Litchi preservative and preparation method thereof

A technology of preservative and lychee, which is applied in the field of lychee preservative and its preparation, can solve the problems of restricting the sales of fresh fruit, affecting commodity value, short shelf life and cold freshness period, etc., and achieves the improvement of freshness preservation efficiency, freshness preservation effect and freshness preservation time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

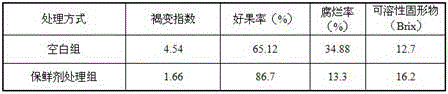

Embodiment 1

[0029] Litchi preservative components, by weight percentage, its formula consists of: honeysuckle extract 4%, licorice extract 2%, litchi bark extract 1%, calcium chloride 0.8%, glycerol 1.5%, chitosan 0.2% %, gibberellin 0.015%, sodium dehydroacetate 0.8%, and the rest is water. Preparation:

[0030] 1) Preparation of honeysuckle extract:

[0031] Put honeysuckle into an ultra-high pressure extraction tank, add 5 times the weight of 95% ethanol, pressurize to 100Mpa and maintain the pressure for 12 minutes, release the pressure, filter, and refrigerate the filtrate for the first time, the refrigerated temperature is 4°C, and the refrigerated time is 5h. The final filtrate is centrifuged for the first time, the speed is 3000r / min, and the separation time is 15min. The supernatant is collected and refrigerated again. , the separation time was 5 min, and the supernatant was collected to obtain the honeysuckle extract.

[0032] 2) Preparation of licorice extract:

[0033] Wei...

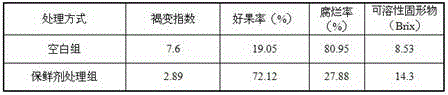

Embodiment 2

[0046] Litchi preservative components, by weight percentage, its formula consists of: honeysuckle extract 6%, licorice extract 2.5%, litchi bark extract 2%, calcium chloride 1%, glycerol 1.8%, chitosan 0.4% %, gibberellin 0.018%, sodium dehydroacetate 1%, and the rest is water.

[0047] Preparation:

[0048] 1) Preparation of honeysuckle extract:

[0049] Put honeysuckle into an ultra-high pressure extraction tank, add 6 times the weight of 95% ethanol, pressurize to 400Mpa and maintain the pressure for 10 minutes, release the pressure, filter, and refrigerate the filtrate for the first time. The final filtrate was centrifuged for the first time at a speed of 3500r / min, and the separation time was 12 minutes. The supernatant was collected and refrigerated again at a temperature of 2°C for 3 hours. , the separation time was 8 min, and the supernatant was collected to obtain the honeysuckle extract.

[0050] 2) Preparation of licorice extract:

[0051] Weigh the powdered lic...

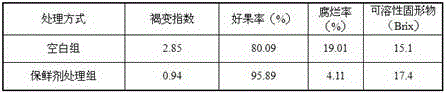

Embodiment 3

[0061] Honeysuckle extract 8%, licorice extract 3%, litchi peel extract 3%, calcium chloride 1.2%, glycerol 2%, chitosan 0.6%, gibberellin 0.02%, sodium dehydroacetate 1.2%, The rest is water.

[0062] Preparation:

[0063] 1) Preparation of honeysuckle extract:

[0064] Put the honeysuckle into the ultra-high pressure extraction tank, add 8 times the weight of 95% ethanol, pressurize the pressure to 300Mpa and keep the pressure for 15 minutes, release the pressure, filter, and refrigerate the filtrate for the first time. The final filtrate was centrifuged for the first time at a speed of 3500r / min, and the separation time was 15 minutes. The supernatant was collected and refrigerated again at a temperature of 4°C for 3 hours. The second centrifugation was performed at a speed of 6000r / min. , the separation time was 8 min, and the supernatant was collected to obtain the honeysuckle extract.

[0065] 2) Preparation of licorice extract:

[0066] Weigh the powdered licorice a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com