Catalyst for methanol aromatization and preparation and application thereof

A catalyst and aromatization technology, applied in the field of methanol aromatization catalyst and preparation thereof, can solve the problems of low selectivity of BTX, rapid catalyst deactivation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

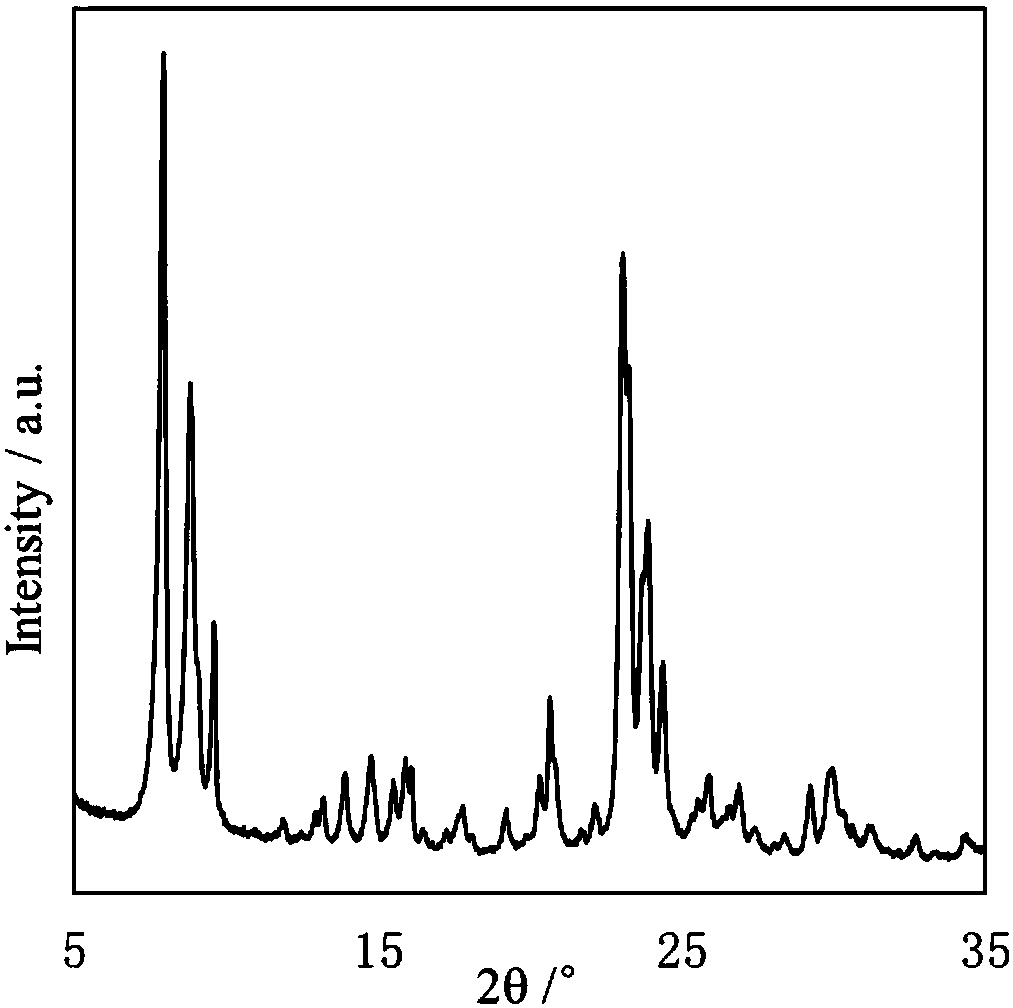

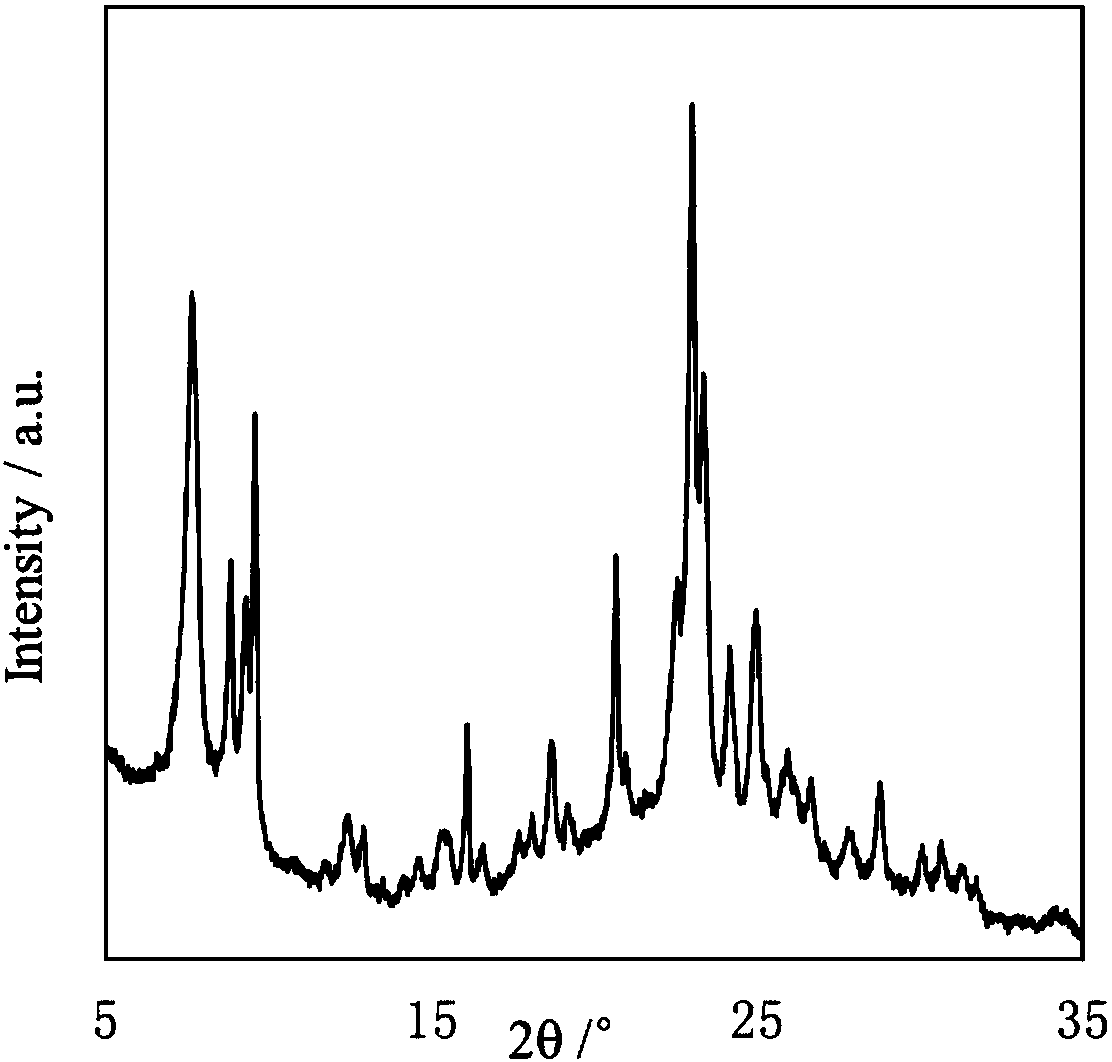

Image

Examples

preparation example Construction

[0017] The preparation method of the catalyst provided by the invention comprises uniformly mixing the modified IM-5 / SAPO-34 composite molecular sieve and silica sol, molding, drying and roasting.

[0018] The preparation method of described modified IM-5 / SAPO-34 composite molecular sieve, comprises the steps:

[0019] (1) Silicon source, aluminum source, phosphorus source, organic template R and water are mixed to obtain SAPO-34 synthetic mother liquor, wherein the amount of silicon source is SiO 2 In terms of, the amount of aluminum source is Al 2 o 3 In terms of phosphorus sources, the amount of P 2 o 5 Calculated, the molar ratio of each material is Al 2 o 3 :P 2 o 5 : SiO 2 :R:H 2 O=1: 0.5~1.5: 0.2~2.0: 0.2~3.0: 20~70,

[0020] (2) Add the modified IM-5 molecular sieve to the SAPO-34 synthetic mother liquor prepared in step (1), stir evenly to form a mixed liquor, and the dry basis mass ratio of the added modified IM-5 molecular sieve to the synthetic mother liq...

example 1

[0048] (1) Preparation of modified H-IM-5 molecular sieve

