Method for synthesizing hierarchical-pore SAPO-34 molecular sieve through post-treatment of solid acid

A molecular sieve and multi-stage pore technology, applied in the field of solid acid post-treatment to synthesize multi-stage pore SAPO-34 molecular sieve, can solve problems such as environmental pollution and a large amount of waste water, and achieve the advantages of reducing environmental pollution, saving costs, and reducing the discharge of waste liquid. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 10 g of commercial SAPO-34 molecular sieve and 0.10 g of solid-phase oxalic acid, put them into a pulverizer and pulverize them, so that the solid-state reactants are uniformly mixed. Then the raw material was transferred to a 100ml polytetrafluoroethylene-lined stainless steel autoclave, and placed in an oven, and reacted at 60° C. for 6 hours to obtain a multi-stage porous SAPO-34 molecular sieve.

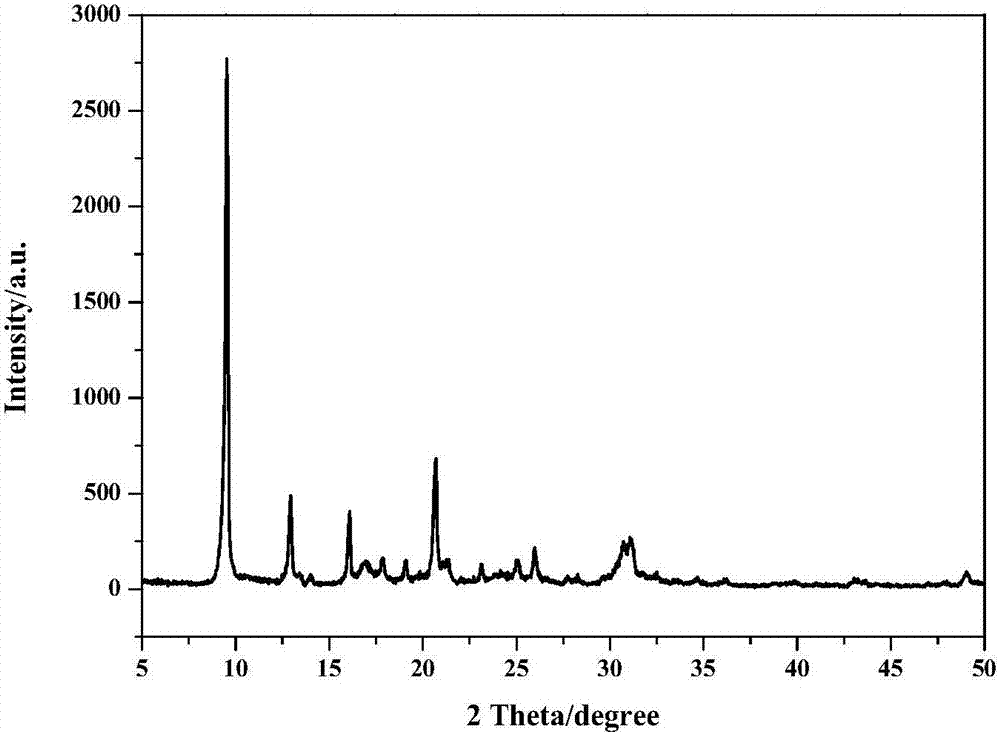

[0032] figure 1 It is the XRD characterization result of the product, it can be seen that the product is a typical CHA structure and has a good relative crystallinity.

