Catalyst for preparing hydrocarbons from oxygen-containing compounds, and preparation method and application thereof

A catalyst and compound technology, applied in the preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of no systematic reports, etc., achieve small crystallinity loss, high hydrocarbon selectivity, and long single-pass life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

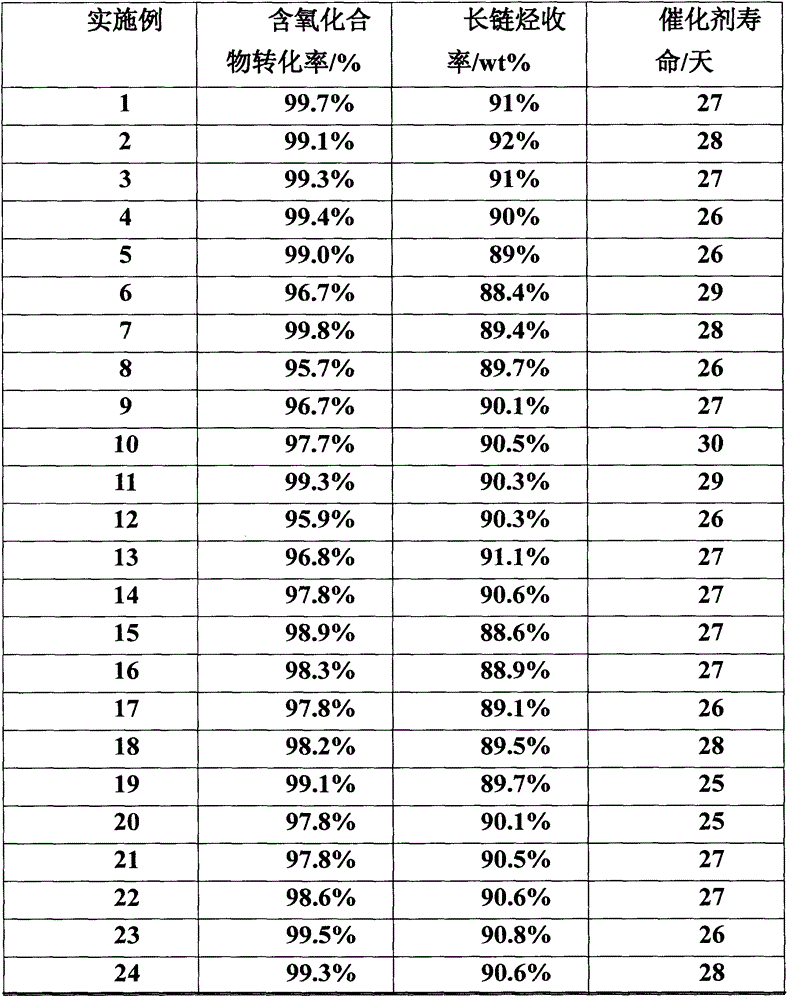

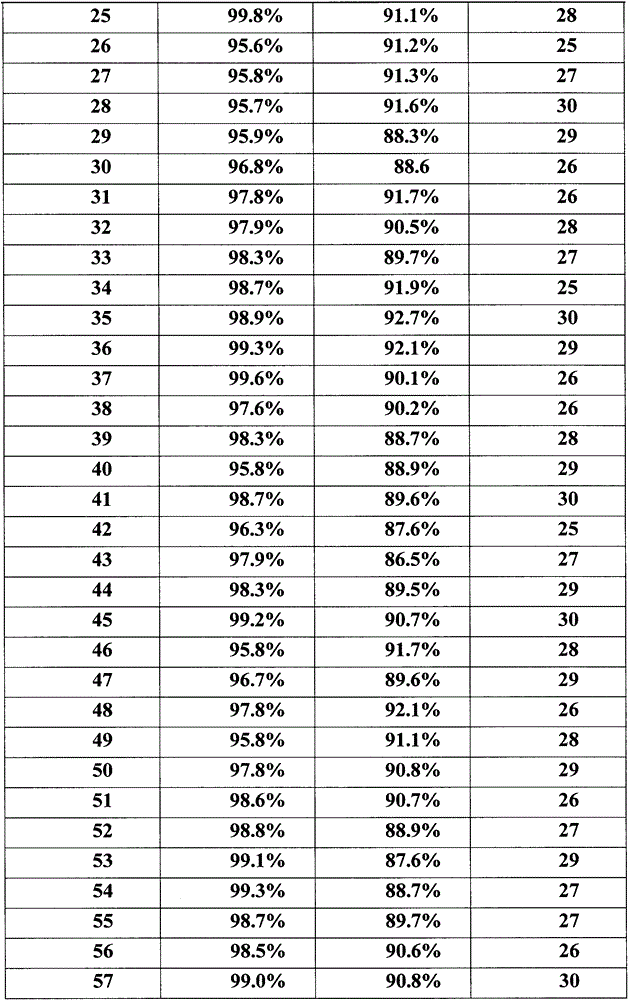

Examples

Embodiment 1

[0035]Pour the nitrate solution of the modifying element Zn into a commercially available ZSM-5 molecular sieve, the modifying element accounts for 4.0% of the mass of the catalyst, stir well, let stand for 24h, dry at 100°C, and roast at 550°C for 5h to obtain Modified ZSM-5 molecular sieve, the modified molecular sieve and the binder SB powder were kneaded and extruded into rods, left standing at room temperature for 24 hours, dried at 100°C, and calcined at 550°C for 5 hours. The strip catalyst obtained is subjected to alkali treatment in a fixed bed reactor, the concentration of sodium hydroxide used is 0.1mol / L, the treatment conditions are temperature 90°C, and the mass space velocity of sodium hydroxide solution is 3h -1 , the treatment time is 6h, after the sodium hydroxide solution is processed, the ammonium nitrate solution is replaced for ammonium exchange treatment. -1 , the treatment time is 6h, the catalyst exchanged by ammonium nitrate is at 600℃, and the mass s...

Embodiment 2~7

[0038] According to the method of embodiment 1, the modifying elements accounted for 4.0% of the mass of the catalyst into 1%, 2%, 6%, 8%, 10%, the ZSM-5 content remains unchanged, and the corresponding binder content is 19% , 18%, 14%, 12%, 10% others are identical with embodiment 1.

Embodiment 8

[0040] According to the method of embodiment 1, change binder SB powder into pseudo-boehmite, all the other steps are the same as embodiment 1, and the final composition of catalyst is that ZSM-5 content is 80%, and binder pseudo-boehmite content It is 16%, and the content of modifying elements is 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com