Patents

Literature

41results about How to "Increase aromatics yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

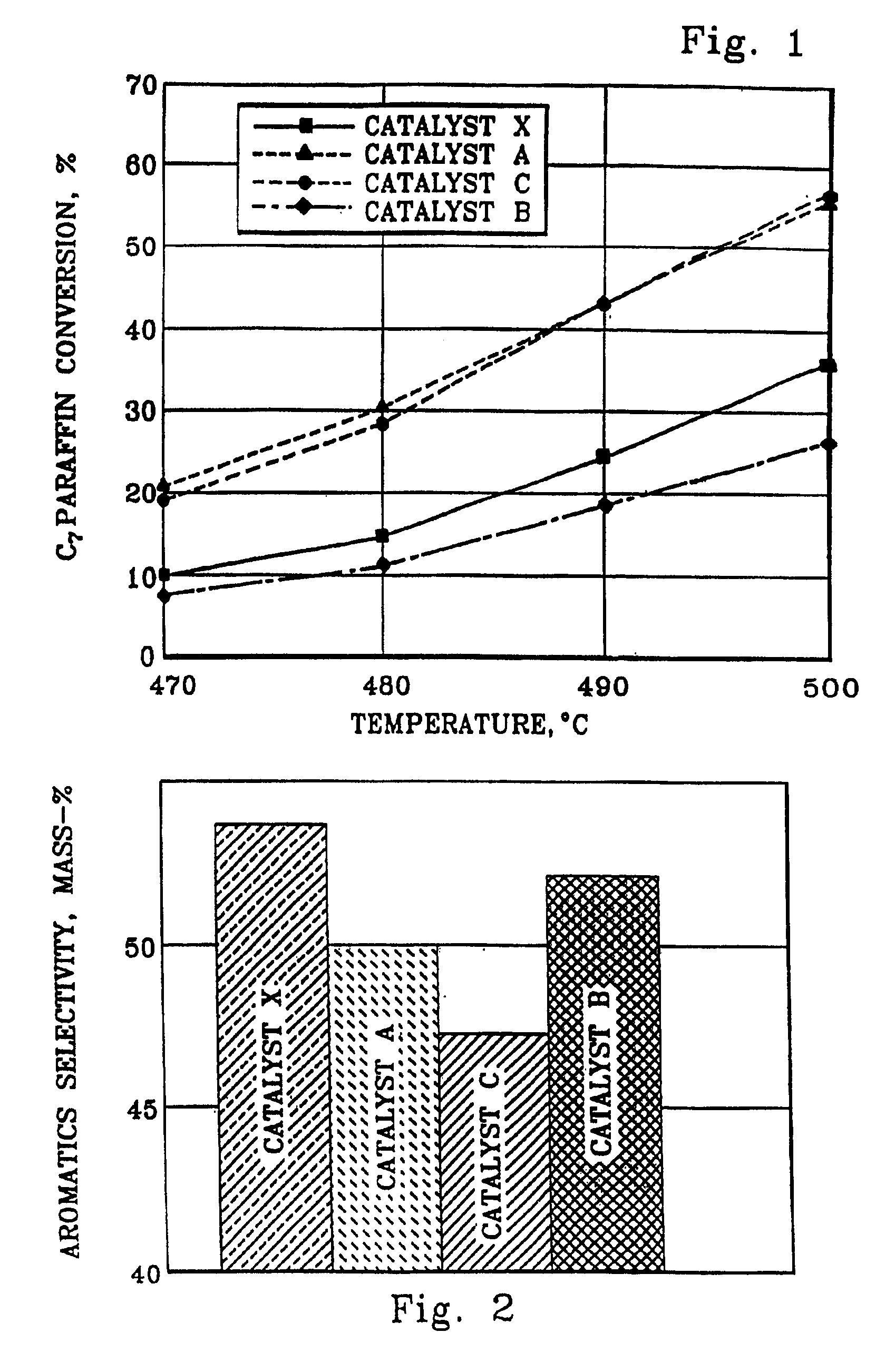

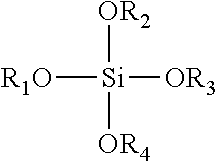

Reforming process using a selective bifunctional multimetallic catalyst

InactiveUS6884340B1High selectivityIncrease productionCatalytic naphtha reformingMetal/metal-oxides/metal-hydroxide catalystsIndiumGasoline

The use of a novel catalyst in a reforming process is disclosed. The catalyst comprises a refractory inorganic oxide, platinum-group metal, Group IVA(IUPAC 14) metal, indium and lanthanide-series metal. Utilization of this catalyst in the conversion of hydrocarbons, especially in a reforming process, results in significantly improved selectivity to the desired gasoline or aromatics products.

Owner:UOP LLC

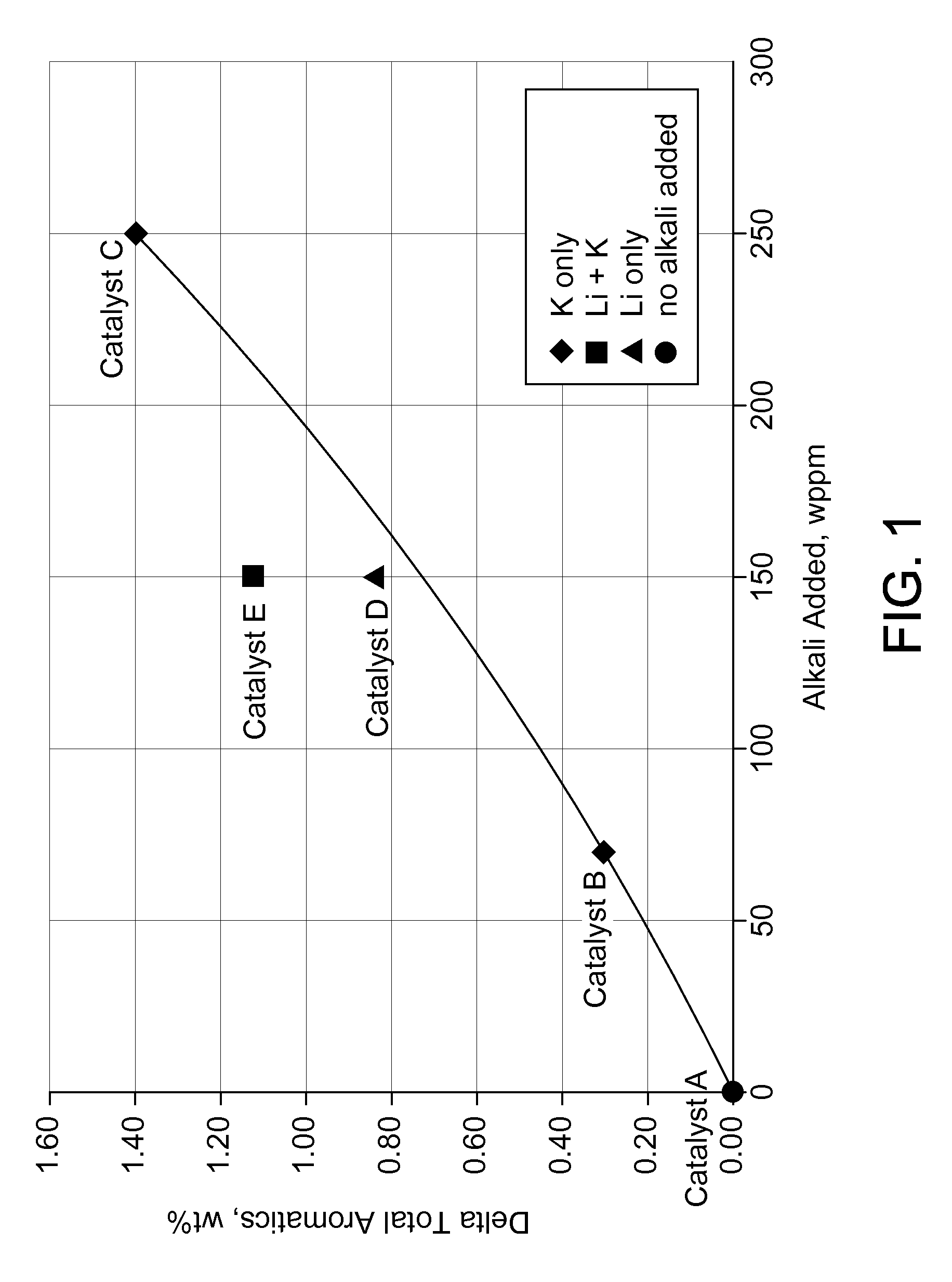

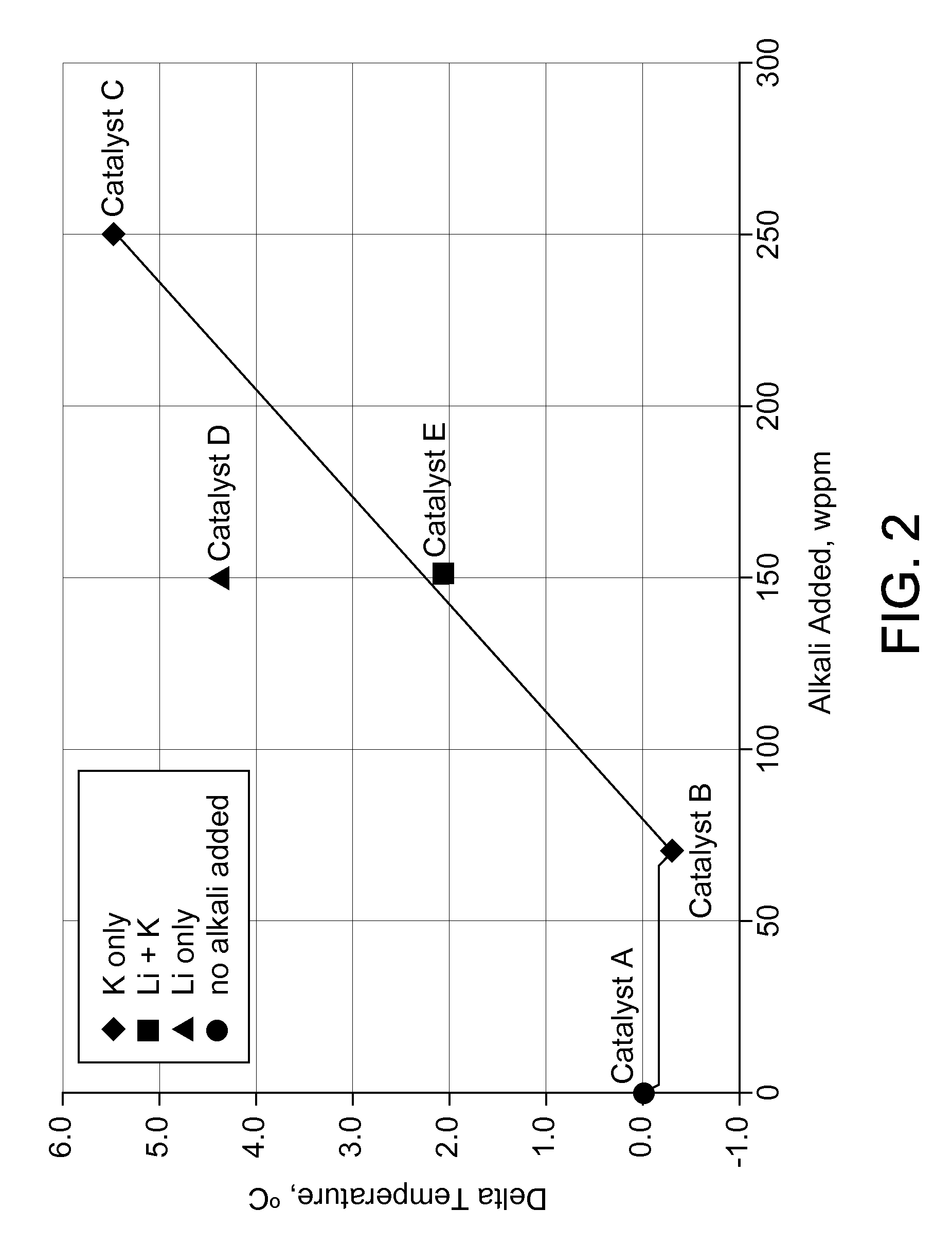

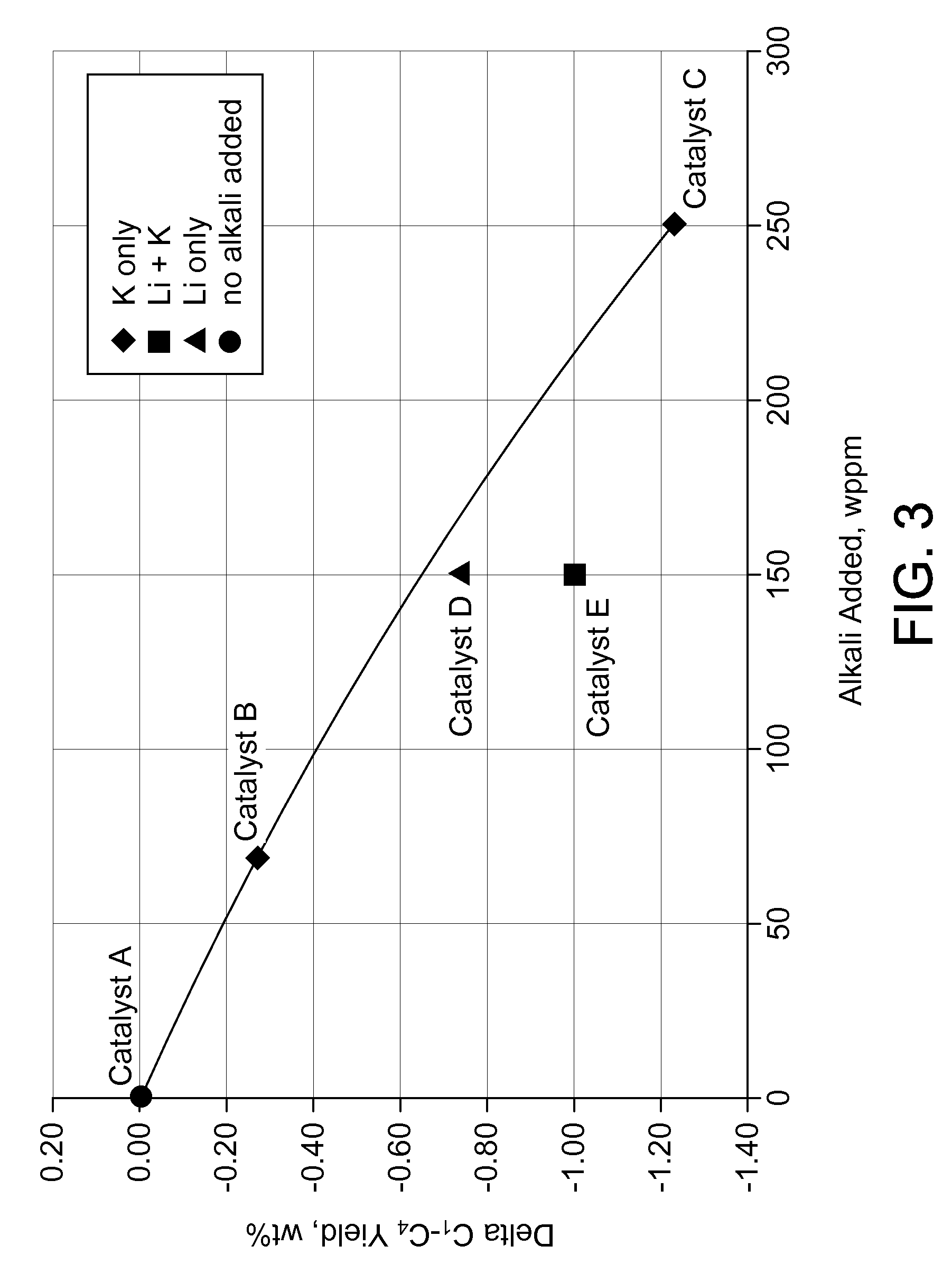

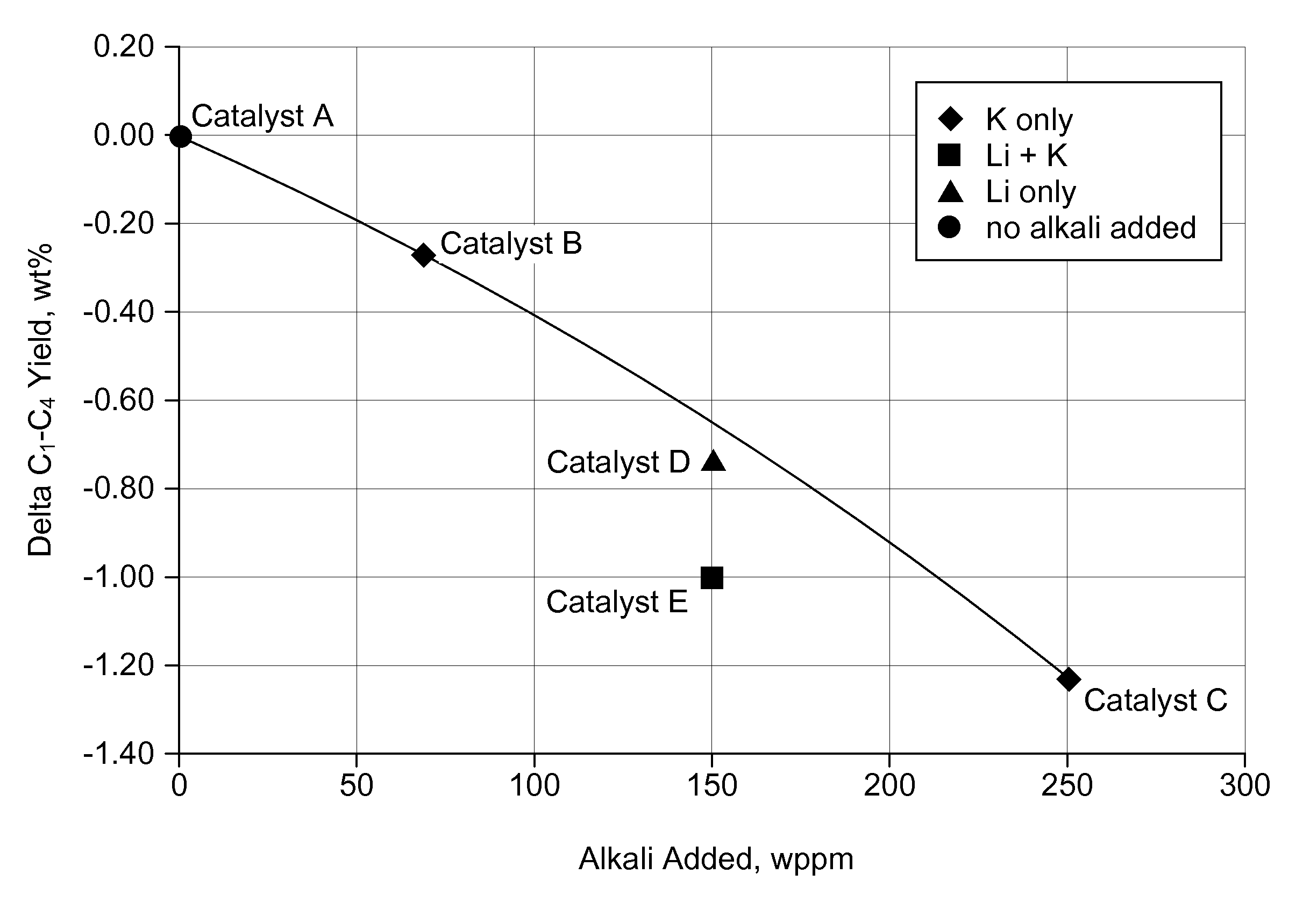

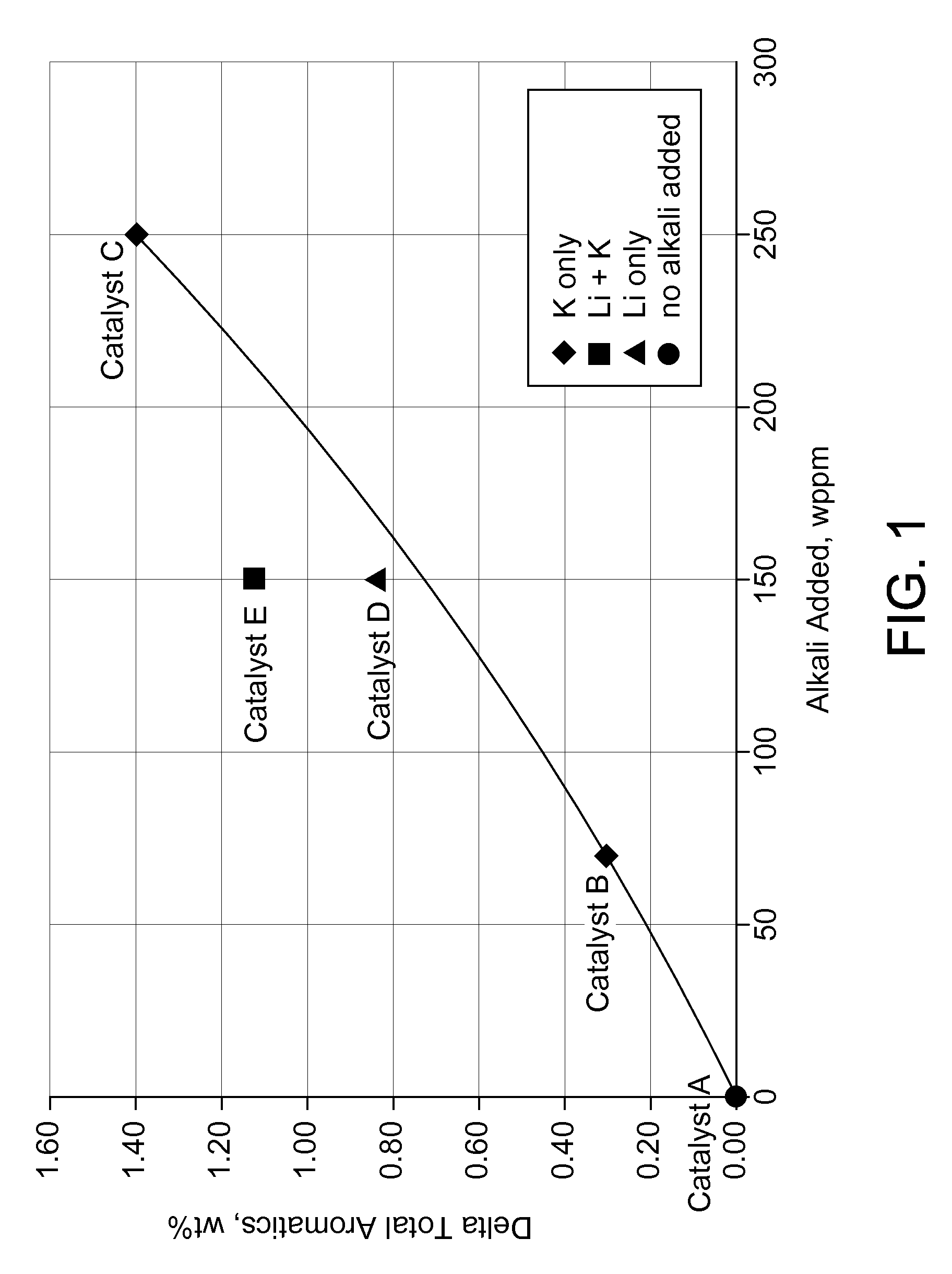

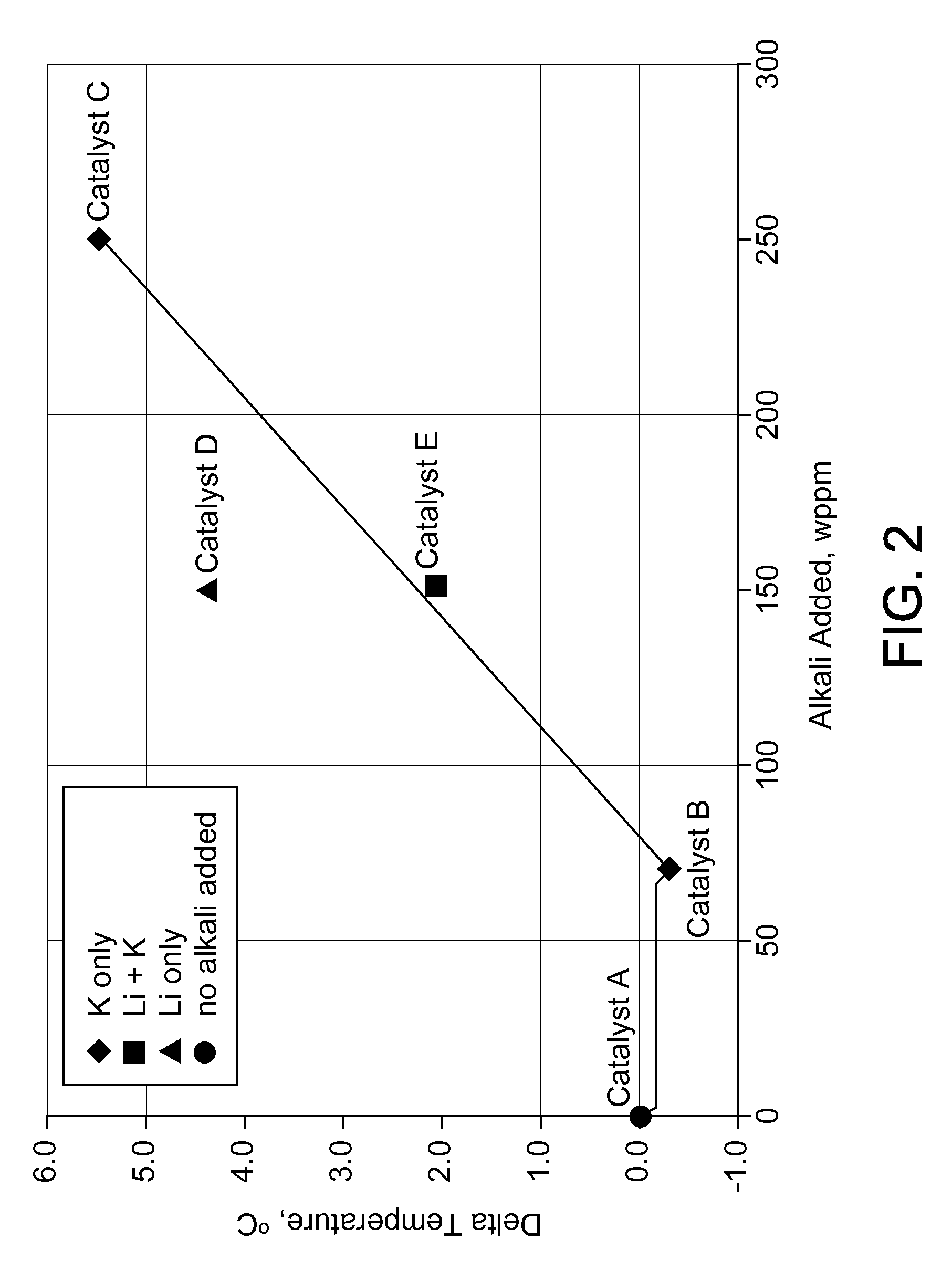

Reforming catalysts with tuned acidity for maximum aromatics yield

ActiveUS20130256194A1Increase aromatics yieldIncrease productionCatalytic naphtha reformingCatalyst activation/preparationPlatinumCatalytic reforming

One exemplary embodiment can be a catalyst for catalytic reforming of naphtha. The catalyst can have a noble metal including one or more of platinum, palladium, rhodium, ruthenium, osmium, and iridium, at least two alkali metals or at least two alkaline earth metals, or mixtures of alkali metals and alkaline earth metals and a support.