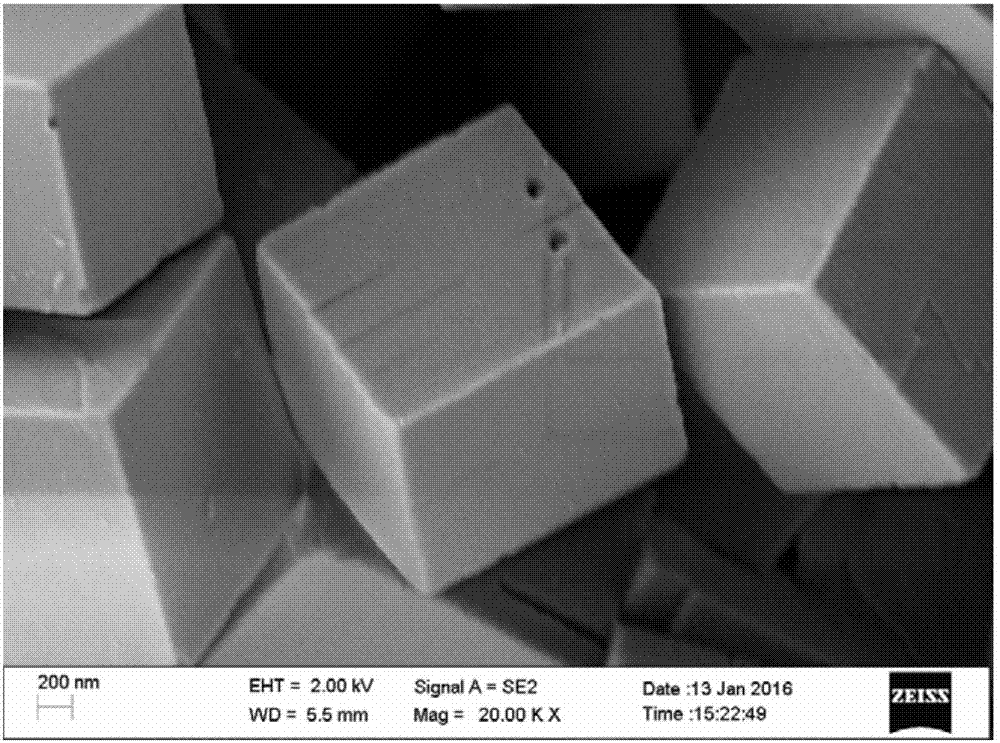

[0033] figure 2 It is the SEM scanning electron microscope photo of the product. It can be seen that the particles of the product are cubic crystals of 1-4 μm, and the surface is not significantly different from the original powder.

Embodiment 2

[0035] Weigh 10 g of commercial SAPO-34 molecular sieve and 0.20 g of solid-phase oxalic acid, put them into a pulverizer and pulverize them, so that the solid-state reactants are evenly mixed. Then the raw material was transferred to a 100ml polytetrafluoroethylene-lined stainless steel autoclave, and placed in an oven, and reacted at 80°C for 6h to obtain a multi-stage porous SAPO-34 molecular sieve.

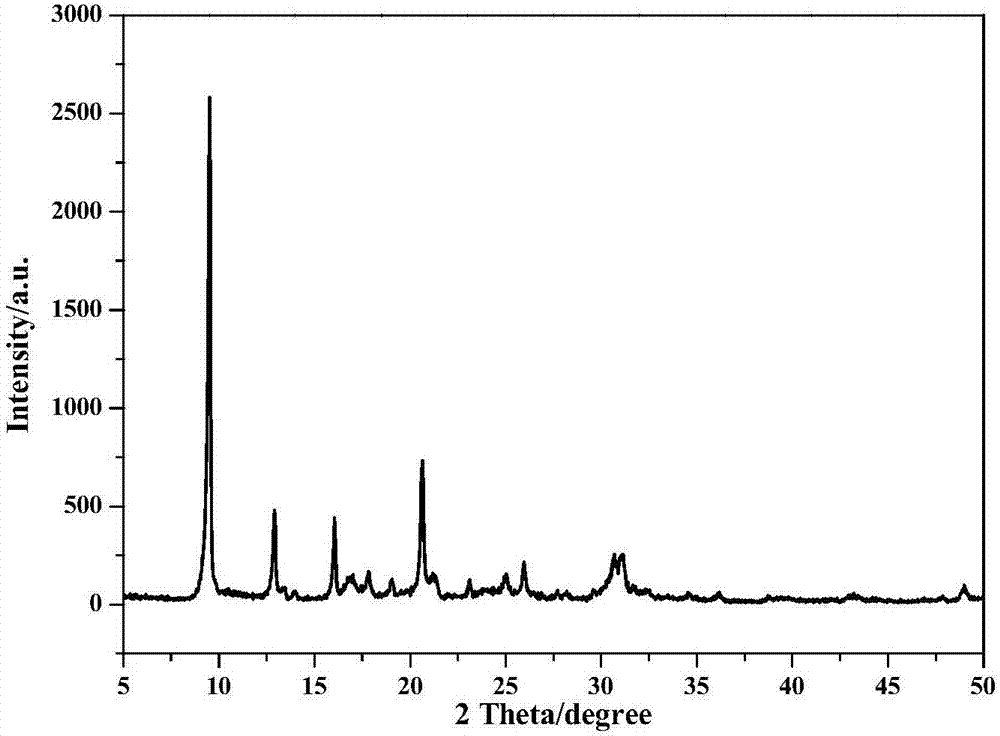

[0036] image 3 It is the XRD characterization result of the product, it can be seen that the product has a typical CHA structure and has good crystallinity.

[0037] Figure 4 It is the SEM scanning electron microscope photo of the product. It can be seen that the particles of the product are cubic crystals of about 1-4 μm, and the surface is slightly rougher than that of the original industrial molecular sieve powder.

Embodiment 3

[0039] Weigh 10 g of commercial SAPO-34 molecular sieve and 0.30 g of solid oxalic acid, put them into a pulverizer and pulverize them, so that the solid reactants are uniformly mixed. Then the raw material was transferred to a 100ml polytetrafluoroethylene-lined stainless steel autoclave, and placed in an oven, and reacted at 100°C for 6h to obtain a multi-stage porous SAPO-34 molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com