Synchronous water injection and humidification device for lime-soil compaction pile

A technology of lime-soil compaction pile and humidification device, which is applied in sheet pile wall, soil protection, construction, etc., can solve the problem of not being able to meet the requirements of short construction period of return on investment period, etc., and achieve good hole compaction effect and shorten construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

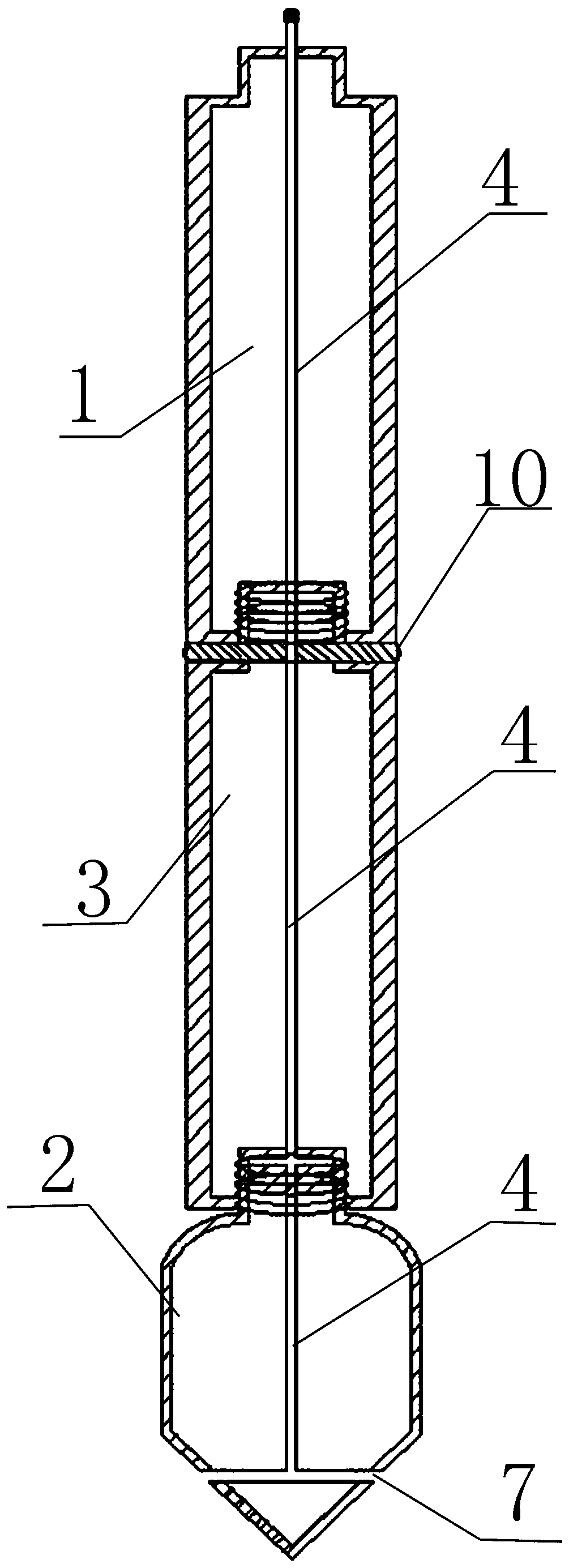

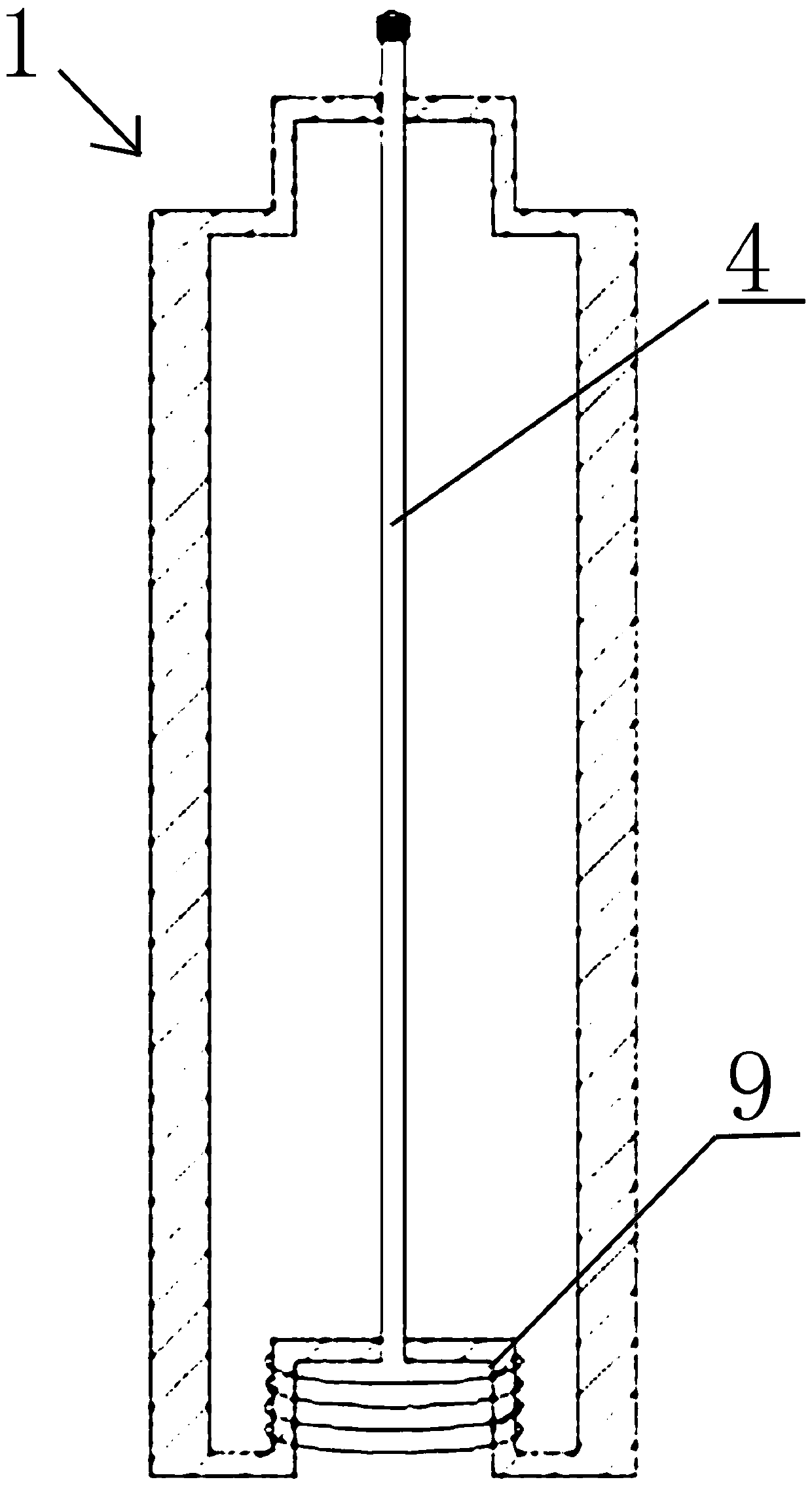