Owner:UOP LLC

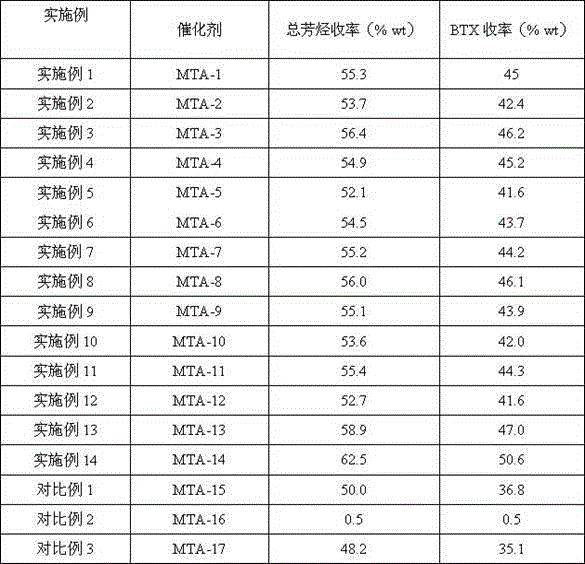

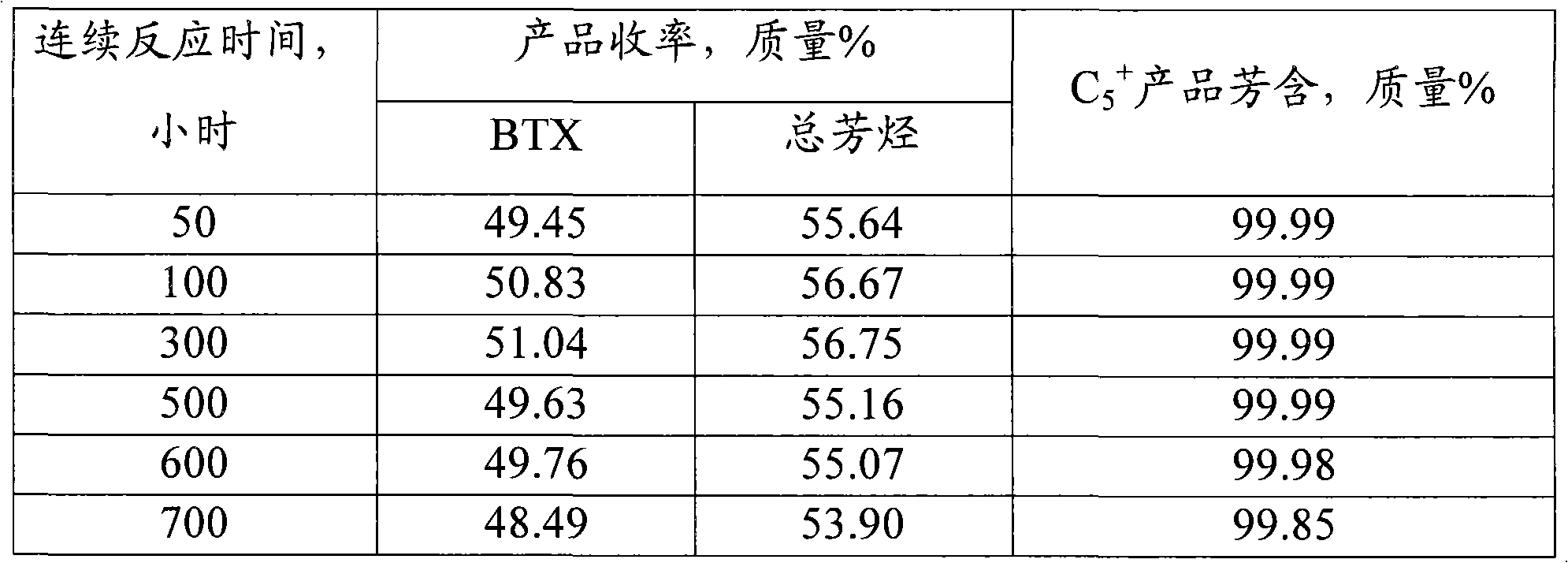

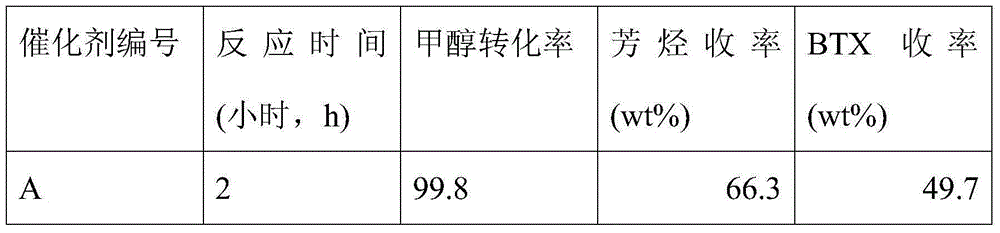

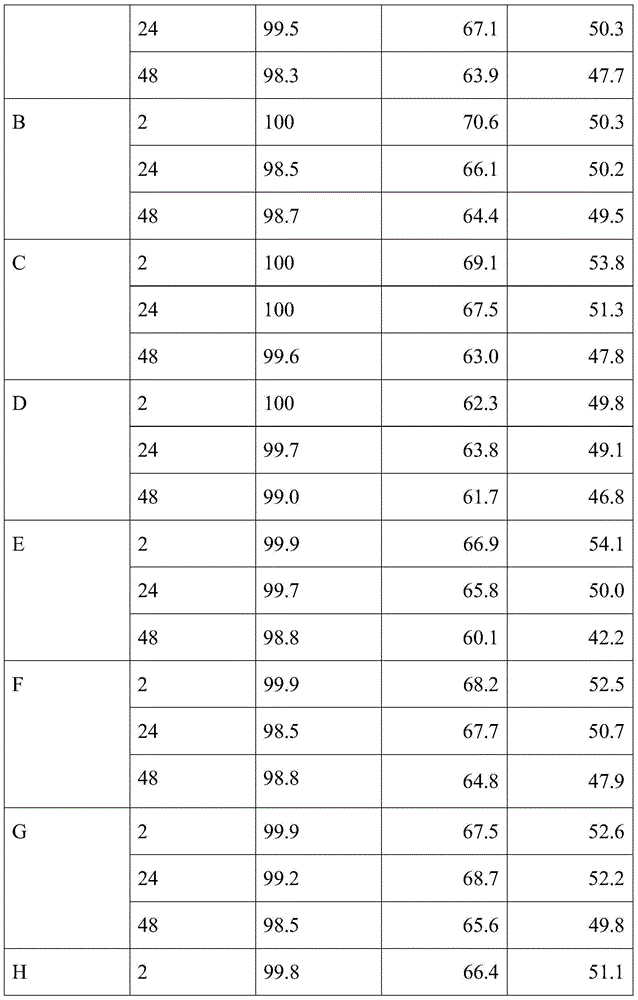

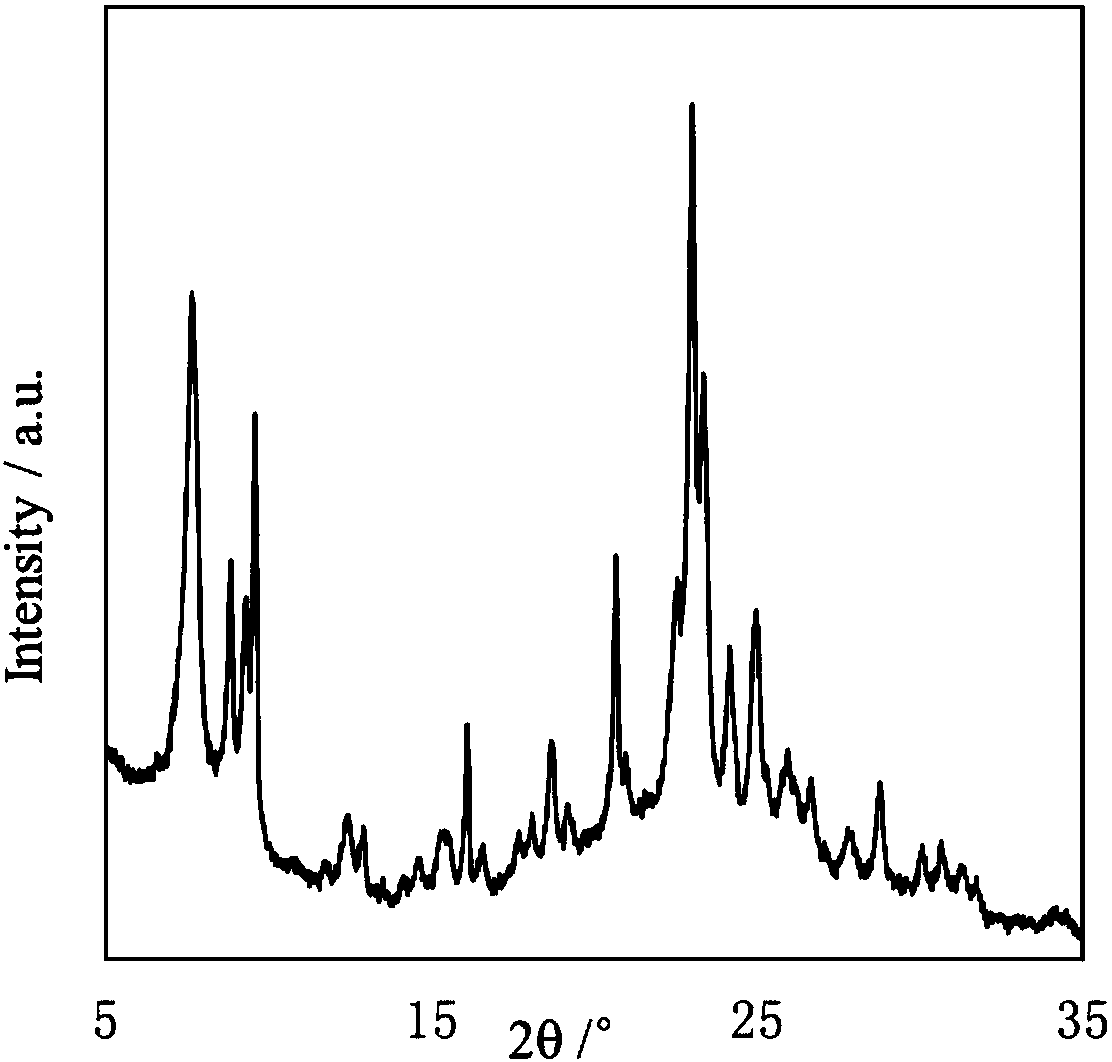

Catalyst for preparing aromatics by use of methanol and preparation method of catalyst

ActiveCN104549479AIncrease aromatics yieldHigh BTX yieldMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePtru catalyst

The invention relates to a catalyst for preparing aromatics by use of methanol and a preparation method of the catalyst, aiming at solving the problem that the catalyst in the prior art has low reaction activity. The catalyst is prepared from the following raw materials in parts by weight: (a) 25-85 parts of SAPO-34 / ZSM-5 composite molecular sieve; (b) 1-10 parts of metal element; and (c) 10-70 parts of structural promoter. The catalyst can solve the above problem well and can be used for industrial production for preparing aromatics by use of methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

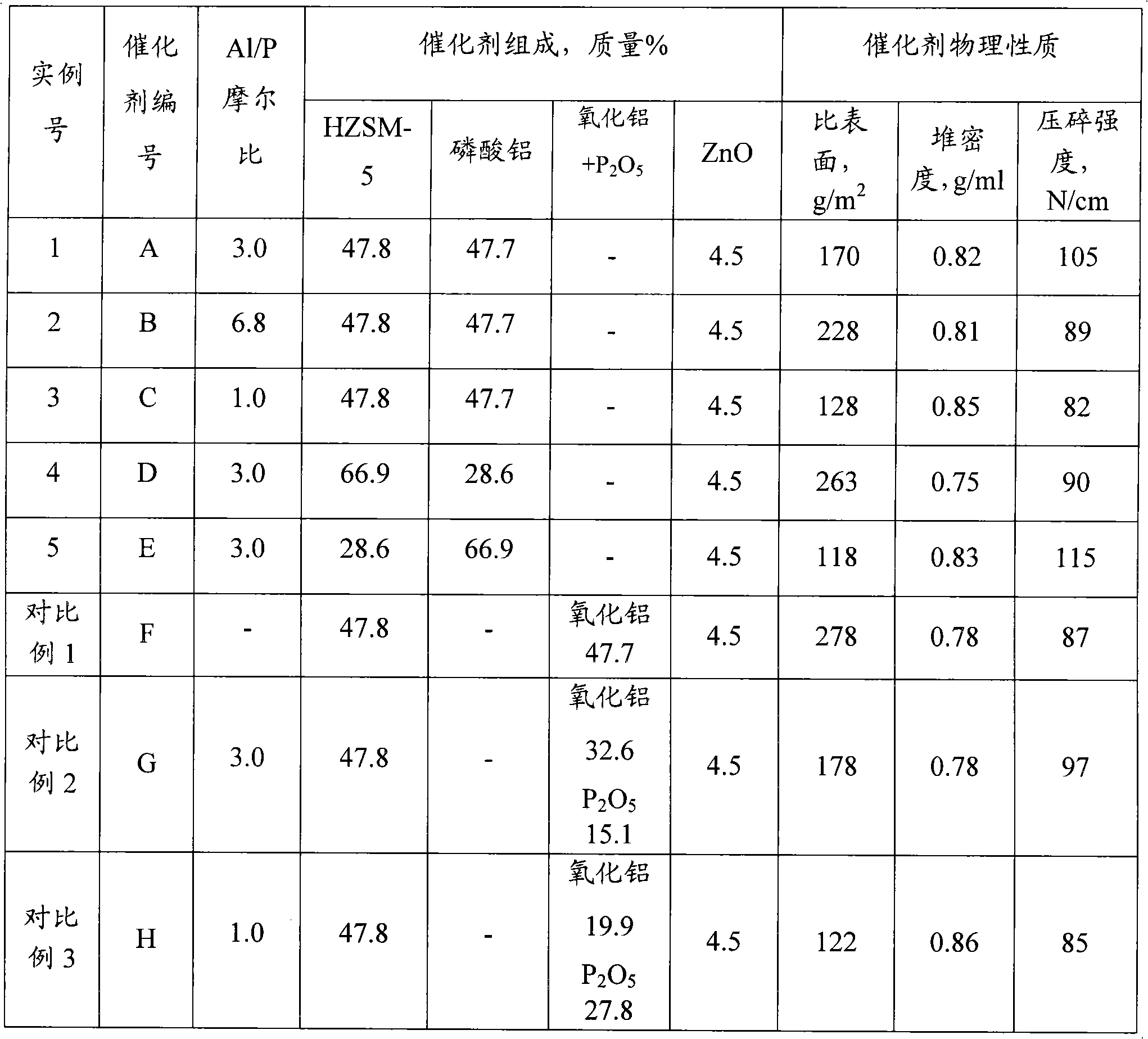

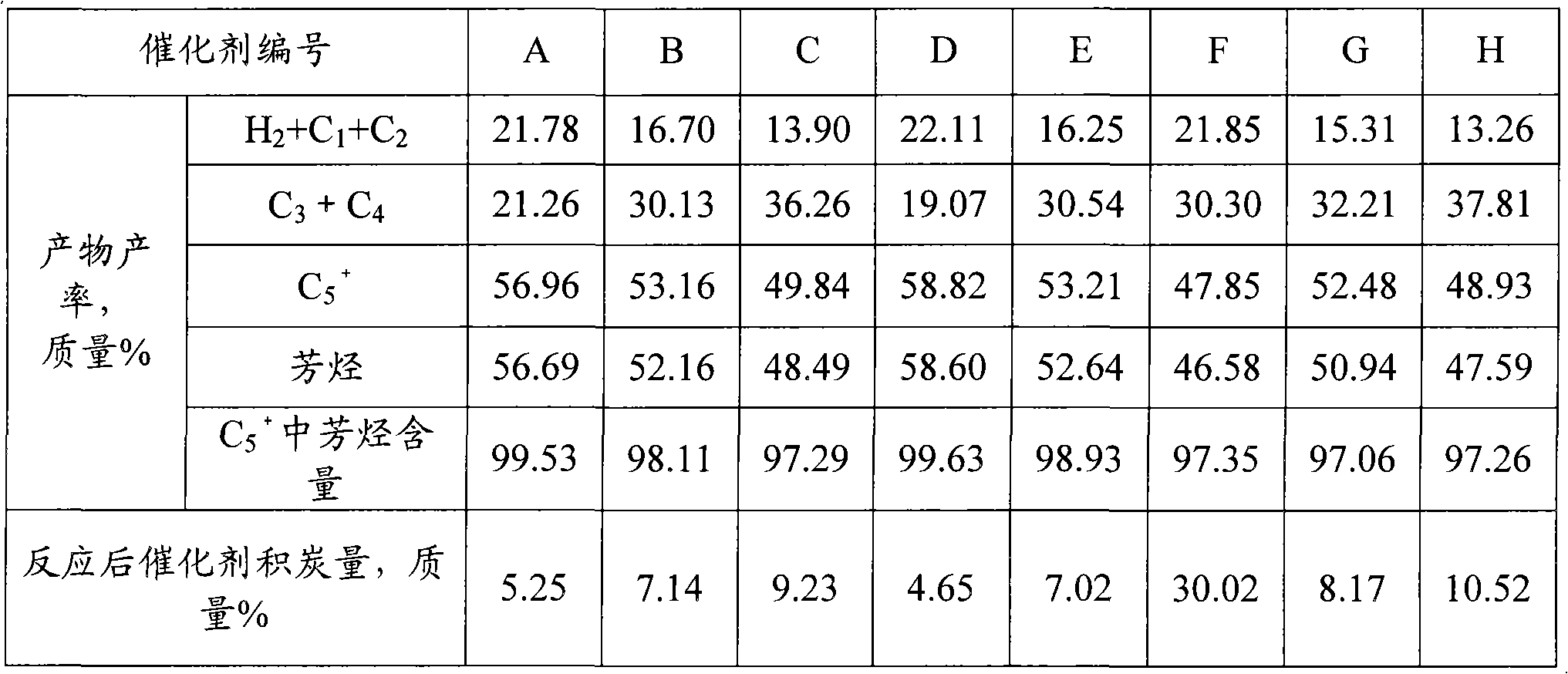

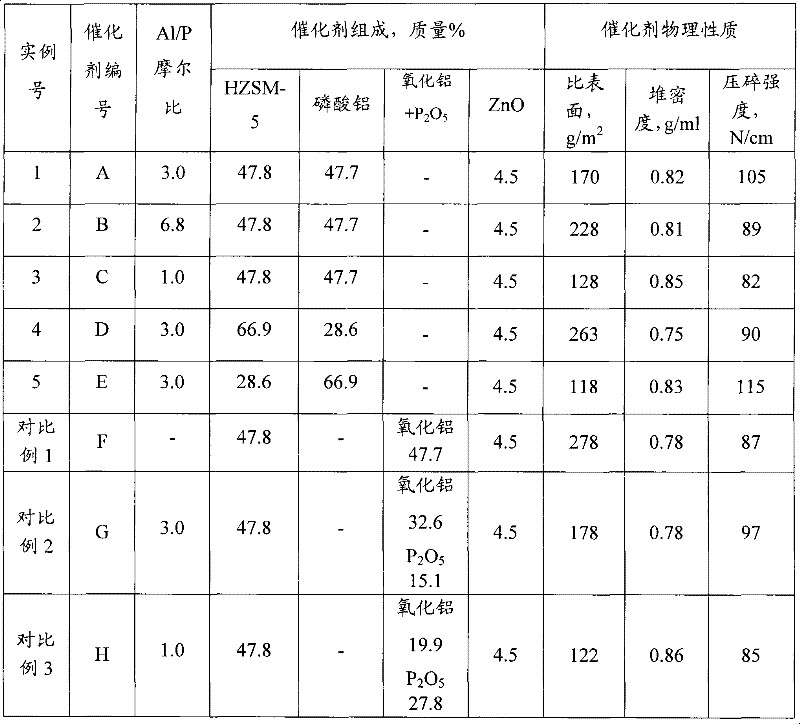

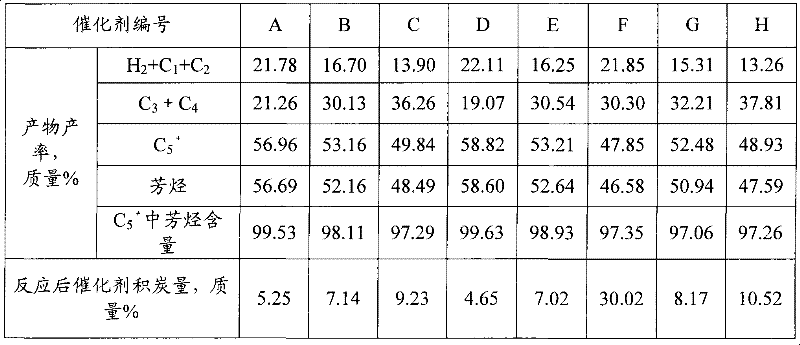

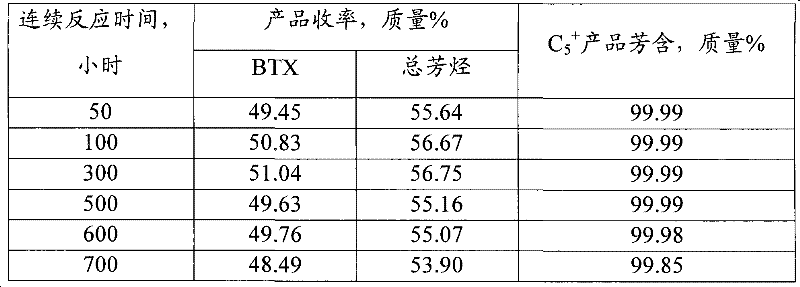

Light-hydrocarbon aromatized catalyst and preparation method thereof

ActiveCN101596461AIncrease aromatics yieldLong life one wayMolecular sieve catalystsHydrocarbon oils refiningPhosphoric acidOxide

The invention relates to a light-hydrocarbon aromatized catalyst which comprises the following components according to the mass percent: 20-75 percent of zeolite with MFI structure, 20-75 percent of aluminum phosphate and 0.5-8.0 percent of zinc oxide. The catalyst is used for the light-hydrocarbon aromatization reaction and has better aromatization activity, low carbon deposition rate in the reaction and long one-way service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

