Catalyst for producing gasoline by refinery dry gas and preparation method thereof

A refinery dry gas and catalyst technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of high gasoline yield, long single-pass life, and less carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

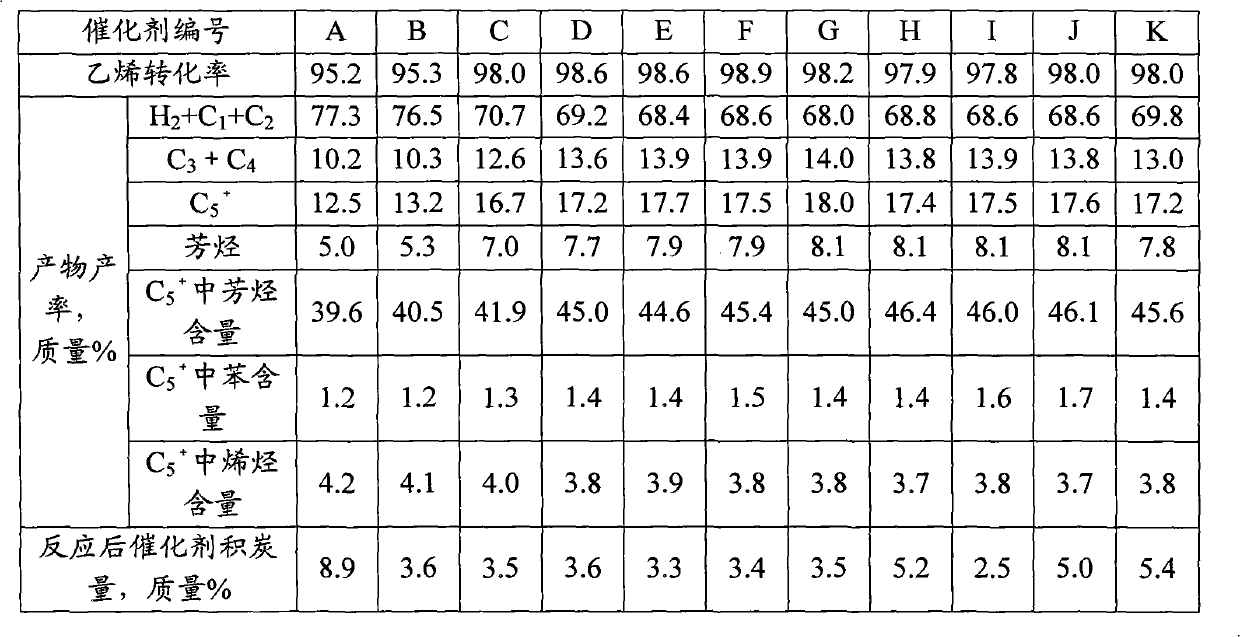

Examples

preparation example Construction

[0019] The preparation method of catalyst of the present invention comprises the steps:

[0020] (1) Mix hydrogen-type ZSM-5 zeolite and hydrogen-type ZSM-35 zeolite with hydrated alumina, extrude, dry and roast to obtain a composite carrier,

[0021] (2) treating the composite carrier with water vapor,

[0022] (3) impregnating the steam-treated composite carrier with an impregnating solution containing VA group element compounds and rare earth compounds, then drying and calcining.

[0023] In the above method, step (1) is the preparation of a composite carrier, and the hydrated alumina is preferably pseudoboehmite. When molding, it is preferable to add a peptizer to knead the powder, and the peptizer is preferably nitric acid or acetic acid.

