Methanol aromatization technology

A technology of aromatization and methanol, which is applied in the field of aromatization technology, can solve the problems of low oil phase yield, which is difficult to be higher than 30%, and achieve the improvement of oil phase yield, high utilization rate of methanol, and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

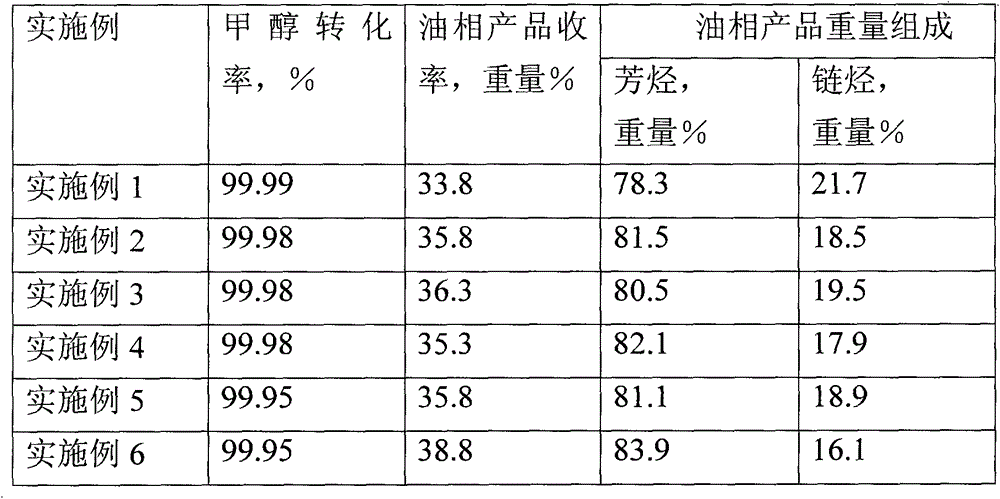

Examples

Embodiment 1

[0034] 1. Preparation of tube-side catalyst

[0035] 1) Weigh 70 g of ZSM-5 molecular sieve with a silicon-aluminum ratio of 38, and calcinate it at 550° C. for 4 hours to remove physically adsorbed impurities.

[0036] 2) Weigh 10g of SAPO-34 molecular sieve, 20g of coagulant SB powder, and 3g of Tianqing powder, and mix them evenly with the ZSM-5 roasted in step (1).

[0037]3) Weigh 50g of water, add 3g of citric acid, 5ml of nitric acid and stir evenly, add to the mixture in step 2), stir well, extrude it into a columnar shape of Φ2 with a screw extruder, and place it in an oven at 120°C Dry at 550°C for 4 hours to remove nitric acid and moisture. The calcined catalyst is crushed into 20-40 mesh particles for later use.

[0038] 4) Weigh an appropriate amount of Cu and P nitrate to form a solution, weigh 20 g of the catalyst prepared in step 3) and impregnate it in equal volume, stand at room temperature for 24 hours, and dry at 120 ° C. During this period, stir once ever...

Embodiment 2

[0055] 1. Preparation of tube-side catalyst

[0056] 1) Weigh 60 g of ZSM-5 molecular sieve with a silicon-aluminum ratio of 38, and calcinate it at 550° C. for 4 hours to remove physically adsorbed impurities.

[0057] 2) Weigh 20g of SAPO-34 molecular sieve, 20g of coagulant SB powder, and 3g of Tianqing powder, and mix them evenly with the ZSM-5 roasted in step 1).

[0058] 3) Weigh 50g of water, add 3g of citric acid, 5ml of nitric acid and stir evenly, add to the mixture in step 2), stir well, extrude it into a columnar shape of Φ2 with a screw extruder, and place it in an oven at 120°C Dry at 550°C for 4 hours to remove nitric acid and moisture. The calcined catalyst is crushed into 20-40 mesh particles for later use.

[0059] 4) Weigh an appropriate amount of Cu and Zn nitrate to form a solution, weigh 20 g of the catalyst prepared in step 3) and impregnate it in equal volume, stand still at room temperature for 24 hours, and dry at 120 ° C. During this period, stir on...

Embodiment 3

[0076] 1. Preparation of tube-side catalyst

[0077] 1) Weigh 60 g of ZSM-5 molecular sieve with a silicon-aluminum ratio of 60, and bake it at 550° C. for 4 hours to remove physically adsorbed impurities.

[0078] 2) Weigh 20g of 5APO-34 molecular sieve, 20g of coagulant SB powder, and 3g of Tianqing powder, and mix them evenly with the ZSM-5 roasted in step 1).

[0079] 3) Weigh 50g of water, add 3g of citric acid, 5ml of nitric acid and stir evenly, add to the mixture in step 2), stir well, extrude it into a columnar shape of Φ2 with a screw extruder, and place it in an oven at 120°C Dry at 550°C for 4 hours to remove nitric acid and moisture. The calcined catalyst is crushed into 20-40 mesh particles for later use.

[0080] 4) Weigh an appropriate amount of Cu, Zn, and P nitrates to make a solution, weigh 20g of the catalyst prepared in step 3) and impregnate it in equal volume, stand at room temperature for 24h, dry at 120°C, and stir once every 1h during this period , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com