Light oil non-hydroaromatization catalyst as well as preparation method and application thereof

A catalyst and aromatization technology, applied in the field of non-hydrogen reforming catalysts, can solve the problems of low processing utilization rate of carbon four fractions, poor combustion quality, less than 20%, etc., and achieve high catalytic activity and stability. The effect of small investment and reduced preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

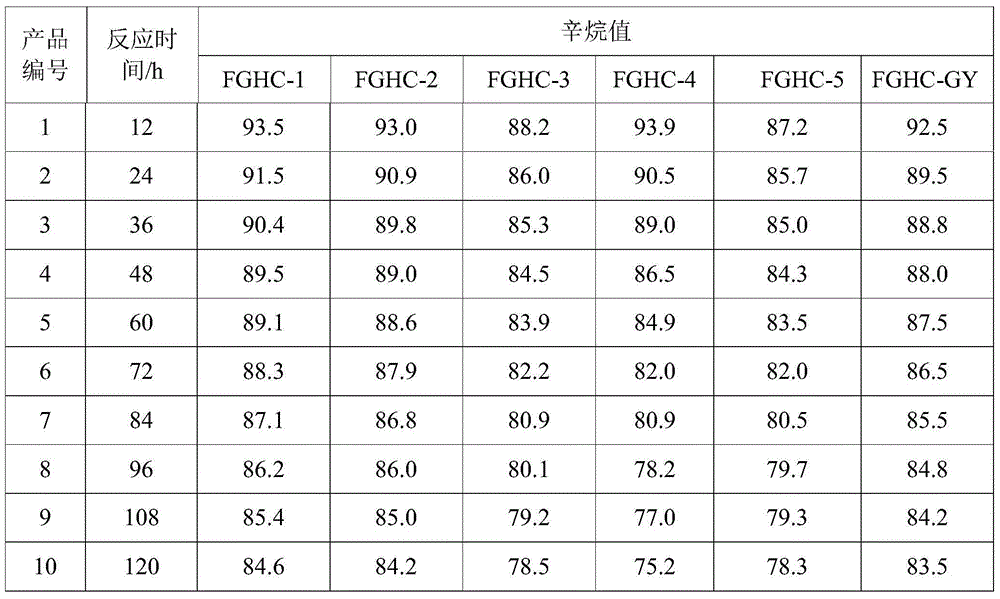

Embodiment 1

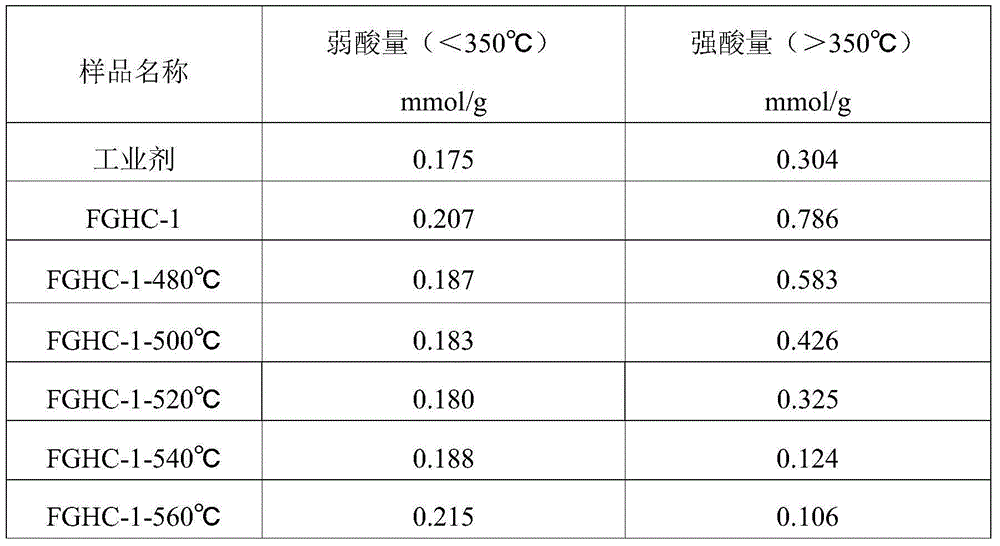

[0034] (1) Modification of molecular sieve with Zn: Weigh 8.0g zinc nitrate, dissolve it in 175ml distilled water, and weigh 100g SiO 2 / Al 2 O 3 The HZSM-5 molecular sieve with a molar ratio of 35 was put into the prepared zinc nitrate aqueous solution and stirred rapidly at 35°C for 3 hours. Ensure that the exchange is complete, then filter the slurry, dry the filter cake at 100°C for 2 hours, and roast the filter cake at 550°C for 4 hours. After crushing, Zn / HZSM-5 is obtained.

[0035] (2) Molecular sieve P modification: Weigh 9.98g phosphoric acid (85%) solution, dissolve it in 180ml distilled water, weigh Zn / HZSM-5 into the phosphoric acid aqueous solution, exchange for 3h, and then filter the slurry at 100℃ The filter cake was dried for 2 hours, and the filter cake was calcined at 550°C for 4 hours and crushed to obtain ZnP / HZSM-5.

[0036] (3) Preparation of carrier: Weigh 3.5 g of Sesbania powder and 49.8 g of SB powder and mix them evenly, and add 70.3 g of modified molec...

Embodiment 2

[0040] (1) Modification of molecular sieve with Zn: Weigh 12.0g zinc nitrate, dissolve it in 263ml distilled water, and weigh 150g SiO 2 / Al 2 O 3 The HZSM-5 molecular sieve with a molar ratio of 35 was put into the prepared zinc nitrate aqueous solution and stirred rapidly at 35°C for 3 hours. Ensure that the exchange is complete, then filter the slurry, and dry the filter cake at 100°C for 2 hours. The filter cake is calcined at 550°C for 4 hours and crushed to obtain Zn / HZSM-5.

[0041] (2) Molecular sieve P modification: Weigh 14.97g phosphoric acid (85%) solution, dissolve it in 270ml distilled water, weigh Zn / HZSM-5 into the phosphoric acid aqueous solution, exchange for 3h, and then filter the slurry at 100℃ The filter cake was dried for 2 hours, and the filter cake was calcined at 550°C for 4 hours and crushed to obtain ZnP / HZSM-5.

[0042] (3) Preparation of carrier: Weigh 5.3 g of sesame powder and 74.7 g of SB powder and mix them uniformly, and add 105.5 g of modified mo...

Embodiment 3

[0046] (1) Modification of molecular sieve with Zn: Weigh 8.0g zinc nitrate, dissolve it in 175ml distilled water, and weigh 100g SiO 2 / Al 2 O 3 The HZSM-5 molecular sieve with a molar ratio of 50 was put into the prepared zinc nitrate aqueous solution and stirred rapidly at 35°C for 3 hours. Ensure that the exchange is complete, then filter the slurry, and dry the filter cake at 100°C for 2 hours. The filter cake is calcined at 550°C for 4 hours and crushed to obtain Zn / HZSM-5.

[0047] (2) Modification of molecular sieve P: Same as described in Example 1(2).

[0048] (3) Preparation of carrier: same as described in Example 1(3).

[0049] (4) Preparation of the dipping solution: same as described in Example 1(4).

[0050] (5) Preparation of catalyst: As described in Example 1(2), the light oil aromatization catalyst FGHC-3 was finally prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com