Catalyst for producing gasoline component by naphtha and methanol, and preparation method and application thereof

A catalyst and naphtha technology, which can be used in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of limiting the application of low-carbon alkane aromatization technology, high energy consumption, etc., and achieve less carbon deposition. , the effect of long one-way life and high gasoline yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of catalyst of the present invention comprises the steps:

[0026] (1) Mix hydrogen type ZSM-5 zeolite, alumina and silica sol, add peptizing agent to form, obtain carrier after drying and roasting,

[0027] (2) steaming the carrier at 450-700°C,

[0028] (3) impregnating the steam-treated carrier with a solution containing Ag compound, VA group element compound and rare earth element-containing compound solution, then drying and calcining.

[0029] In the above method, the (1) step is carrier molding, first mixing hydrogen ZSM-5 zeolite with alumina and silica sol and then molding. SiO in the silica sol 2 The content is 20-30% by mass, and the molding can be extrusion molding, drop ball molding, rolling ball molding or tablet molding. Preferably extrusion molding, during extrusion molding, preferably add appropriate amount of peptizer kneading, extrusion molding in the mixture, described peptizer is preferably nitric acid or hydrochloric acid,...

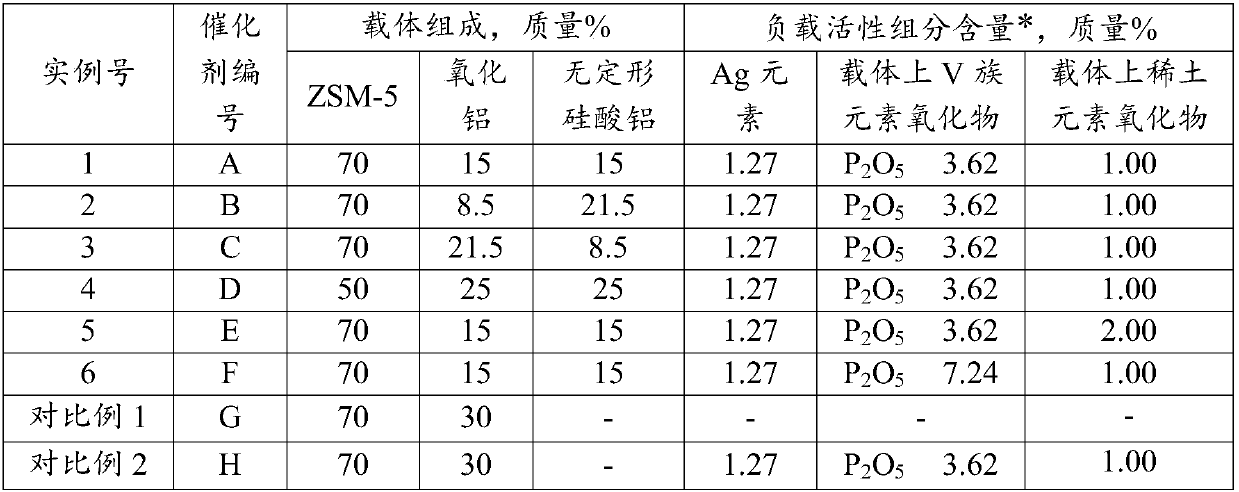

example 1

[0050] Preparation of the catalyst of the present invention.

[0051] (1) Preparation of carrier

[0052] Take 130 grams of SiO 2 / Al 2 o 3 The mol ratio is the HZSM-5 zeolite powder of 56, 35 grams of pseudo-boehmite powder, 35 grams of silica sol (SiO 2 Content is 30% by mass), add 100g concentration and be 1.0m% nitric acid aqueous solution peptization, knead and extrude into the bar of diameter 2 millimeters, 110 ℃ of drying hours, cut into the particle of length 2~3 millimeters, 550 ℃ of roasting 4 hours, make Get the carrier, the alumina in it is γ-Al 2 o 3 .

[0053] (2) steam treatment

[0054] Put the carrier prepared in step (1) into a tubular reactor, raise the temperature to 550° C. under 0.1 MPa and air flow, and pass in steam for 4 hours.

[0055] (3) Preparation of catalyst

[0056] Take 100 grams of the carrier treated with water vapor in step (2), soak it with 50ml of phosphoric acid solution with a concentration of 100mg / ml at 80°C for 1 hour, take t...

example 2

[0059] Prepare catalyst by the method for example 1, difference is (1) step gets 130 grams of SiO 2 / Al 2 o 3 HZSM-5 zeolite powder with a molar ratio of 56, 20 grams of pseudoboehmite powder, 50 grams of silica sol, adding 100 g concentration of 1.0 m% nitric acid aqueous solution for peptization, the α value of the prepared catalyst B is 32, see the composition Table 1.

