Regeneration method of deactivated titanium-silicon catalyst, regenerated catalyst and application thereof

A titanium-silicon catalyst, a technology for regenerating catalysts, applied in the direction of catalyst regeneration/reactivation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of complex regeneration methods, long regeneration process, difficult recovery of titanium-silicon catalyst activity, etc. The effect of less loss and generation of wastewater, short regeneration process, and easy industrial scale-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

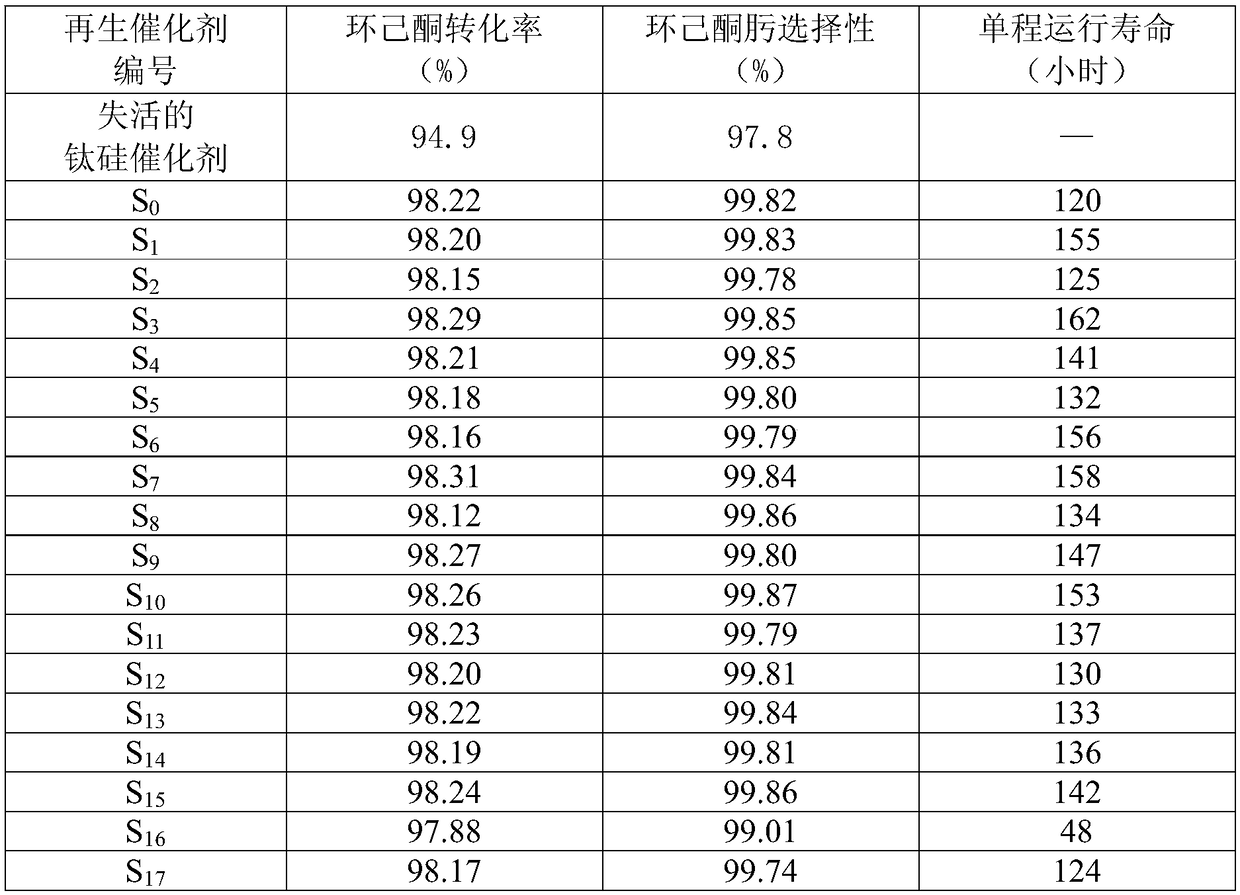

[0054] Embodiment 1, the preparation of regenerated catalyst

[0055] The regeneration method of the deactivated titanium-silicon catalyst of the present embodiment may further comprise the steps:

[0056] (1) Take by weighing 14.5g dehydrated alcohol, 15g 30% hydrogen peroxide, 6.0g mass concentration be 25% TPAOH aqueous solution and 2.0g TBOT to join in the container of 250ml successively, then weigh 12.5g water and add in the container, stir until After TBOT is completely dissolved, the regeneration mixture R is obtained 1 , then weigh 10g of deactivated titanium-silicon catalyst wet material and add it to the regeneration mixture R 1 In, stir evenly, pour into the colloid mill and grind for 5h, the rotating speed is 3500rpm, and the uniform material M 1 .

