Catalyst, preparation method and application of methyl acrylate and formaldehyde for producing methyl acrylate

A technology of methyl acrylate and methyl acetate, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. It can solve problems such as the need for regeneration, catalyst deactivation, and carbon deposition on the surface of the catalyst. Increased performance, prolonging one-way life, and prolonging the effect of one-way life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

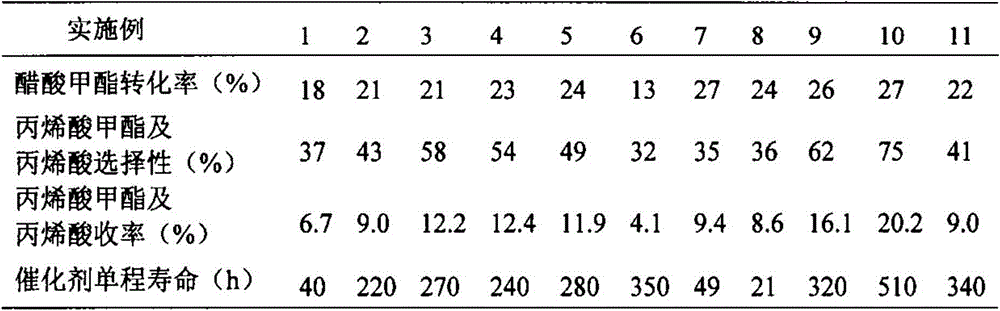

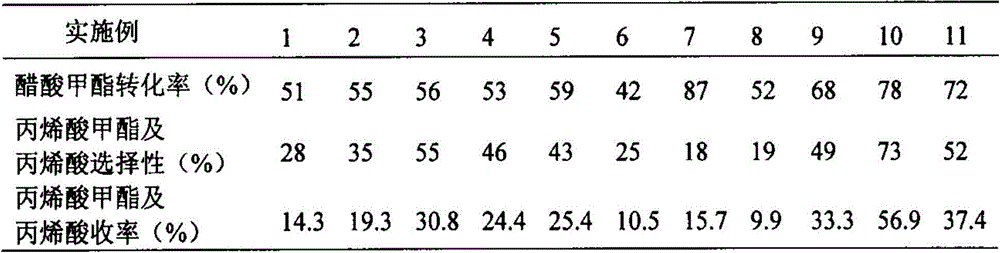

Examples

Embodiment 1

[0030] Weigh 1.2g of strontium nitrate, add 90ml of deionized water to prepare an additive impregnation solution, put 100g of silica carrier in the impregnation solution, soak at room temperature for 4 hours, and dry at 120°C for 4 hours to obtain a carrier containing additives .

[0031] Weigh 15g of cesium nitrate (calculated as cesium oxide), add 90ml of deionized water to prepare a cesium nitrate solution, add the carrier containing additives into the cesium nitrate solution, soak at room temperature for 4h, dry at 120°C for 4h, and 400°C Under roasting for 4h, a catalyst containing cesium and strontium was obtained.

Embodiment 2

[0033] Weigh 5.5g of tin dichloride, add 90ml of deionized water to prepare an additive impregnation solution, put 100g of silica carrier in the impregnation solution, soak at room temperature for 4h, and dry at 120°C for 4h to obtain Carrier.

[0034] Weigh 15g of cesium nitrate (calculated as cesium oxide), add 90ml of deionized water to prepare a cesium nitrate solution, add the carrier containing additives into the cesium nitrate solution, soak at room temperature for 4h, dry at 120°C for 4h, and 500°C Under roasting for 4h, a catalyst containing cesium and strontium was obtained.

Embodiment 3

[0036] Weigh 5.5g of tin dichloride, 1.2g of strontium nitrate, and 0.5g of potassium nitrate, add 90ml of deionized water to prepare an auxiliary impregnation solution, put 100g of silica carrier in the impregnation solution, and immerse at room temperature for 4h, Dry at 120° C. for 4 hours to obtain a carrier containing additives.

[0037] Weigh 15g of cesium nitrate (calculated as cesium oxide), add 90ml of deionized water to prepare a cesium nitrate solution, add the carrier containing additives into the cesium nitrate solution, soak at room temperature for 4h, dry at 120°C for 4h, and 500°C Under roasting for 4h, a catalyst containing cesium, strontium, tin and potassium was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com