Degradable food preservation pad capable of inhibiting bacteria, preventing vibration and absorbing moisture, and preparation method thereof

A food preservation and antibacterial agent technology, applied in the field of foamed plastics, can solve problems such as loading antibacterial agents, and achieve the effects of reducing spoilage, inhibiting growth and reproduction, and ensuring freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

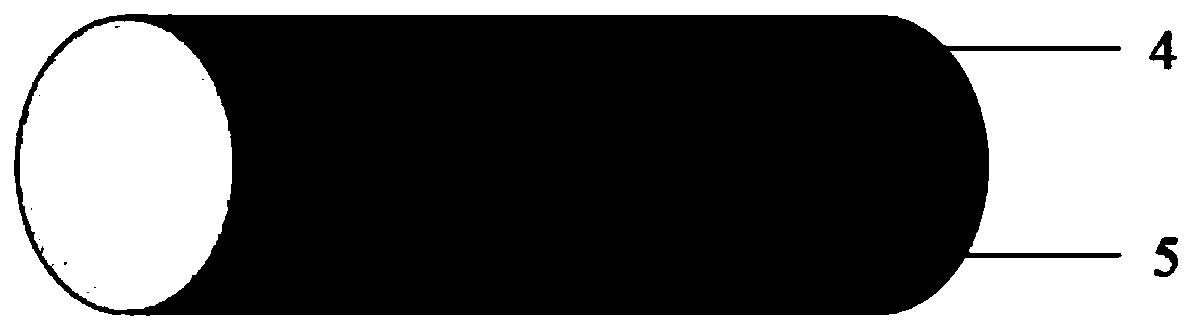

Image

Examples

Embodiment 1

[0050] A preparation method of a bacteriostatic, shockproof and moisture-absorbing degradable food preservation mat, comprising the following steps:

[0051] (1) Dry the PLA granules and starch in an oven at 65°C for 4 hours, and mix them evenly according to the weight ratio after cooling to obtain mixed granules;

[0052] (2) Mix the AC foaming agent, the HNTs-nano Ag composite material and the compatibilizer evenly according to the weight ratio, then pour them into a beaker containing the mixed particles, stir and mix them evenly, and obtain the mixed material;

[0053] (3) Put the mixed material into the twin-screw extruder and extrude foaming. The processing temperatures of zones 1 to 7 of the twin-screw extruder are 145°C, 155°C, 160°C, 175°C, 175°C, 165°C, 150°C, the twin-screw speed is 200r / min, after cooling and shaping, the antibacterial PLA / starch foaming material is obtained;

[0054] (4) natural antibacterial agent is dissolved in distilled water, is made into the...

Embodiment 2

[0070] A preparation method of a bacteriostatic, shockproof and moisture-absorbing degradable food preservation mat, comprising the following steps:

[0071] (1) Dry the PLA granules and starch in an oven at 65°C for 4 hours, and mix them evenly according to the weight ratio after cooling to obtain mixed granules;

[0072](2) After mixing the AC foaming agent, HNTs-cinnamaldehyde composite material, HNTs-citral composite material and compatibilizer uniformly according to the weight ratio, pour them into a beaker containing the mixed particles, stir and mix to obtain the mixed material;

[0073] (3) Put the mixed material into the twin-screw extruder and extrude foaming. The processing temperatures of zones 1 to 7 of the twin-screw extruder are 145°C, 155°C, 160°C, 175°C, 175°C, 165°C, 150°C, the twin-screw speed is 280r / min, after cooling and shaping, the antibacterial PLA / starch foaming material is obtained;

[0074] (4) join chitosan and clove essential oil in the aqueous a...

Embodiment 3

[0090] A preparation method of a bacteriostatic, shockproof and moisture-absorbing degradable food preservation mat, comprising the following steps:

[0091] (1) Dry the PLA granules and starch in an oven at 65°C for 4 hours, and mix them evenly according to the weight ratio after cooling to obtain mixed granules;

[0092] (2) AC blowing agent, HNTs-nano TiO 2 The composite material, the HNTs-sorbic acid composite material, the HNTs-nano Ag composite material, and the compatibilizer are uniformly mixed according to the weight ratio, and then poured into a beaker containing the mixed particles, stirred and mixed to obtain a mixed material;

[0093] (3) Put the mixed material into the twin-screw extruder and extrude foaming. The processing temperatures of zones 1 to 7 of the twin-screw extruder are 145°C, 155°C, 160°C, 175°C, 175°C, 165°C, 150°C, the twin-screw speed is 280r / min, after cooling and shaping, the antibacterial PLA / starch foaming material is obtained;

[0094] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com