[0057] (2) Transfer the homogeneous material in step (1) to a 100ml crystallization kettle, and conduct hydrothermal crystallization at a temperature of 170° C. for 15 hours to obtain a crystallized product;

[005...

Embodiment 2

[0062] Embodiment 2, the preparation of regeneration catalyst

[0063] The regeneration method of the deactivated titanium-silicon catalyst of the present embodiment, other conditions are all the same as embodiment 1, the difference is that the grinding time of the colloid treatment mill is 1h, and the regenerated catalyst S is obtained. 2 .

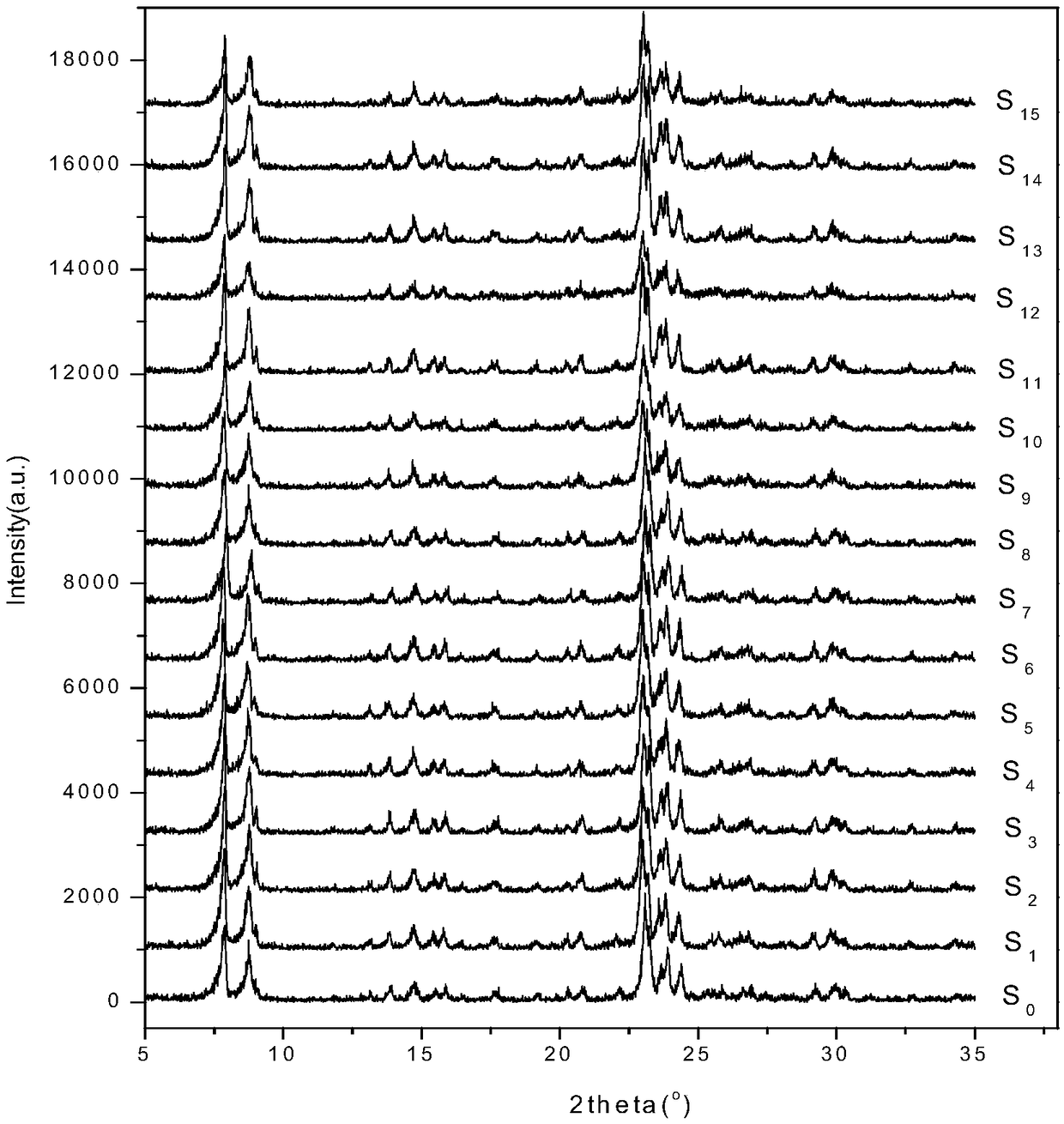

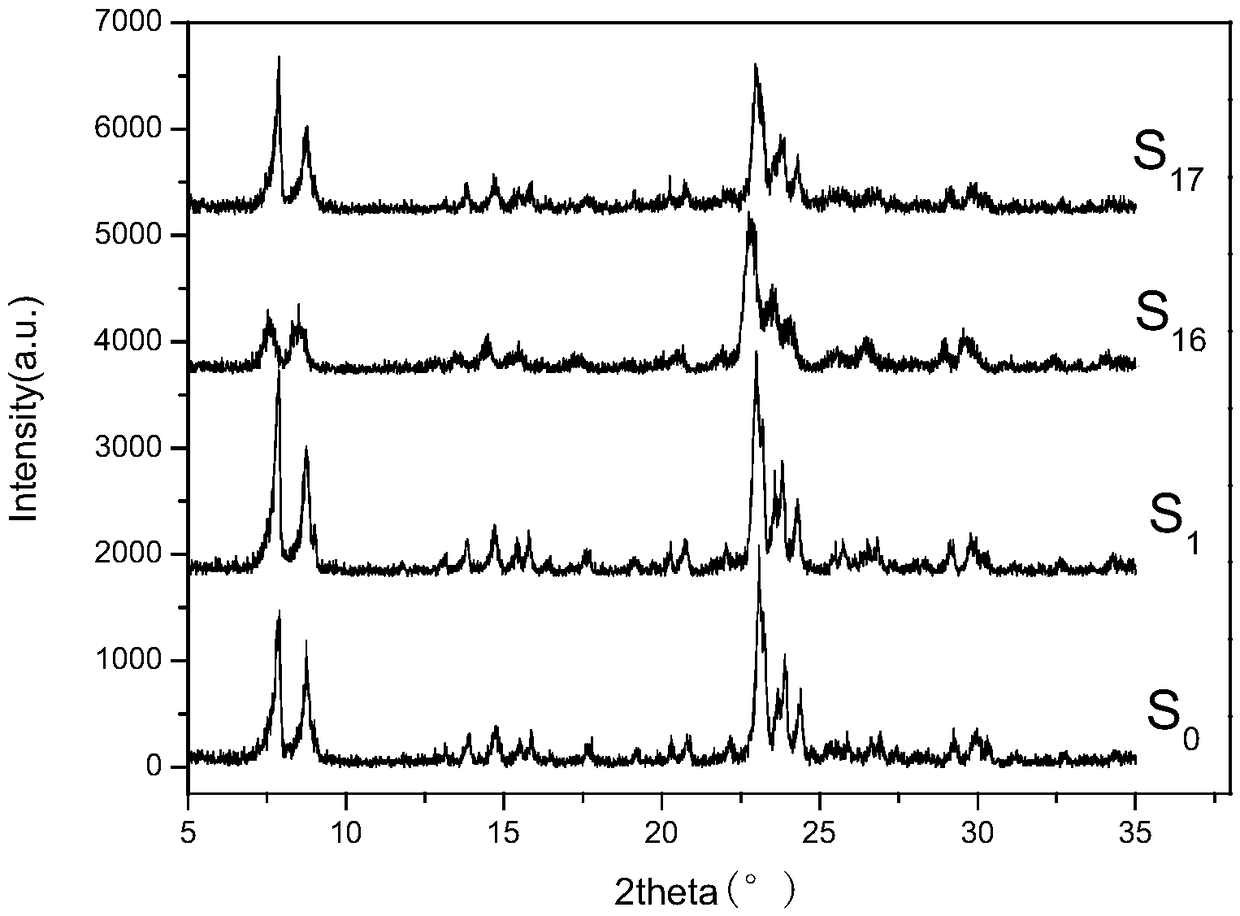

[0064] For regenerated catalyst S 2 Carry out XRD detection, the result is as follows figure 1 shown.

Embodiment 3

[0065] Embodiment 3, the preparation of regeneration catalyst

[0066] The regeneration method of the deactivated titanium-silicon catalyst of the present embodiment may further comprise the steps:

[0067] (1) Take by weighing 4.8g of absolute ethanol, 17.2g of 30% hydrogen peroxide, 7.5g of 25% TPAOH aqueous solution and 2.5g of TBOT in a 250ml container, then weigh 18.0g of water and add to the container, stir After TBOT is completely dissolved, the regeneration mixture R is obtained 3 , then weigh 10g of deactivated titanium-silicon catalyst wet material and add it to the regeneration mixture R 3 In, stir evenly, pour into the colloid mill and grind for 10h, the rotating speed is 3500rpm, and the uniform material M 3 .

[0068] (2) Transfer the homogeneous material in step (1) to a 100ml crystallization kettle, and conduct hydrothermal crystallization at a temperature of 170° C. for 15 hours to obtain a crystallized product;

[0069] (3) The crystallized product of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com