Hierarchical pore nanometer SAPO-34 molecular sieve, preparation method and applications thereof

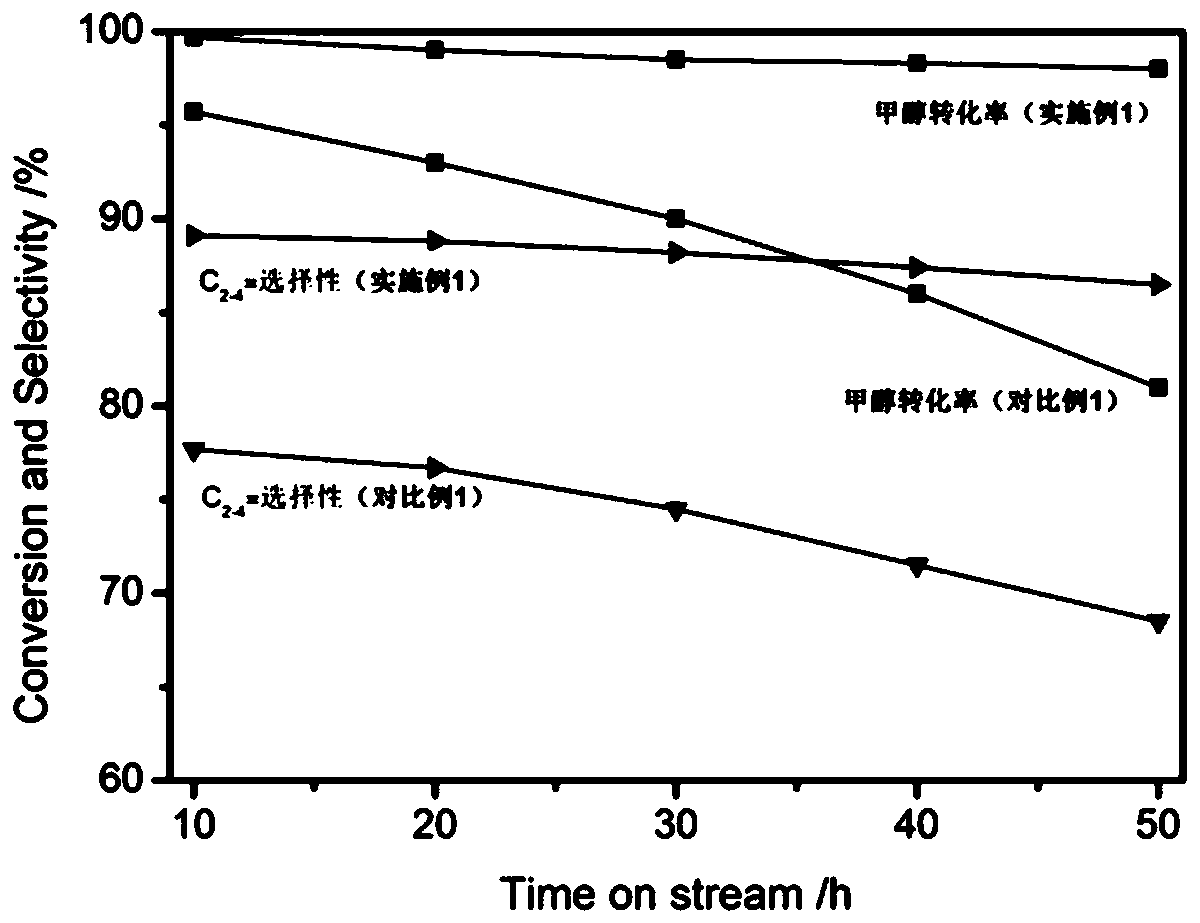

A SAPO-34, molecular sieve technology, applied in the field of catalysis, can solve the problems of limited application scope, and achieve the effect of improving conversion rate and selectivity, maintaining stability, and prolonging single-pass life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

