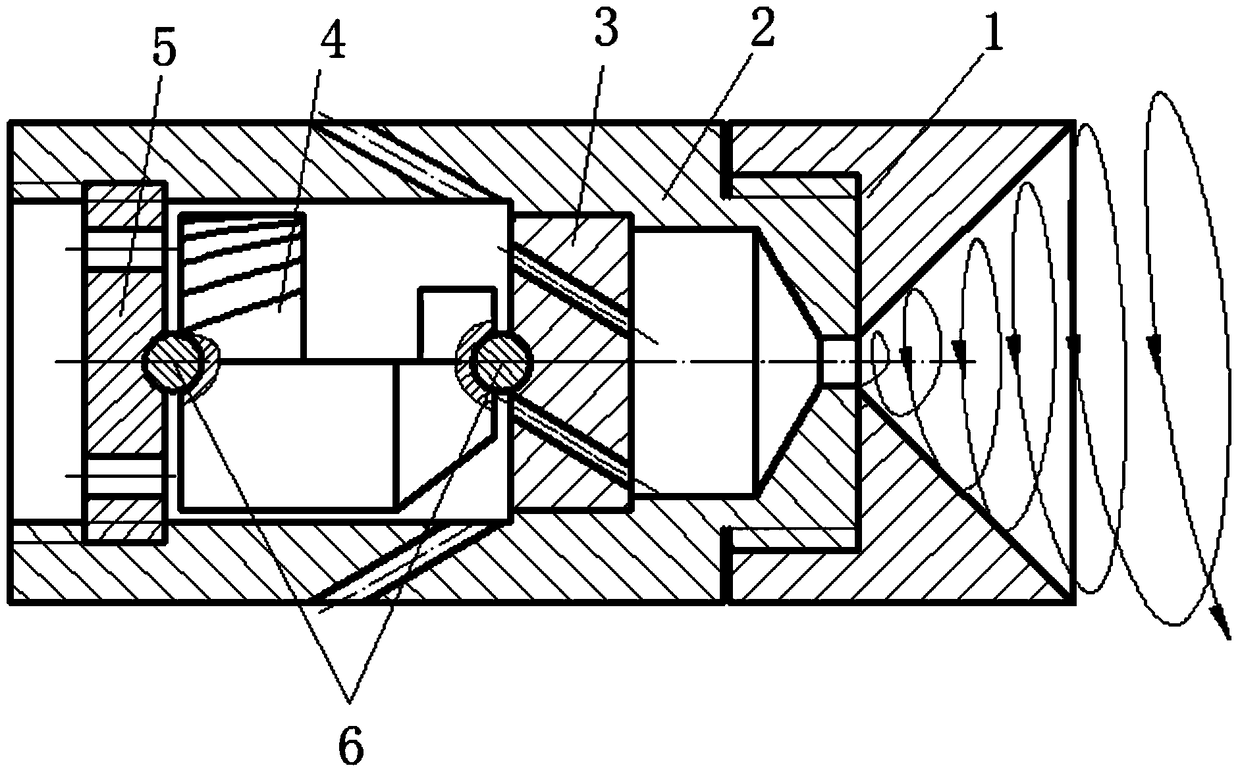

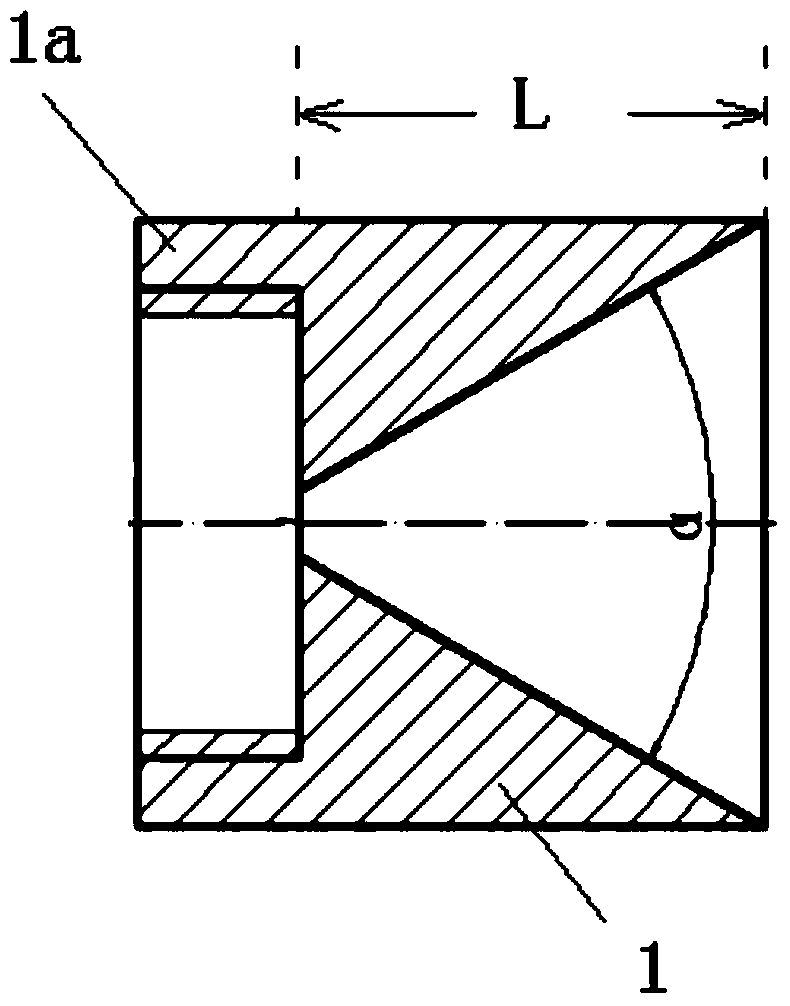

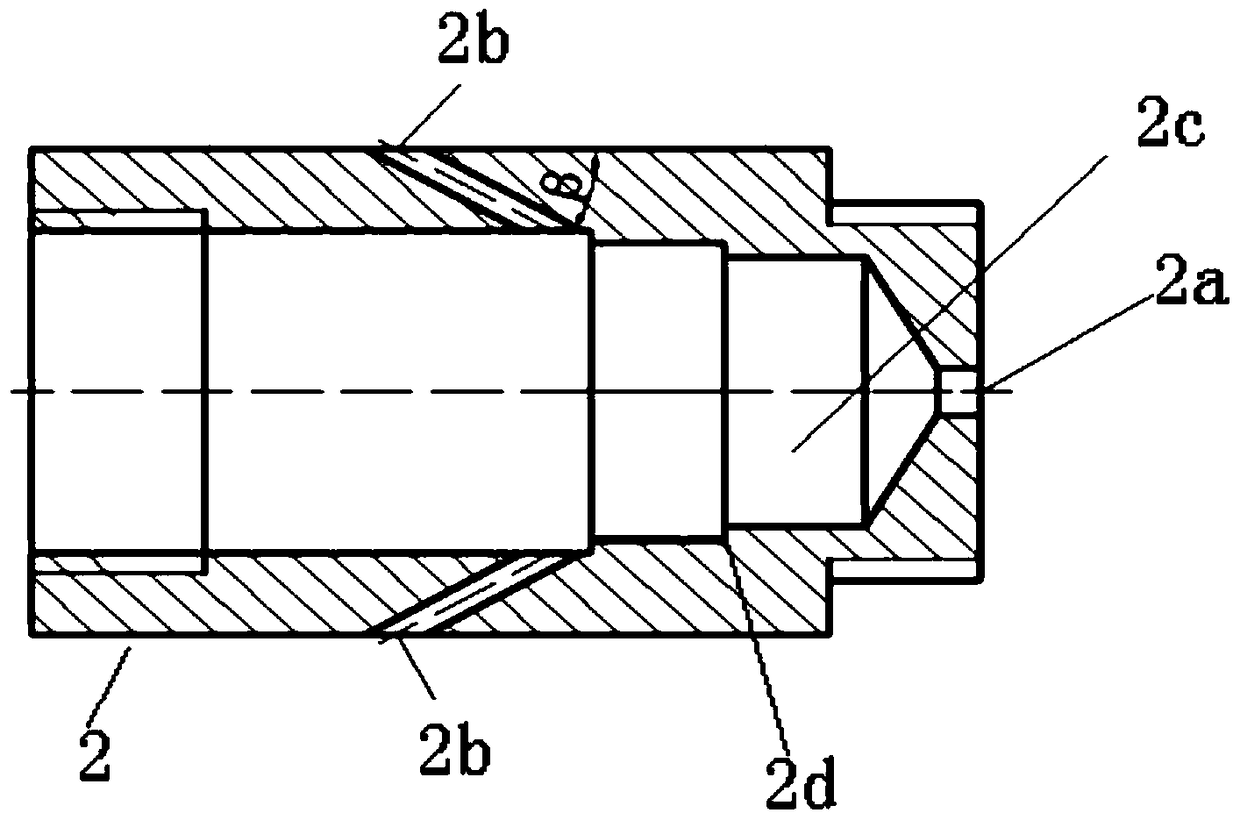

[0055] Connect the vibrating rotary jet bit with the high-pressure hose and place it in the pilot hole drilled in the sandstone. The rock strength is 25MPa, the pump pressure is 40Mpa and the flow rate is 100L / min during operation; the outer diameter of the bit body 2 is 18mm, length 35mm, the diameter of the first nozzle hole 2a is 1.8mm, length is 1.8mm, the diameter of the second nozzle hole 2b is 1.3mm, the number is 3, β is 30°; the diameter of the impeller 3 is 12mm , The thickness is 3mm, the number of first impeller grooves 3a is 6, the width is 0.5mm, and the inclination angle is 30°; the diameter of the eccentric motor 4 is 12mm, the number of second impeller grooves 4a is 5, and the groove depth is 5mm. The inclination angle is 30°; the diameter of the baffle 5 is 13.5mm, the thickness is 3mm, the diameter of the nozzle 5a on the baffle 5 is 2mm, and the number is 4; the cone angle α of the expansion section 1 is 60°. The final measured data is: the drilling speed is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com