Preparation method of enhanced bacteriostatic and breathable composite fiber electrostatic spinning membrane

A technology of electrospinning and composite fibers, which is applied in fiber types, fiber treatment, rayon manufacturing, etc., can solve the problems of poor membrane hydrophobicity, etc., and achieve the effect of extending the shelf life and improving the freshness preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

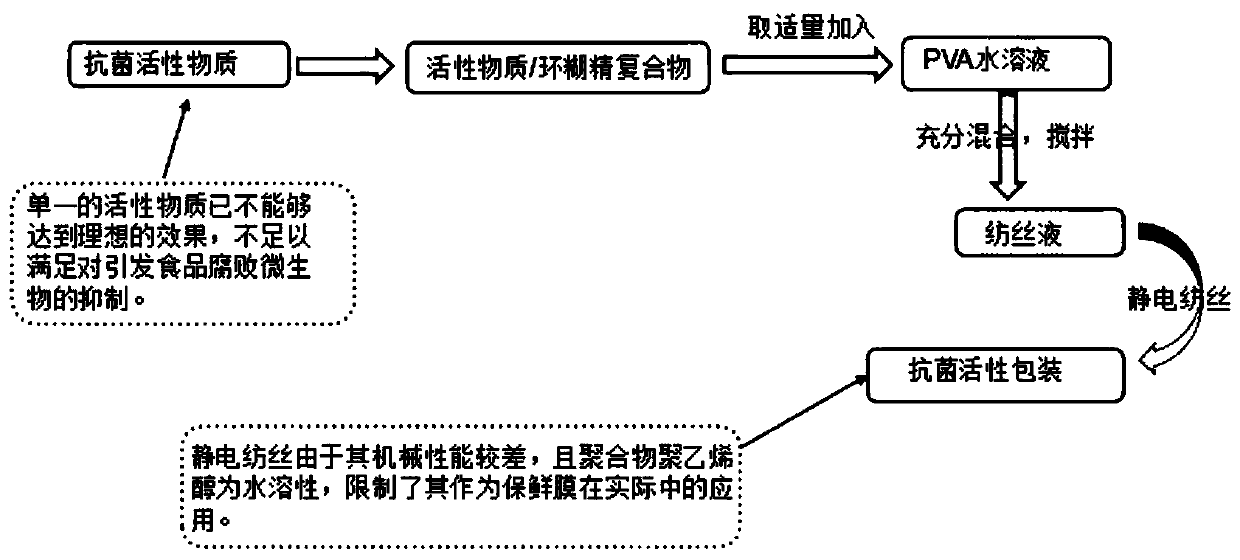

Problems solved by technology

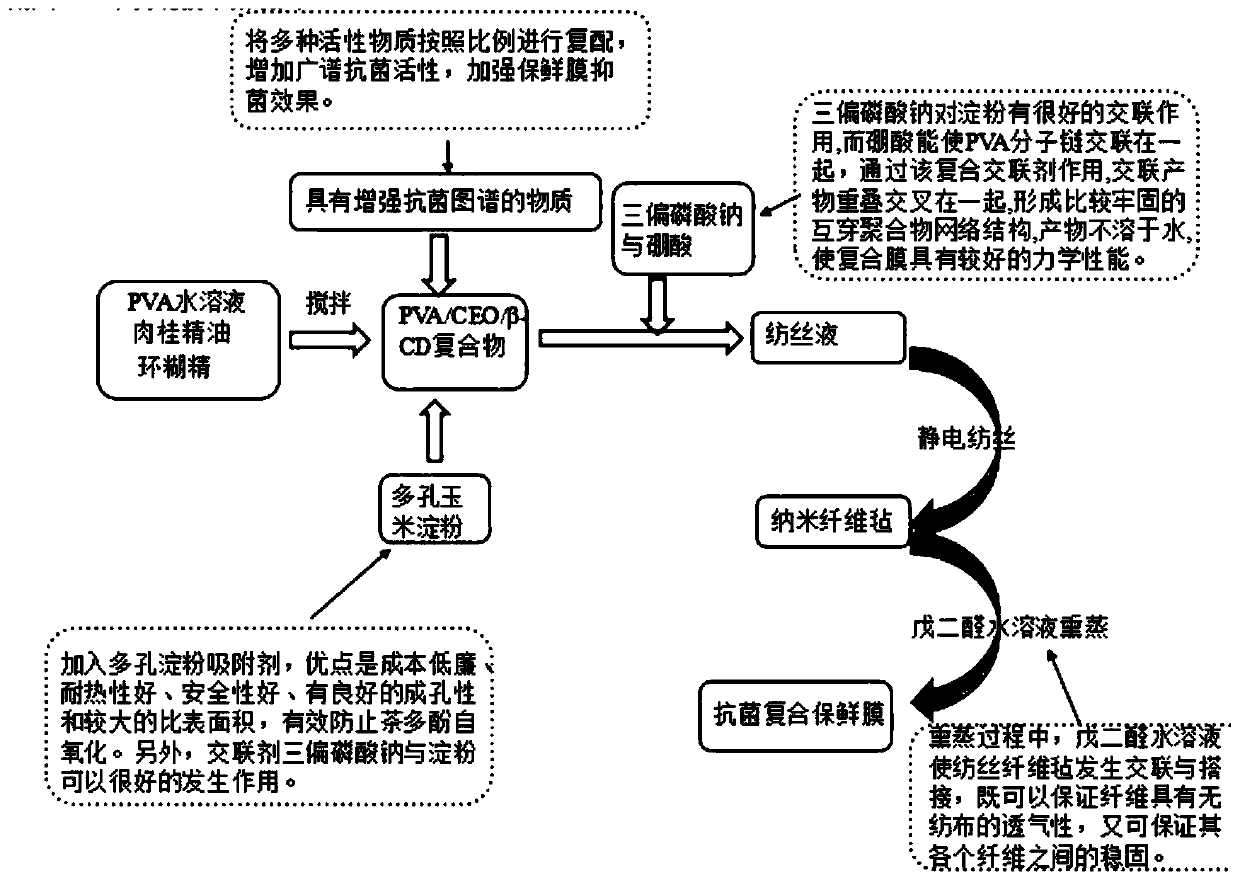

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh 6 parts of polyvinyl alcohol and dissolve it in 100 parts of deionized water at 60°C, stir well to completely dissolve the polyvinyl alcohol until the solution becomes transparent, and make a PVA aqueous solution;

[0027] (2) 4 parts of active antibacterial substances are added in the above-mentioned PVA aqueous solution, and described active antibacterial substances are mixed with cinnamon essential oil, allicin, tea polyphenols and thyme essential oil in a mass ratio of 2:1:0.5:0.4 , then add 0.5 parts of cyclodextrin and 1 part of corn porous starch, after fully mixing and stirring for 5 hours, add 5 parts of sodium trimetaphosphate and boric acid compound for crosslinking, the sodium trimetaphosphate and boric acid compound are made of mass The ratio is 4:5 sodium trimetaphosphate and boric acid are compounded, until the solution becomes uniform, and the spinning solution is obtained;

[0028] (3) The spinning solution is placed on an electrospinning mach...

Embodiment 2

[0032] (1) Weigh 7 parts of polyvinyl alcohol and dissolve it in 100 parts of 70°C deionized water, stir well to completely dissolve the polyvinyl alcohol until the solution becomes transparent, and make a PVA aqueous solution;