[0049] Dissolve 1.8 g of zinc nitrate and 2.5 g of cerium nitrate in 30 mL of water, and add 20 g of SiO at 25°C 2 / Al 2 o 3 In the H-IM-5 molecular sieve raw powder with a molar ratio of 25 and a grain size of 0.5 microns, let it stand for 24 hours, dry the obtained solid at 110°C for 12 hours, and roast at 450°C for 5 hours to obtain zinc and cerium-modified IM -5 molecular sieves Zn-Ce-IM-5, wherein the zinc content as ZnO is 2.46% by mass, as Ce 2 o 3 The calculated cerium content was 4.73% by mass.

[0050] (2) Preparation of modified IM-5 / SAPO-34 composite molecular sieve

[0051] Get 17.8g pseudo-boehmite (aluminum oxide content is 90% by mass) and mix with 94.8g deionized water, add 22.5g orthophosphoric acid (containing H 3 PO 4 85 mass%) solution, after continuing to stir evenly, add 10.9g silica sol (SiO 2 Content is 40 mass %), 12g triethylamine and 12g tetraethylammonium hydroxide, stir, make SAP...

example 2

[0056]Prepare catalyst by the method for example 1, difference is (2) in step, the Zn-Ce-IM-5 molecular sieve of 137g is added in SAPO-34 synthetic mother liquor, the Zn-Ce-IM-5 molecular sieve of adding and synthetic mother liquor The ratio of dry basis mass is 1:0.25, in the Zn-Ce-IM-5 / SAPO-34 composite molecular sieve that makes, the content of SAPO-34 molecular sieve is 20 mass %, the content of Zn-Ce-IM-5 molecular sieve is 80% by mass. Get this composite molecular sieve and make catalyst G by (3) step method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com