A method for improving the stability of catalysts for lightening heavy aromatics

A technology for lightening heavy aromatics and catalysts, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of severe carbon deposition and poor stability of catalysts, achieve low additional cost, improve stability, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

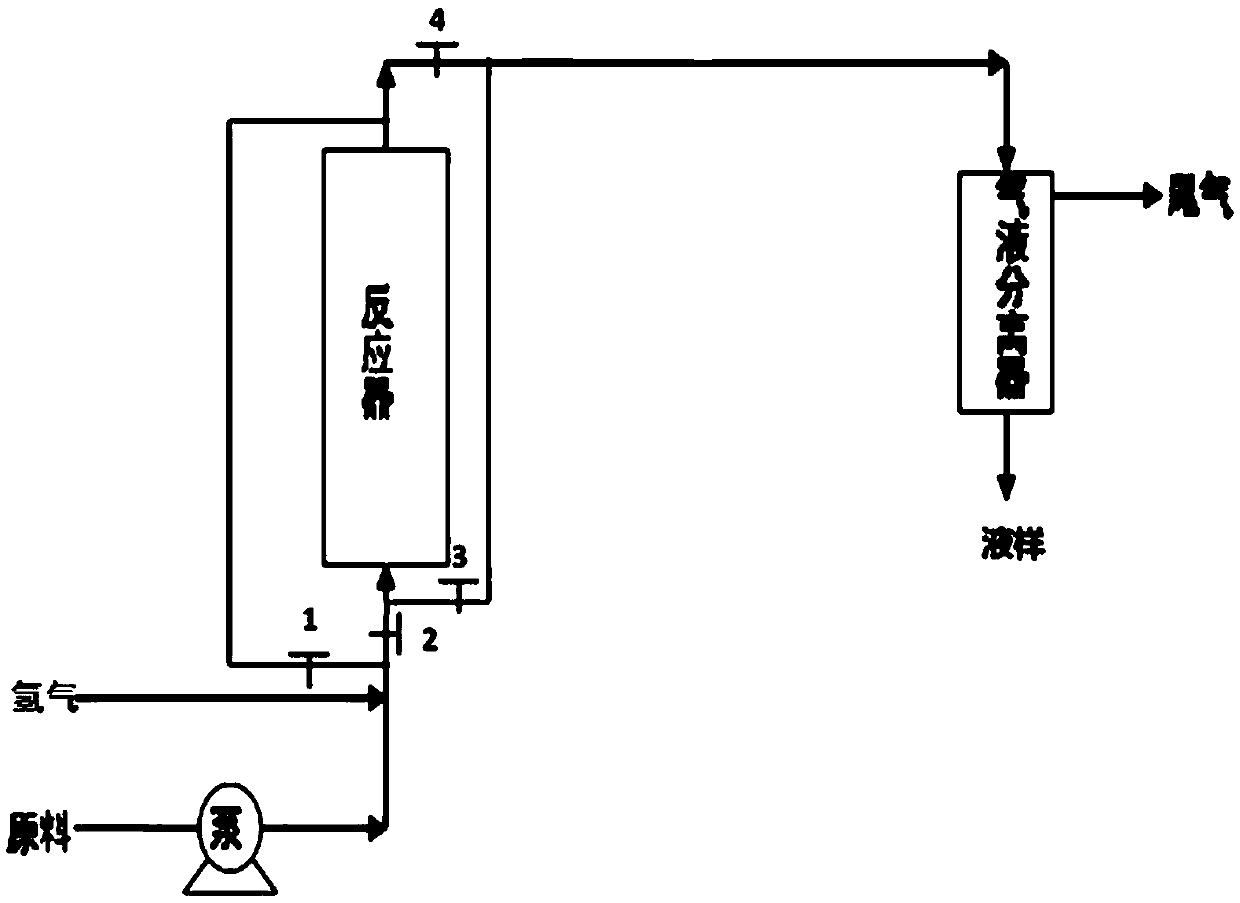

[0022] This example illustrates the method of the present invention for improving the stability of a catalyst for hydrogenation and lightening of heavy aromatics.

[0023] Load and reduce the catalyst according to the method of the comparative example, enter the oil for reaction, and take samples for analysis. When the reaction was carried out for 120 hours, valves 1 and 3 were quickly opened, valves 2 and 4 were closed, and the reaction continued without changing other conditions.

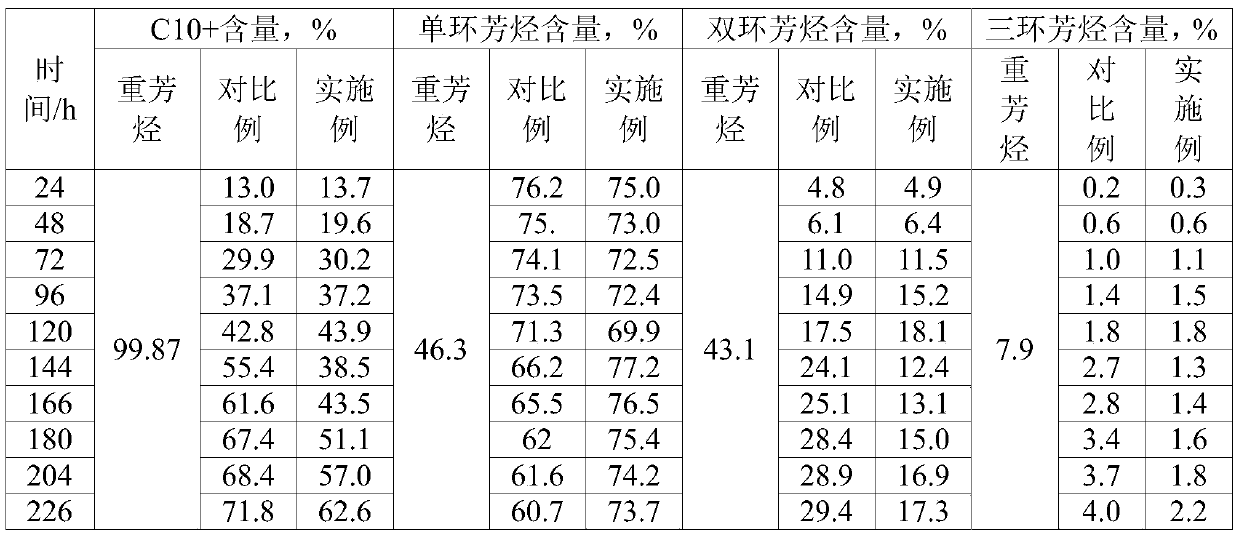

[0024] The liquid phase analysis result of comparative example and embodiment is summarized in table 1:

[0025] Table 1

[0026]

[0027] The comparative example and the embodiment adopt the same catalyst and reduction treatment, so the composition of the product before 120h is basically the same. And after 144h, the C10+ content in the embodiment is lower than the comparative example product, the single-ring aromatic hydrocarbon content is high, and the bicyclic and tricyclic content are lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com