[0033] (2) 4 parts of active antibacterial substances are added in the above-mentioned PVA aqueous solution, and described active antibacterial substances are mixed with cinnamon essential oil, allicin, tea polyphenols and thyme essential oil in a mass ratio of 3:2:1.5:1.4 , then add 1 part of cyclodextrin and 2 parts of corn porous starch, after fully mixing and stirring for 6 hours, add 7 parts of sodium trimetaphosphate and boric acid complex for crosslinking, the sodium trimetaphosphate and boric acid compound are made of mass The ratio is 4:5 sodium trimetaphosphate and boric acid are compounded, until the solution becomes uniform, and the spinning solution is obtained;

[0034] (3) Place the spinning solution on an electrospinning machine for sp...

Embodiment 3

[0038] (1) Weigh 8 parts of polyvinyl alcohol and dissolve it in 100 parts of deionized water at 80°C, stir well to completely dissolve the polyvinyl alcohol until the solution becomes transparent, and make a PVA aqueous solution;

[0039] (2) 4 parts of active antibacterial substances are added in the above-mentioned PVA aqueous solution, and described active antibacterial substances are mixed with cinnamon essential oil, allicin, tea polyphenols and thyme essential oil in a mass ratio of 4:3:2.5:2.4 , then add 1.5 parts of cyclodextrin and 3 parts of corn porous starch, after fully mixing and stirring for 8 hours, add 10 parts of sodium trimetaphosphate and boric acid complex for crosslinking, the sodium trimetaphosphate and boric acid compound are made of mass The ratio is 4:5 sodium trimetaphosphate and boric acid are compounded, until the solution becomes uniform, and the spinning solution is obtained;

[0040] (3) The spinning solution is placed on an electrospinning mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com