Reaction system and reaction method for preparing aromatic hydrocarbon through catalytic conversion of methanol

A technology of catalytic conversion and reaction system, which is applied in the field of reaction systems for catalytic conversion of methanol to aromatics, can solve the problems of low aromatics yield and the like, and achieve the effects of high aromatics yield and good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

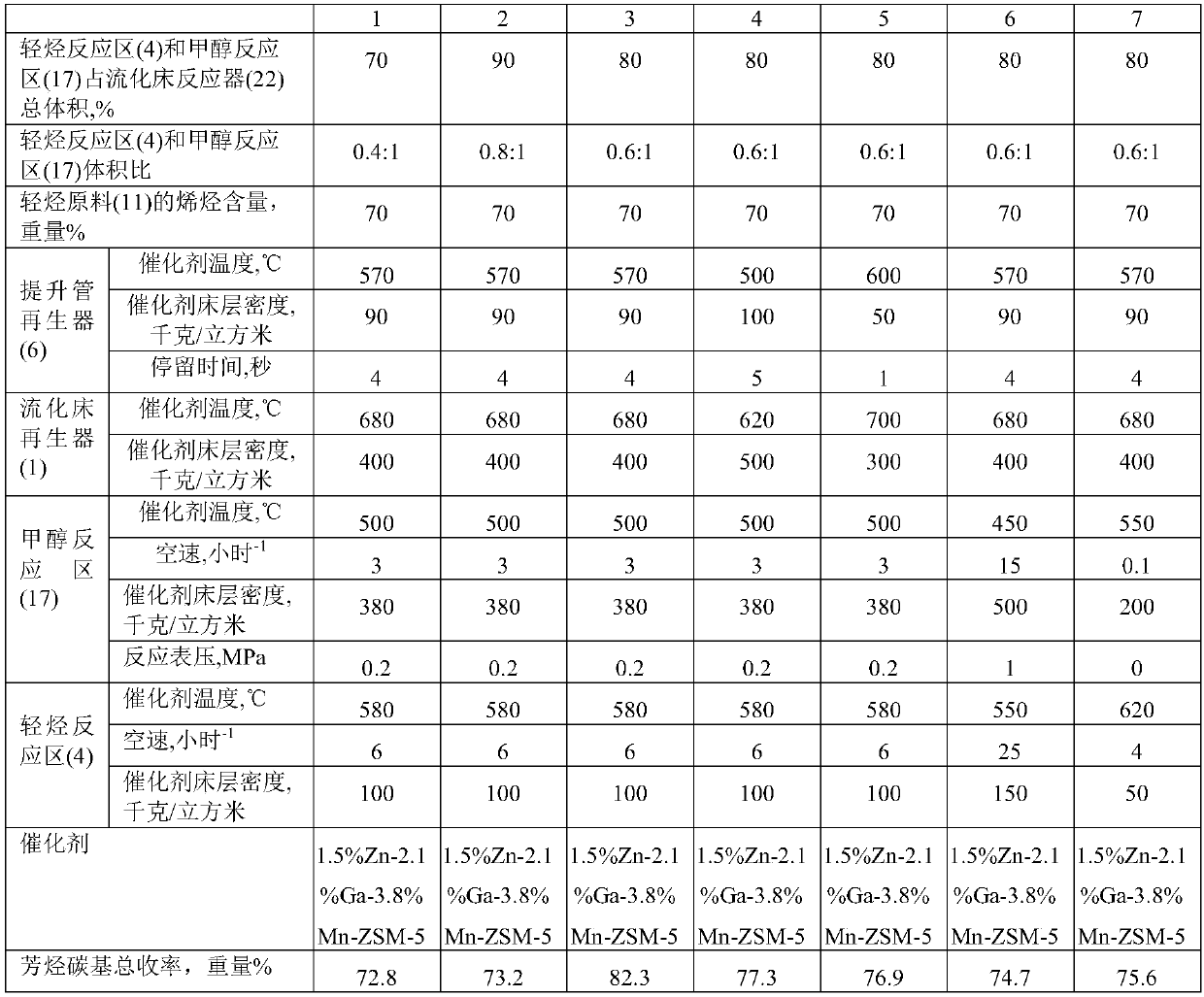

Embodiment 1

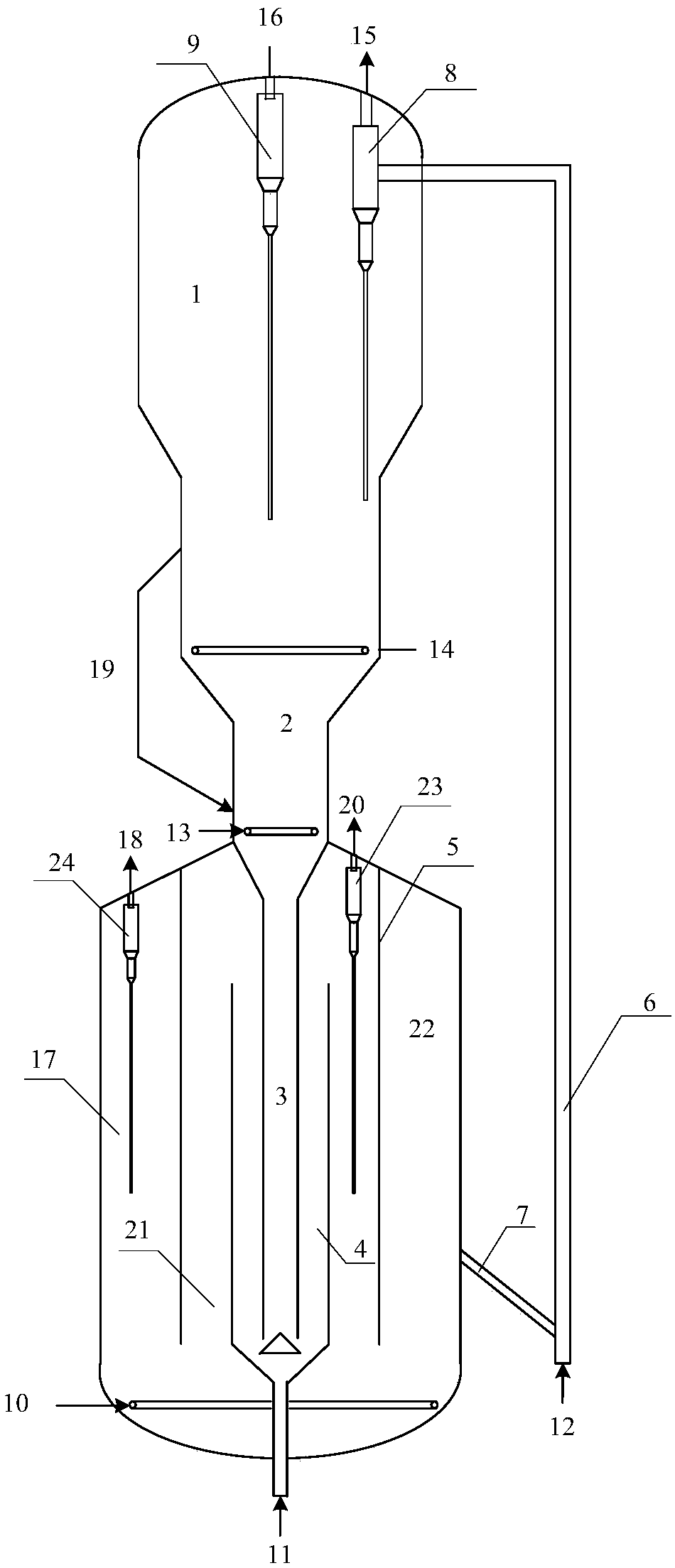

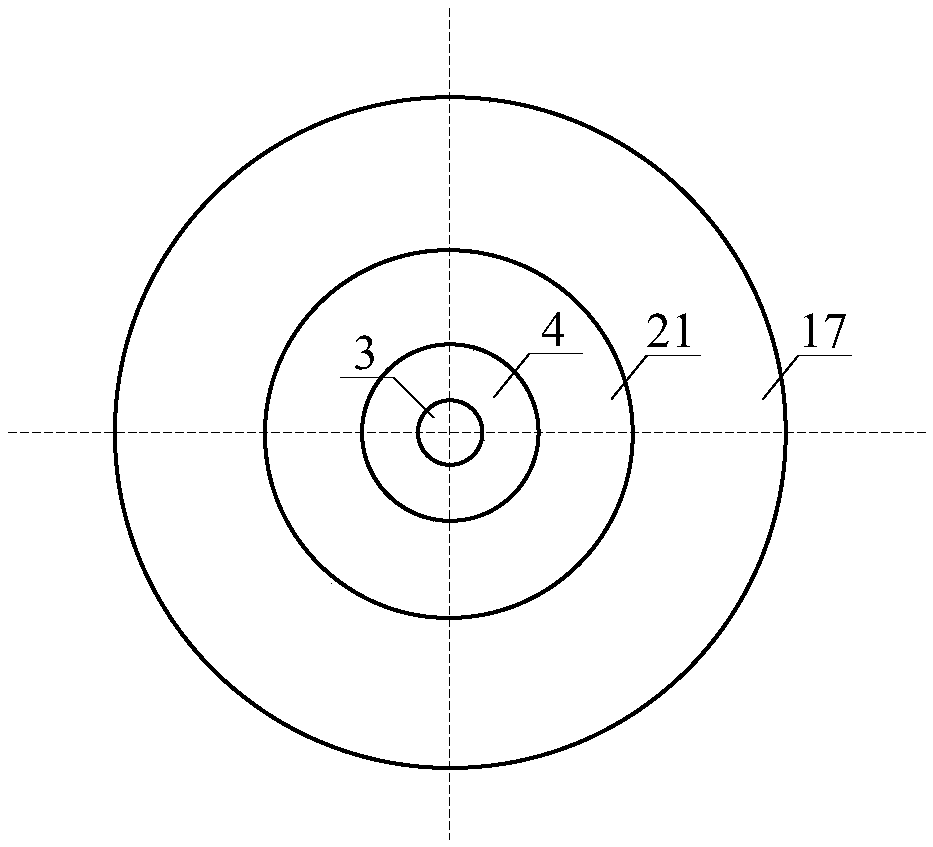

[0038] use as figure 1 As shown in the device, the lower part of the riser regenerator (6) is connected to the inclined pipe (7) to be produced, the outlet of the riser regenerator (6) is connected to the riser regeneration cyclone separator (8), and the riser regeneration cyclone separator (8 ) is located in the fluidized bed regenerator (1); the fluidized bed regenerator (1) is provided with a fluidized bed regeneration cyclone separator (9), and the fluidized bed regenerator (1) is located above the degassing zone (2) The degassing zone (2) is positioned at the top of the standpipe (3); the regeneration inclined pipe (19) connects the fluidized bed regenerator (1) and the degassing zone (2); the standpipe (3) is positioned at the fluidized bed reactor ( 22), the lower part of the standpipe (3) is located in the light hydrocarbon reaction zone (4); the fluidized bed reactor (22) is horizontally arranged in sequence from the inside to the outside of the standpipe (3), the lig...

Embodiment 2

[0050] use as figure 1 In the described device, the bottom of the riser regenerator (6) is connected to the inclined pipe (7) to be produced, the outlet of the riser regenerator (6) is connected to the riser regeneration cyclone separator (8), and the riser regeneration cyclone separator ( 8) Located in the fluidized bed regenerator (1); the fluidized bed regenerator (1) is provided with a fluidized bed regeneration cyclone separator (9), and the fluidized bed regenerator (1) is located in the degassing area (2) above; the degassing zone (2) is located above the standpipe (3); the regeneration inclined pipe (19) connects the fluidized bed regenerator (1) and the degassing zone (2); the standpipe (3) is located in the fluidized bed reactor (22), the lower part of the standpipe (3) is located in the light hydrocarbon reaction zone (4); the fluidized bed reactor (22) is horizontally arranged in turn from the inside to the outside of the standpipe (3), the light hydrocarbon reacti...

Embodiment 3

[0062] use as figure 1In the described device, the bottom of the riser regenerator (6) is connected to the inclined pipe (7) to be produced, the outlet of the riser regenerator (6) is connected to the riser regeneration cyclone separator (8), and the riser regeneration cyclone separator ( 8) Located in the fluidized bed regenerator (1); the fluidized bed regenerator (1) is provided with a fluidized bed regeneration cyclone separator (9), and the fluidized bed regenerator (1) is located in the degassing area (2) above; the degassing zone (2) is located above the standpipe (3); the regeneration inclined pipe (19) connects the fluidized bed regenerator (1) and the degassing zone (2); the standpipe (3) is located in the fluidized bed reactor (22), the lower part of the standpipe (3) is located in the light hydrocarbon reaction zone (4); the fluidized bed reactor (22) is horizontally arranged in turn from the inside to the outside of the standpipe (3), the light hydrocarbon reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com