Method for removing aldehyde and ketone in HPPO process by molecular sieve catalytic reaction

A catalytic reaction and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of difficult wastewater treatment, frequent regeneration, and high safety requirements, and achieve long service life, long single-pass life, and regeneration. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

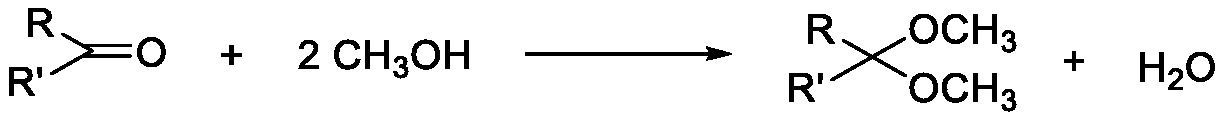

Image

Examples

Embodiment 1

[0022] Mix NaY molecular sieve and 0.3mol / L ammonium chloride solution according to the liquid / solid weight ratio of 3, exchange at 90°C for 4h, filter with molecular sieve, rinse, dry at 105°C for 5h, and roast at 500°C for 5h, repeat the above steps 3 times , to obtain a modified molecular sieve catalyst.

[0023] The above-mentioned modified molecular sieve catalyst is loaded into a tubular fixed bed, the aspect ratio of the catalyst bed is 100, and the circulating methanol (aldehyde and ketone impurity content 2500ppm) from the HPPO process is used at a volume space velocity of 0.5h -1 Pumped into a tubular fixed bed, treated at 75°C and 4MPa, the initial discharge contains 3 ppm of aldehydes and ketones, and 4,892 ppm of acetals and ketals. It is required that the output index of aldehydes and ketones impurity index is less than or equal to 8ppm, and the operating time of the device is 1200h.

[0024] The above-mentioned catalyst to be treated is first purged with nitrog...

Embodiment 2

[0026] Mix NaY molecular sieve and 0.2mol / L stannous chloride solution according to the liquid / solid weight ratio of 2, exchange at 60°C for 8h, filter with molecular sieve, rinse, dry at 105°C for 5h, roast at 500°C for 5h, repeat the above steps for 5 hours Second, a modified molecular sieve catalyst was obtained.

[0027] The above-mentioned modified molecular sieve catalyst is loaded into a tubular fixed bed, the aspect ratio of the catalyst bed is 50, and the circulating methanol (aldehyde and ketone impurity content 1000ppm) from the HPPO process is used at a volume space velocity of 2h -1 Pumped into the reactor, treated at 60°C and 3MPa, the initial output aldehyde and ketone impurity content was 8ppm, and the acetal ketal content was 1902ppm. It is required that the output index of aldehydes and ketones impurity index is less than or equal to 12ppm, and the operating time of the device is 1600h.

[0028] The above-mentioned catalyst to be treated is first purged with...

Embodiment 3

[0030] Mix MCM-22 molecular sieve and 0.1mol / L ammonium chloride solution according to the liquid / solid weight ratio of 4, exchange at 95°C for 4h, filter with molecular sieve, rinse, dry at 105°C for 5h, and roast at 550°C for 7h, repeat the above steps 4 times to obtain a modified molecular sieve catalyst.

[0031] The above-mentioned modified molecular sieve catalyst is loaded into a tubular fixed bed, the aspect ratio of the catalyst bed is 50, and the circulating methanol (aldehyde and ketone impurity content 200ppm) from the HPPO process is used at a volume space velocity of 4h -1 Pumped into a tubular fixed bed, treated at 40°C and 1MPa, the initial discharge contains 15ppm of aldehydes and ketones, and 362ppm of acetals and ketals. It is required that the output index of aldehydes and ketones impurities is less than or equal to 20ppm, and the operating time of the device is 900h.

[0032]The above-mentioned catalyst to be treated is first purged with nitrogen at 300-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com