Silicon-aluminum material, preparation thereof and low-green-coke high-activity heavy oil conversion catalytic cracking catalyst

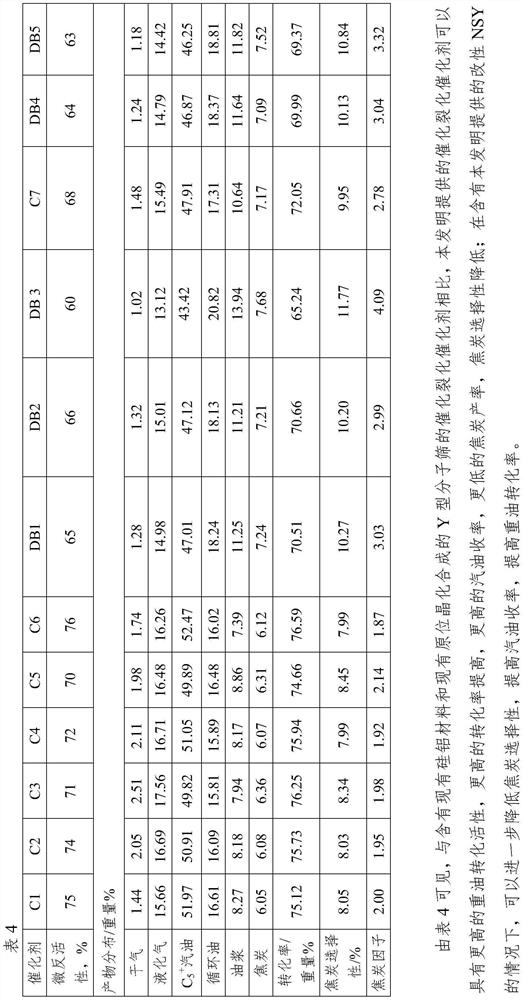

A silicon-aluminum material and catalytic cracking technology, which is applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problem of high coke formation of catalytic cracking catalysts, and achieve low coke selectivity, high conversion activity and coke selectivity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the preparation method of the silicon-aluminum material of the present invention, the acidic aluminum source is selected from the group consisting of aluminum sulfate, aluminum chloride, aluminum sol, and the acidic hydrolyzate of the metal alkoxide of aluminum, that is, the hydrolysis product of the metal alkoxide under acidic conditions. product, the metal alkoxide is, for example, aluminum alkoxide, and the aluminum alkoxide is, for example, one or more of aluminum isopropoxide, aluminum sec-butoxide, aluminum triethoxide, and the like.

[0034] In the preparation method of the silicon-aluminum material described in the present invention, the alkaline silicon source is selected from alkaline hydrolysis products of alkaline silica sol, water glass, sodium silicate, and silicon esters, that is, silicon esters are hydrolyzed under alkaline conditions. The product, the silicon ester is, for example, one or more of methyl orthosilicate, tetraethyl orthosilicate, isoprop...

Embodiment approach

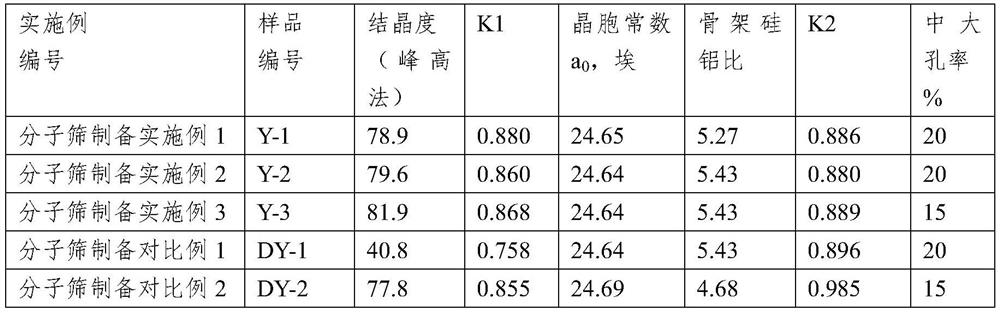

[0052] One embodiment, the NSY molecular sieve synthesized by in-situ crystallization of kaolin has a unit cell constant a 0 The measured silicon to aluminum ratio is 5.2-5.5.

[0053] The NSY molecular sieve synthesized by in-situ crystallization of kaolin described in the present invention is a Y-type molecular sieve composite material, and a preparation method thereof comprises the following steps: (1) transforming kaolin into metakaolin by roasting and dehydrating at 500-900°C, pulverizing, Make metakaolin powder with a particle size of less than 10 microns; (2) add sodium silicate, guiding agent, sodium hydroxide solution and water to metakaolin powder to make a molar ratio of (1-2.5) Na 2 O: Al 2 o 3 : (4-9) SiO 2 : (40-100)H 2The reaction raw material A of O, wherein the mass ratio of directing agent to metakaolin is 0.01-1.0; (3) The reaction raw material A is crystallized under stirring at 88-98°C, and the second silicon is added after the crystallization time rea...

preparation Embodiment 1

[0079] At room temperature (25°C), under stirring, according to SiO 2 :Al 2 o 3 The weight ratio of =75:25 will water glass solution (SiO 2 Concentration 250g / L) is added dropwise to aluminum sulfate solution (aluminum sulfate solution uses Al 2 o 3The concentration is 90g / L); after adding, add sodium hydroxide solution (concentration: 300g / L) until the pH value of the slurry is 10, and then age at 50°C for 6 hours. The obtained solid precipitate was dried at 120° C. for 6 hours, then washed with ammonium chloride solution (concentration: 50 g / L), and filtered to obtain a silica-alumina material B1 with a sodium content of less than 1%. Its elemental analysis chemical weight composition is 0.2Na 2 O·25Al 2 o 3 74.8 SiO2 2 ; Specific surface area 324m 2 / g, pore volume 1.26cm 3 / g, the pore diameter is larger than 10nm, accounting for 82%, the average size of pseudoboehmite crystal grains in the material is 2.2nm, and the possible pore diameter is 33.2nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com