Catalyst for preparing propylene by propane dehydrogenation as well as preparation and application thereof

A propane dehydrogenation and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrocarbons, etc., can solve the problems of unestablished propane dehydrogenation and achieve long single-pass life , high conversion rate of propane, good selectivity of propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 3g 40-80 mesh γ-Al 2 o 3 , baked at 550°C for 4 hours, and prepared with 0.0965M SnCl 2 Immersed in ethanol solution for 12h, removed the solvent with a rotary evaporator at 60°C under reduced pressure, dried at 120°C for 12h, and roasted at 550°C for 4 hours, and then added 0.0945M Zn(NO 3 ) 2 Immerse in the solution for 12 hours, remove the solvent with a rotary evaporator under reduced pressure at 60°C, dry at 120°C for 8-12 hours, and roast at 550°C for 4 hours, then use 0.096M Ce(NO 3 ) 3 Immerse in the solution for 12 hours, remove the solvent with a rotary evaporator at 60°C under reduced pressure, dry at 120°C for 8-12 hours, bake at 550°C for 4 hours, and finally use 0.01913M H 2 PtCl 6 The solution was soaked for 12 hours, the solvent was removed by a rotary evaporator under reduced pressure at 60°C, dried at 120°C for 8-12 hours, and calcined at 550°C for 4 hours. Prepare catalyst (1), catalyst component is: Pt-Sn-Ce-Zn / γ-Al 2 o 3 .The percentag...

