CFG pile implanting construction method suitable for composite soft and hard geology

A construction method and geological technology, applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve problems such as difficulty in adapting and solving spinning problems, long auger drilling machine cannot form holes, construction period cannot be guaranteed, etc., and achieves low vibration , The effect of simple construction machinery and equipment, and easy control of sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

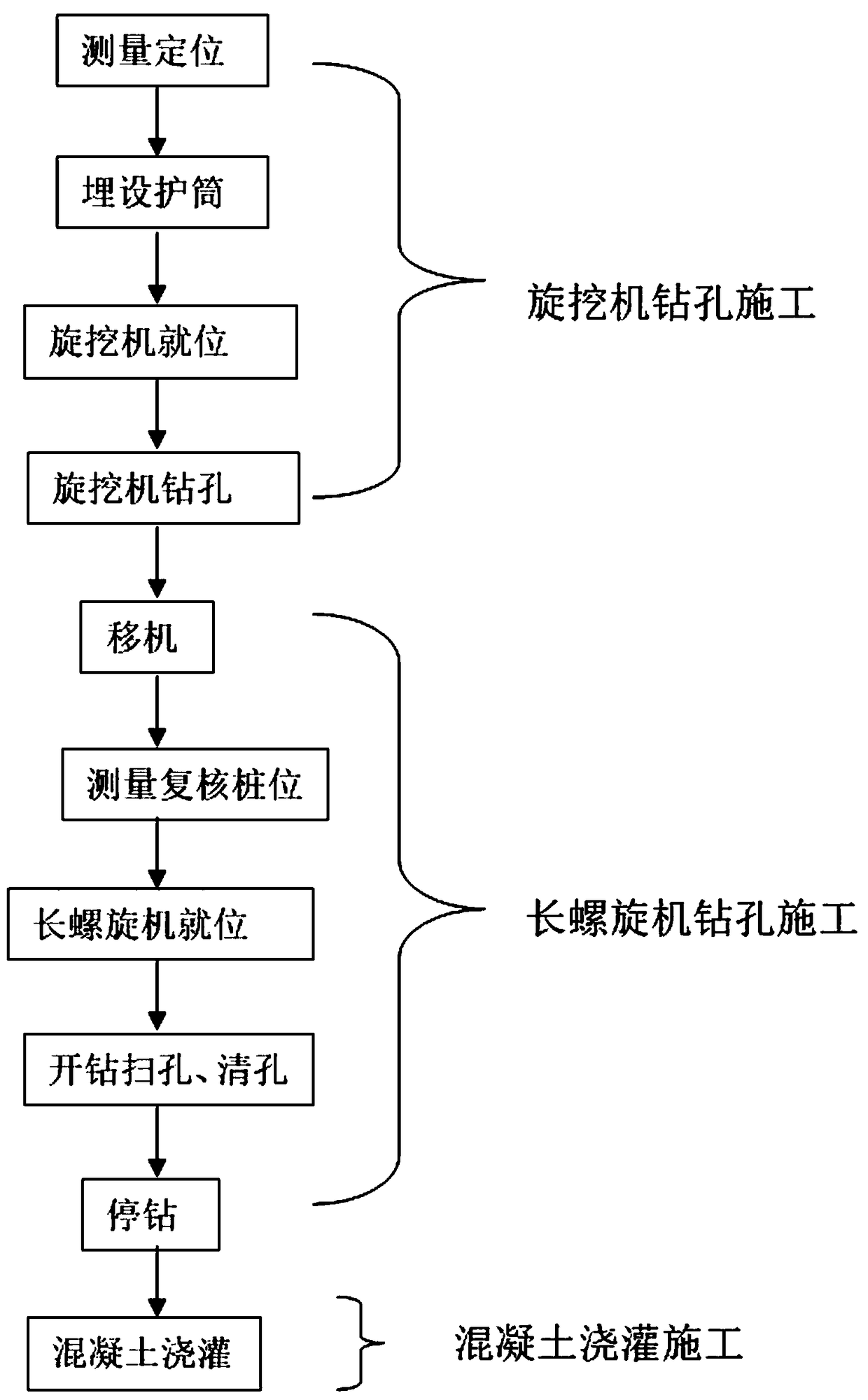

[0028] A CFG pile implantation construction method suitable for composite soft and hard geology of the present invention, first adopts the rotary excavator to drill through the hard stratum, then repeats the long screw machine to drill holes to the design elevation, and finally pours concrete; The interval between the drilling of the rotary drilling machine and the drilling of the long screw machine is controlled within 1 hour.

[0029] Such as figure 1 Shown, the construction method of described rotary excavator drilling comprises the following steps:

[0030] (1) Measurement and positioning: Calculate the coordinate position according to the coordinates of the control points that have been laid out. After leveling the ground near the pile position, use the total station to release the pile position, and use the cross mark to determine the pile position; determine the center point of the pile , measure the elevation of the original ground, set the front, rear, left, and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com