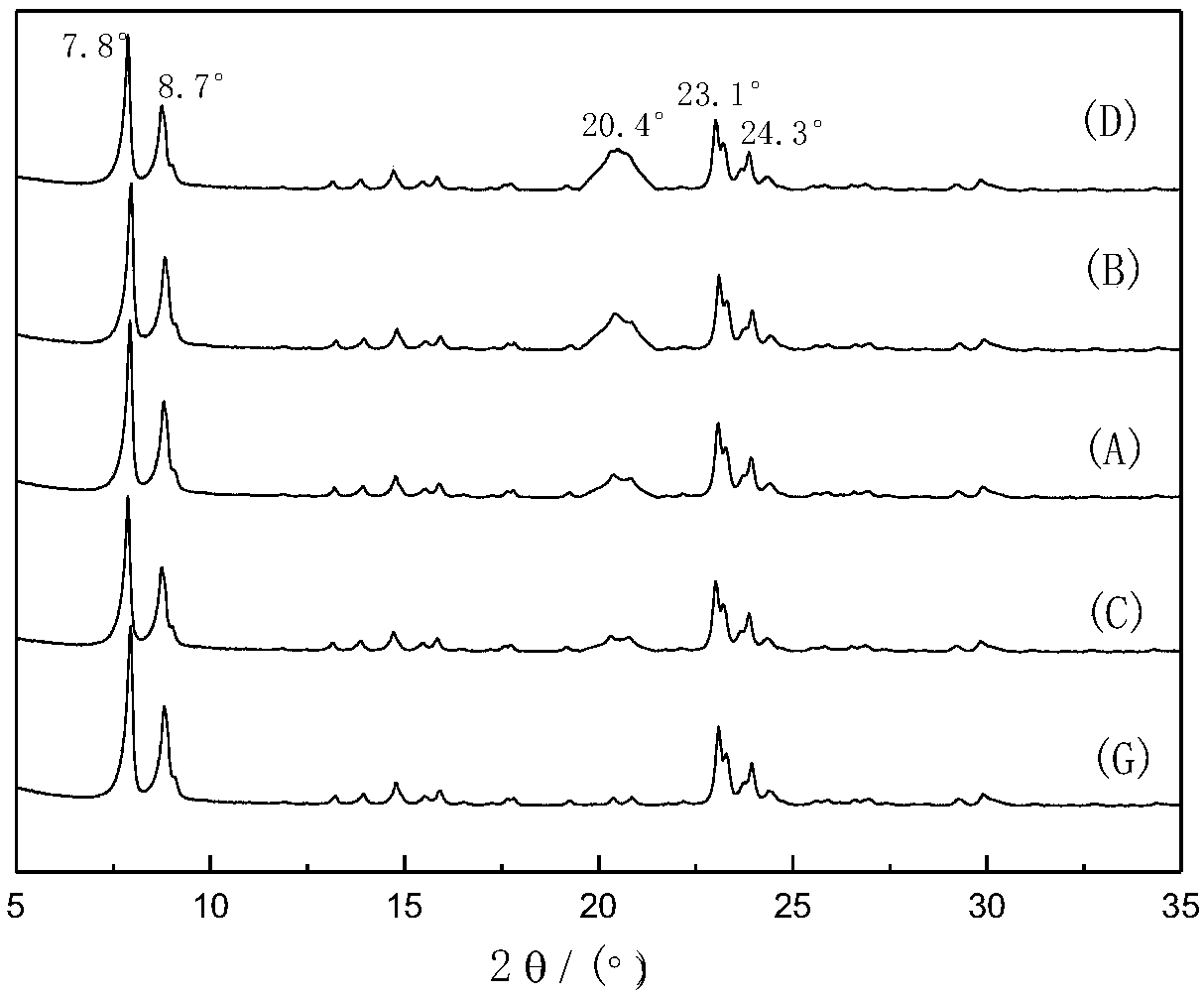

[0060] The XRD diffraction pattern of catalyst B is shown in figure 2 , it can be seen that a new diffraction peak appears near 2θ of 20°, which is the diffraction peak of amorphous aluminum silicate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com