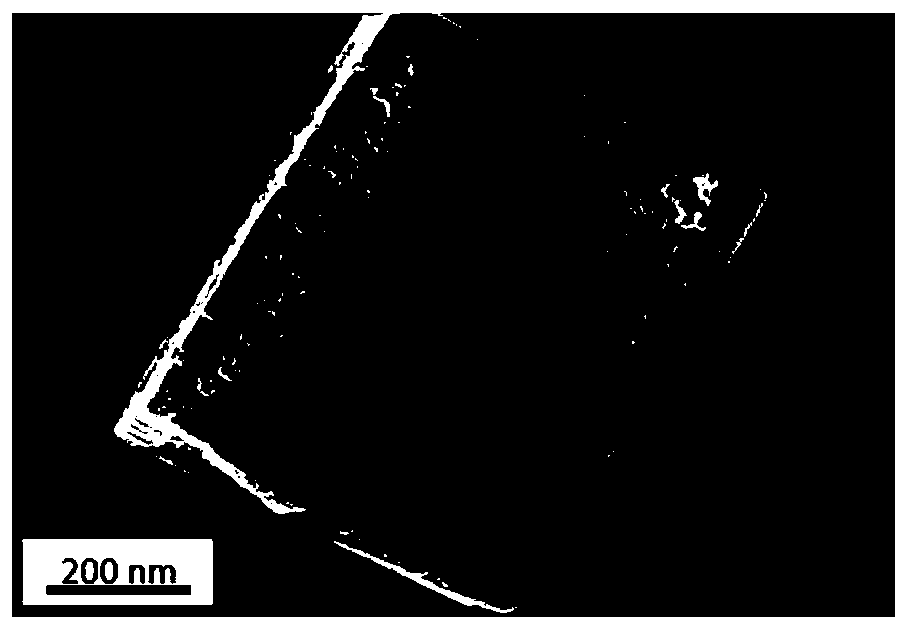

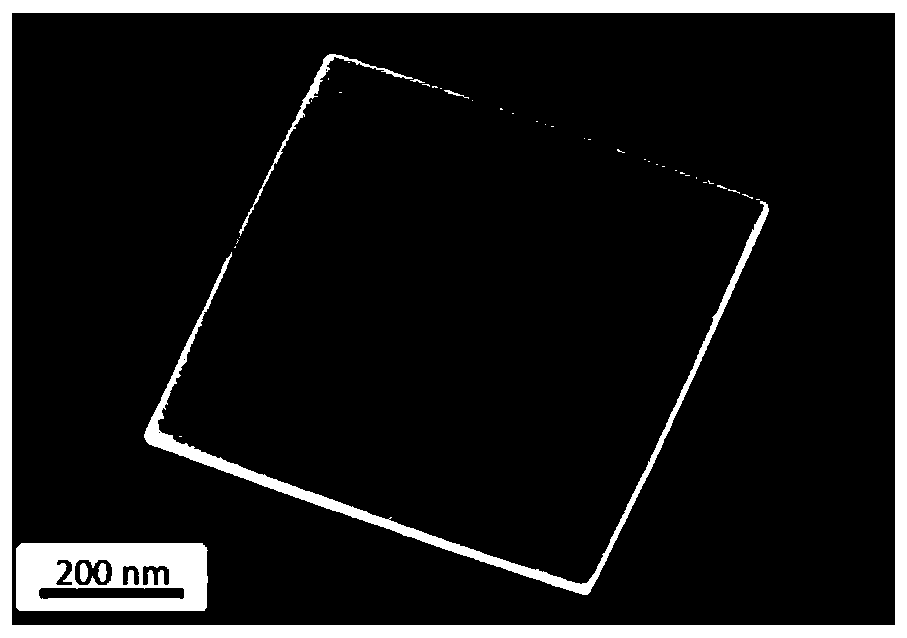

[0027] Weigh 3g SAPO-34 and put it in a beaker, then add 0.1g mass fraction of 40% hydrogen fluoride solution, stir at room temperature for 3min to obtain suspension A; weigh 0.2g ammonium fluoride and add it to suspension A, Stir at room temperature for 3 minutes to obtain suspension B; weigh 18g of deionized water and add it to suspension B, stir for 5 minutes to obtain suspension C; put suspension C in an ultrasonic cleaner at 25°C Ultrasound for 15 minutes to obtain suspension D; put suspension D for 1 hour and then remove the supernatant water; then put it in a centrifuge and centrifuge at a speed of 12000r / min, and centrifuge several times until the solution is neutral; then Put it into an oven at 100°C and dry it for 12 hours; place the obtained sample in dry air, raise the temperature to 550°C at a rate of 3°C / min and roast for 6 hours, shape the solid sample after roasting, and sieve to obtain 30-60 Object particles, namely the hierarchically porous nanometer SAPO-34 ...

Embodiment 2

[0030] Weigh 3g SAPO-34 and put it in a beaker, then add 0.2g hydrogen fluoride solution with a mass fraction of 40%, stir at room temperature for 3min to obtain suspension A; weigh 0.2g ammonium fluoride and add it to suspension A , stirred at room temperature for 3 minutes to obtain suspension B; weighed 18 g of deionized water and added to suspension B, stirred for 5 minutes to obtain suspension C; put suspension C in an ultrasonic cleaner at 25 ° C Ultrasound for 15 minutes to obtain suspension D; put the suspension D to stand for 1 hour and remove the supernatant water; then put it in a centrifuge and centrifuge at a speed of 12000r / min, and centrifuge several times until the solution is neutral; then Put it into an oven at 100°C and dry it for 12 hours; place the obtained sample in dry air, raise the temperature to 550°C at a rate of 3°C / min and roast for 6 hours, shape the solid sample after roasting, and sieve to obtain 30~ The 60-mesh particle is the hierarchical poro...

Embodiment 3

[0033]Weigh 3g of SAPO-34 and put it in a beaker, then add 0.3g of hydrogen fluoride solution with a mass fraction of 40%, stir at room temperature for 3min to obtain suspension A; weigh 0.2g of ammonium fluoride and add it to suspension A , stirred at room temperature for 3 minutes to obtain suspension B; weighed 18 g of deionized water and added to suspension B, stirred for 5 minutes to obtain suspension C; put suspension C in an ultrasonic cleaner at 25 ° C Ultrasound for 15 minutes to obtain suspension D; put the suspension D to stand for 1 hour and remove the supernatant water; then put it in a centrifuge and centrifuge at a speed of 12000r / min, and centrifuge several times until the solution is neutral; then Put it into an oven at 100°C and dry it for 12 hours; place the obtained sample in dry air, raise the temperature to 550°C at a rate of 3°C / min and roast for 6 hours, shape the solid sample after roasting, and sieve to obtain 30~ The 60-mesh particle is the hierarchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com