Multistage porous ZSM-5 molecular sieve and preparation method thereof as well as method for preparing PX catalyst using same

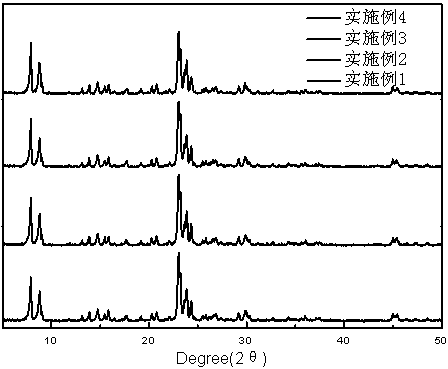

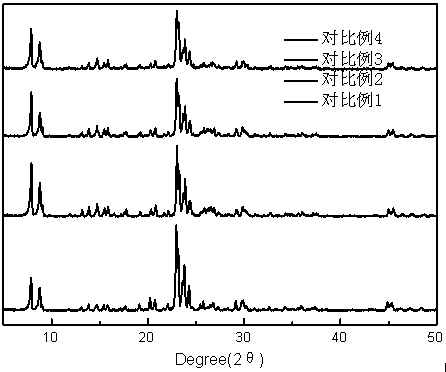

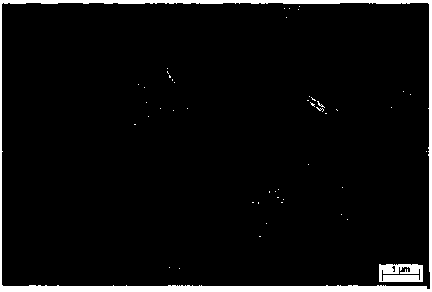

A ZSM-5, molecular sieve technology, applied in the field of molecular sieve, can solve the problems of complex catalyst preparation process, little increase in toluene conversion rate, poor catalyst stability, etc., and achieve good catalytic effect, high selectivity and complete crystal form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]18.9g of sodium metaaluminate, 46.2g of sodium hydroxide, 63.5g of n-butylamine and 3737g of deionized water were stirred at 25°C for 0.5h to form a mixed solution A. Add 45g of isopropanol to 127.5g of polyether polyol with a molecular weight of 500-1000 (functionality: 2-3; hydroxyl value: 25-45; initiator: glycerin or ethylene glycol), and stir for 10 minutes to form a mixed solution b. Mixed solution B was dropped into mixed solution A, and stirred for 0.5h to form mixed solution C. 3404g of silica sol was slowly added to the mixed solution C, stirred for 0.5h, 30.6g of all-silicon seed crystals were added thereto, and stirred for 2h to form a mixed solution D. Add 3.1g of ammonium fluoride to the mixed solution D, and stir for 2 hours to form the mixed mother solution E. The mother liquor was transferred into a 10L stainless steel hydrothermal crystallization kettle, and the temperature was raised to 180° C. for 17 hours for crystallization. After crystallization...

Embodiment 2

[0045] Mix 216.2g of sodium carbonate, 58.1g of aluminum sulfate, 82.8g of tetrapropylammonium hydroxide and 3790g of deionized water and stir until they are completely dissolved, and stir for 1 hour to form a mixed solution A. Add 55.2 g of ethanol to 153 g of polyether polyol with a molecular weight of 400-600 (functionality: 2-3; hydroxyl value: 100-200; initiator: glycerin or ethylene glycol), and stir to form a mixed solution B. Add mixed solution B to mixed solution A, stir well to form mixed solution C. Add 1040g of white carbon black to the mixed liquid C, stir for 0.5h, add 41g of all-silicon seed, stir for 4h, and form the mixed liquid D. Add 7.1g of sodium fluoride to the mixed solution D, and stir for 2h to form the mixed mother solution E. The mother liquor E was transferred into a stainless steel hydrothermal crystallization kettle, and the temperature was raised to 190° C. for 15 hours after 7 hours. After the reaction, the product was washed with deionized wa...

Embodiment 3

[0047] 285.6g of sodium bicarbonate, 141.7g of aluminum isopropoxide, 85.9g of triethylamine and 2080g of deionized water were mixed and stirred until completely dissolved, and stirred for 2 hours to form a mixed solution A. Add 76.8g of methanol to 212.5g of polyether polyol with a molecular weight of 150-400 (functionality: 4-6; hydroxyl value: 350-450; initiator: sorbitol or pentaerythritol), heat to 40°C, and stir to form Mixture B. Add mixed solution B to mixed solution A, stir well to form mixed solution C. Add 5210g of water glass into the mixed solution C, then add 20.3g of all-silicon seed crystals, stir for 1 hour, and form the mixed solution D. Add 8.2g of ammonium carbonate to the mixed solution D, and stir for 4h to form the mixed mother solution E. The mother liquor E was transferred into a stainless steel hydrothermal crystallization kettle, and the temperature was raised to 170° C. for 24 hours after 4 hours. After the reaction, the product was washed with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com