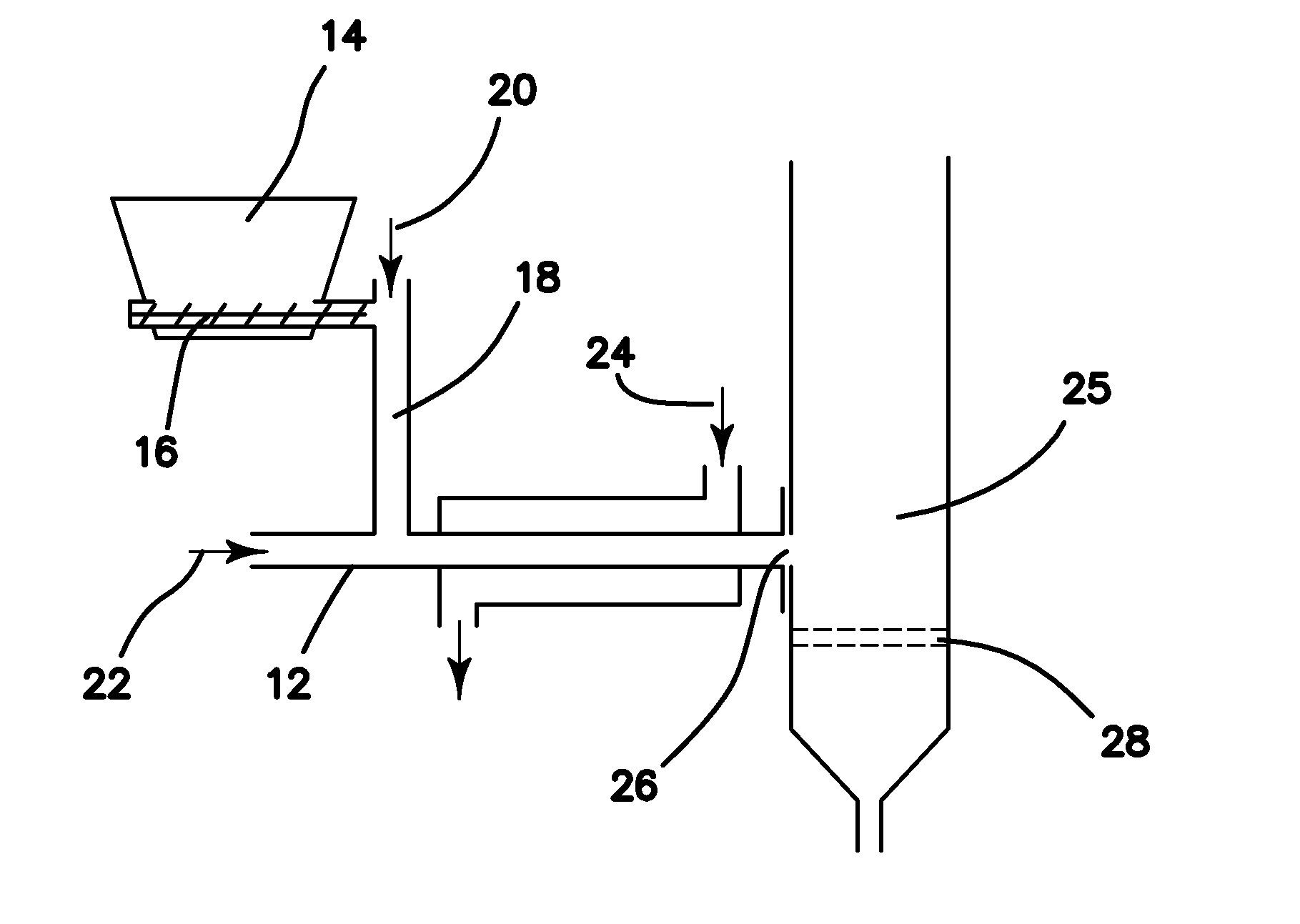

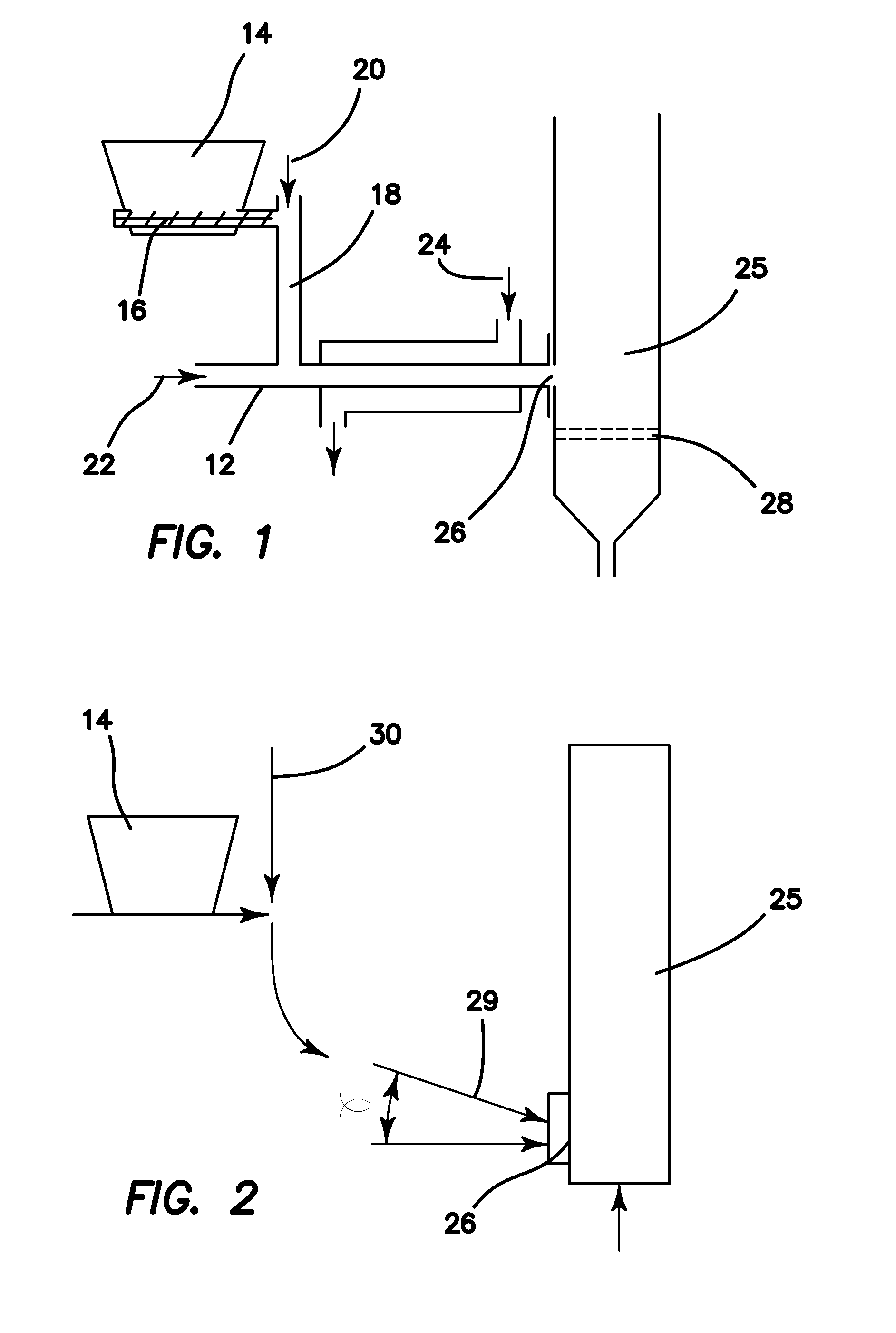

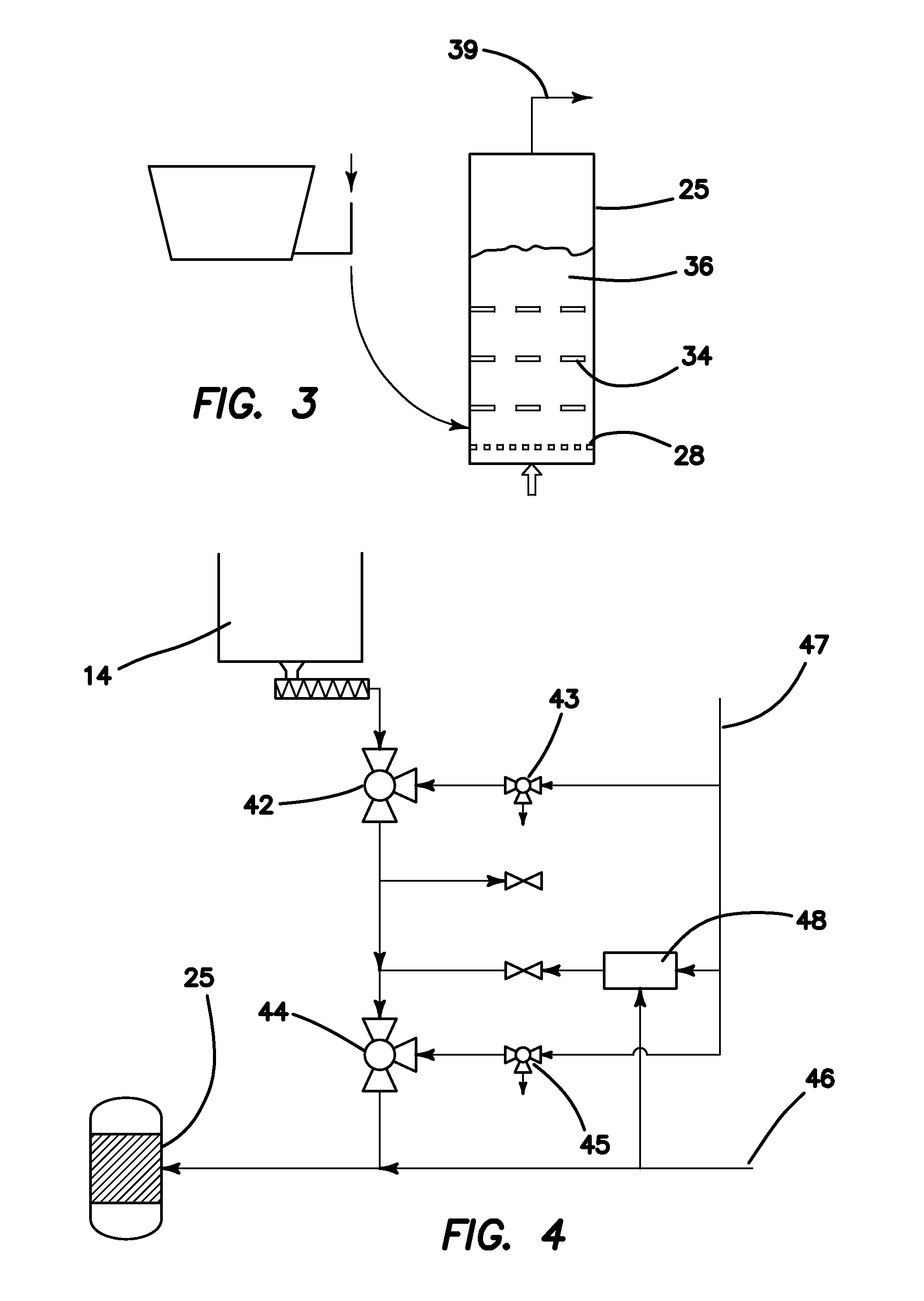

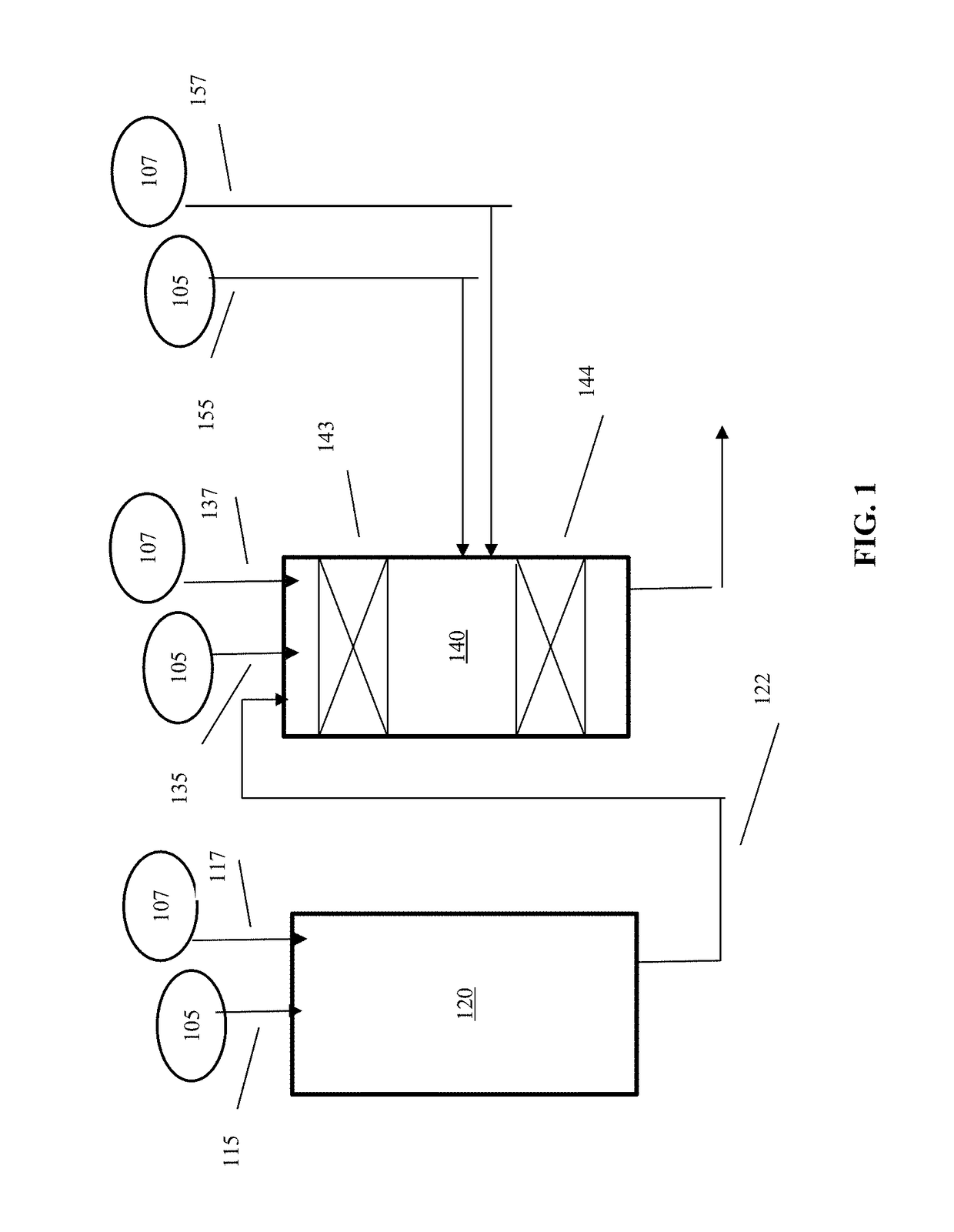

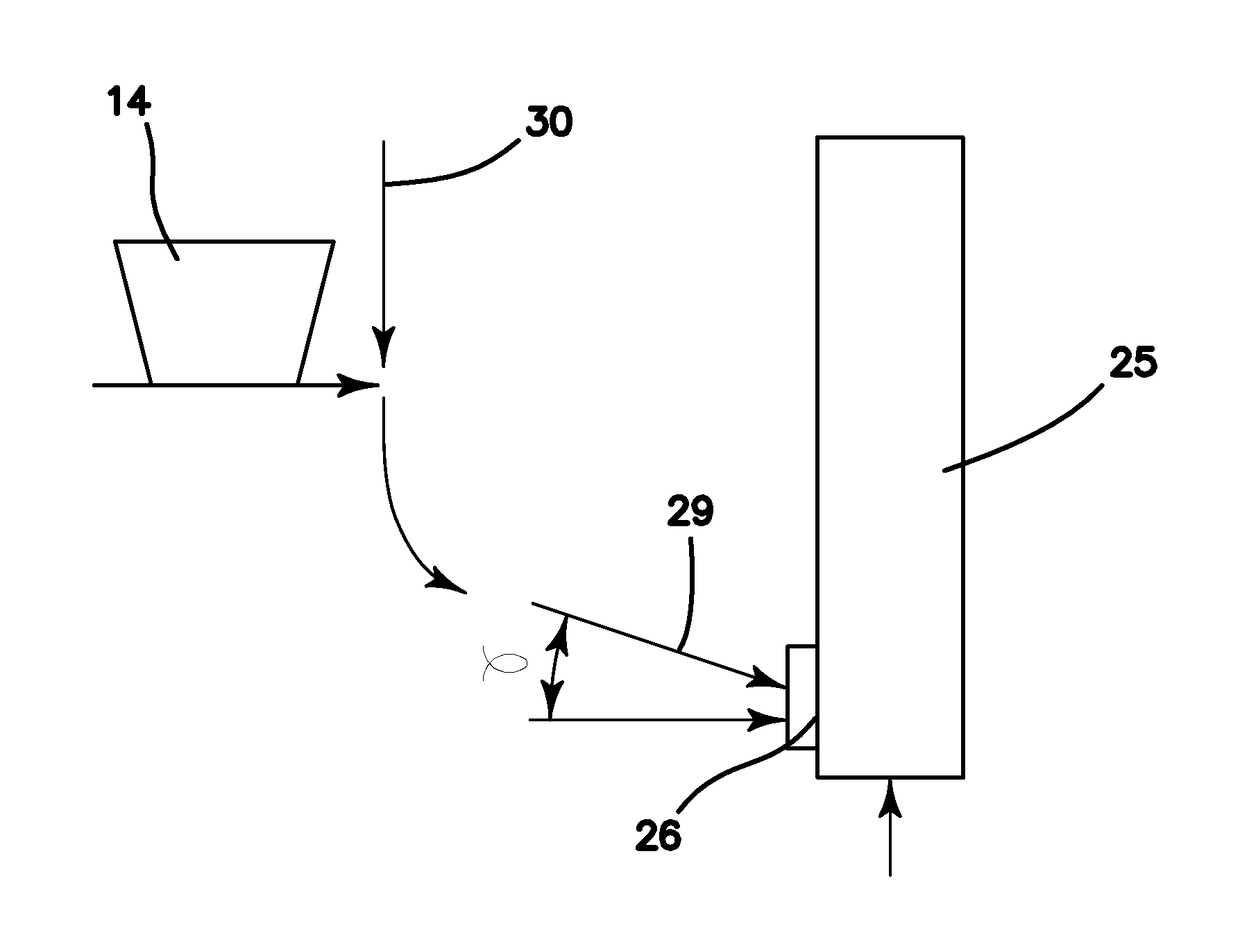

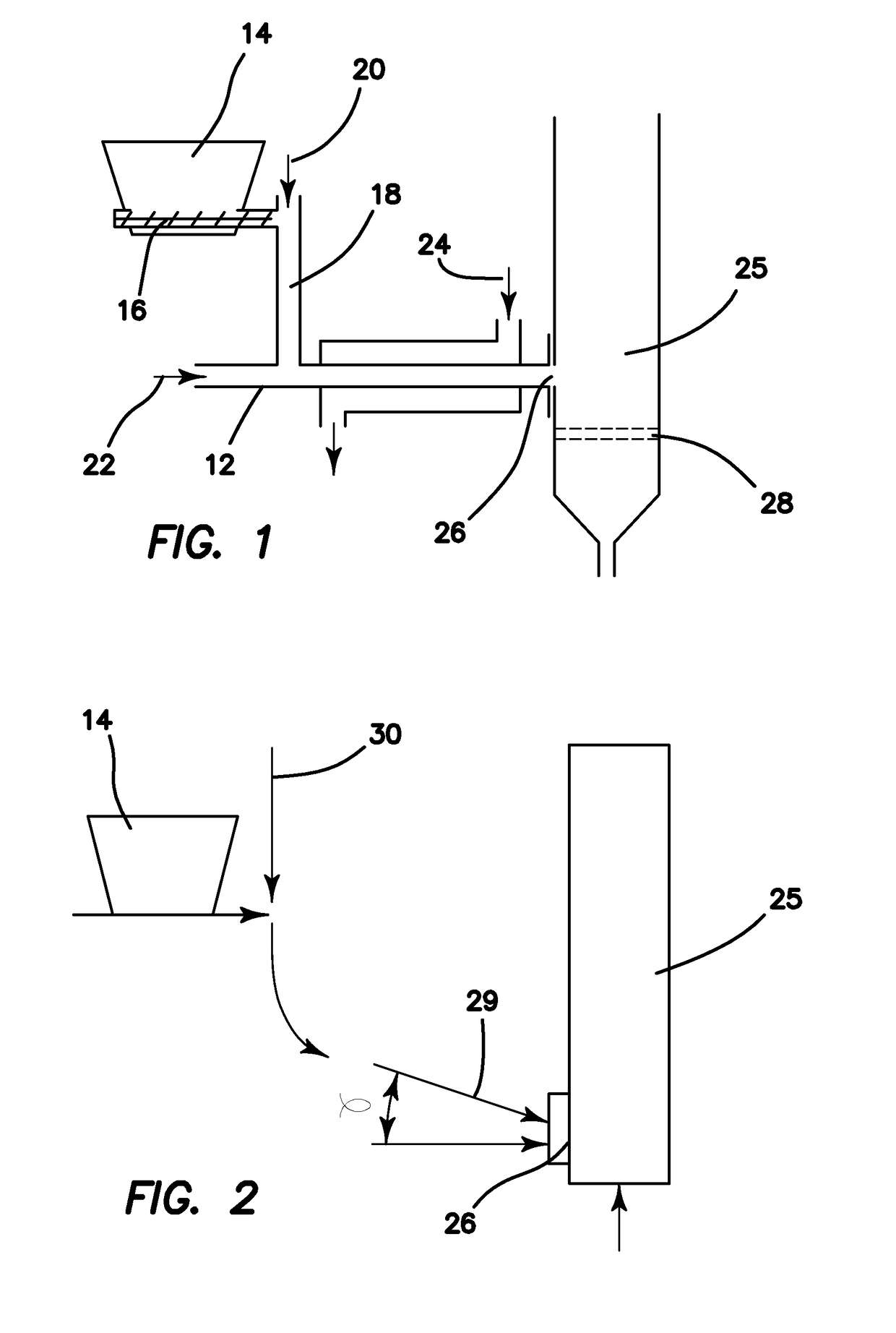

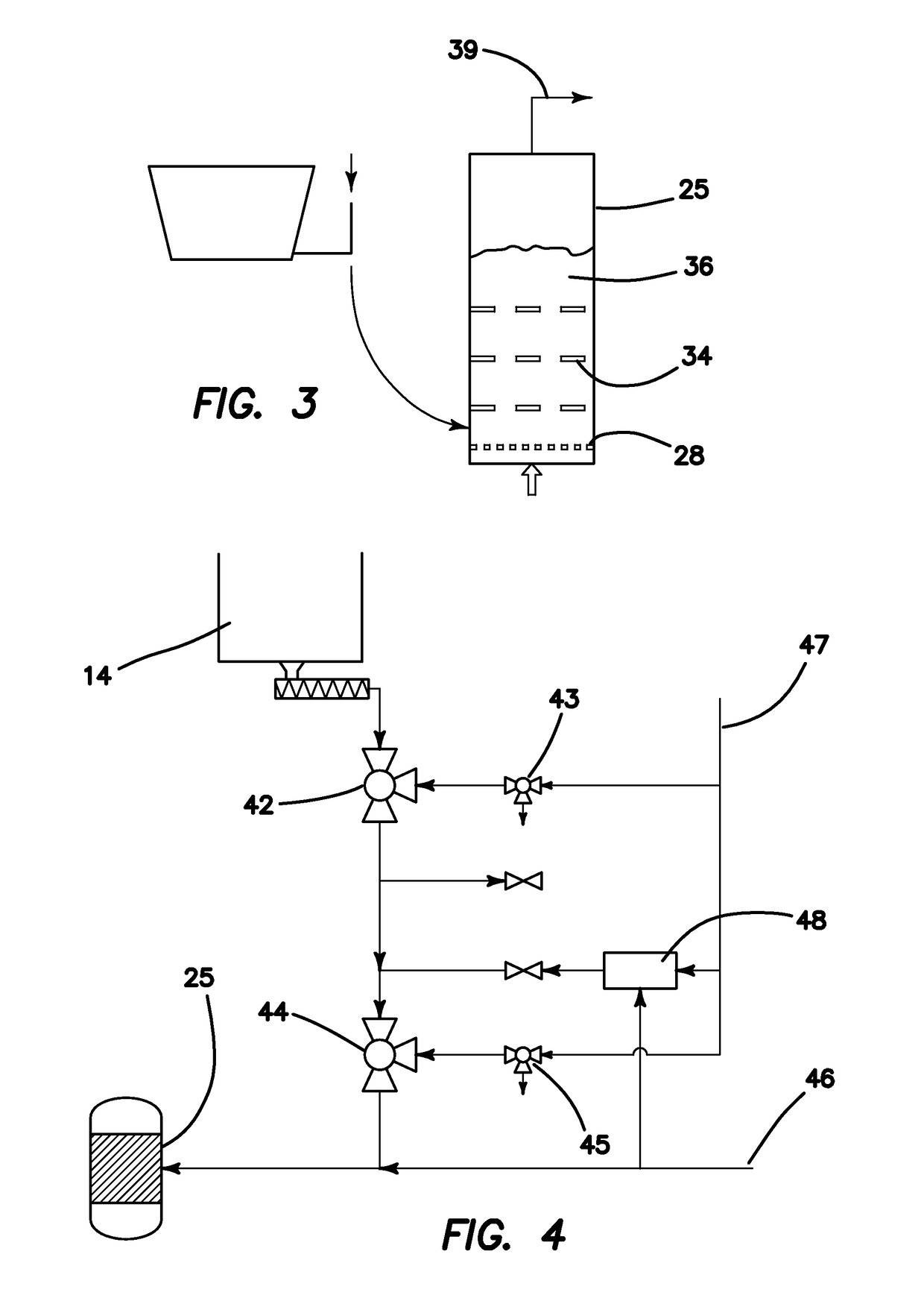

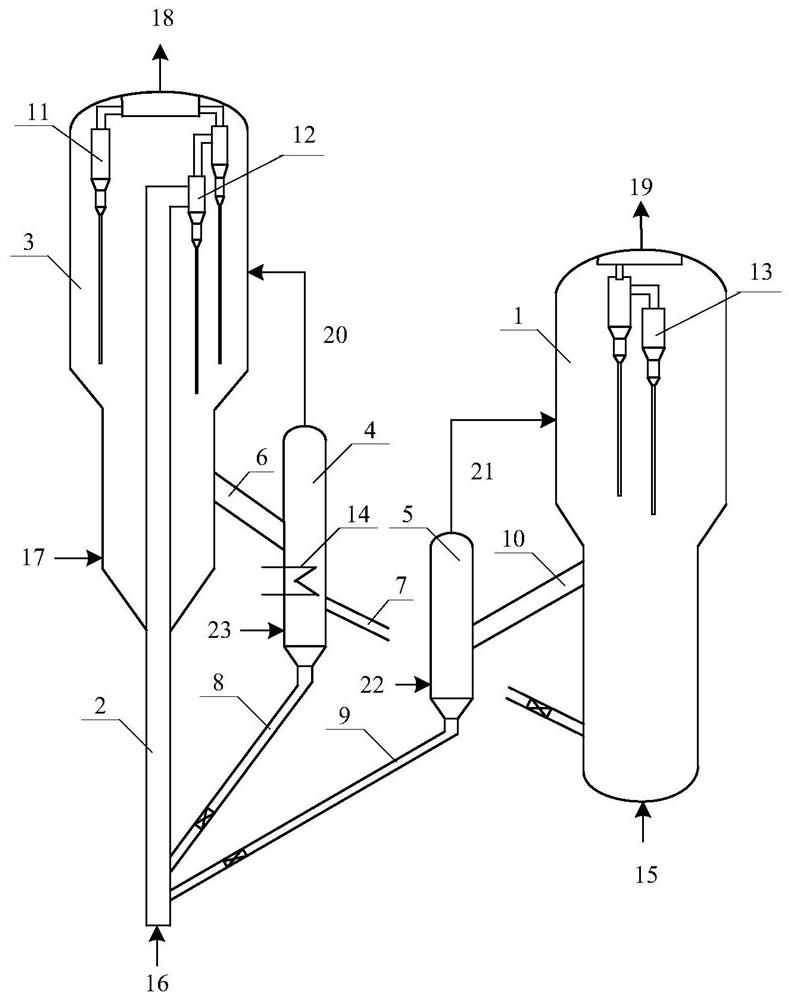

Gas jet injector reactor for catalytic fast pyrolysis process

ActiveUS20140206913A1Heating fastIncrease pressureDirect heating destructive distillationBiofuelsProcess engineeringProduct gas

Methods and systems utilizing gas jets to carry biomass into a biomass conversion reactor are described. Reactor configurations and conditions for carrying out processes utilizing the gas jets are also described. The use of gas jets has been found to be especially desirable for operation with pyrolysis of biomass in catalytic fluidized bed reactors.