[0024] (2) The first step is to perform steam treatment on the composite carrier to adjust the α value of the composite carrier. The temperature of steam treatment is 450-700°C, preferably 500-600°C, and the treatment time is prefer...

example 1

[0045] Prepare catalyst of the present invention

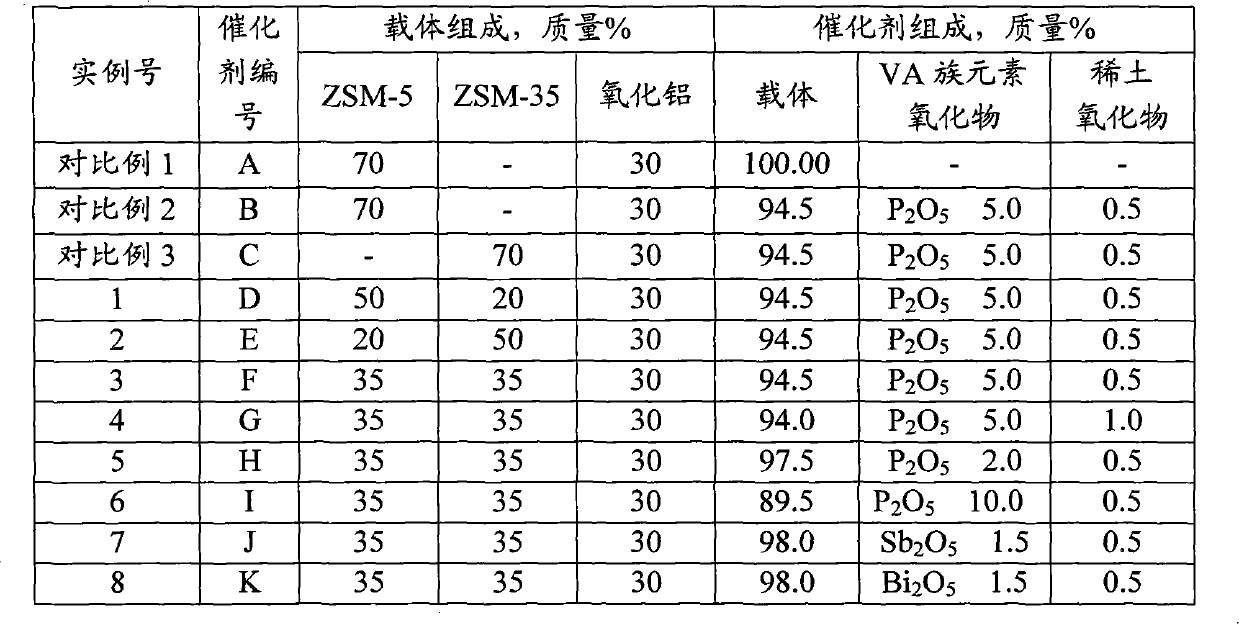

[0046] Prepare catalyst by the method for comparative example 3, difference is (1) step gets 92.8 grams of silicon oxide / alumina mol ratios and be that the HZSM-5 zeolite powder of 56, 37.2 grams of silicon oxide / alumina mol ratios are the HZSM-35 of 15 Zeolite powder and 70 g of pseudo-boehmite powder were mixed evenly, and 100 g of nitric acid aqueous solution with a concentration of 1.0% by mass was added for peptization. The composite carrier was obtained by extruding, drying, and roasting. After steam treatment, its α value was 29. Then, the steam-treated carrier was introduced into phosphorus and mixed rare earths according to the method of step (3), and the composition of the prepared catalyst D was shown in Table 1.

example 2

[0048] Prepare catalyst by the method for comparative example 3, difference is (1) step gets 37.2 grams of silica / alumina mol ratios and is the HZSM-5 zeolite powder of 56, and 92.8 grams of silica / alumina mol ratio is the HZSM-35 of 15 Zeolite powder and 70 g of pseudo-boehmite powder were mixed evenly, and 100 g of nitric acid aqueous solution with a concentration of 1.0% by mass was added for peptization. The composite carrier was obtained by extruding, drying, and roasting. After steam treatment, its α value was 33. Then, the steam-treated carrier was introduced into phosphorus and mixed rare earths according to the method of step (3), and the composition of the prepared catalyst E was shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com