Embodiment 2

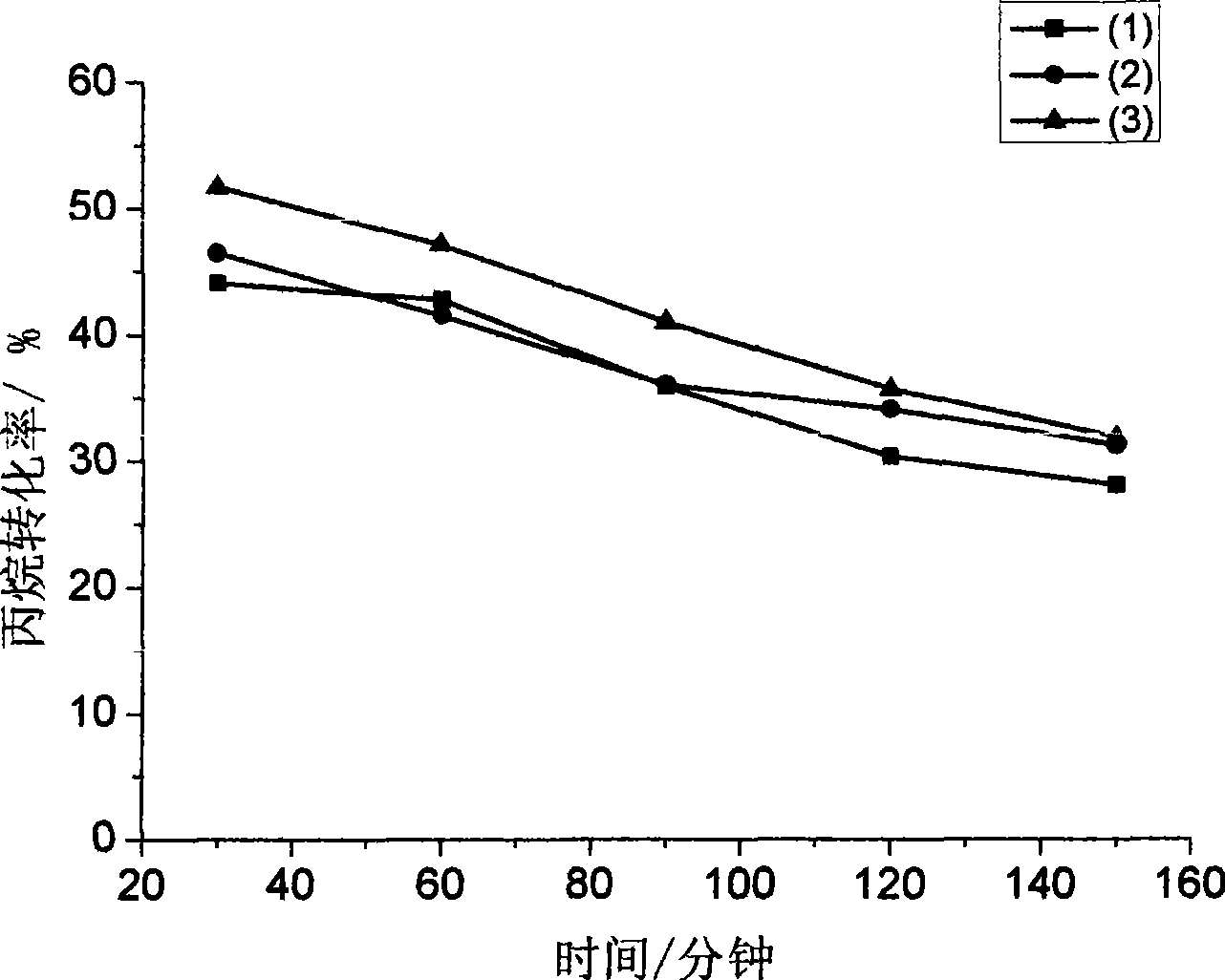

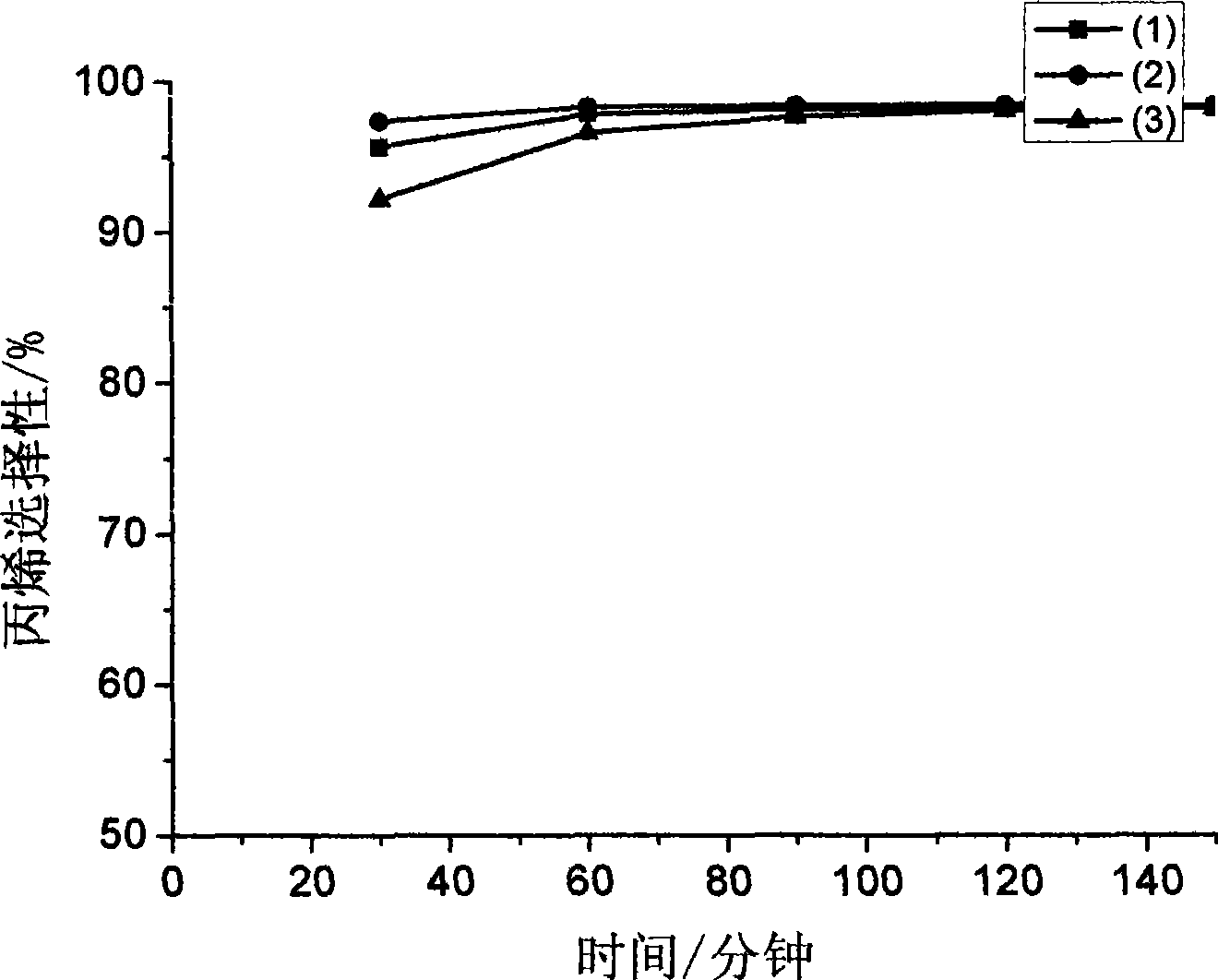

[0025] Catalyst (1) As a catalyst, the reaction temperature is 550-620°C, the pressure is normal pressure, and the feed gas propane space velocity is 3000-4000h -1 , also have hydrogen and nitrogen in the feed gas, hydrogen: hydrocarbon: nitrogen molar ratio is 1:1:7, and reaction product gas is through gas chromatography on-line analysis, and propane conversion ratio is as follows: figure 1 , propylene selectivity such as figure 2 .

Embodiment 3

[0027] Change the percentage of Zn from 4% to 8% in Example 1, and the others are the same as in Example 1 to prepare the catalyst (2). Propane conversion rate as figure 1 , propylene selectivity such as figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com