Owner:ANELLOTECH INC

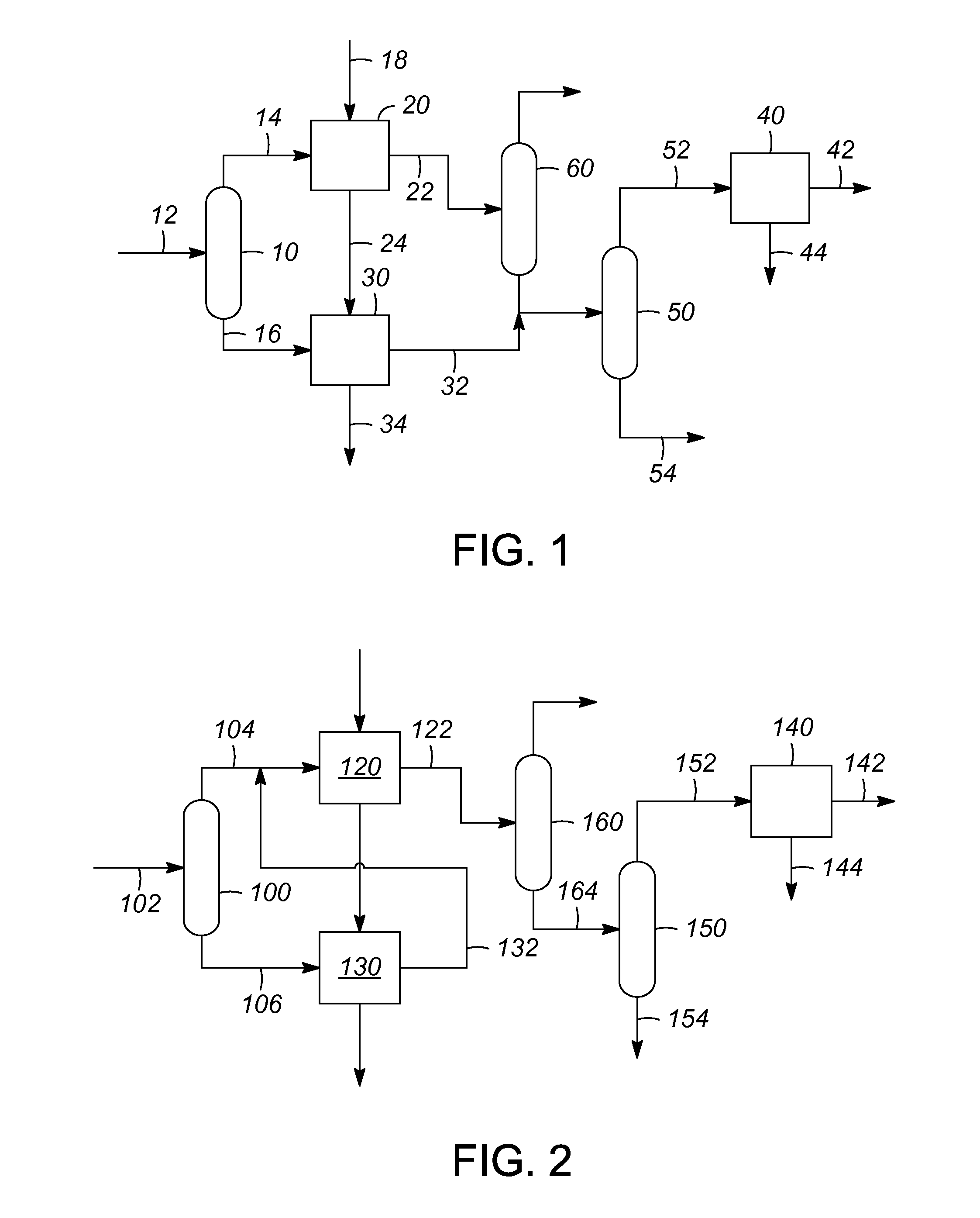

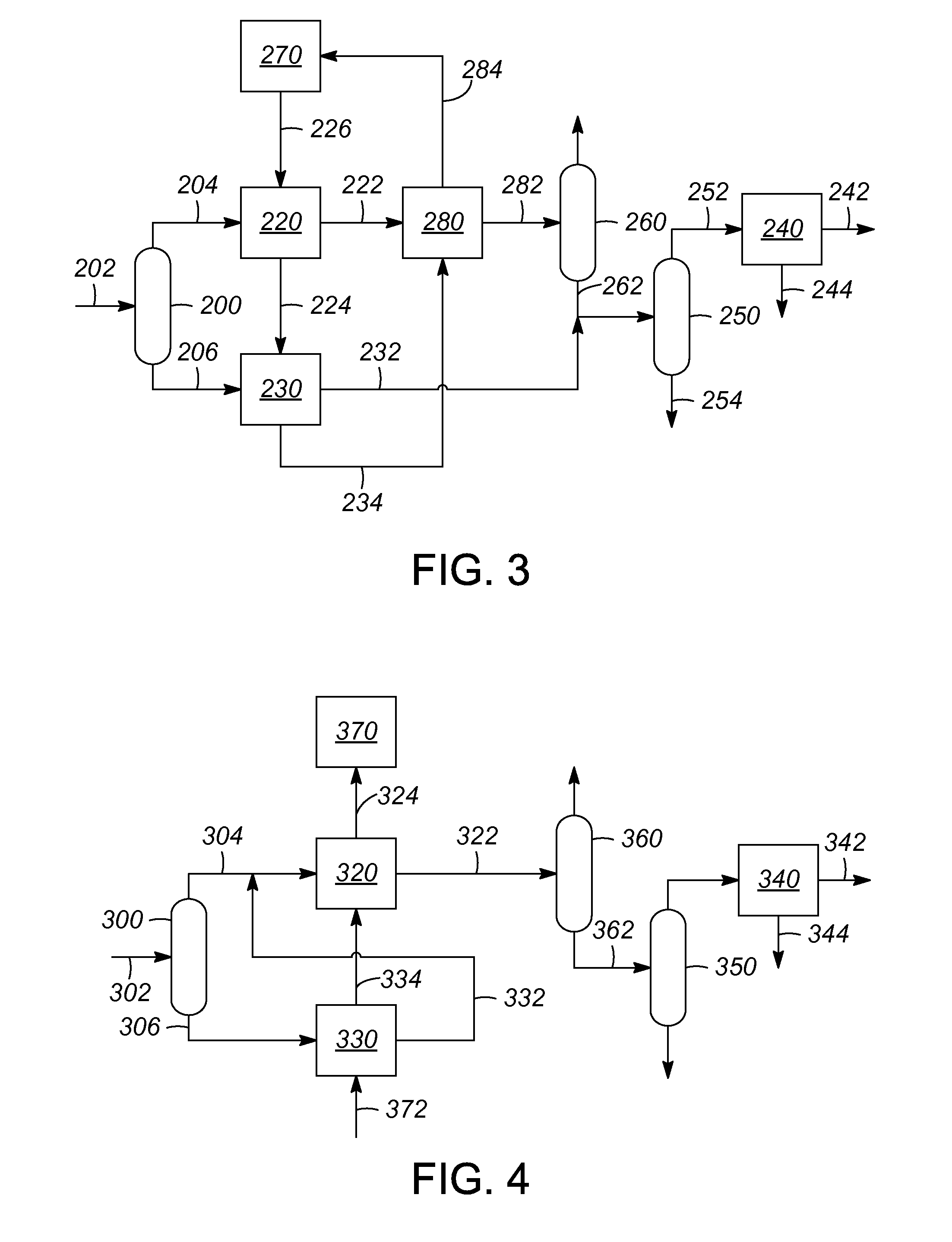

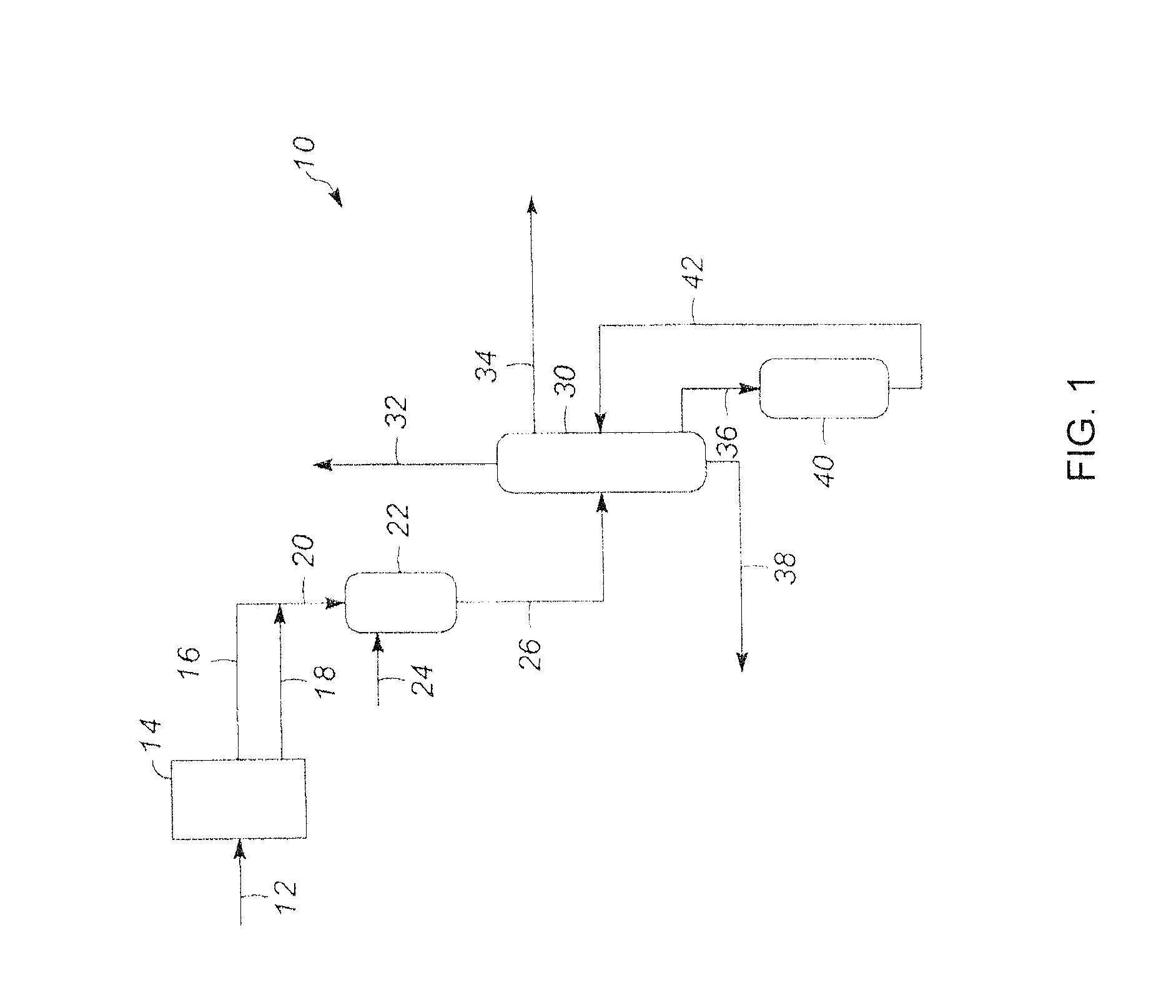

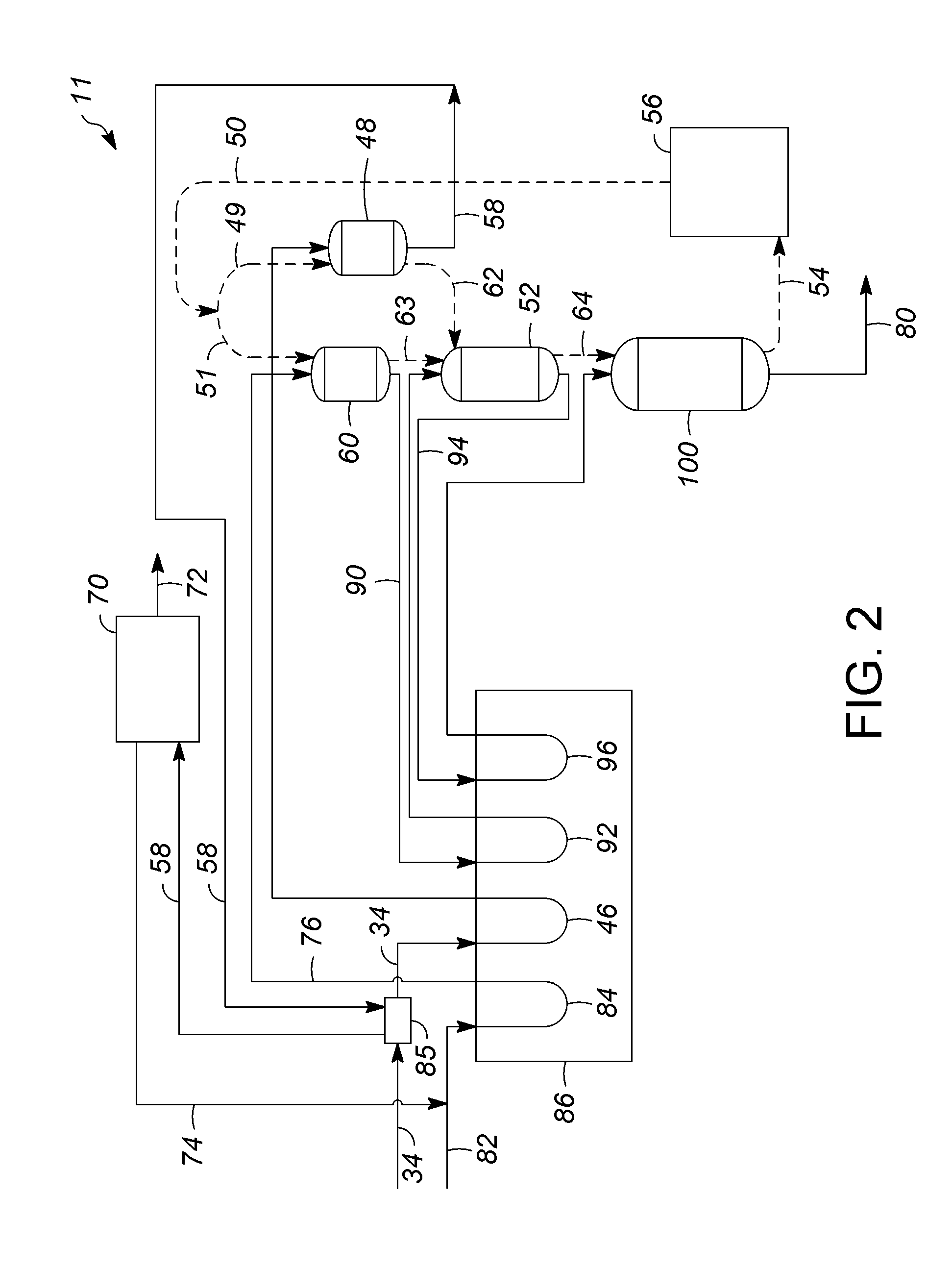

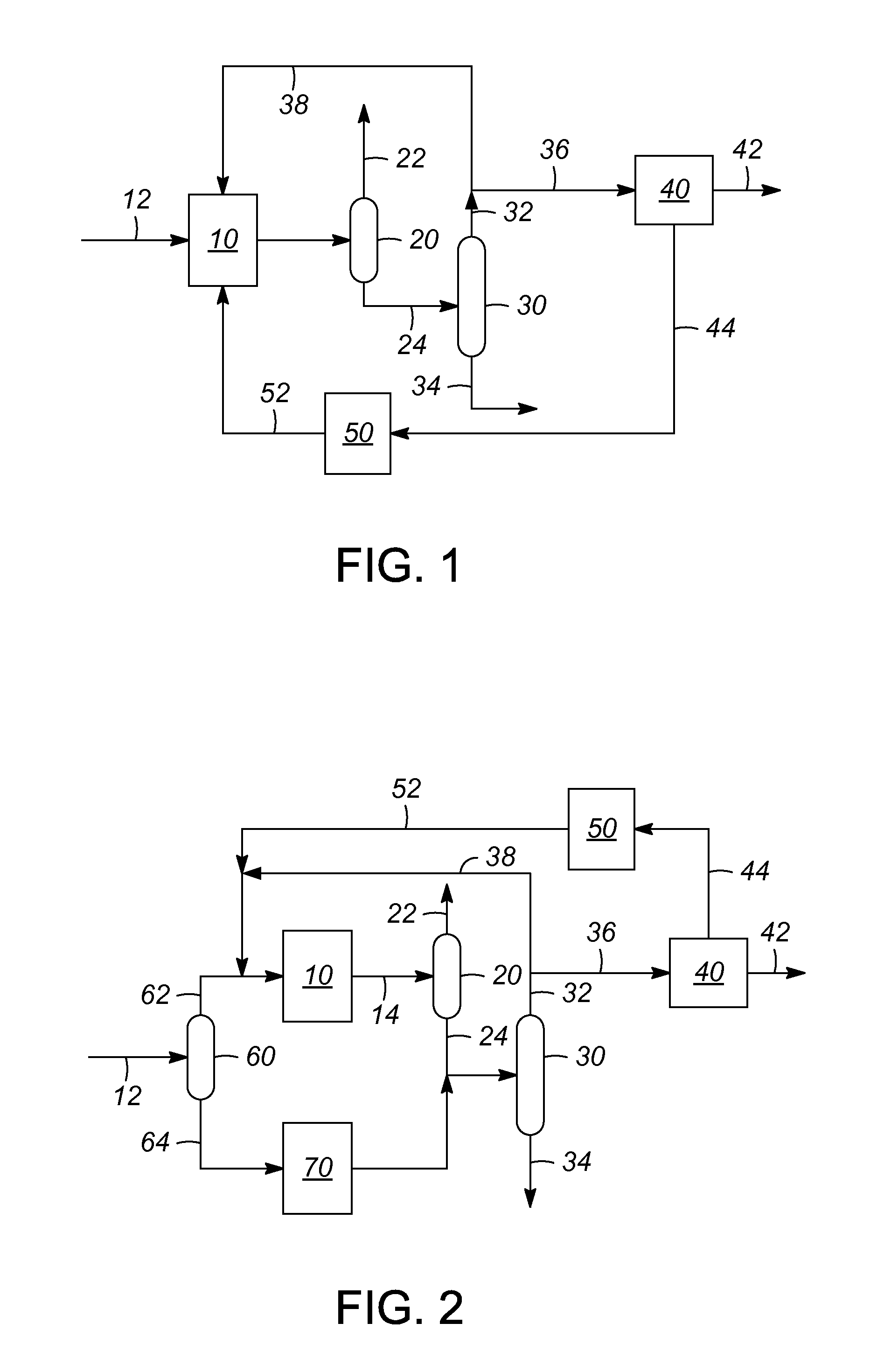

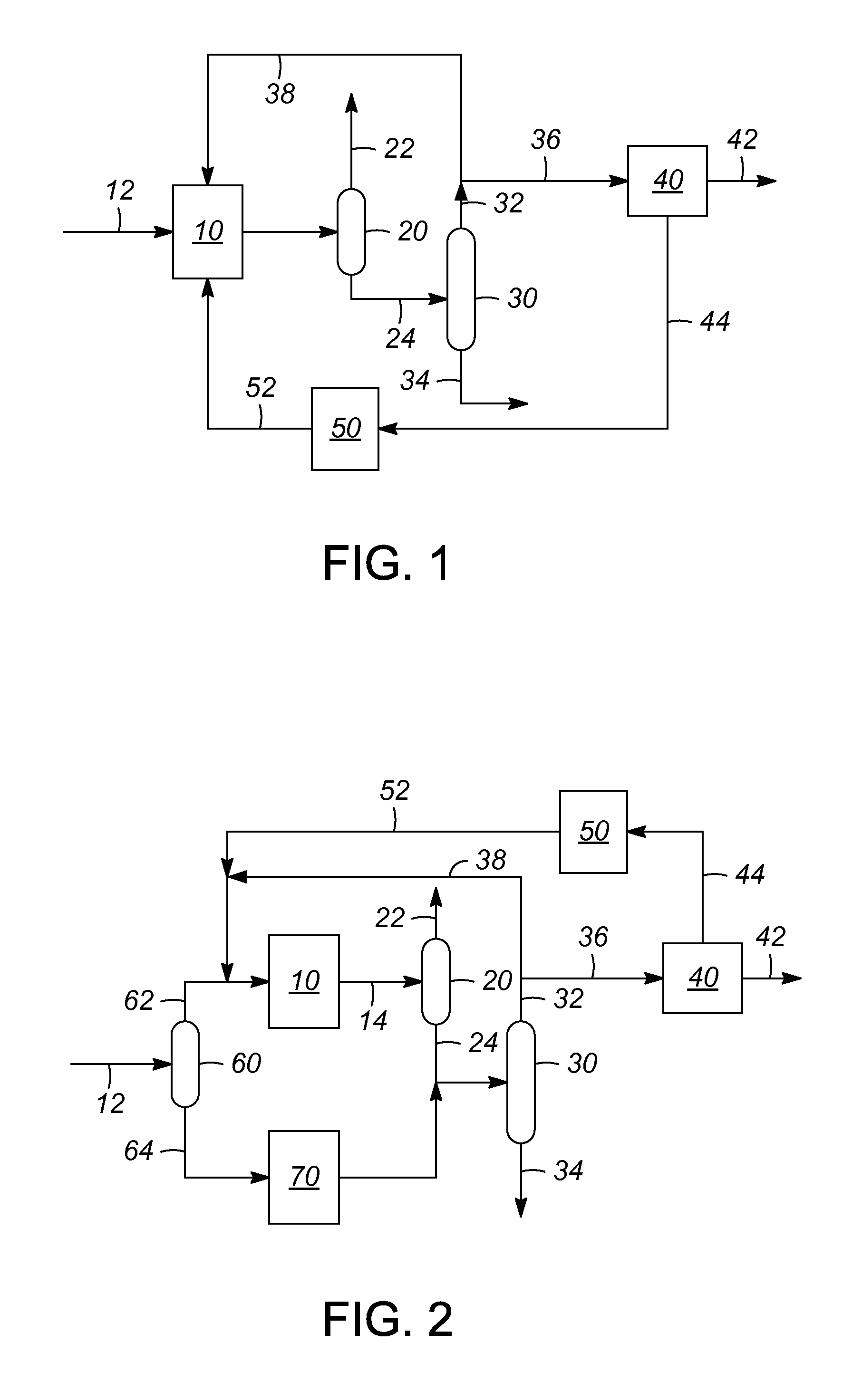

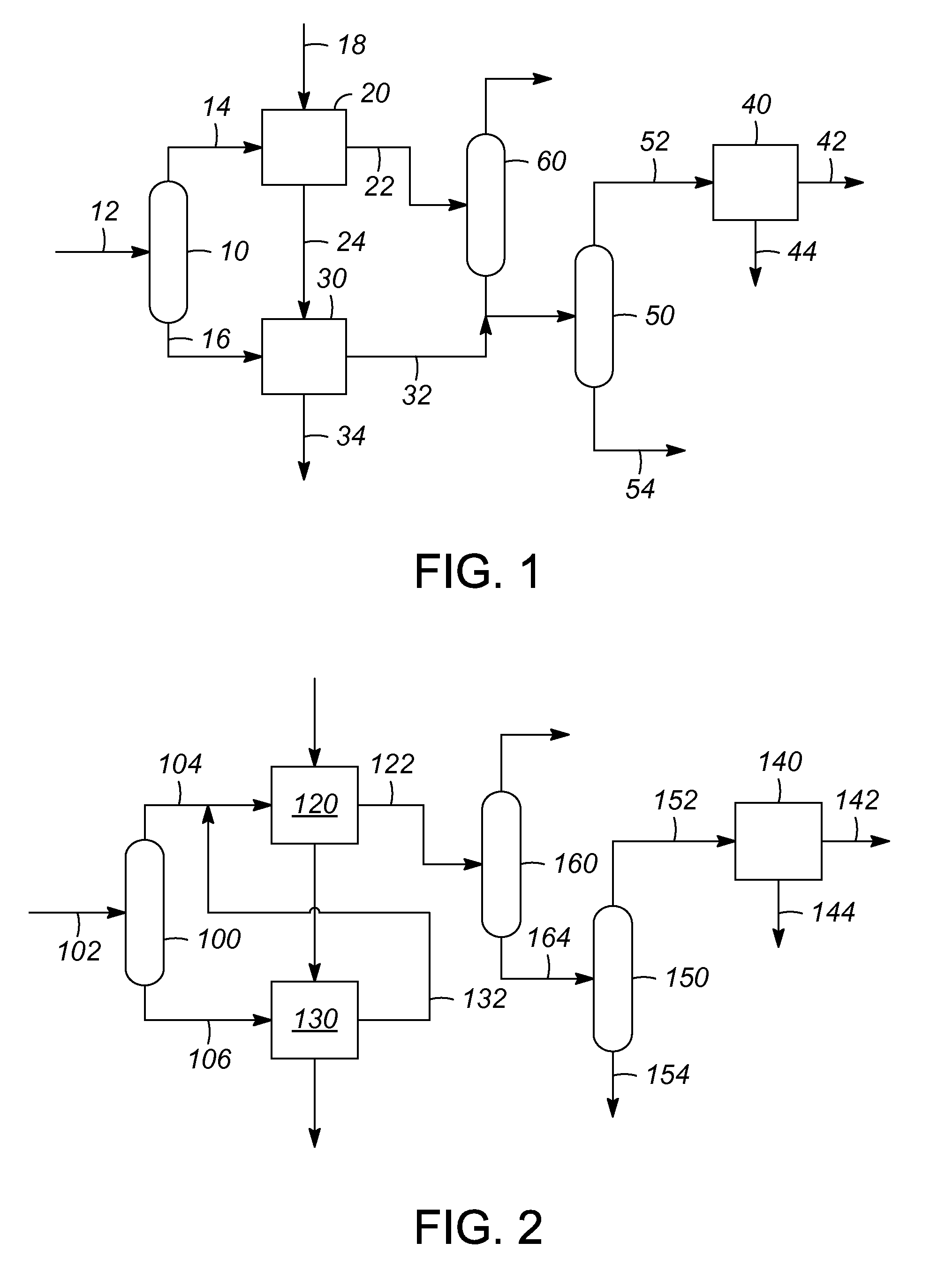

Process for increasing benzene and toluene production

ActiveUS20120277505A1Increase productionIncrease aromatics yieldHydrocarbon purification/separationCatalytic naphtha reformingBenzeneNaphtha

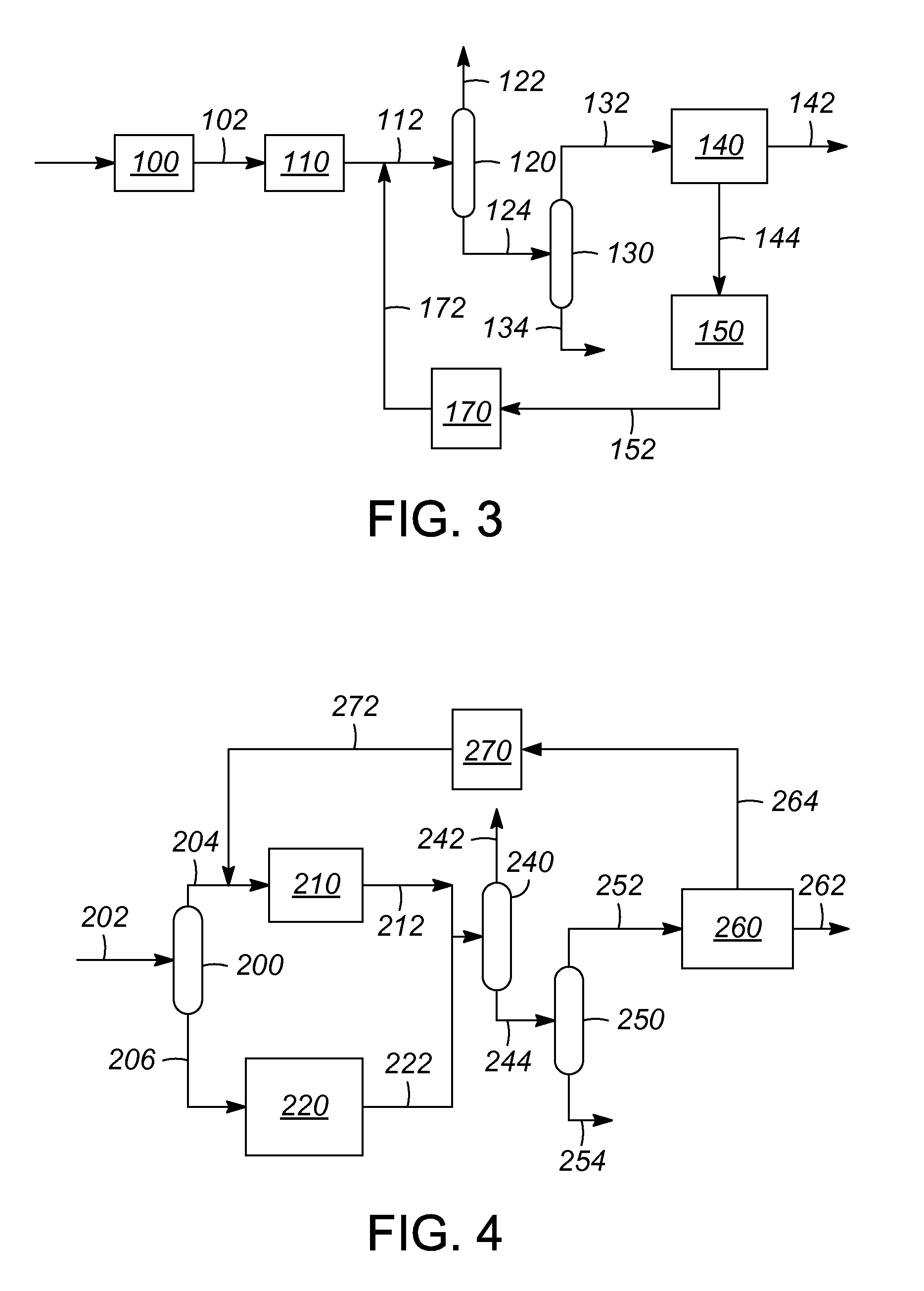

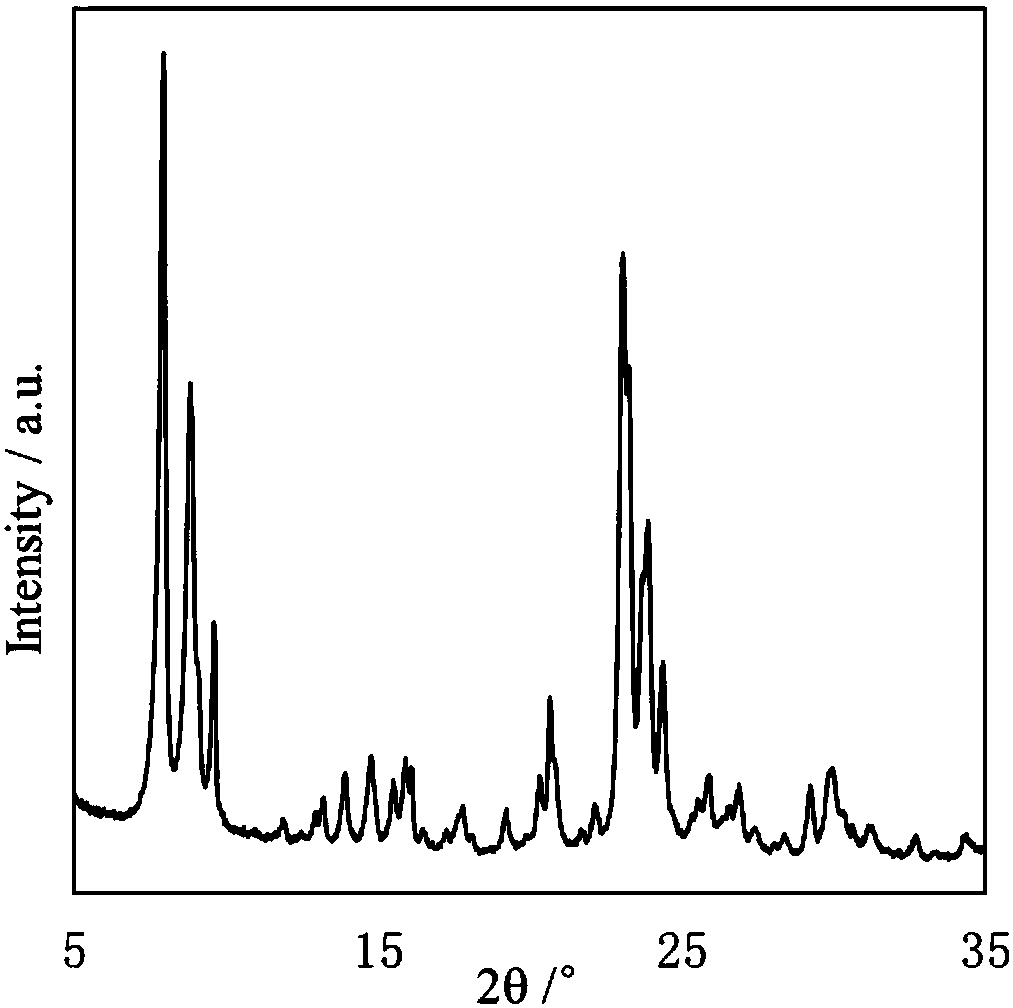

A process for reforming a hydrocarbon stream is presented. The process involves splitting a naphtha feedstream to at least two feedstreams and passing each feedstream to separation reformers. The reformers are operated under different conditions to utilize the differences in the reaction properties of the different hydrocarbon components. The process utilizes a common catalyst, and common downstream processes for recovering the desired aromatic compounds generated.

