A methanol aromatization process

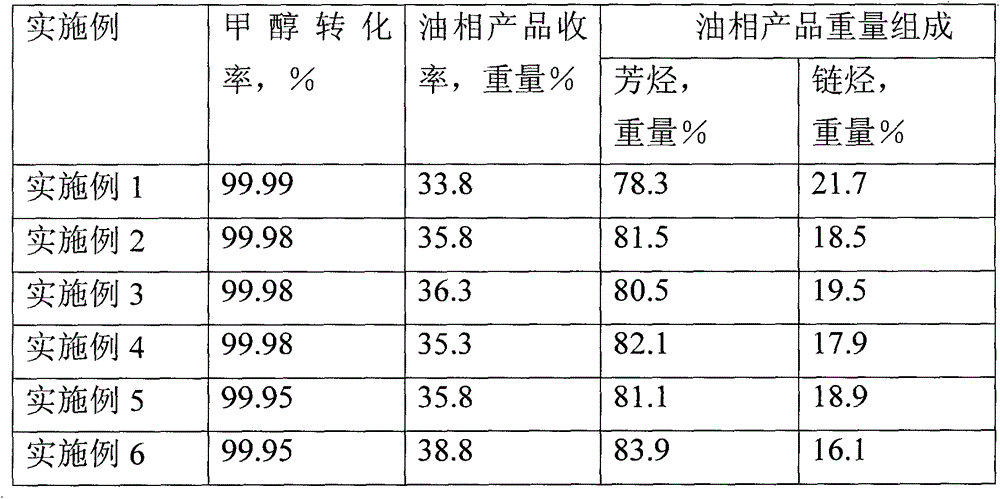

A technology of aromatization and methanol, which is applied in the field of aromatization technology, can solve the problems of low oil phase yield, which is difficult to exceed 30%, and achieve improved oil phase yield, high methanol utilization rate, and good selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of tube-side catalyst

[0035] 1) Weigh 70 g of ZSM-5 molecular sieve with a silicon-aluminum ratio of 38, and calcinate it at 550° C. for 4 hours to remove physically adsorbed impurities.

[0036] 2) Weigh 10g of SAPO-34 molecular sieve, 20g of coagulant SB powder, and 3g of Tianqing powder, and mix them evenly with the ZSM-5 roasted in step (1).

[0037]3) Weigh 50g of water, add 3g of citric acid, 5ml of nitric acid and stir evenly, add to the mixture in step 2), stir well, extrude it into a columnar shape of Φ2 with a screw extruder, and place it in an oven at 120°C Dry at 550°C for 4 hours to remove nitric acid and moisture. The calcined catalyst is crushed into 20-40 mesh particles for later use.

[0038] 4) Weigh an appropriate amount of Cu and P nitrate to form a solution, weigh 20 g of the catalyst prepared in step 3) and impregnate it in equal volume, stand at room temperature for 24 hours, and dry at 120 ° C. During this period, stir once ever...

Embodiment 2

[0055] 1. Preparation of tube-side catalyst

[0056] 1) Weigh 60 g of ZSM-5 molecular sieve with a silicon-aluminum ratio of 38, and calcinate it at 550° C. for 4 hours to remove physically adsorbed impurities.

[0057] 2) Weigh 20g of SAPO-34 molecular sieve, 20g of coagulant SB powder, and 3g of Tianqing powder, and mix them evenly with the ZSM-5 roasted in step 1).

[0058] 3) Weigh 50g of water, add 3g of citric acid, 5ml of nitric acid and stir evenly, add to the mixture in step 2), stir well, extrude it into a columnar shape of Φ2 with a screw extruder, and place it in an oven at 120°C Dry at 550°C for 4 hours to remove nitric acid and moisture. The calcined catalyst is crushed into 20-40 mesh particles for later use.

[0059] 4) Weigh an appropriate amount of Cu and Zn nitrate to form a solution, weigh 20 g of the catalyst prepared in step 3) and impregnate it in equal volume, stand still at room temperature for 24 hours, and dry at 120 ° C. During this period, stir on...

Embodiment 3

[0076] 1. Preparation of tube-side catalyst

[0077] 1) Weigh 60 g of ZSM-5 molecular sieve with a silicon-aluminum ratio of 60, and bake it at 550° C. for 4 hours to remove physically adsorbed impurities.

[0078] 2) Weigh 20g of 5APO-34 molecular sieve, 20g of coagulant SB powder, and 3g of Tianqing powder, and mix them evenly with the ZSM-5 roasted in step 1).

[0079] 3) Weigh 50g of water, add 3g of citric acid, 5ml of nitric acid and stir evenly, add to the mixture in step 2), stir well, extrude it into a columnar shape of Φ2 with a screw extruder, and place it in an oven at 120°C Dry at 550°C for 4 hours to remove nitric acid and moisture. The calcined catalyst is crushed into 20-40 mesh particles for later use.

[0080] 4) Weigh an appropriate amount of Cu, Zn, and P nitrates to make a solution, weigh 20g of the catalyst prepared in step 3) and impregnate it in equal volume, stand at room temperature for 24h, dry at 120°C, and stir once every 1h during this period , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com