Catalyst for preparing butene/butadiene by dehydrogenation of butane and application of catalyst

A technology for butane dehydrogenation and butadiene, applied in physical/chemical process catalysts, catalyst carriers, catalyst activation/preparation, etc., can solve problems such as selectivity decline, poor single-pass stability, and low conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

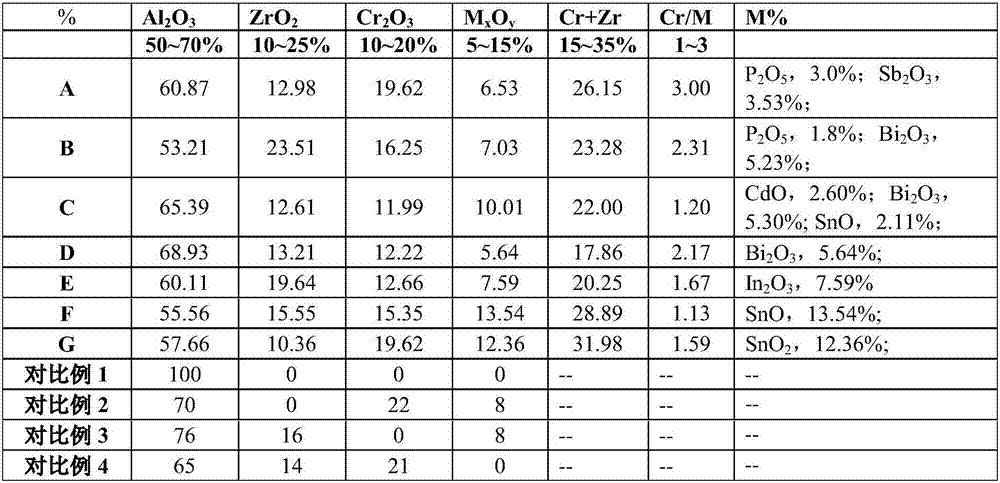

[0024] Take 26.0g zirconia (ZrO 2 ), 39.2g chromium oxide (Cr 2 o 3 ), 7.0g antimony oxide (Sb 2 o 3 ), 6.0g phosphorus pentoxide (P 2 o 5) and 121.7g of alumina (Al 2 o 3 ), then add 9.0g of starch, then mix in a ball mill for 200 minutes, use a standard sieve to sieve >200 mesh powder, add about 6.5g of turnip powder, a small amount of 20% nitric acid aqueous solution and an appropriate amount of water into the kneader for kneading , extruded, dried at 120°C, and then calcined at 680°C for 10 hours to obtain a composite oxide catalyst carrier. Pore volume 0.52cm 3 / g, specific surface area 86m 2 / g. The weight percent composition of the obtained catalyst carrier is shown in Table 1.

[0025] The carrier that obtains adopts impregnation technology to load active component, namely at room temperature with the carrier 15.0g impregnation containing ammonium chloroiridate (NH 4 ) 2 IrCl 6 , 0.12g) and 0.1g potassium nitrate aqueous solution (10ml) for 24 hours (me...

Embodiment 2

[0028] Take 47.0g zirconia (ZrO 2 ), 32.5g chromium oxide (Cr 2 o 3 ), 10.5g bismuth oxide (Bi 2 o 3 ), 3.6g phosphorus pentoxide (P 2 o 5 ) and 106.4g alumina (Al 2 o 3 ), then add 9.2g of starch, then mix in a ball mill for 180 minutes, use a standard sieve to sieve >200 mesh powder, add about 6.5g of turnip powder, a small amount of 25% nitric acid aqueous solution and an appropriate amount of water into the kneader for kneading , extruded, dried at 120°C, and then calcined at 680°C for 10 hours to obtain a composite oxide catalyst carrier. Pore volume 0.57cm 3 / g, specific surface area 93m 2 / g. The weight percent composition of the obtained catalyst carrier is shown in Table 1.

[0029] The carrier that obtains adopts impregnation technology to load active component, namely at room temperature with the carrier 15.0g impregnation containing ammonium chloroiridate (NH 4 ) 2 IrCl 6 (0.08g), ammonium chlororuthenate (NH 4 ) 2 RuCl 6 (0.05g) and calcium nitr...

Embodiment 3

[0032] Take 25.2g zirconia (ZrO 2 ), 24.0g chromium oxide (Cr 2 o 3 ), 10.6g bismuth oxide (Bi 2 o 3 ), 5.2g cadmium oxide (CdO), 4.2g stannous oxide (SnO) and 130.8g aluminum oxide (Al 2 o 3 ), then add 8.8g of starch, then mix in a ball mill for 180 minutes, use a standard sieve to sieve >220 mesh powder, add about 7.5g of turnip powder, a small amount of 20% nitric acid aqueous solution and an appropriate amount of water in the kneader for kneading , extruded, dried at 120°C, and then calcined at 680°C for 10 hours to obtain a composite oxide catalyst carrier. Pore volume 0.53cm 3 / g, specific surface area 82m 2 / g. The weight percent composition of the obtained catalyst carrier is shown in Table 1.

[0033] The carrier that obtains adopts impregnation technology to load active component, namely at room temperature with the carrier 15.0g impregnation containing ammonium chloroiridate (NH 4 ) 2 IrCl 6 (0.11g) and potassium nitrate 0.09g aqueous solution (10ml) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com