Owner:UOP LLC

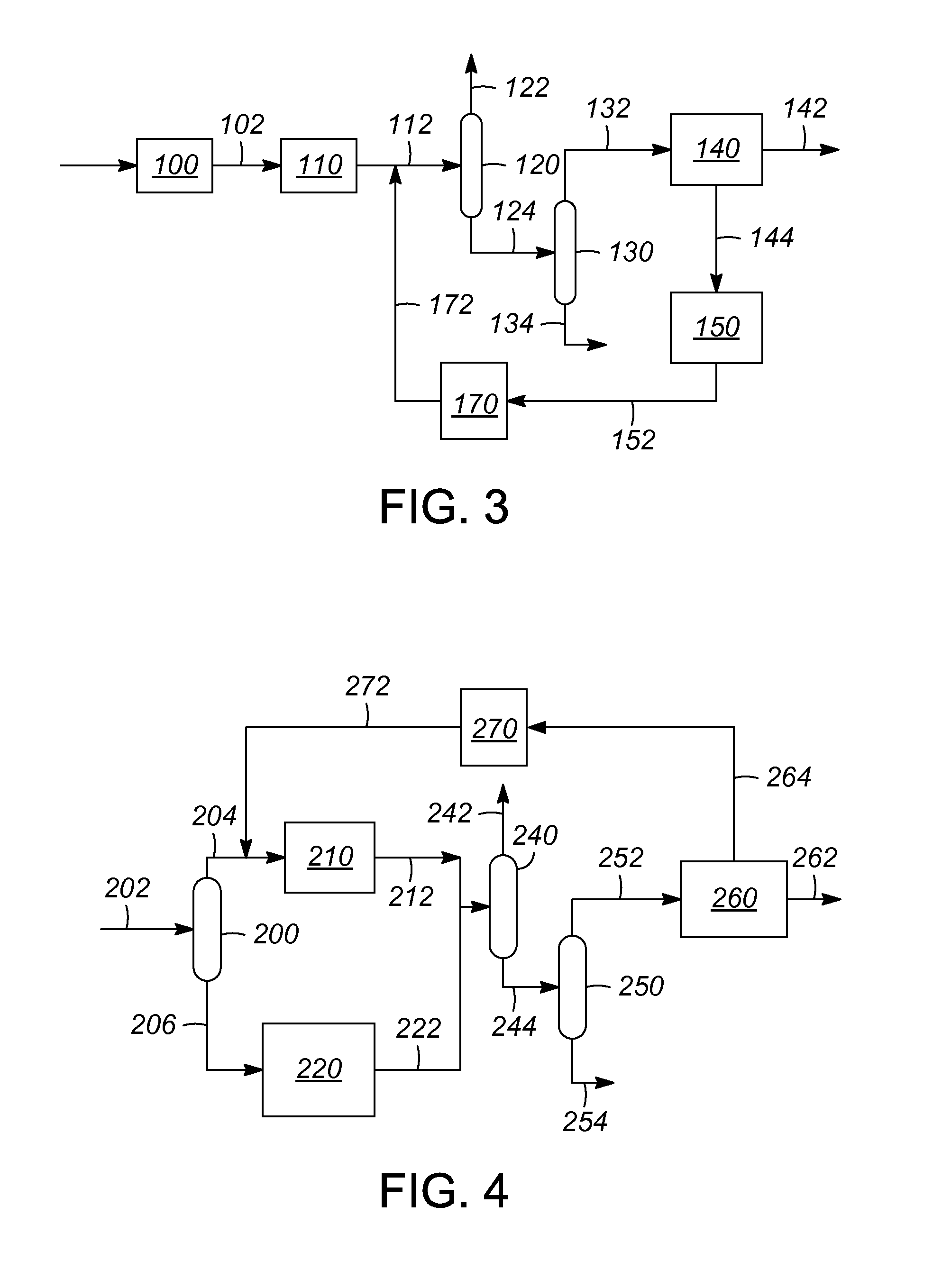

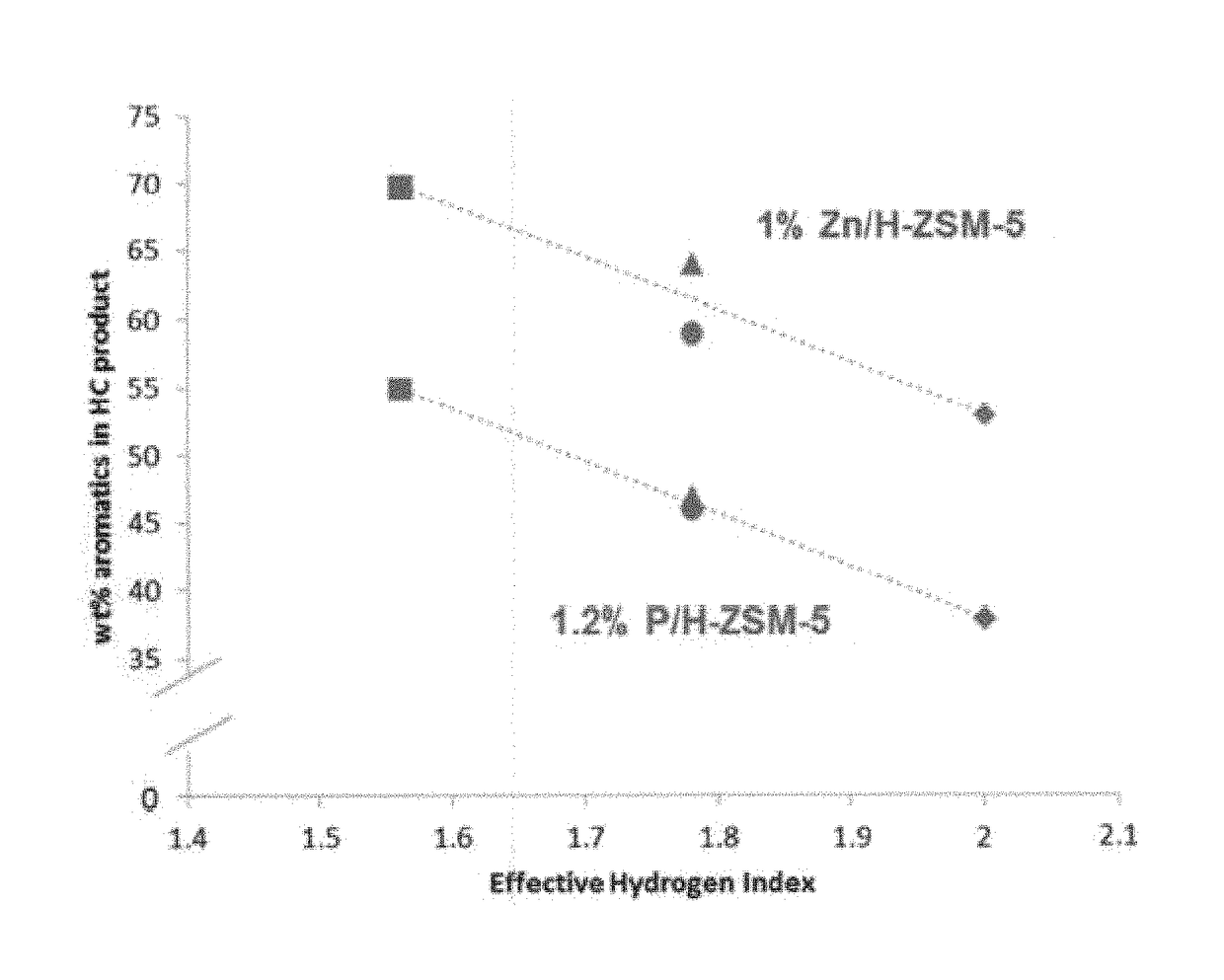

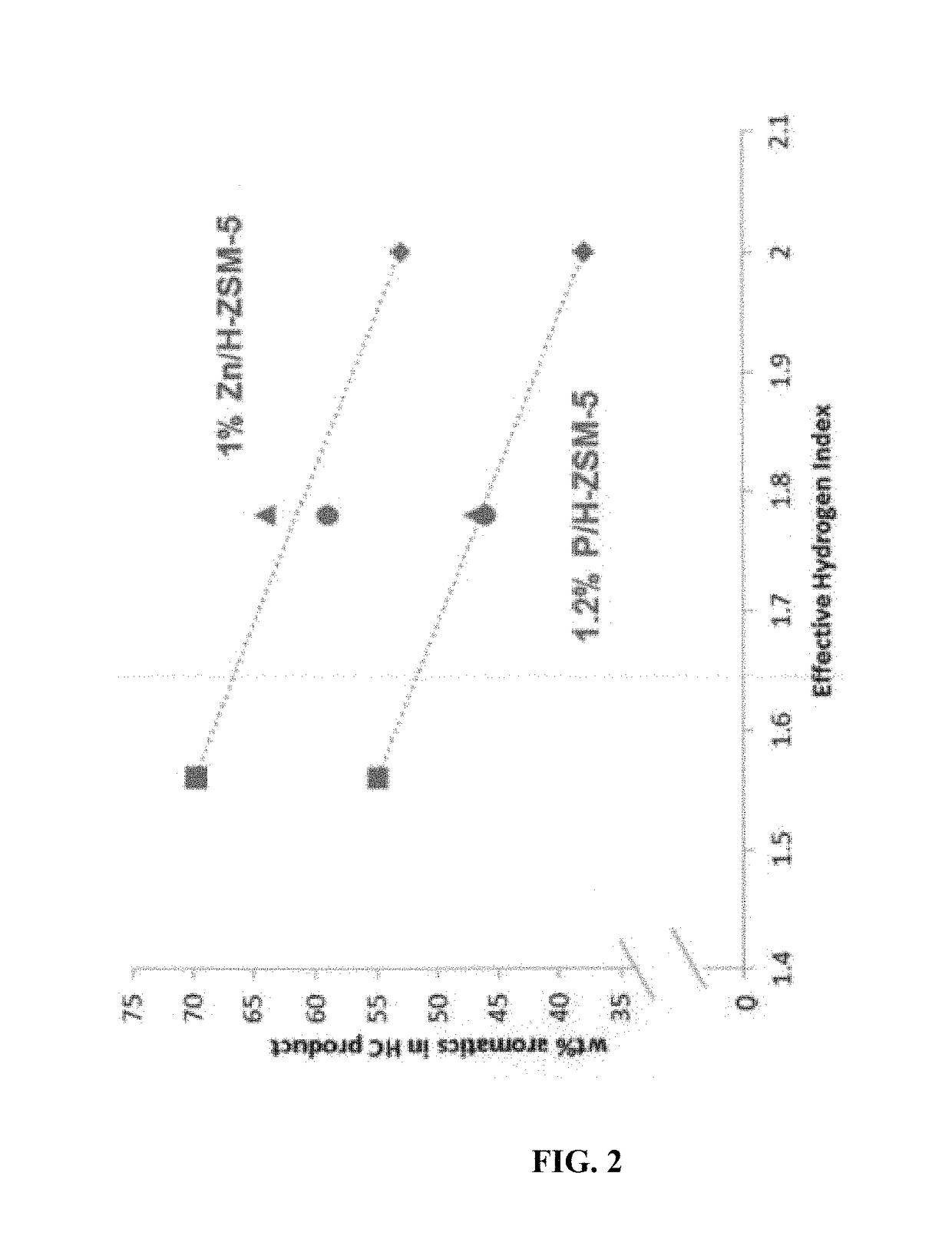

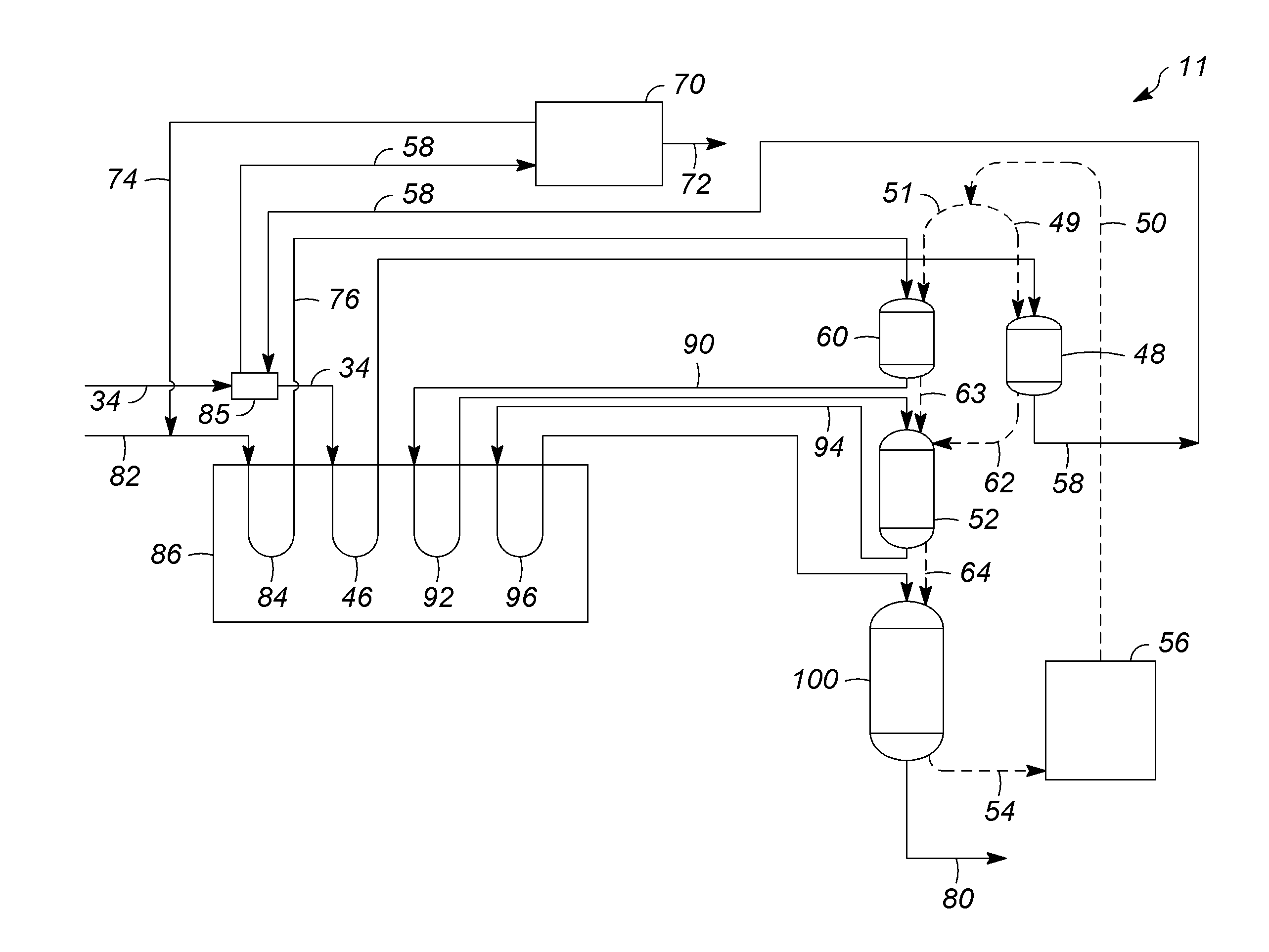

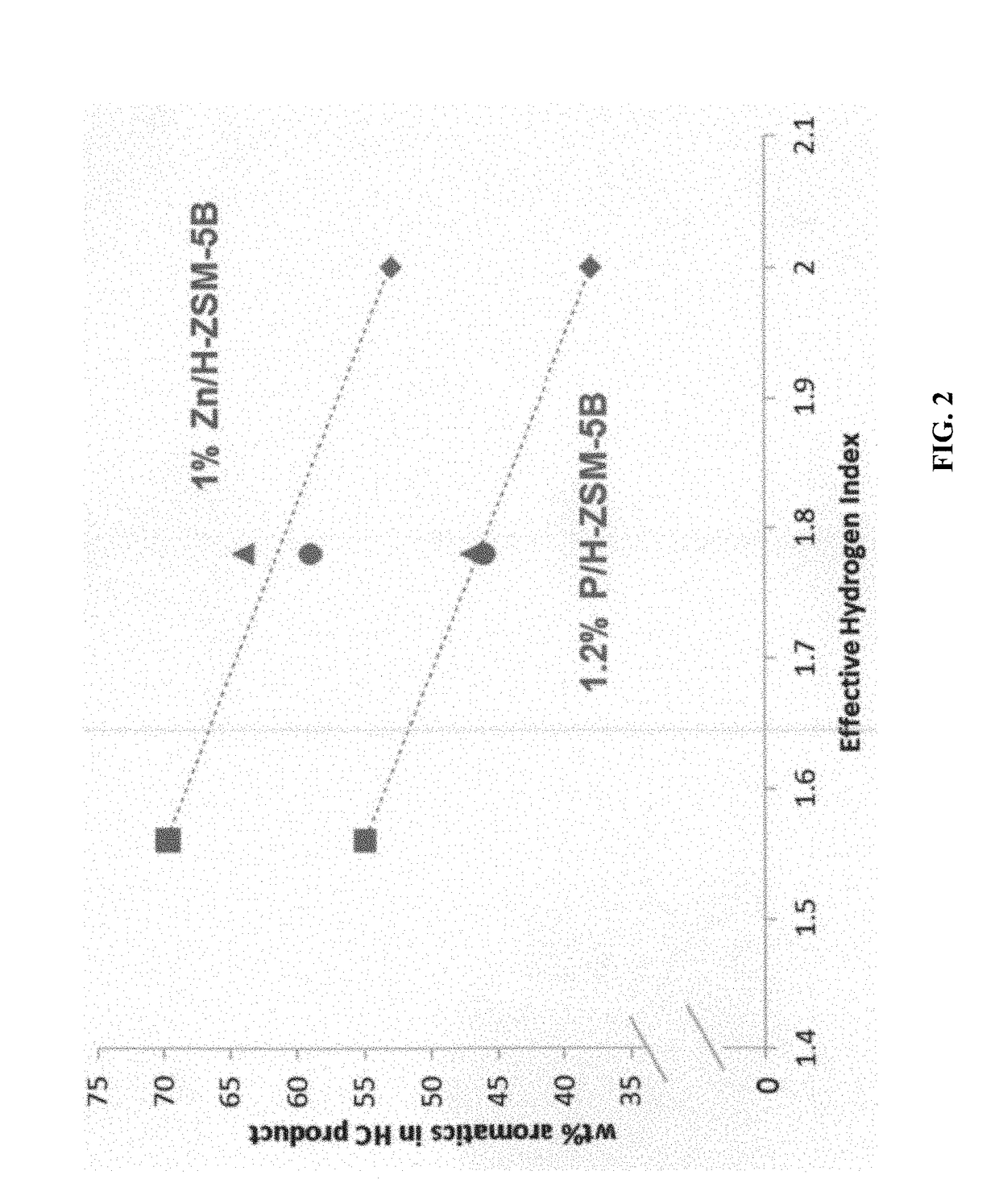

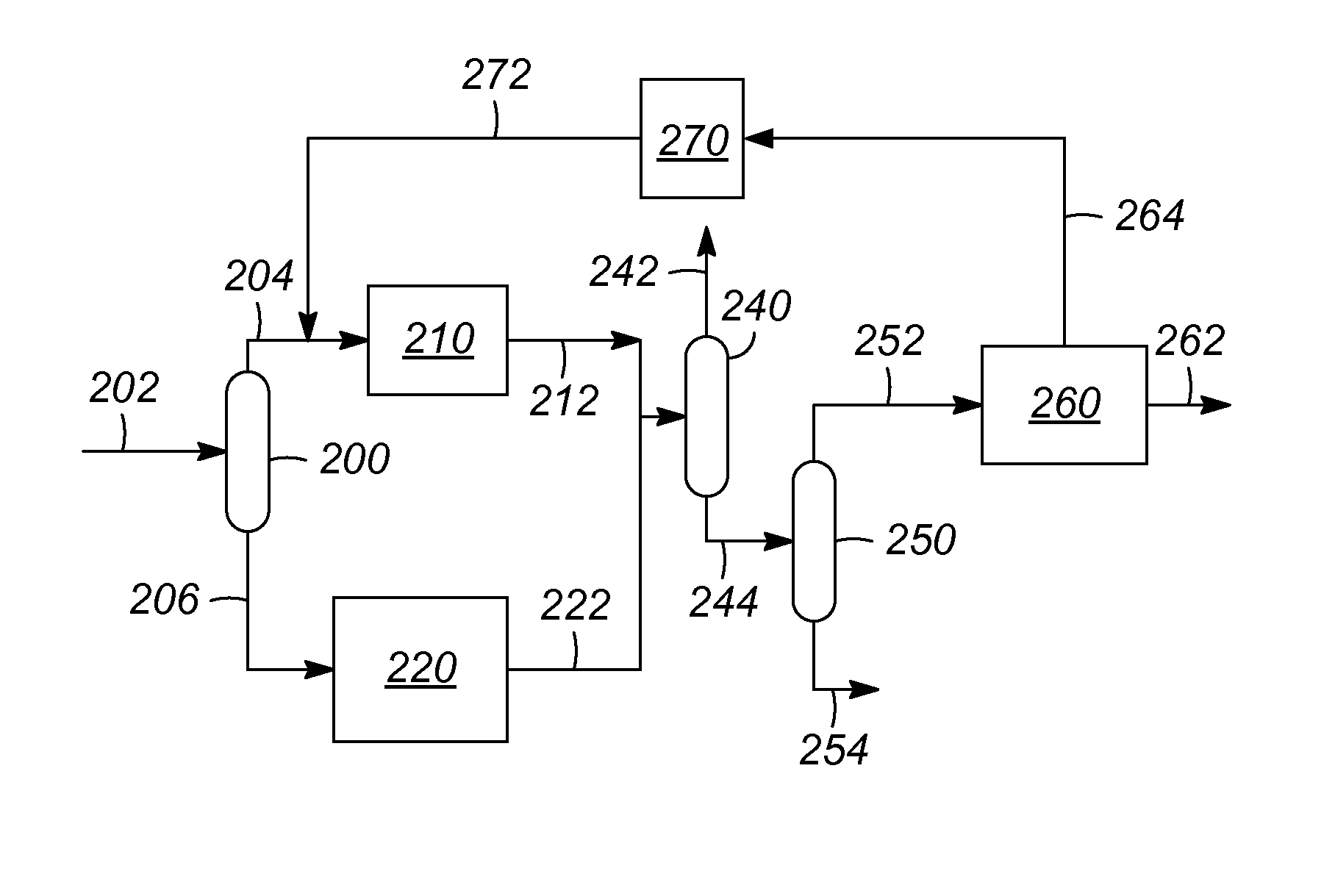

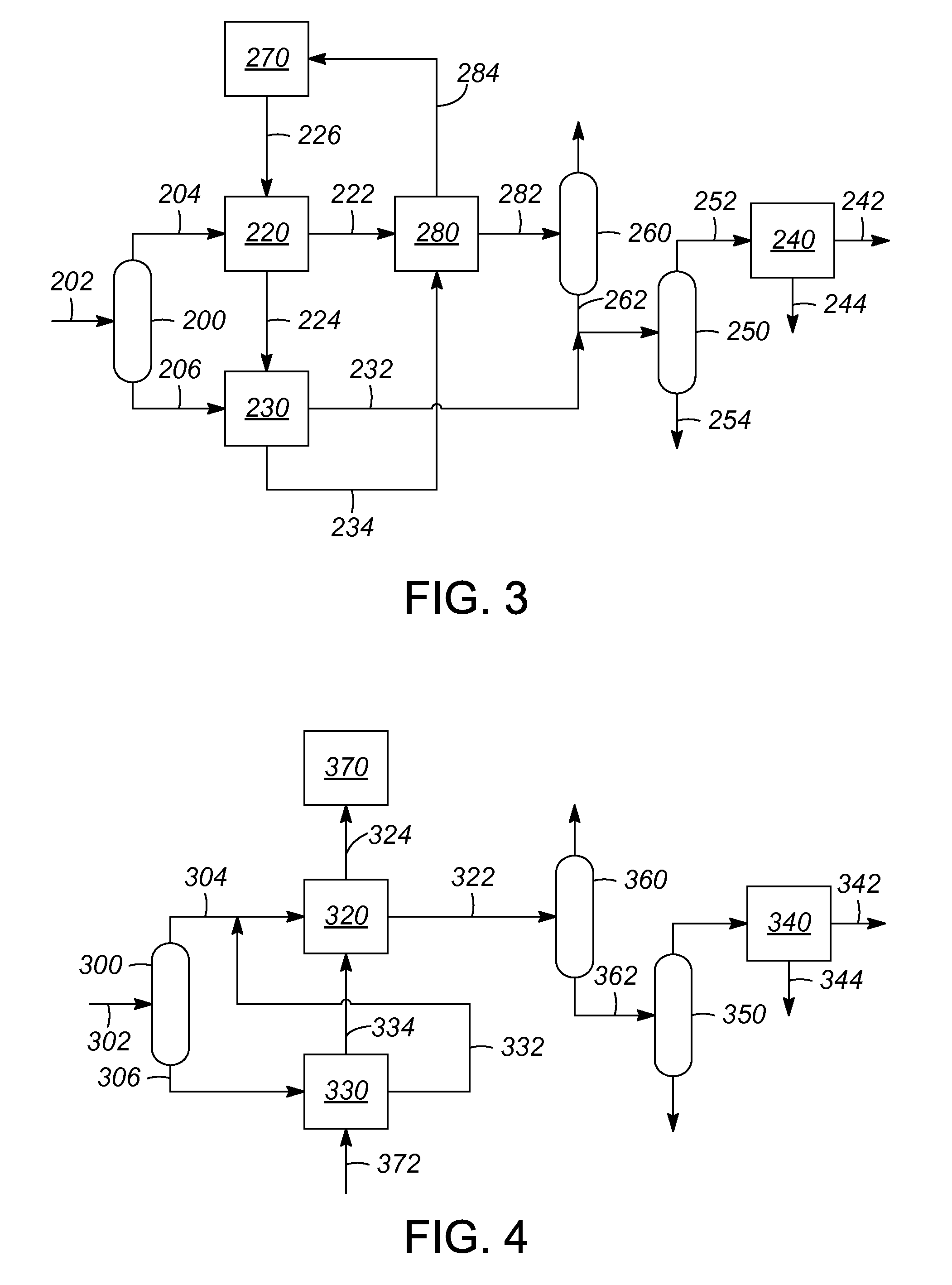

Production of aromatics from methanol and co-feeds

ActiveUS9732013B2Increase aromatics yieldReduce and minimize cokingMolecular sieve catalystCatalystsHydrogenOxygenate

Methods are provided for improving the yield of aromatics during conversion of oxygenate feeds. An oxygenate feed can contain a mixture of oxygenate compounds, including one or more compounds with a hydrogen index of less than 2, so that an effective hydrogen index of the mixture of oxygenates is between about 1.4 and 1.9. Methods are also provided for converting a mixture of oxygenates with an effective hydrogen index greater than about 1 with a pyrolysis oil co-feed. The difficulties in co-processing a pyrolysis oil can be reduced or minimized by staging the introduction of pyrolysis oil into a reaction system. This can allow varying mixtures of pyrolysis oil and methanol, or another oxygenate feed, to be introduced into a reaction system at various feed entry points.

Owner:EXXONMOBIL CHEM PAT INC

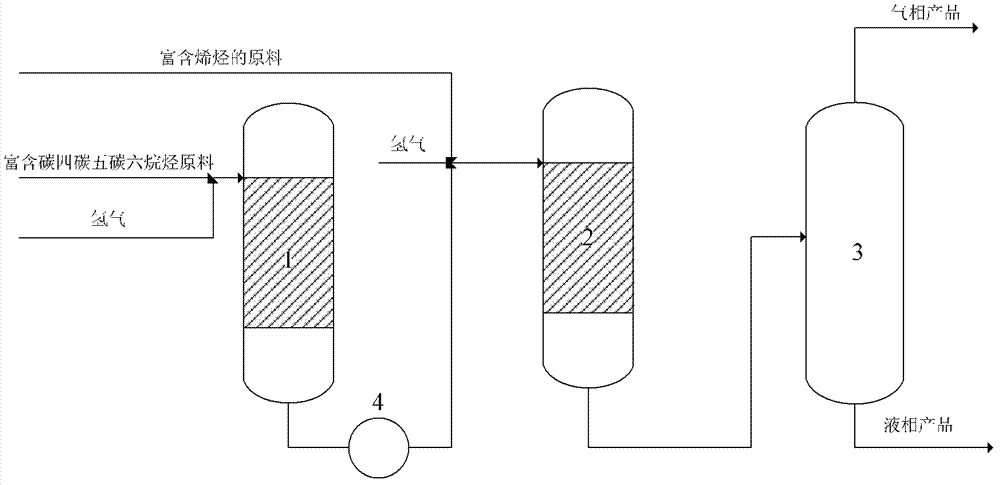

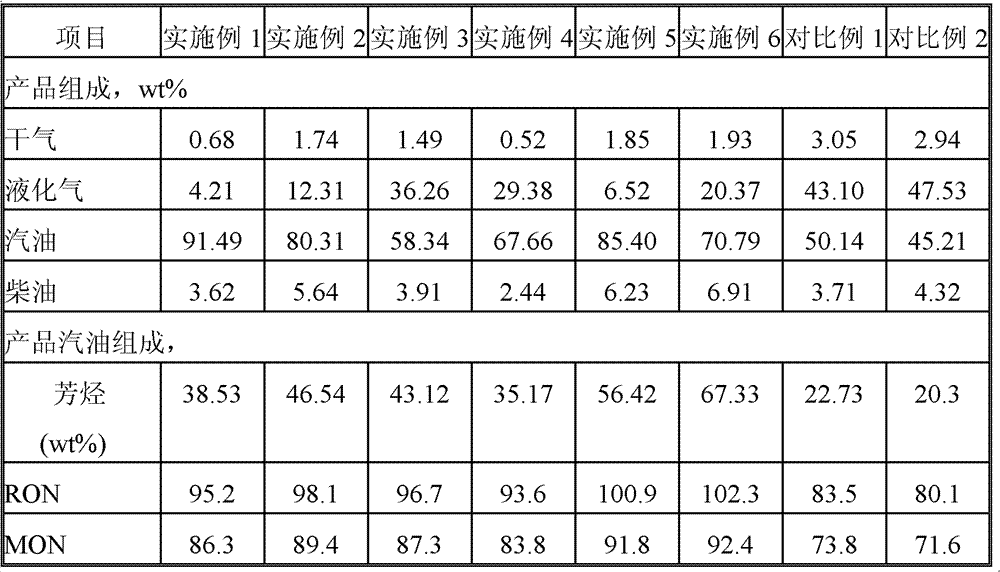

Process for producing high-octane gasoline through raw material rich in C4, C5 and C6 alkane

The invention provides a process for producing a high-octane gasoline component. The process comprises the following steps of: mixing enriched C4, C5 and C6 alkane with hydrogen; feeding the mixture into a reactor containing a dehydrogenation catalyst and performing an alkane dehydrogenation reaction; treating a dehydrogenation product through a non-condensable gas separating device; then mixing with a raw material rich in alkane; and then transferring the mixture into a reactor containing an aromatization catalyst and aromizing to produce a low-benzene high-octane gasoline component rich in aromatic hydrocarbon. The modified gasoline is high in content of non-benzenoid aromatics, lower in content of benzene and low in content of olefin.

Owner:PETROCHINA CO LTD

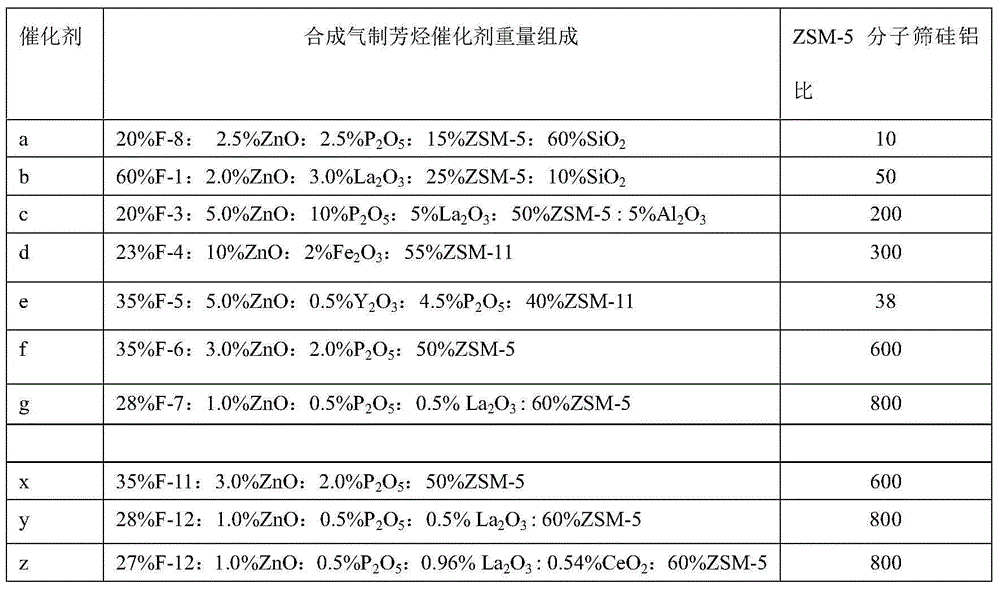

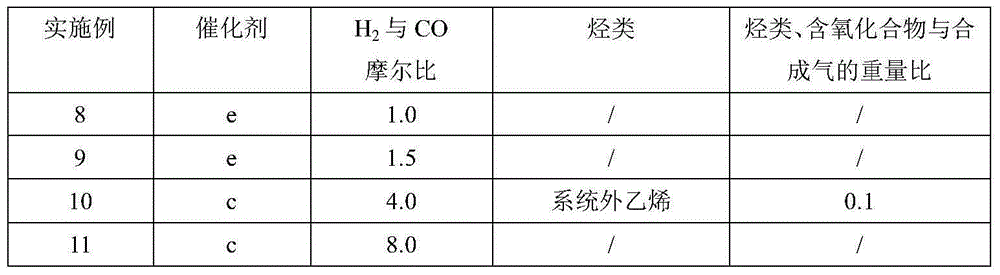

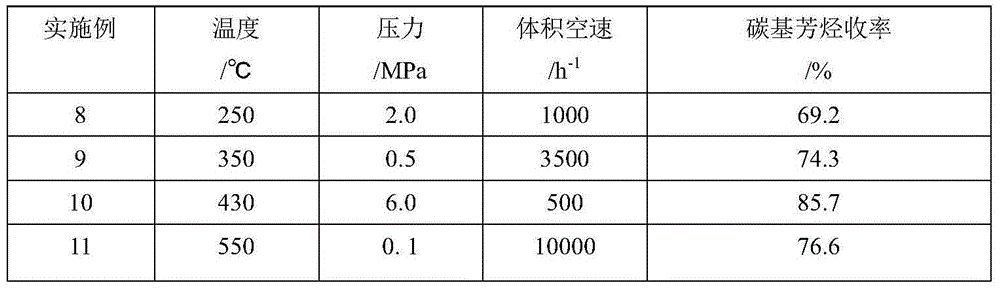

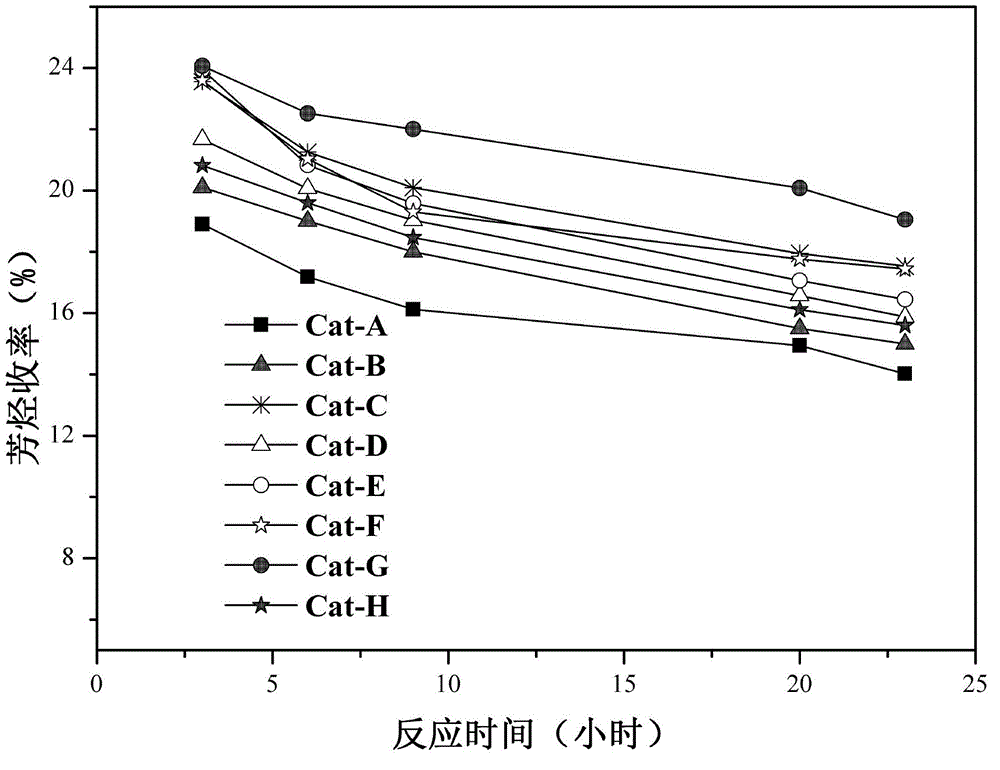

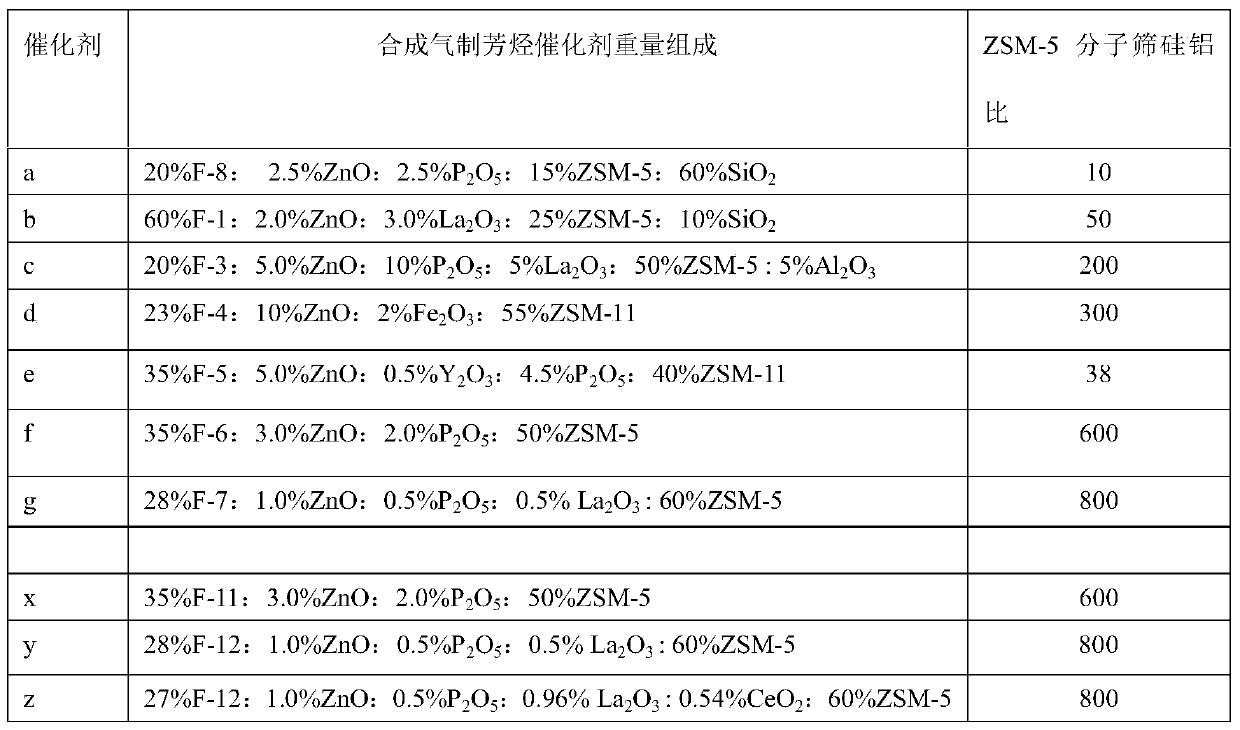

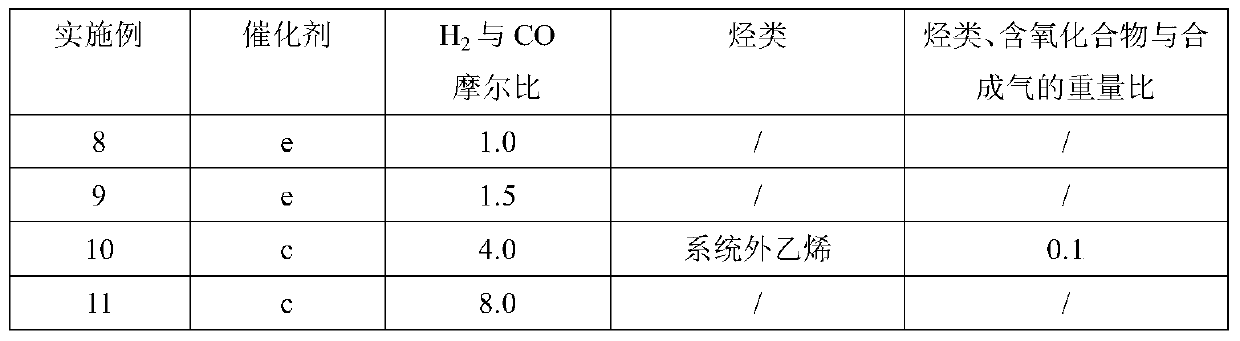

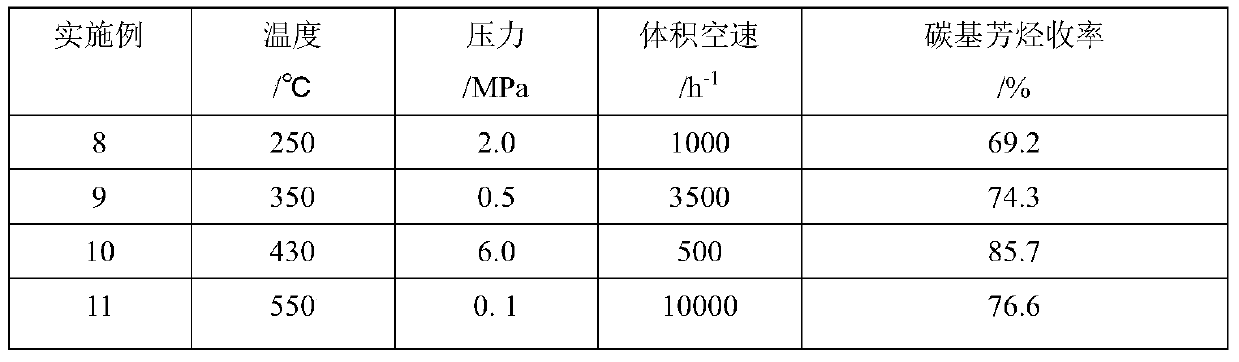

Catalyst for preparing arene from synthesis gas and use method of catalyst

ActiveCN106607083AEffective modification of shape-selective propertiesImprove aromatization yieldHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveSpace velocity

