High-pressure jet grouting enlarged footing anchor rod and construction method thereof

A technology of high-pressure rotary grouting and construction methods, which is applied in the direction of excavation, foundation structure engineering, and sheet pile walls, etc., and can solve the problem of not being able to improve the pull-out force of the anchor rod, affecting the pull-out force and quality of the anchor rod, and the pull-out force of the anchor rod No advanced problems, good construction effect, simple construction method and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

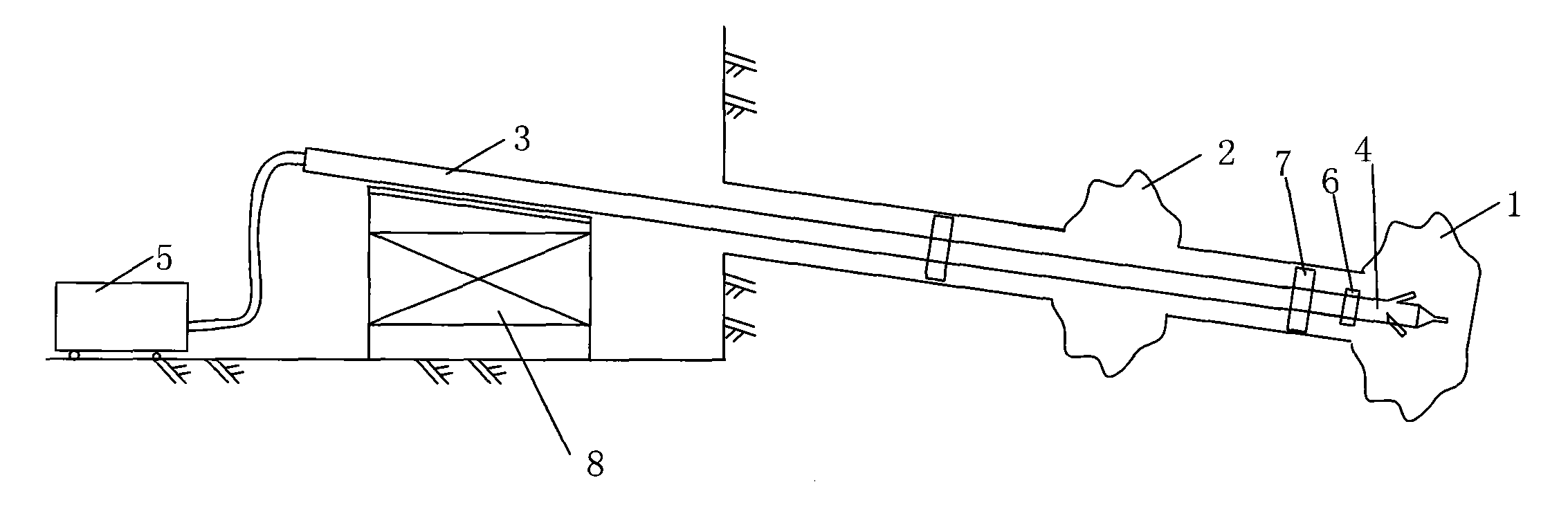

[0043] Such as Figure 6 As shown, the high-pressure rotary spraying expansion head bolt described in the present invention includes a bolt body and a local expansion head 9 arranged in the middle of the bolt body and / or a bottom enlargement head 10 arranged at the bottom of the bolt body, The number of said local enlargement heads 9 is one or more. In this embodiment, the middle part of the anchor body is provided with a local expansion head 9 and the number of the local expansion head 9 is one, and the bottom of the anchor body is provided with a bottom expansion head 10 .

