Wire joint connection terminal and wire joint connection method

A technology for wire joints and connecting terminals, which is applied in the field of polymer material pipes, can solve the problems of weak sealing and waterproofing, strong pulling force, difficult center positioning, etc., and achieves good waterproof sealing, improved pulling force and high pulling force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

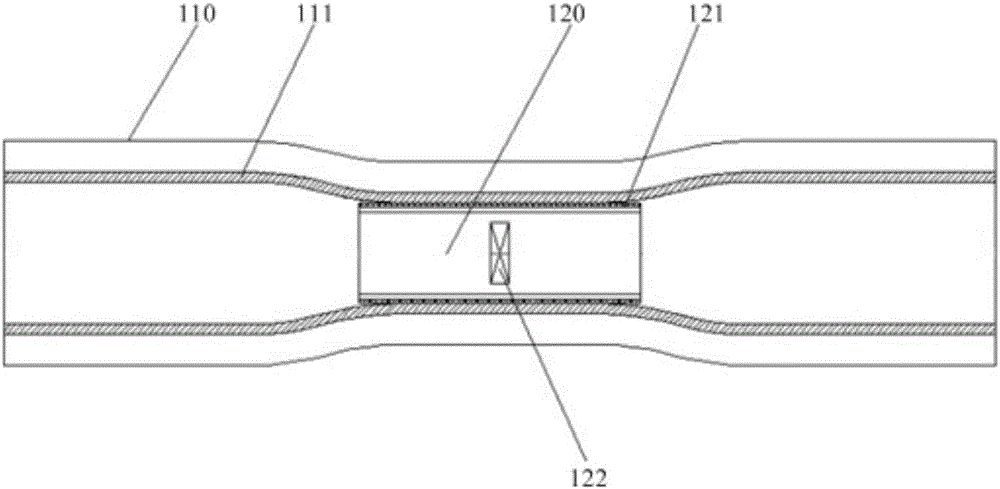

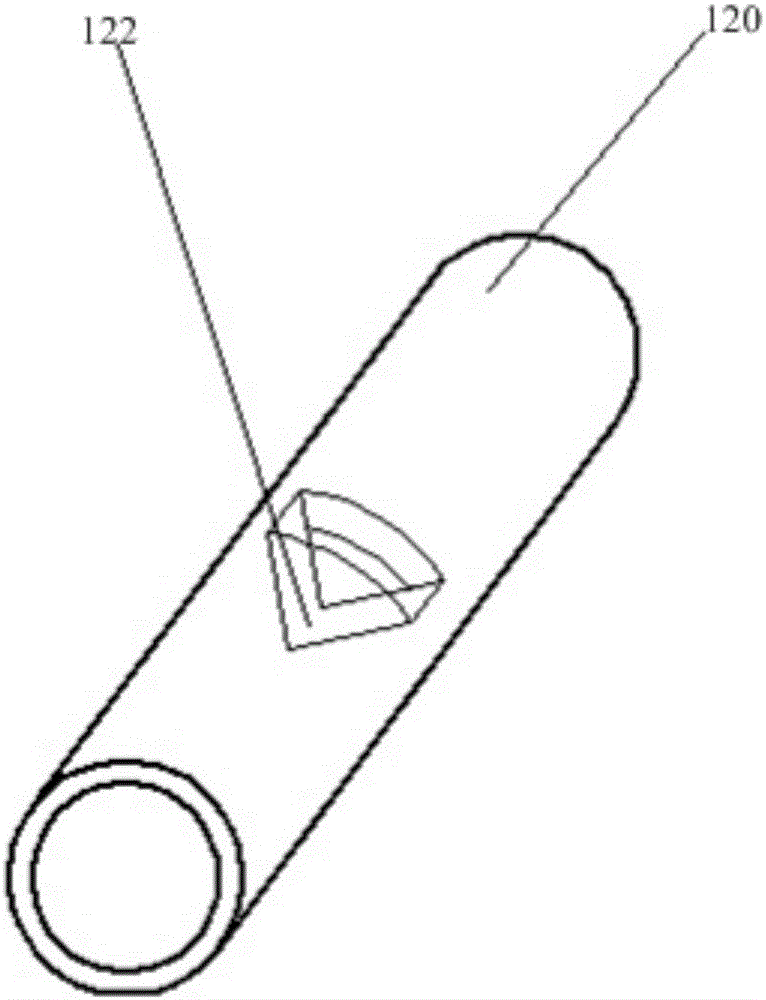

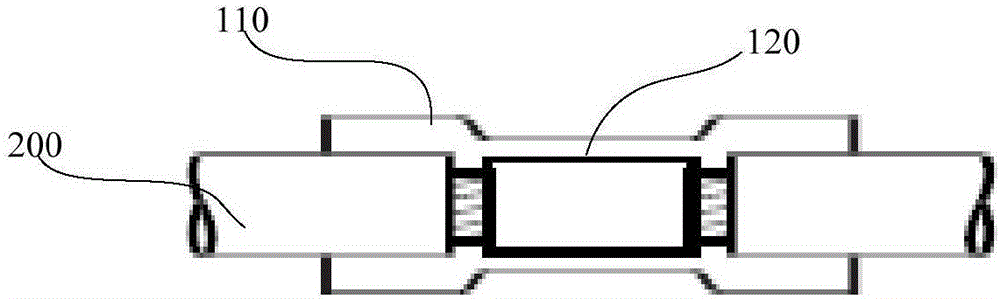

[0027] In view of the prior art, in the joint connection process of the existing wires and cables, the joints of the connection mode are not firm and the waterproof performance is relatively poor, and the wires are aging and falling off during the use of the wires, resulting in leakage, short circuit, etc., the present invention designs The heat-shrinkable tube is combined with the tinned copper tube. On the one hand, the physical characteristics of the heat-shrinkable tube are used to ensure the waterproof and airtightness of the wire connection. On the other hand, the tinned copper tube is used to strengthen the pulling force of the wire connection. At the same time, the effect of waterproof sealing and high firmness is achieved.

[0028] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com