The invention relates to a catalyst for preparing arene from synthesis gas and a use method of the catalyst, and mainly solves the technical problems of long technological process, high production cost and low arene yield which exist during a process of preparing the arene from the synthesis gas in the prior art. According to the use method, under the condition of the temperature of 250-450 DEG C, pressure of 0.01-8.0 MPa and synthesis gas volume space velocity of 400-10000h<-1>, an oxygenated compound is taken as raw material, the raw material is in contact with and is reacted with the catalyst in an reactor, so that a material flow containing the arene is obtained; by utilizing the technical scheme of a Fe-containing composite oxide and a molecular sieve composite catalyst, the above problems are well solved; and the catalyst can be applied to industrial production of preparing the arene from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Zn/ZSM-11 molecular sieve catalyst modification method

ActiveCN104624224AIncrease aromatics yieldHigh yieldMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveNeutral state

The present invention provides a Zn / ZSM-11 molecular sieve catalyst modification method, which concretely comprises: carrying out heating stirring on a Na-type ZSM-11 molecular sieve for 1-5 h at a temperature of 65-85 DEG C by using an alkali and organic surfactant mixing solution; washing to achieve a neutral state; carrying out drying baking; carrying out exchange at a temperature of 70-90 DEG C by using a 0.5-1.0 mol / L ammonium nitrate solution; drying, and then baking to prepare an H- type molecular sieve; loading zinc on the obtained molecular sieve by using an equal volume impregnation method, wherein the zinc loading amount is 0.5-10.0 wt%; and drying, and then baking to prepare the catalyst. According to the present invention, the aromatic hydrocarbon yield of the Zn / ZSM-11 molecular sieve catalyst treated by the surfactant and the alkali can be further increased compared with the aromatic hydrocarbon yield of the Zn / ZSM-11 molecular sieve catalyst being subjected to the conventional alkali treatment or with no alkali treatment.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Methanol-to-aromatic hydrocarbon catalyst and uses tehreof

InactiveCN106607079AIncrease aromatics yieldImprove stabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveReaction temperature

The present invention relates to a methanol-to-aromatic hydrocarbon catalyst and uses thereof. A purpose of the present invention is mainly to solve the problems of low selectivity and poor catalyst stability in the conversion of methanol into aromatic hydrocarbons in the prior art. The technical scheme of the present invention comprises that a modified mesoporous and microporous compounded molecular sieve is adopted as a catalyst, methanol is adopted as a raw material, and the raw material is subjected to an aromatization reaction at a reaction temperature of 360-500 DEG C under a reaction pressure of 0-1.0 MPa at a raw material mass space velocity of 0.4-8 h<-1> under the effect of the catalyst. With the technical scheme, the problems in the prior art are well solved. The catalyst of the present invention can be used for the industrial production of methanol-to-aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

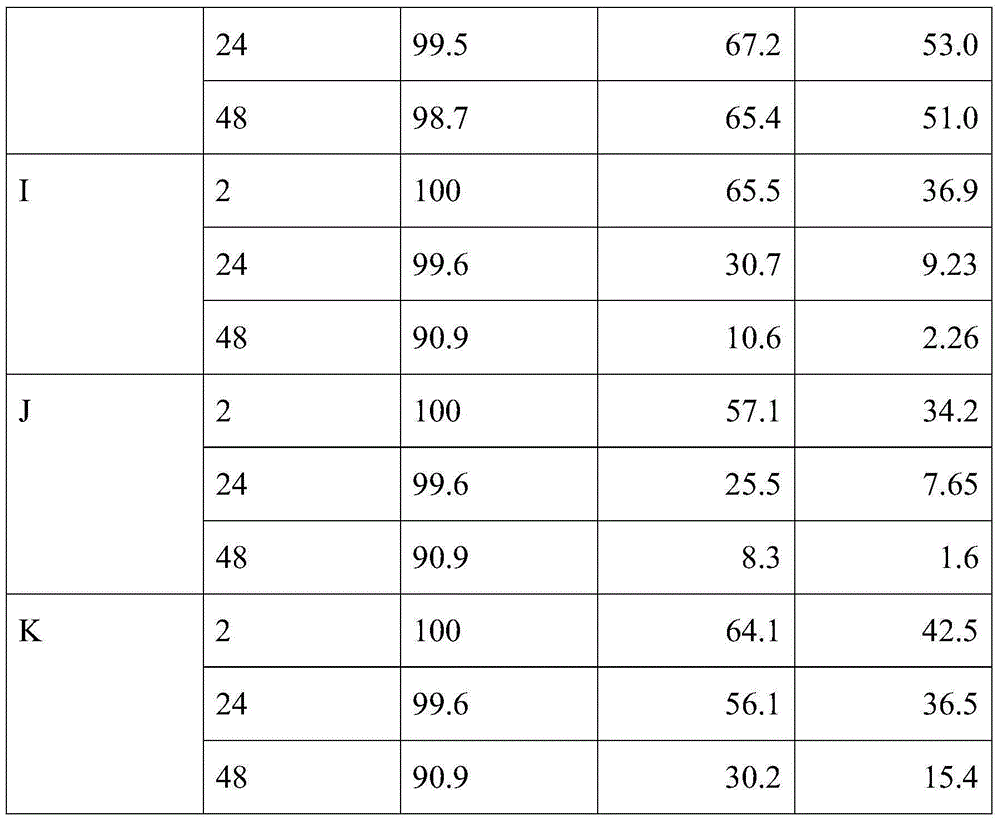

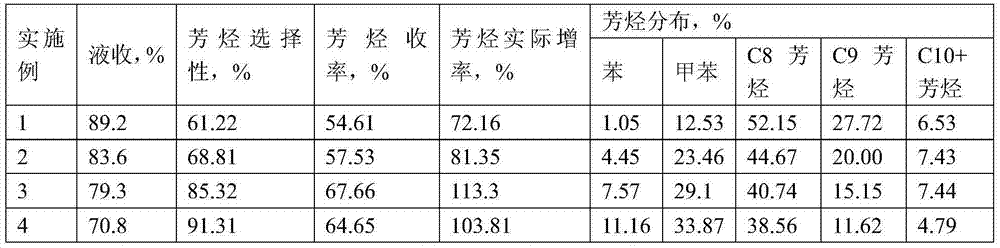

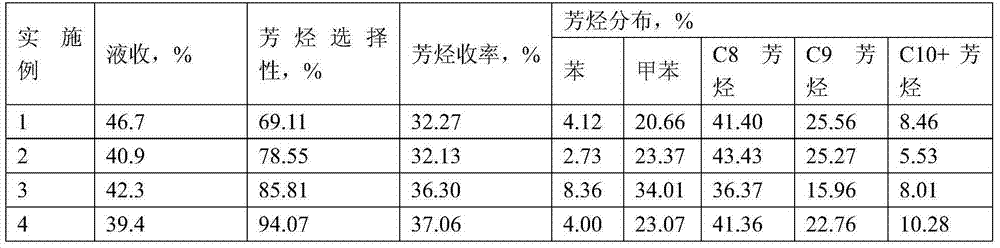

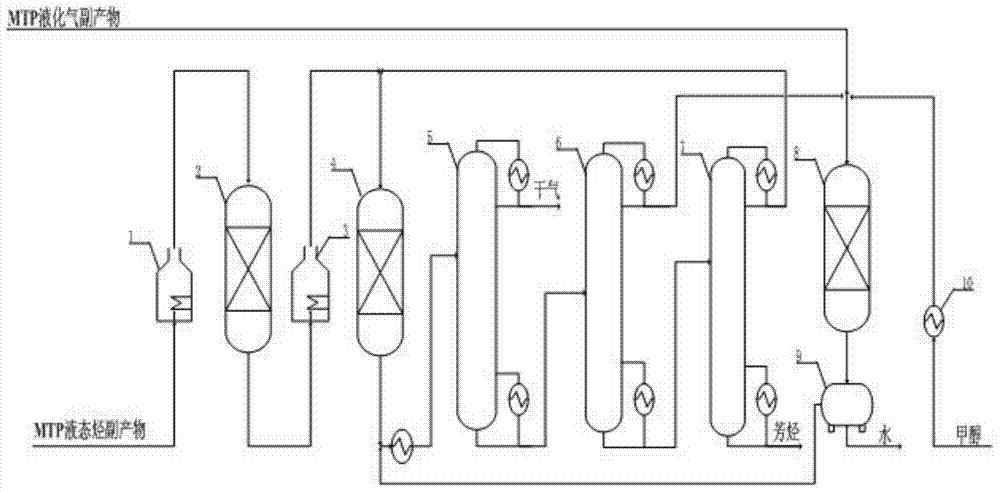

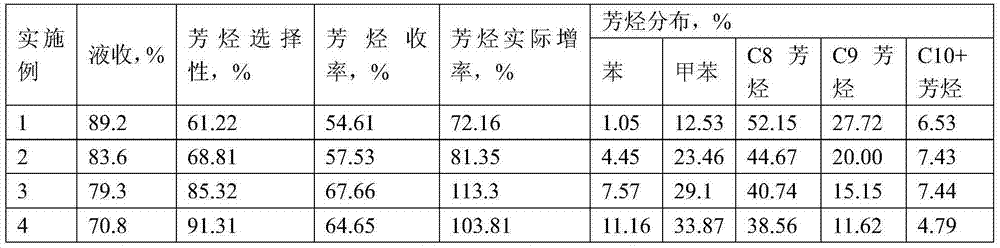

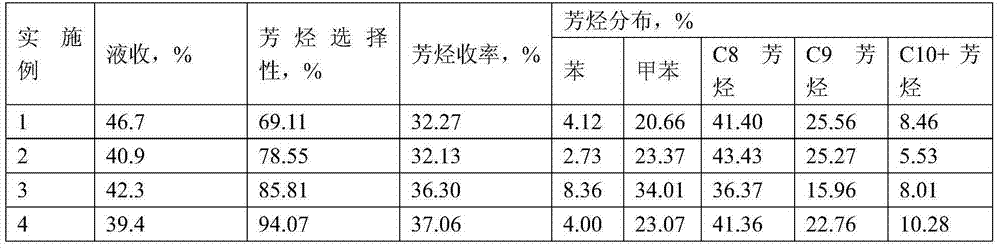

Technique for processing methanol-to-propylene by-products

ActiveCN103864564AIncrease aromatics yieldReduce energy consumptionHydrocarbon by hydrocarbon condensationHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveDry gas

The invention relates to a technique for processing methanol-to-propylene by-products. The technique is characterized by comprising the steps as follows: a liquid hydrocarbon by-product of methanol-to-propylene (MTP) is separated to obtain a dry gas, a liquefied gas and C5<+> non-aromatic and aromatic hydrocarbons after passing through two sections of fixed bed reactors of olefin aromatization and alkane aromatization; the dry gas and aromatic hydrocarbon are discharged out of a reaction system as products; the C5<+> non-aromatic hydrocarbon is returned to the alkane aromatization reactor to continue to react; the liquefied gas and the liquefied gas of the MTP process by-product enter the alkane aromatization reactor; a heat source required for aromatization of the liquefied gas is provided by a mode of adding methanol; the liquefied gas is converted into a mixed hydrocarbon product of taking aromatic hydrocarbon as a main component under the action of a molecular sieve based catalyst; and the mixed hydrocarbon product enters the dethanizer to separate after being processed by an oil-water separator. By adopting the process, gasoline aromatization and liquefied gas aromatization are combined, and the MTP by-product is effectively converted into the hydrocarbons. By adopting the process, the actual gaining rate of the liquid hydrocarbon by-product of the MTP can be up to 65-120%, and the hydrocarbon yield of liquid aromatization can be up to 32-40%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