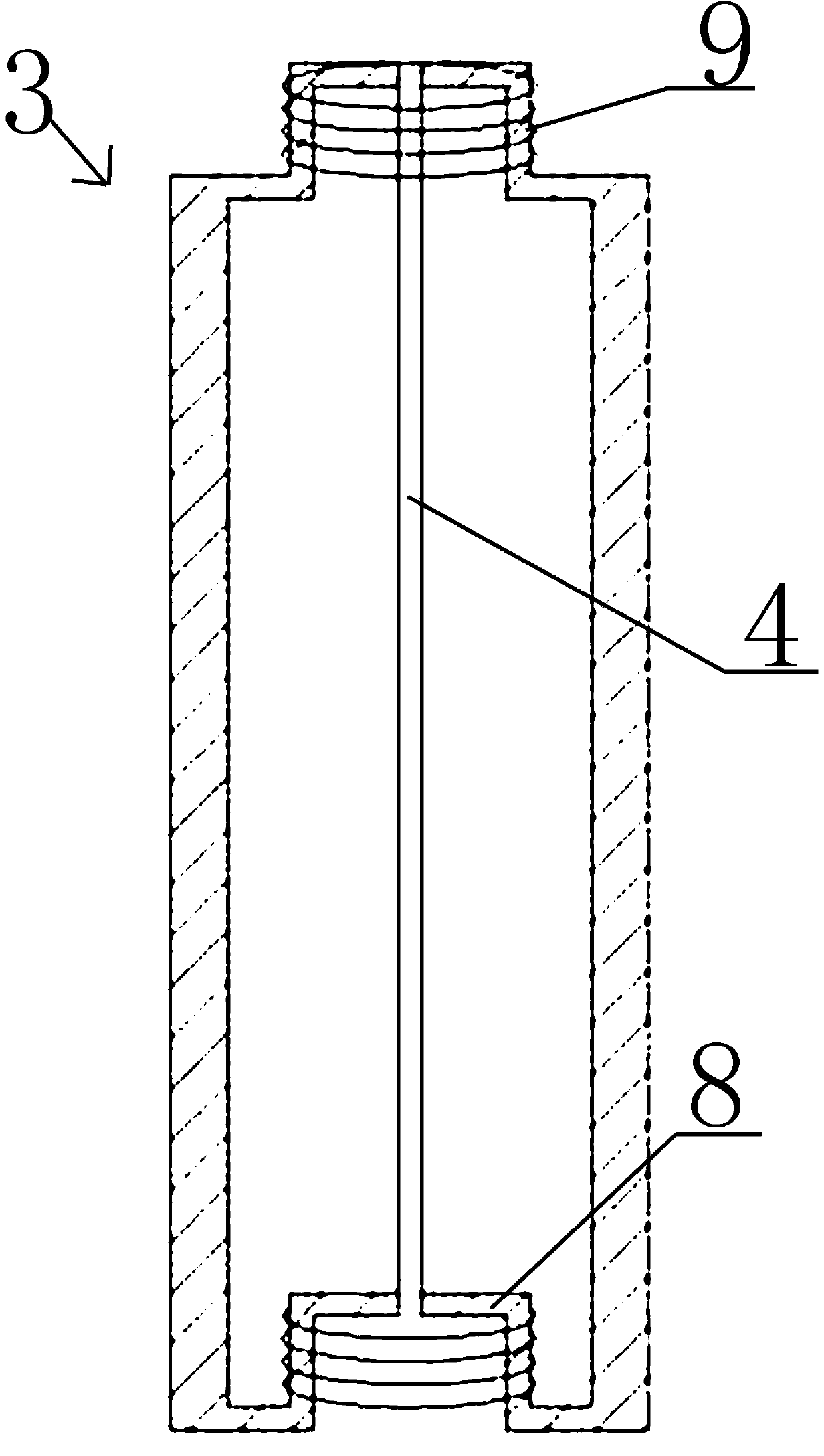

[0022] refer to Figure 1 to Figure 2 , a synchronous water injection and humidification device for lime-soil compaction piles of the present invention will be described in detail.

[0023] A synchronous water injection and humidification device for lime-soil compaction piles, such as figure 1 As shown, it includes a top section pile tube 1, a bottom pile tip 2 and several standard section pile tubes 3, and the top section pile tube 1, the standard section pile tube 3 and the bottom pile tip 2 are the same from top to bottom Axes are set and connected sequentially, such as figure 1 , figure 2 with image 3 As shown, the central axis of the top section pile pipe 1 and the standard section pile pipe 3 is provided with a water injection pipe 4, such as figure 1 with figure 2 As shown, the end of the water injection pipe 4 at the top of the top section pile pipe 1 extends to the outside; as Figure 4 As shown, the bottom pile point 2 includes a cylindrical upper part 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com