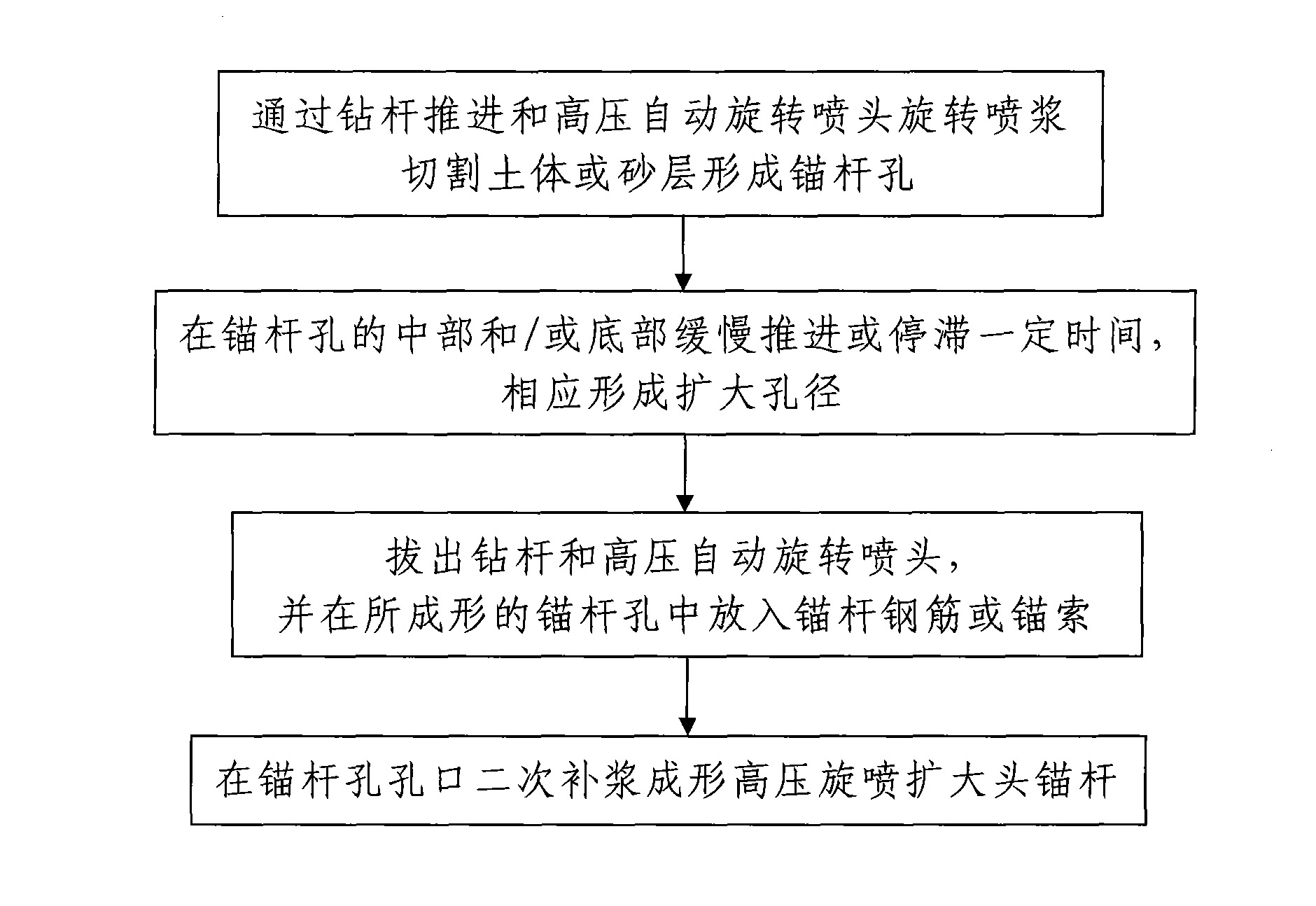

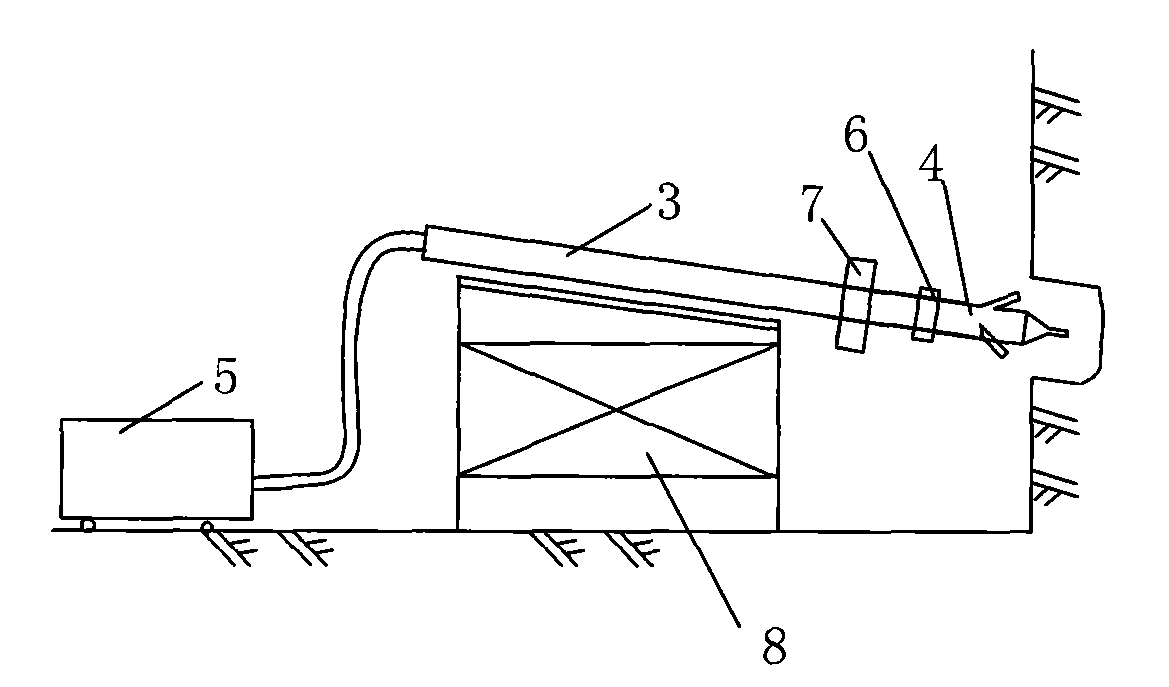

[0044] Such as figure 1 , figure 2 and image 3 As shown, the construction method of the above-mentioned high-pressure rotary spraying expansion head anchor rod includes the following steps:

[0045] Step 1, the bolt body is hole-forming construction, and the construction process is as follows:

[0046] 101. A high-pressure automatic rotary sprinkler 4 is coaxially sealed and installed at the front...

Embodiment 2

[0059] Such as Figure 7 As shown, in this embodiment, the difference from Embodiment 1 is that the formed high-pressure rotary spraying expansion head anchor rod includes an anchor rod body and a local expansion head 9 arranged in the middle of the anchor rod body, and the local The quantity of the enlarged head 9 is one, that is to say, the bottom of the formed anchor body is not provided with a bottom enlarged head 10 .

[0060] Correspondingly, in this embodiment, the construction method of the high-pressure rotary spraying expanding head bolt is different from that in Example 1 in that: in step 2, during the forward advancement of the drill pipe 3 and the high-pressure automatic rotary nozzle 4, When the two advance to the design position of the local expansion body 2 (i.e. the design depth of the local expansion head on the pre-determined anchor rod body), specifically advance to the design position or reach the design position, correspondingly slowly advance or Stand s...

Embodiment 3

[0062] Such as Figure 8 As shown, in this embodiment, the difference from Embodiment 1 is that the formed high-pressure rotary spraying expansion head anchor rod includes an anchor rod body and a bottom expansion head 10 arranged at the bottom of the anchor rod body, that is to say, The formed bolt body is not provided with a local enlarged head 9 in the middle.

[0063] Correspondingly, in this embodiment, the construction method of the high-pressure rotary spraying expanding head bolt is different from that in Example 1 in that: in step 2, during the forward advancement of the drill pipe 3 and the high-pressure automatic rotary nozzle 4, When the drill pipe 3 and the high-pressure automatic rotating nozzle 4 are pushed forward to the design depth of the bolt body, specifically to the design depth or to the design depth, they will be pushed forward slowly or stagnant for a period of time, so that The high-pressure automatic rotating nozzle 4 rotates continuously for a long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com