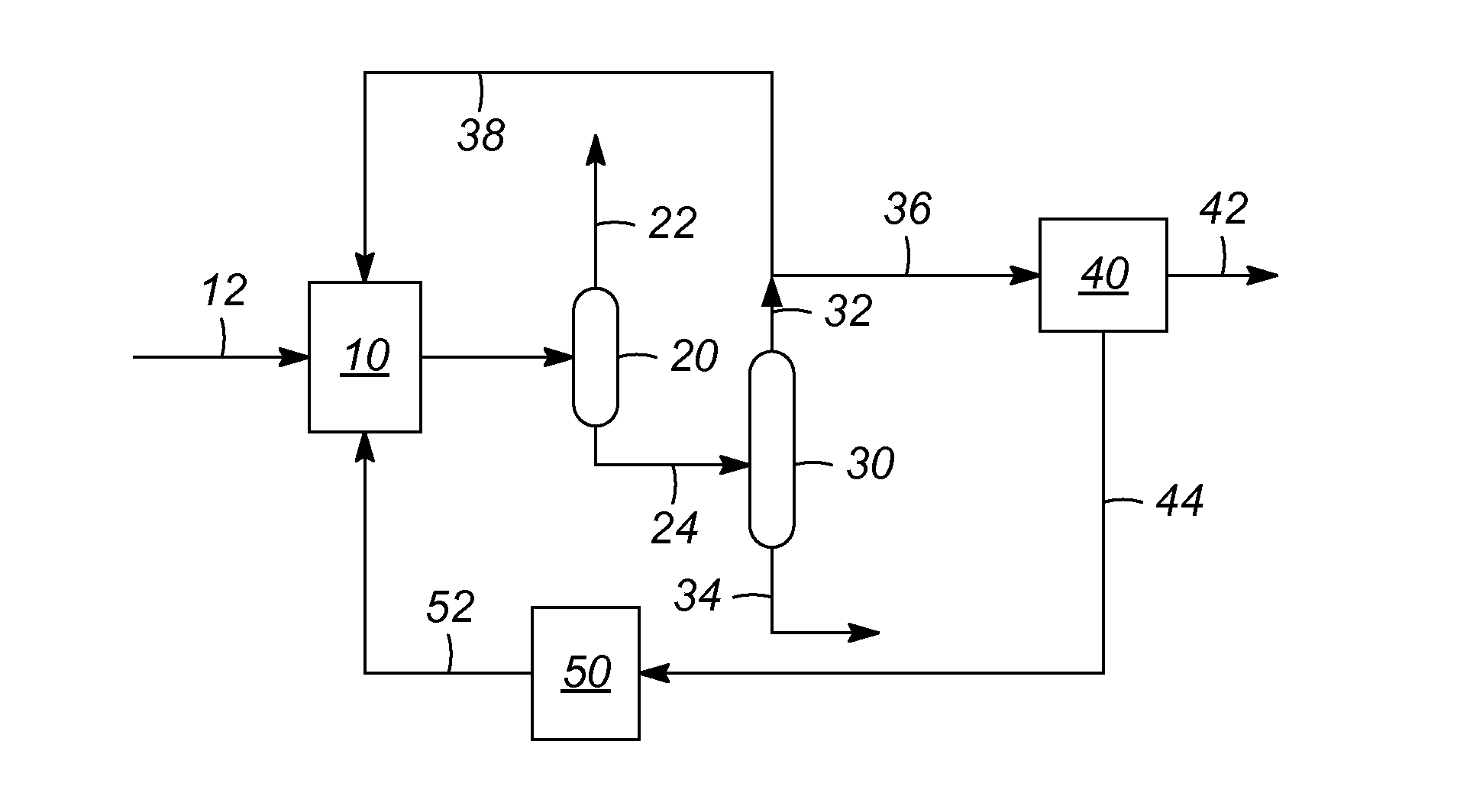

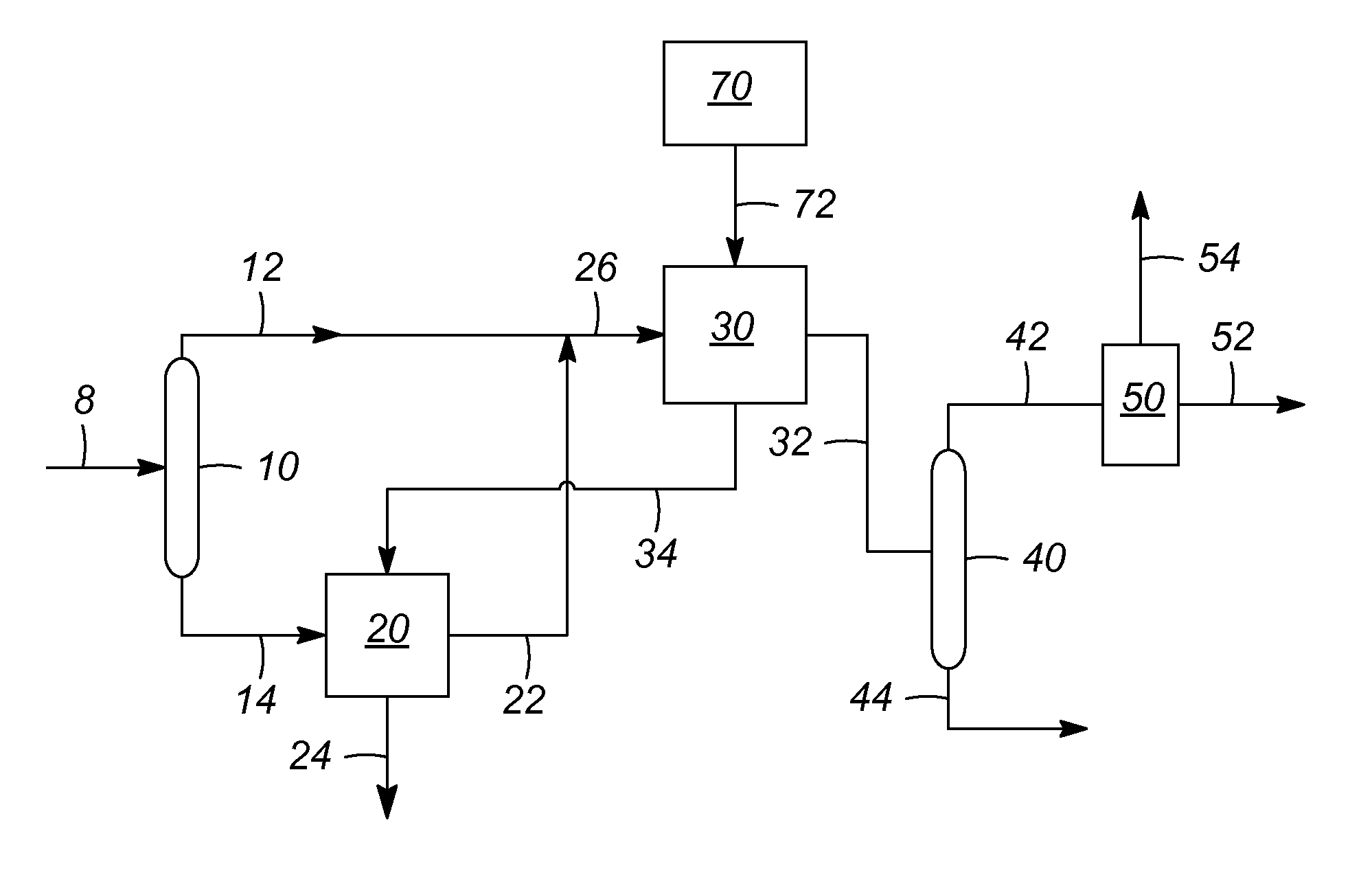

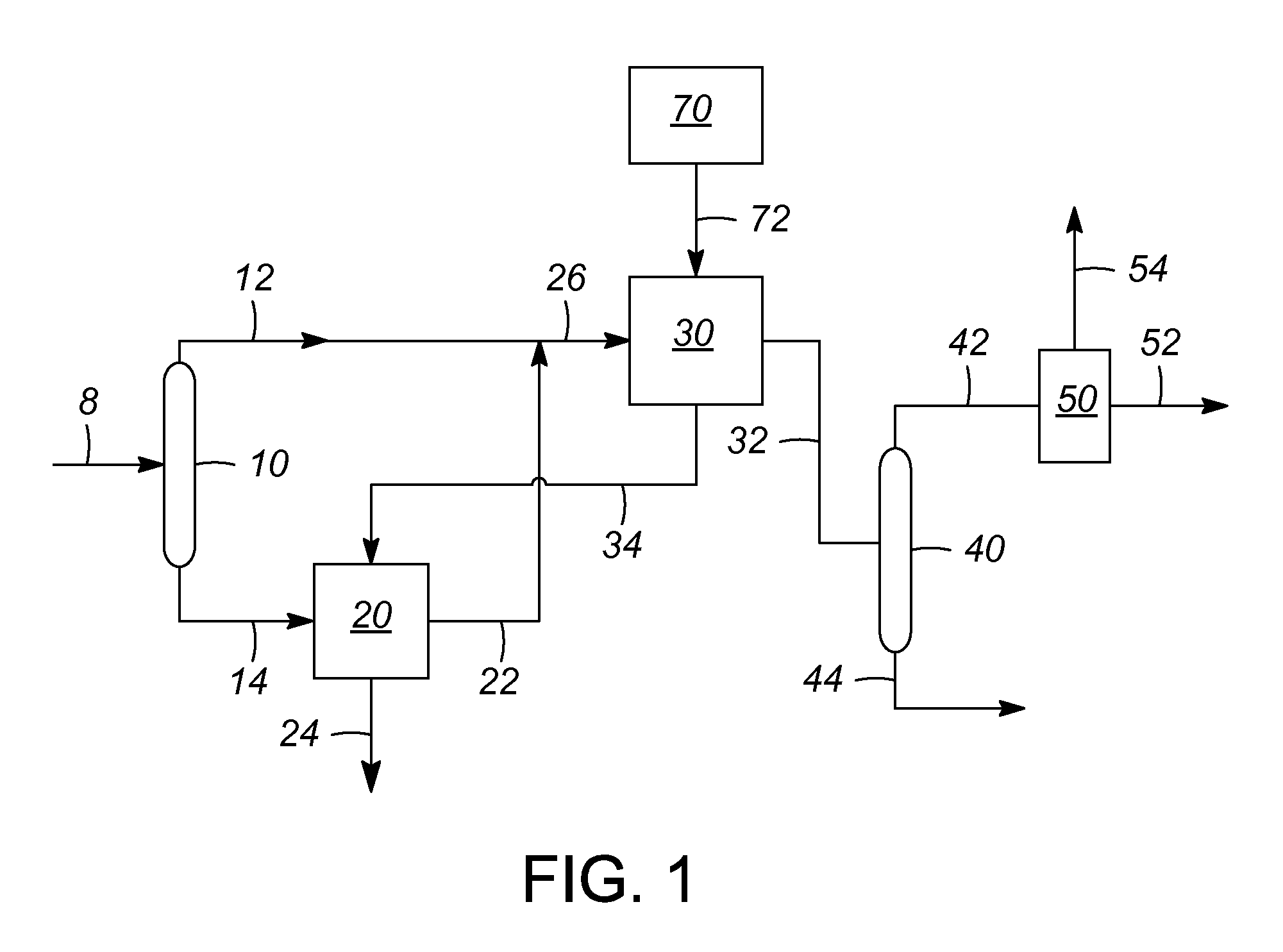

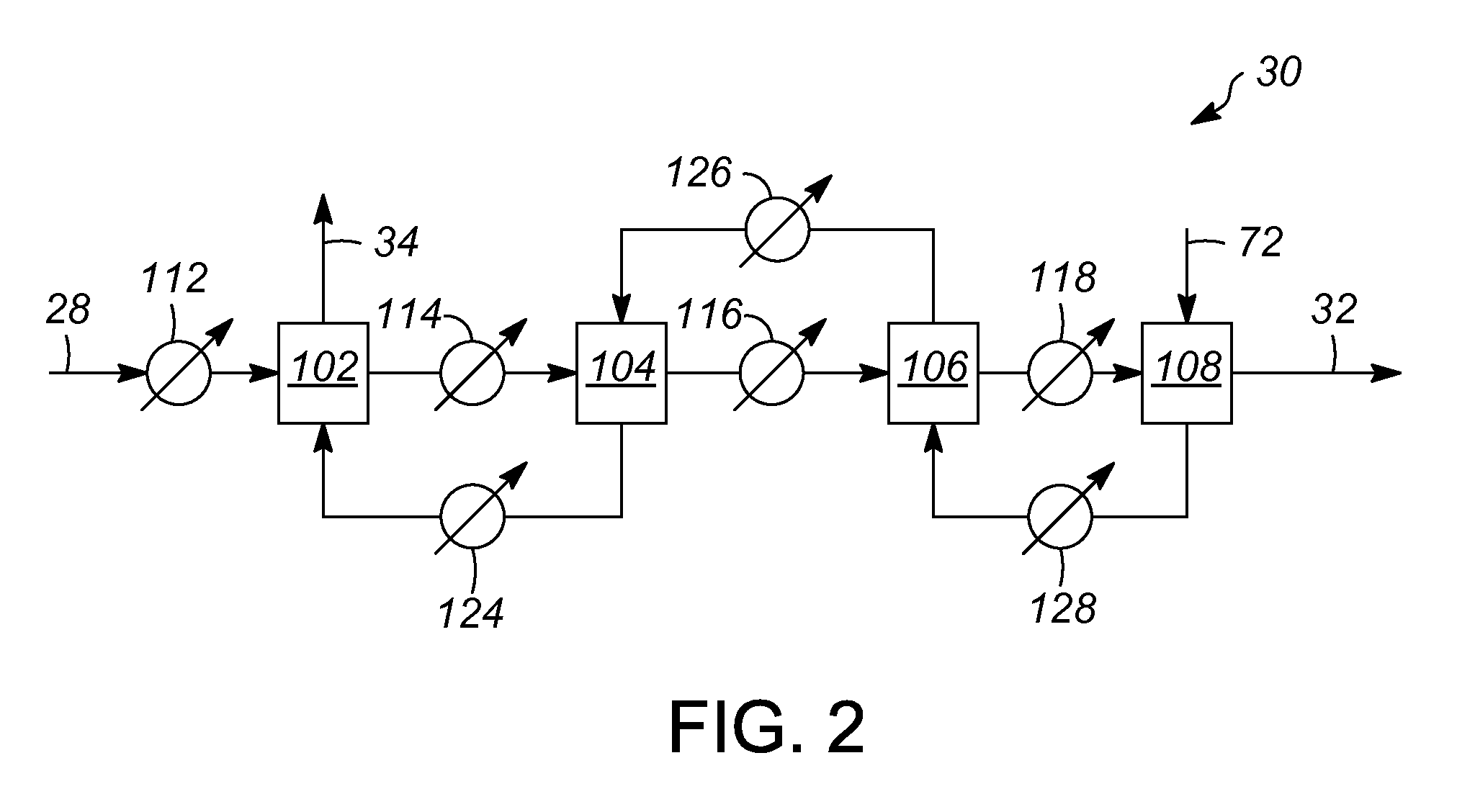

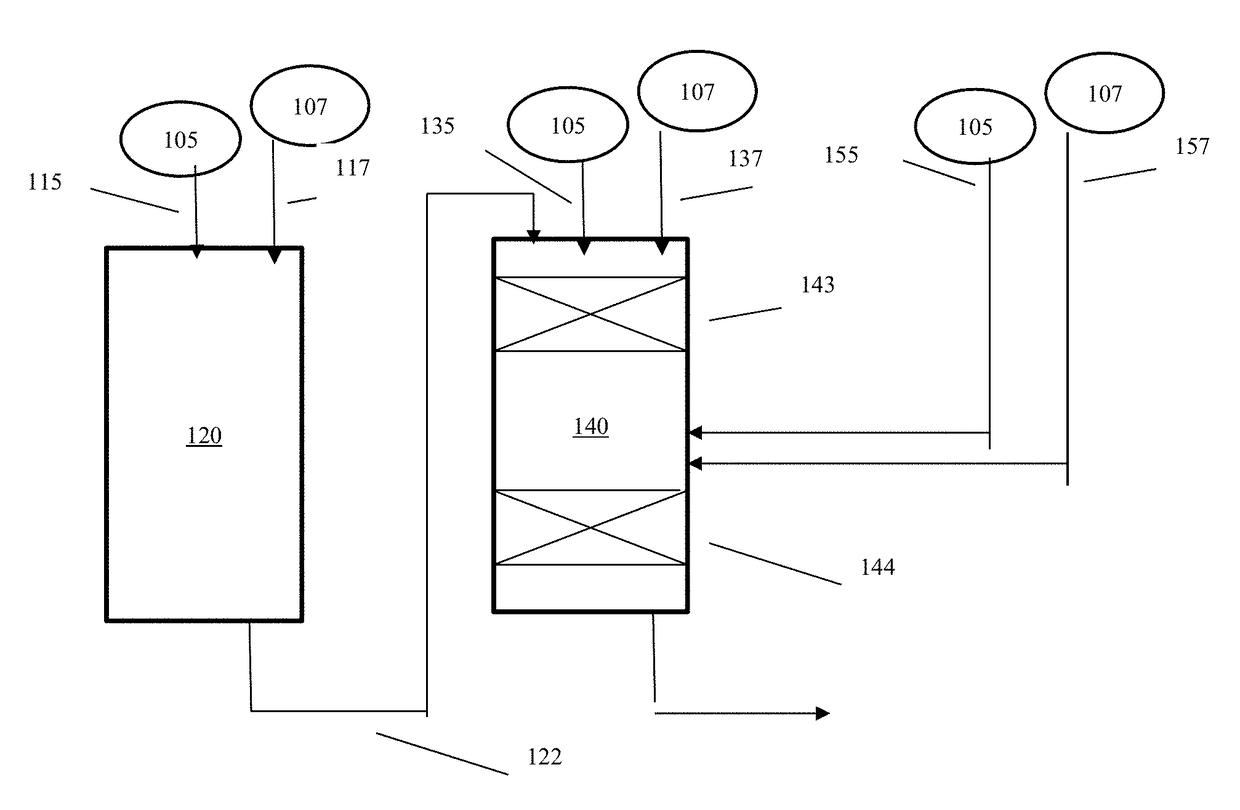

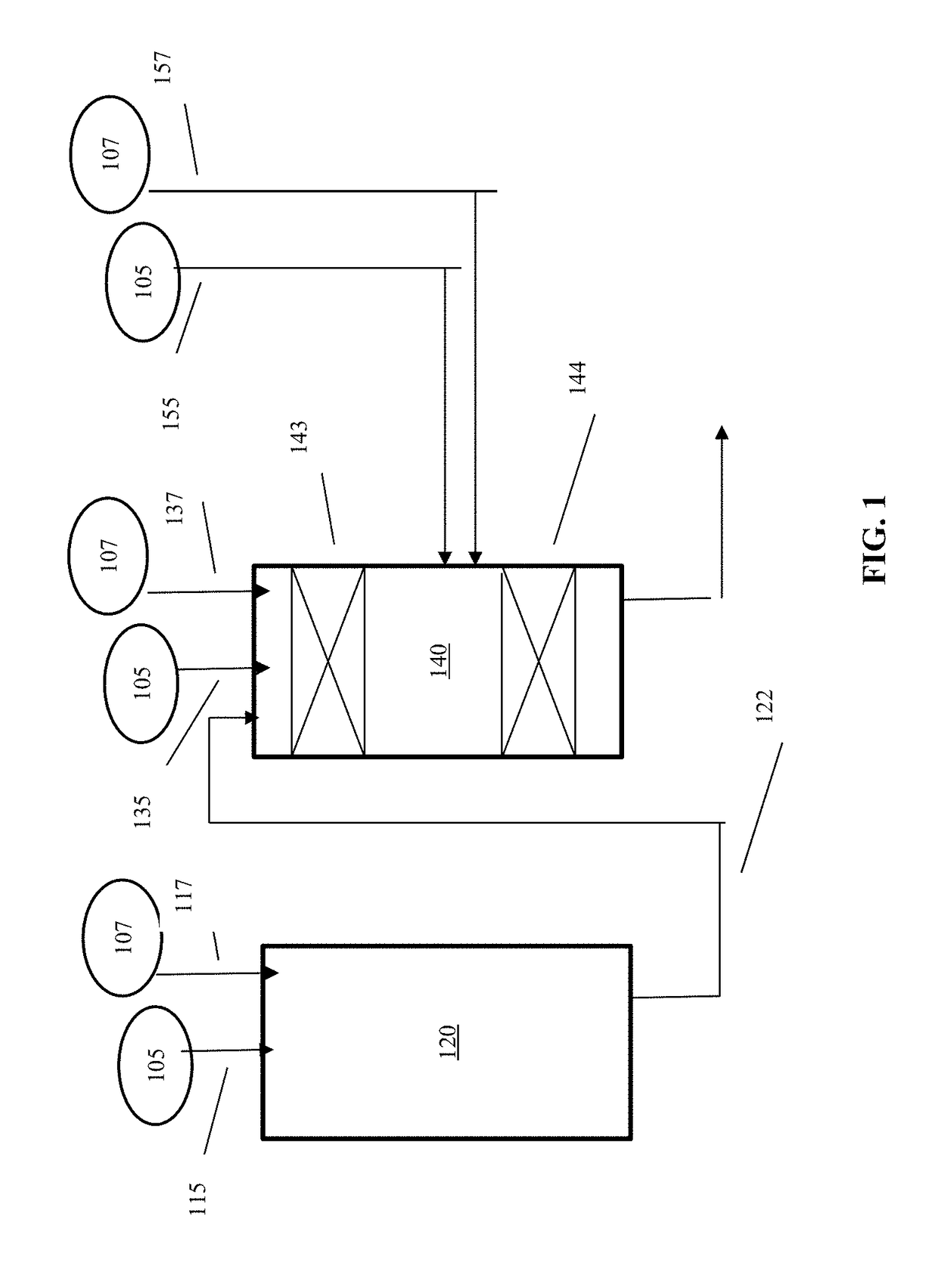

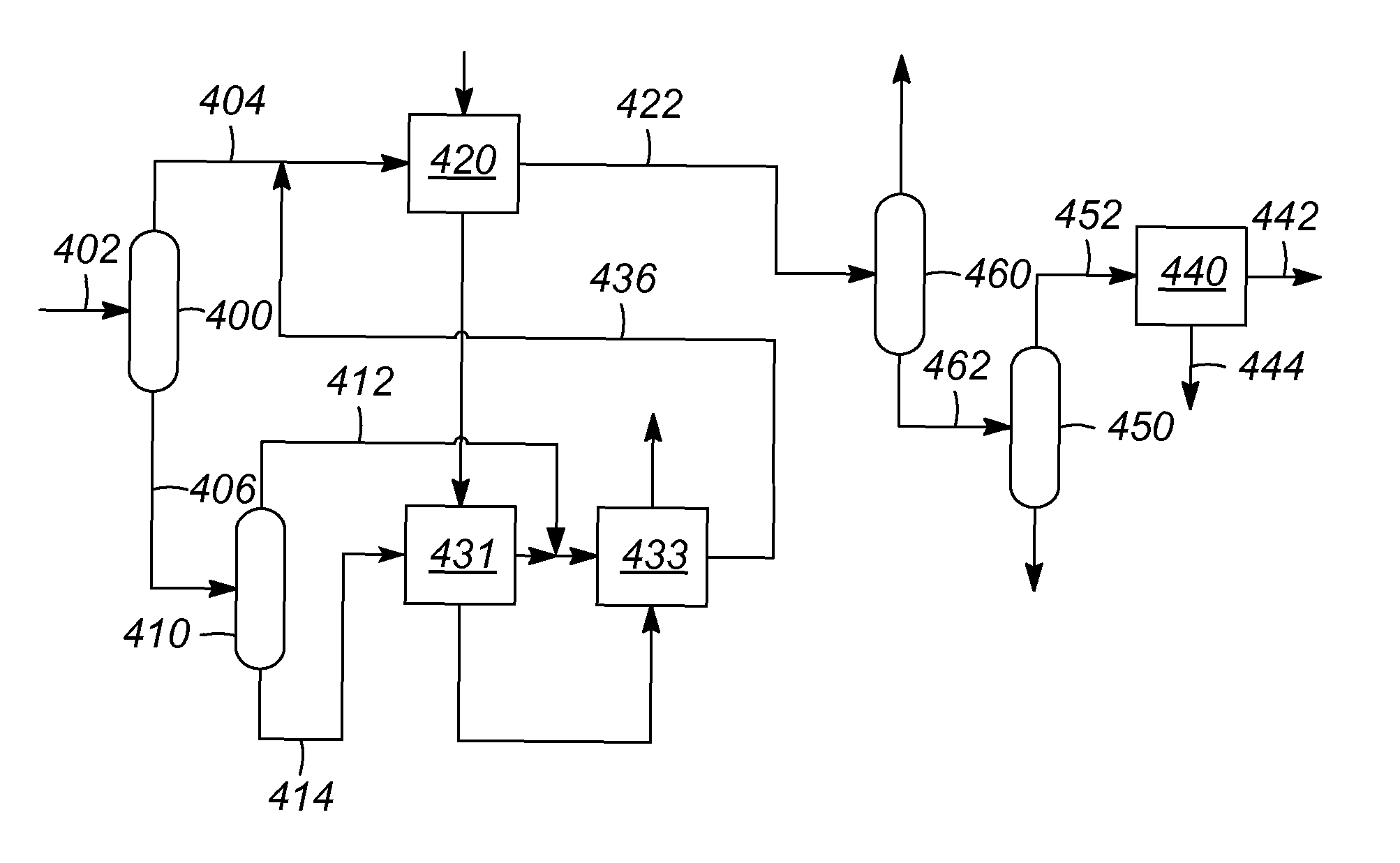

Process for increasing aromatics production

ActiveUS20120277508A1Increase aromatics yieldCatalytic naphtha reformingHydrocarbonsNaphthaHydrocarbon

A process for reforming a hydrocarbon stream is presented. The process involves splitting a naphtha feedstream to at least two feedstreams and passing each feedstream to separation reformers. The reformers are operated under different conditions to utilize the differences in the reaction properties of the different hydrocarbon components. The process utilizes a common catalyst, and common downstream processes for recovering the desired aromatic compounds generated.

Owner:UOP LLC

Reforming catalysts with tuned acidity for maximum aromatics yield

ActiveUS9266091B2Increase aromatics yieldIncrease productionCatalytic naphtha reformingCatalyst activation/preparationIridiumPlatinum

One exemplary embodiment can be a catalyst for catalytic reforming of naphtha. The catalyst can have a noble metal including one or more of platinum, palladium, rhodium, ruthenium, osmium, and iridium, at least two alkali metals or at least two alkaline earth metals, or mixtures of alkali metals and alkaline earth metals and a support.

Owner:UOP LLC

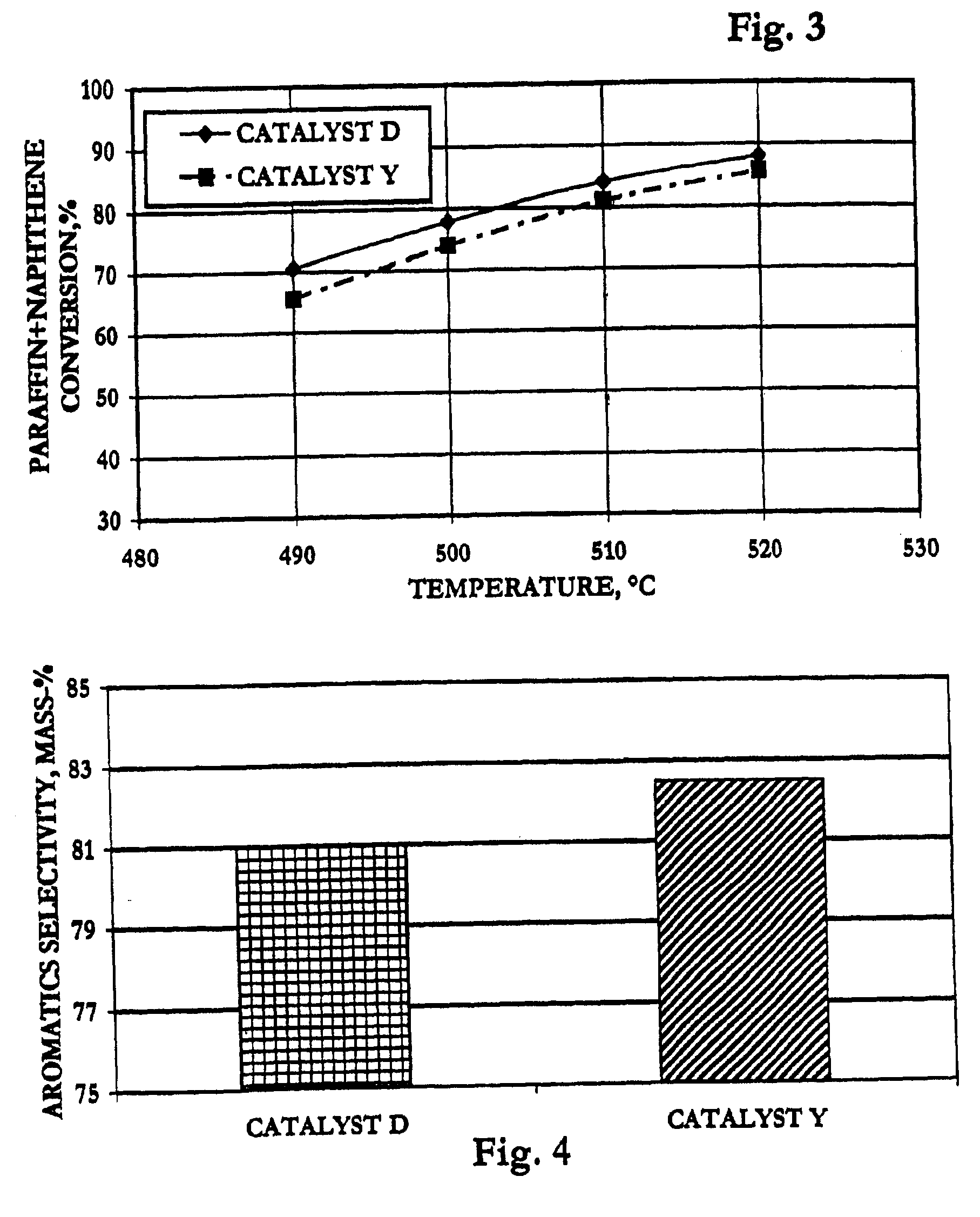

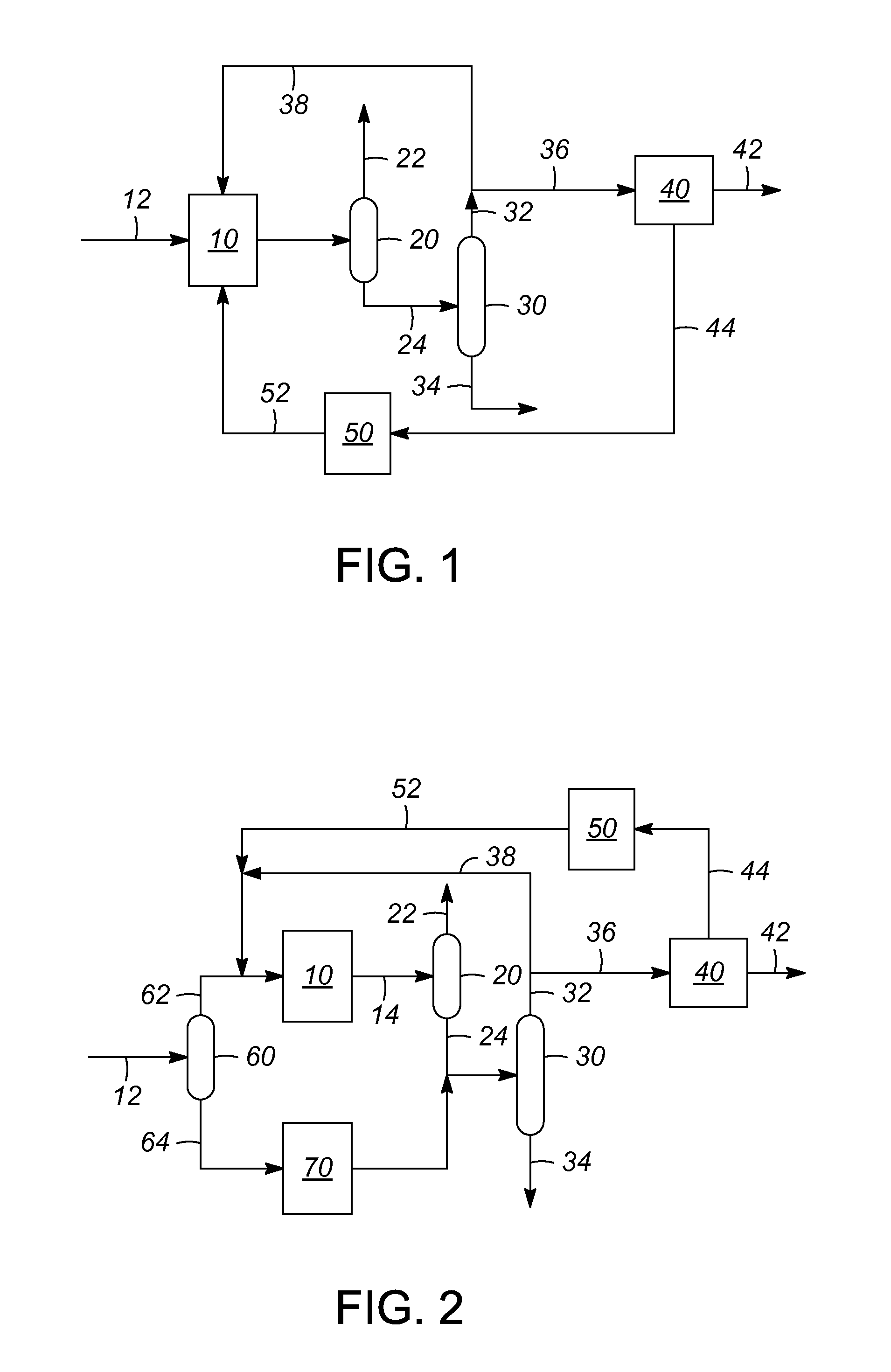

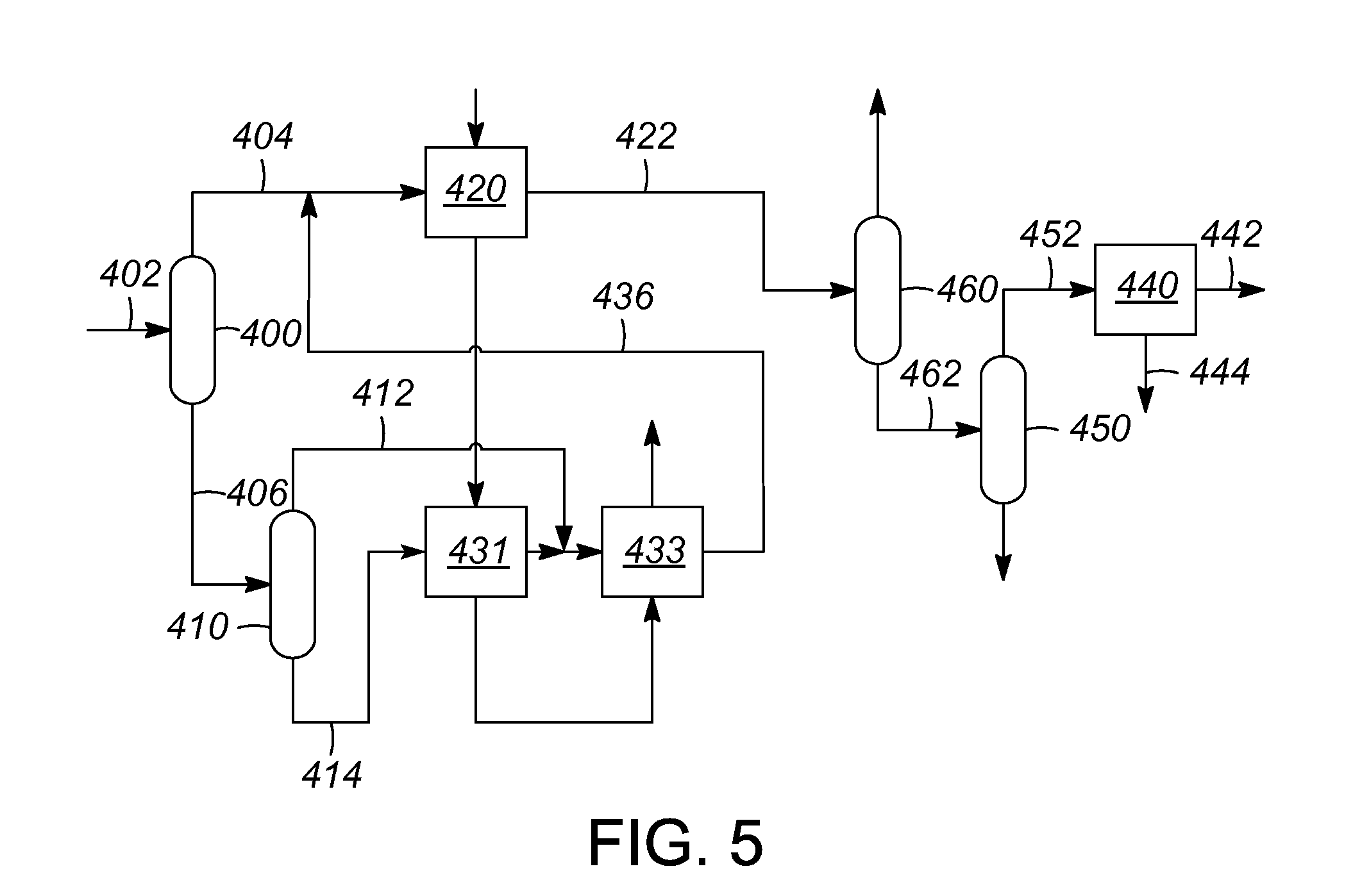

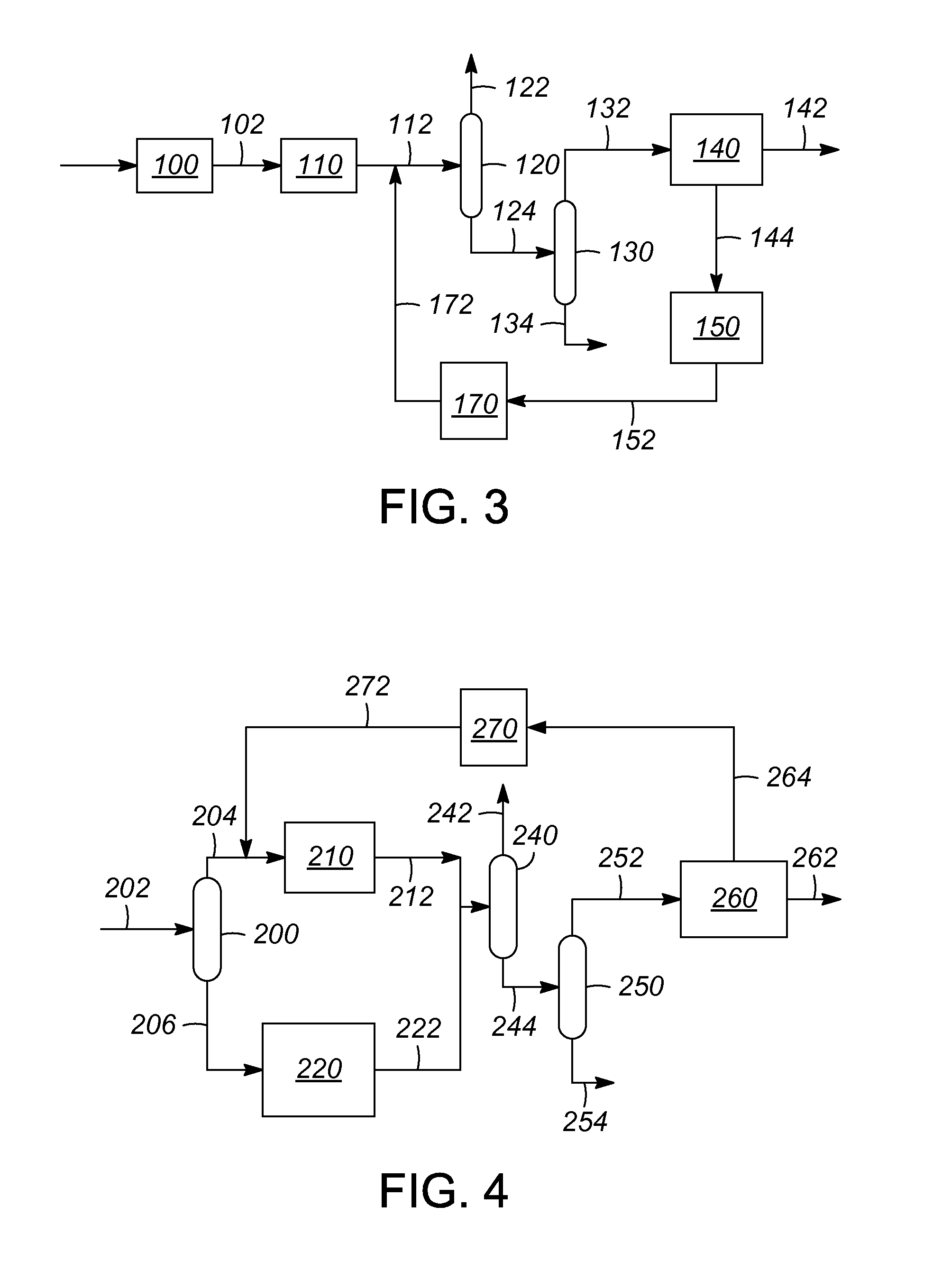

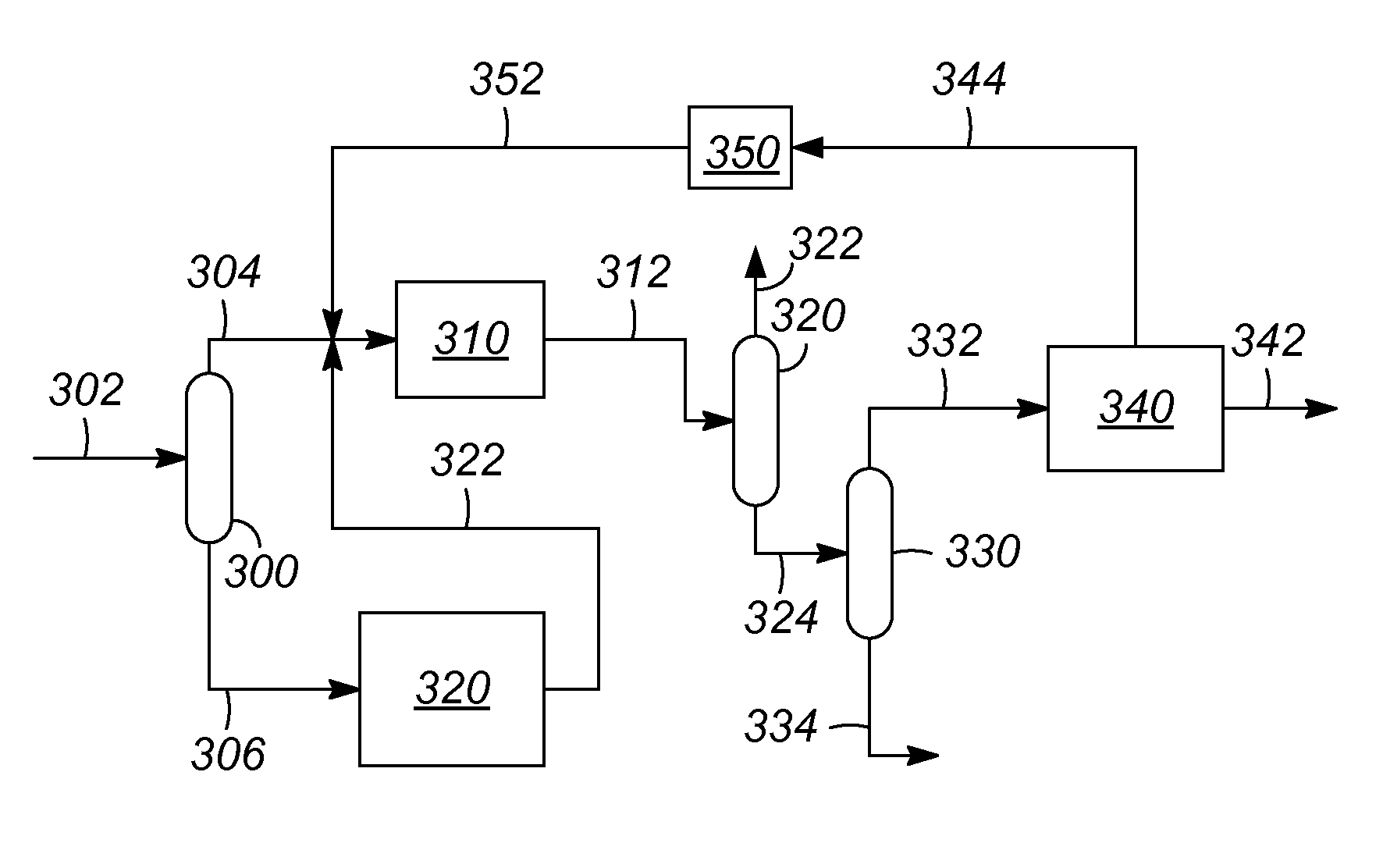

Counter-current catalyst flow with split feed and two reactor train processing

ActiveUS8882994B2Increase aromatics yieldMinimizing temperature dropTreatment with plural parallel cracking stages onlyHydrocarbon purification/separationNaphthaHydrocarbon

A process is presented for the increasing the yields of aromatics from reforming a hydrocarbon feedstream. The process includes splitting a naphtha feedstream into a light hydrocarbon stream, and a heavier stream having a relatively rich concentration of naphthenes. The heavy stream is reformed to convert the naphthenes to aromatics and the resulting product stream is further reformed with the light hydrocarbon stream to increase the aromatics yields. The process includes passing a catalyst stream in a counter-current flow relative to the hydrocarbon process stream.

Owner:UOP LLC

Integrated catalytic cracking and reforming processes to improve p-xylene production

ActiveUS20130087483A1High selectivityReduce conversionTreatment with plural serial cracking stages onlyCoke ovensNaphthaFractionation

A process for maximizing p-xylene production includes producing a naphtha fraction and a light cycle oil fraction from a fluid catalytic cracking zone. These fractions are combined and hydrotreated. Fractionation of the hydrotreated product makes a hydrocracker feed that is sent to a hydrocracking zone to make a naphtha cut and a hydrocracker product. The hydrocracker product is recycled back to the fractionation zone, and the naphtha cut is dehydrogenated in a dehydrogenation zone to make aromatics. Reforming catalyst from a catalyst regenerator moves downward through the dehydrogenation zone. Straight run naphtha and raffinate from the aromatics unit are introduced to an additional series of reforming zones. The reforming catalyst moves in parallel through the first reforming zone and the dehydrogenation zones, then is combined for entry to the second and subsequent reforming zones prior to regeneration.

Owner:UOP LLC

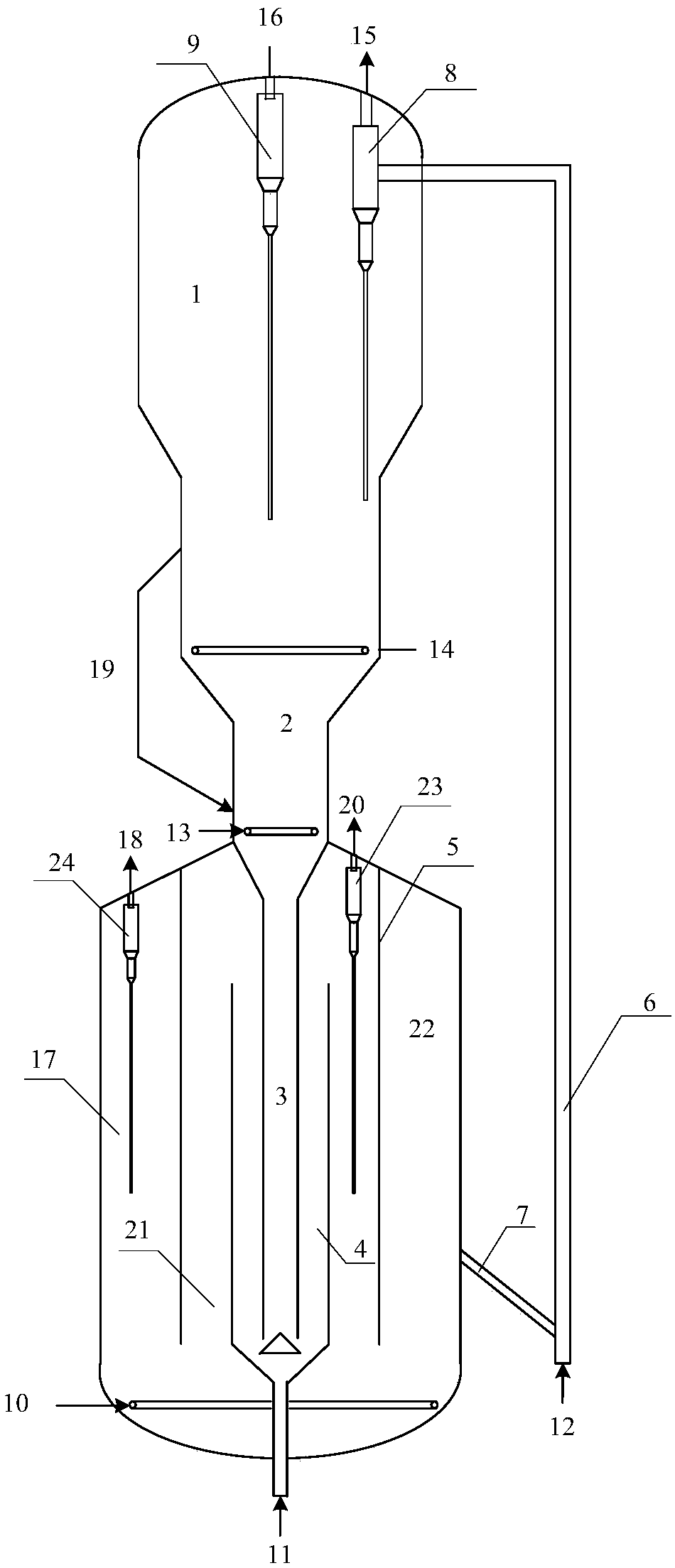

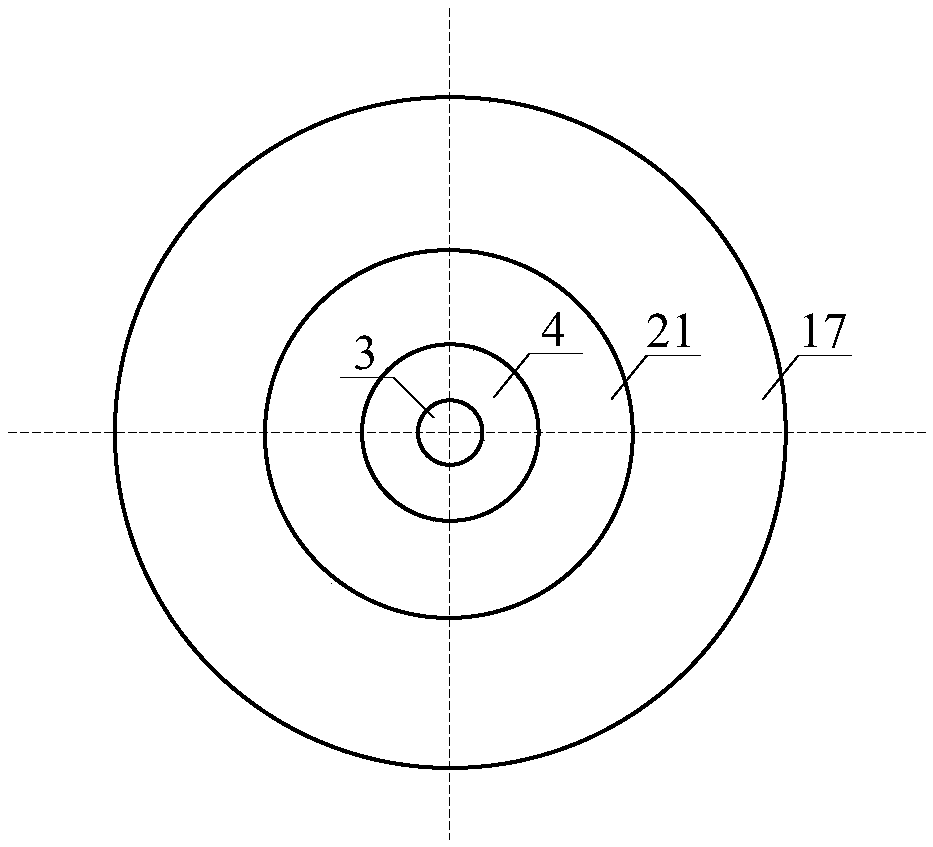

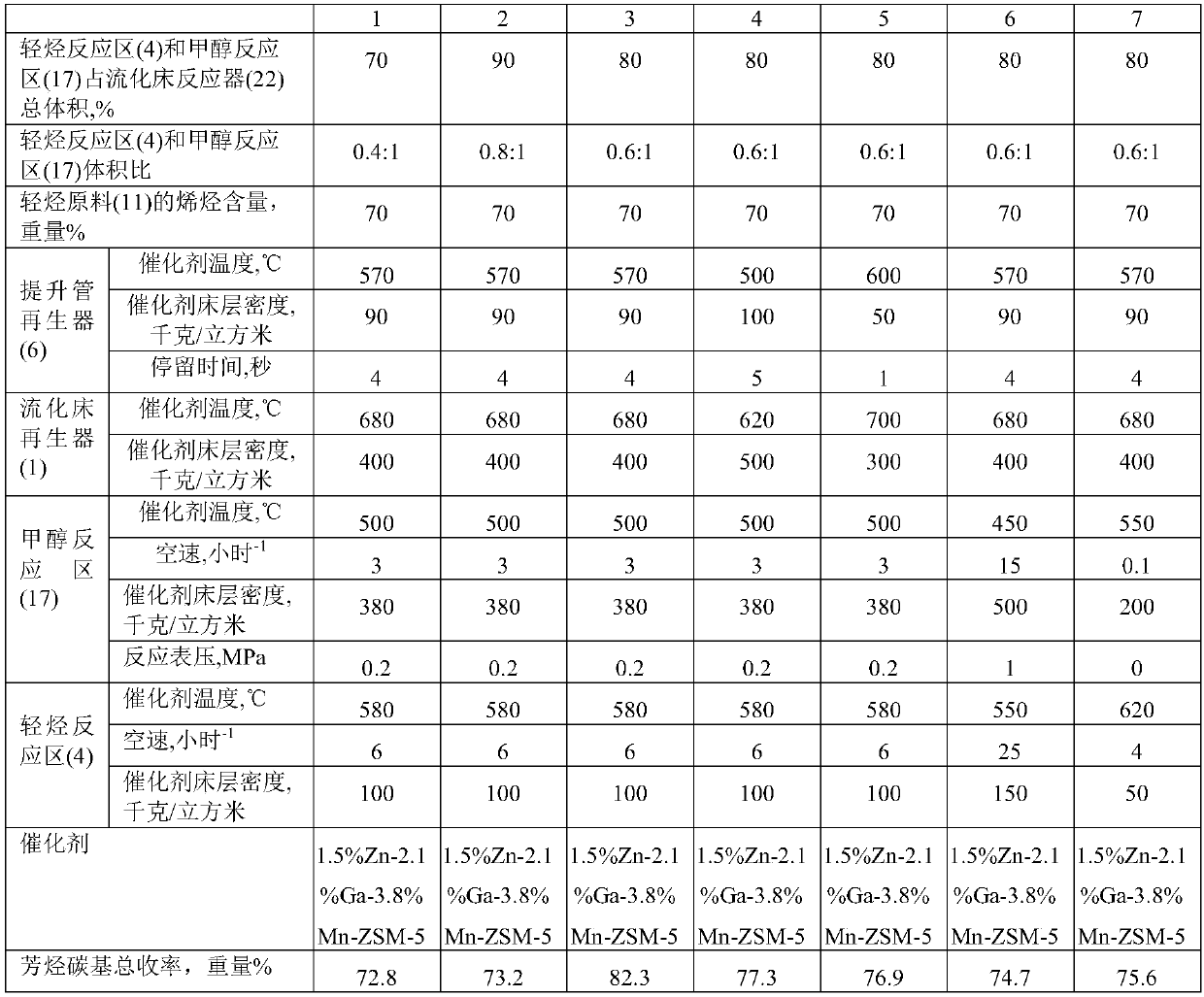

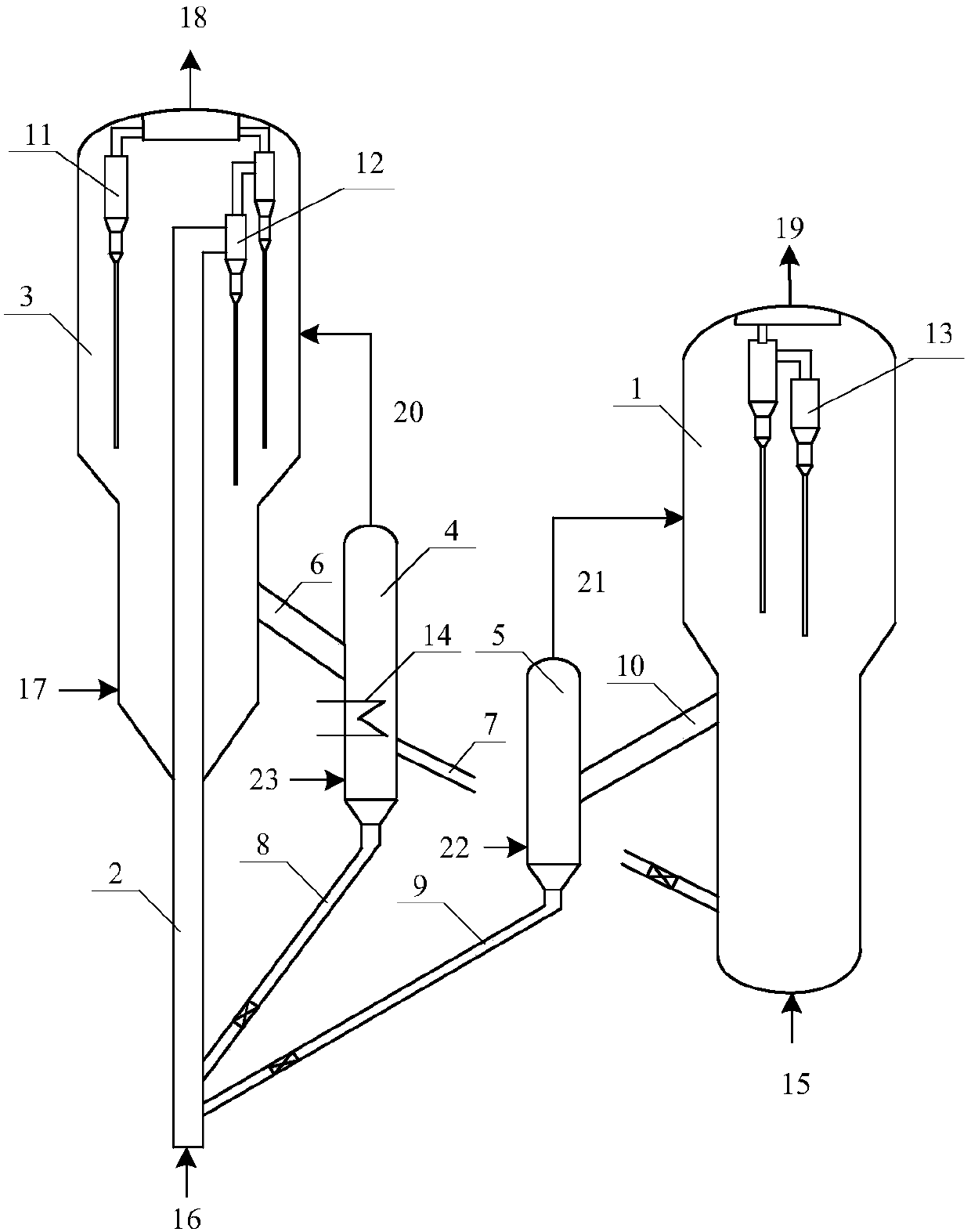

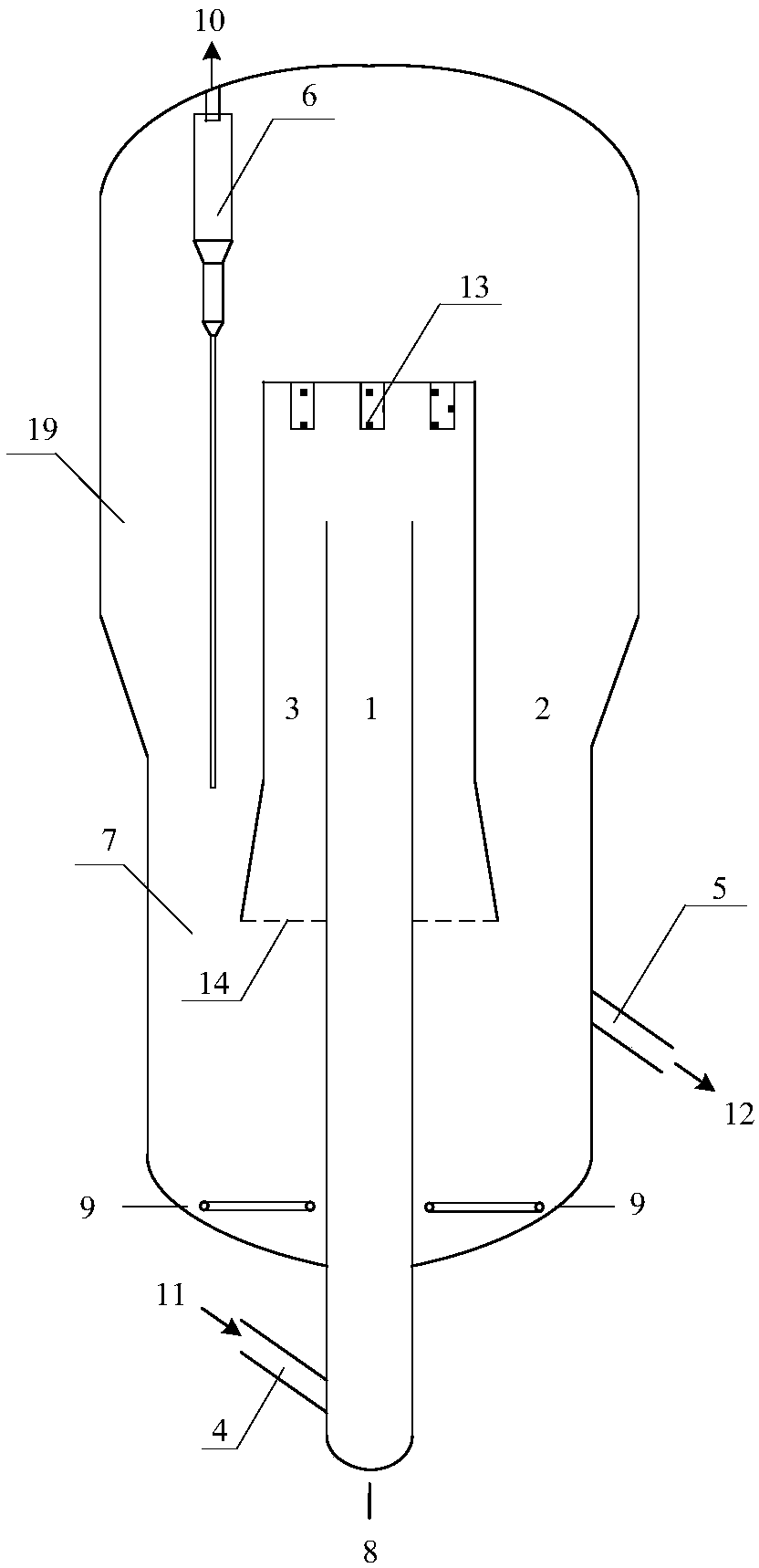

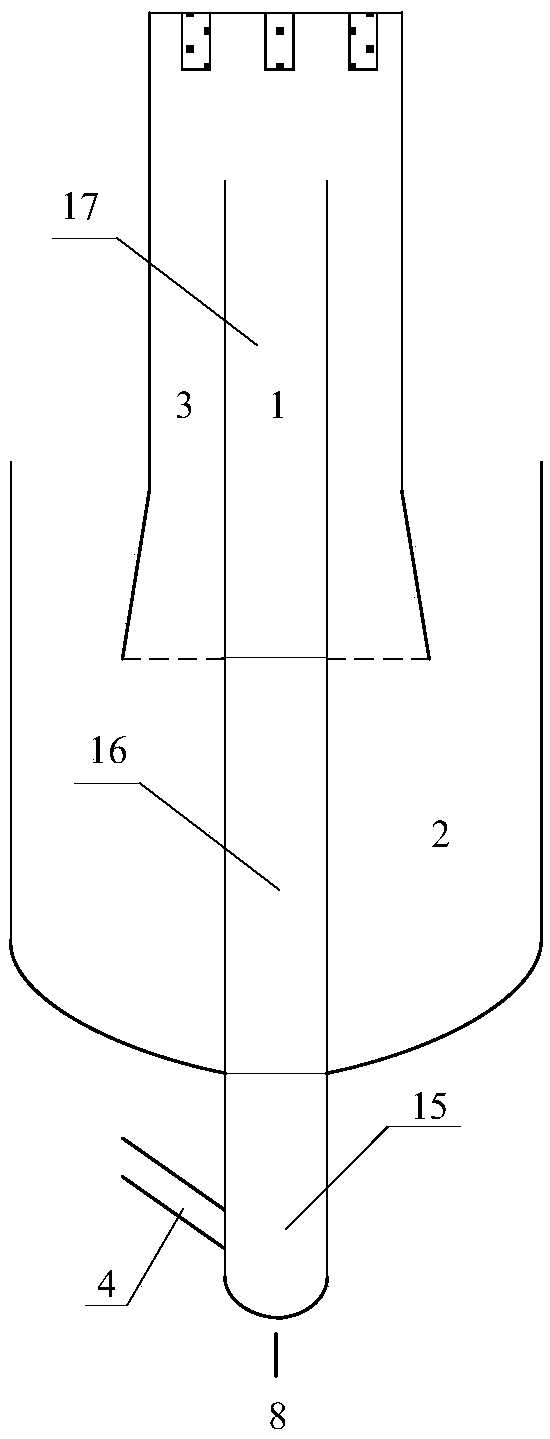

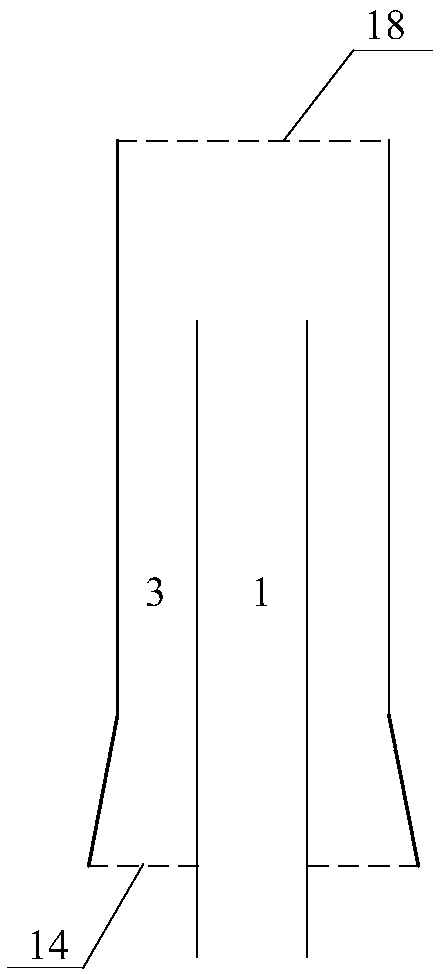

Reaction system and reaction method for preparing aromatic hydrocarbon through catalytic conversion of methanol

ActiveCN111056901AReduce hydrothermal deactivationIncrease aromatics yieldMolecular sieve catalystsMolecular sieve catalystCatalytic transformationPtru catalyst

The invention relates to a reaction system for preparing aromatic hydrocarbon through catalytic conversion of methanol and a reaction method thereof, and mainly solves the problem of low aromatic hydrocarbon yield in the prior art. According to the invention, a methanol raw material enters a methanol reaction zone of a fluidized bed reactor and is subjected to a contact reaction with a modified ZSM-5 catalyst; the obtained spent catalyst enters a riser regenerator through a spent inclined pipe; the obtained semi-regenerated catalyst enters a riser regeneration cyclone separator connected withthe riser regenerator; the separated semi-regenerated catalyst enters a fluidized bed regenerator and is regenerated; the obtained regenerated catalyst enters a degassing zone through a regeneration inclined pipe, the degassed regenerated catalyst enters a light hydrocarbon reaction zone through a vertical pipe and is subjected to a contact reaction with a light hydrocarbon raw material, and the obtained semi-spent catalyst descends in a descending zone and enters a methanol reaction zone, so that the problems are well solved, and the reaction system and reaction method can be used for industrial production of aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of Aromatics from Methanol and Co-Feeds

ActiveUS20170305810A1Increase aromatics yieldReduce and minimize cokingMolecular sieve catalystCatalystsHydrogenOxygenate

Methods are provided for improving the yield of aromatics during conversion of oxygenate feeds. An oxygenate feed can contain a mixture of oxygenate compounds, including one or more compounds with a hydrogen index of less than 2, so that an effective hydrogen index of the mixture of oxygenates is between about 1.4 and 1.9. Methods are also provided for converting a mixture of oxygenates with an effective hydrogen index greater than about 1 with a pyrolysis oil co-feed. The difficulties in co-processing a pyrolysis oil can be reduced or minimized by staging the introduction of pyrolysis oil into a reaction system. This can allow varying mixtures of pyrolysis oil and methanol, or another oxygenate feed, to be introduced into a reaction system at various feed entry points.

Owner:EXXONMOBIL CHEM PAT INC

Method for preparing aromatic hydrocarbons through conversion of methanol

ActiveCN109694296AKeep aliveReduce hydrothermal deactivationMolecular sieve catalystCatalystsCycloneFluidized bed

The invention relates to a method for preparing aromatic hydrocarbons through catalytic conversion of methanol. A purpose of the present invention is mainly to solve the problems of low aromatic hydrocarbon yield and serious hydrothermal deactivation of the catalyst in the prior art. According to the technical scheme, a methanol raw material enters a fluidized bed reactor, and is subjected to a contact reaction with a modified ZSM-5 catalyst to obtain an aromatic hydrocarbon-containing product and a spent catalyst; the steam stripped spent catalyst enters a riser regenerator, and contacts a regeneration medium I, and charring is performed at a temperature of 500-600 DEG C; the outlet of the riser regenerator is connected to at least a set of closed cyclone separators; the semi-regeneratedcatalyst separated by the closed cyclone separators enter a fluidized bed regenerator, and contacts a regeneration medium II, and charring is continuously performed at a temperature of 630-700 DEG C;the regenerated catalyst enters a degassing tank; and the degassed product returns to the fluidized bed regenerator. With the technical scheme, the problems in the prior art are well solved. The method of the present invention can be used in the industrial production of aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas jet injector reactor for catalytic fast pyrolysis process

ActiveUS10093863B2Heating fastIncrease pressureDirect heating destructive distillationBiofuelsFluidized bedProcess engineering

Methods and systems utilizing gas jets to carry biomass into a biomass conversion reactor are described. Reactor configurations and conditions for carrying out processes utilizing the gas jets are also described. The use of gas jets has been found to be especially desirable for operation with pyrolysis of biomass in catalytic fluidized bed reactors.

Owner:ANELLOTECH INC

Technique for processing methanol-to-propylene by-products

ActiveCN103864564BIncrease aromatics yieldReduce energy consumptionHydrocarbon by hydrocarbon condensationHydrocarbon by hydrocarbon and non-hydrocarbon condensationAlkaneLiquid gas

The invention relates to a technique for processing methanol-to-propylene by-products. The technique is characterized by comprising the steps as follows: a liquid hydrocarbon by-product of methanol-to-propylene (MTP) is separated to obtain a dry gas, a liquefied gas and C5<+> non-aromatic and aromatic hydrocarbons after passing through two sections of fixed bed reactors of olefin aromatization and alkane aromatization; the dry gas and aromatic hydrocarbon are discharged out of a reaction system as products; the C5<+> non-aromatic hydrocarbon is returned to the alkane aromatization reactor to continue to react; the liquefied gas and the liquefied gas of the MTP process by-product enter the alkane aromatization reactor; a heat source required for aromatization of the liquefied gas is provided by a mode of adding methanol; the liquefied gas is converted into a mixed hydrocarbon product of taking aromatic hydrocarbon as a main component under the action of a molecular sieve based catalyst; and the mixed hydrocarbon product enters the dethanizer to separate after being processed by an oil-water separator. By adopting the process, gasoline aromatization and liquefied gas aromatization are combined, and the MTP by-product is effectively converted into the hydrocarbons. By adopting the process, the actual gaining rate of the liquid hydrocarbon by-product of the MTP can be up to 65-120%, and the hydrocarbon yield of liquid aromatization can be up to 32-40%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Process for increasing benzene and toluene production

ActiveUS8926829B2Increase productionIncrease aromatics yieldTreatment with plural parallel cracking stages onlyCatalytic naphtha reformingBenzeneNaphtha

Owner:UOP LLC

Process for increasing benzene and toluene production

ActiveUS8680351B2Increase productionIncrease aromatics yieldCatalytic naphtha reformingHydrocarbonsBenzeneNaphtha

Owner:UOP LLC

Catalyst for methanol aromatization and preparation and application thereof

ActiveCN109675617AIncrease aromatics yieldMolecular sieve catalystsMolecular sieve catalystMolecular sieveAromatization

The invention relates to a catalyst for methanol aromatization. The catalyst is prepared from the components in percentage by mass: 55-80% of a modified IM-5 / SAPO-34 composite molecular sieve and 20-45% of silicon dioxide, modified metal in the modified IM-5 / SAPO-34 composite molecular sieve is M and RE, wherein M is selected from Zn, Ga, Cu or Ag, RE is Ce or La, in the modified IM-5 / SAPO-34 composite molecular sieve, the content of a modified IM-5 molecular sieve is 10-95 m%, the content of an SAPO-34 composite molecular sieve is 5-90 m%, the content of M in the modified IM-5 molecular sieveas oxide is 1.0-8.0 m%, and the content of RE as the oxide is 2.0-10.0 m%. The catalyst can directly convert methanol into aromatic products, and has high C8 aromatic yield and p-xylene selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Partition reaction system for preparing aromatic hydrocarbon by methanol conversion and reaction method thereof

ActiveCN111056895AFully contactedIncrease aromatics yieldHydrocarbon from oxygen organic compoundsHydrocarbonsPtru catalystFluidized bed

The invention relates to a partition reaction system for preparing aromatic hydrocarbon through methanol conversion and a reaction method thereof, and mainly solves the problem of low aromatic hydrocarbon yield in the prior art. A methanol raw material enters a methanol reaction zone of a fluidized bed reactor and is subjected to a contact reaction with a modified ZSM-5 catalyst, the obtained spent catalyst enters a regenerator through a spent inclined pipe and is regenerated to obtain a regenerated catalyst; the regenerated catalyst enters a light hydrocarbon reaction zone through a regeneration inclined pipe and carries out contact reaction with a light hydrocarbon raw material;the obtained reaction product and a semi-spent catalyst go up together; the reaction product enters the methanol reaction zone through a filter at the top of the settling zone, the semi-spent catalyst enters the settling zone and enters the methanol reaction zone through a macroporous distribution plate at thebottom of the settling zone, and the reaction product enters a subsequent separation system through a cyclone separator, the problems are well solved, and the reaction system and reaction method canbe used for industrial production of aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for increasing aromatics production

ActiveUS8845884B2Increase aromatics yieldTreatment with plural parallel cracking stages onlyCatalytic naphtha reformingNaphthaHydrocarbon

Owner:UOP LLC

Method for methanol conversion to aromatics

ActiveCN109694296BKeep aliveReduce hydrothermal deactivationMolecular sieve catalystCatalystsCatalytic transformationPtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for producing paraxylene by co-conversion of methanol and/or dimethyl ether and C4 liquefied gas, method for preparing the same and method for using the same

ActiveUS9968922B2Increase aromatics yieldIncrease productionMolecular sieve catalystsMolecular sieve catalystMolecular sieveAromatization

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Light-hydrocarbon aromatized catalyst and preparation method thereof

ActiveCN101596461BLong life one wayLess carbon depositMolecular sieve catalystsHydrocarbon oils refiningAromatizationPhosphoric acid

The invention relates to a light-hydrocarbon aromatized catalyst which comprises the following components according to the mass percent: 20-75 percent of zeolite with MFI structure, 20-75 percent of aluminum phosphate and 0.5-8.0 percent of zinc oxide. The catalyst is used for the light-hydrocarbon aromatization reaction and has better aromatization activity, low carbon deposition rate in the reaction and long one-way service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for producing aromatics from synthesis gas and method of use thereof

ActiveCN106607083BEffective modification of shape-selective propertiesImprove aromatization yieldHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveSpace velocity

The invention relates to a catalyst for preparing arene from synthesis gas and a use method of the catalyst, and mainly solves the technical problems of long technological process, high production cost and low arene yield which exist during a process of preparing the arene from the synthesis gas in the prior art. According to the use method, under the condition of the temperature of 250-450 DEG C, pressure of 0.01-8.0 MPa and synthesis gas volume space velocity of 400-10000h<-1>, an oxygenated compound is taken as raw material, the raw material is in contact with and is reacted with the catalyst in an reactor, so that a material flow containing the arene is obtained; by utilizing the technical scheme of a Fe-containing composite oxide and a molecular sieve composite catalyst, the above problems are well solved; and the catalyst can be applied to industrial production of preparing the arene from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com