Boron-modified ferrierite molecular sieve catalyst as well as preparation method and application thereof

A ferrierite and molecular sieve technology, which is applied to molecular sieve catalysts, including molecular sieve catalysts, molecular sieves and alkali exchange compounds, can solve problems such as difficult to meet market demand, and achieve strong anti-coking ability, high activity, and liquid-phase yield low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a boron-modified ferrierite molecular sieve catalyst, which is prepared by the following steps:

[0050] Add 3.06g of sodium hydroxide, 1.24g of aluminum hydroxide, and 1.03g of boric acid to 101.1g of deionized water, and stir at room temperature until a uniform solution is formed;

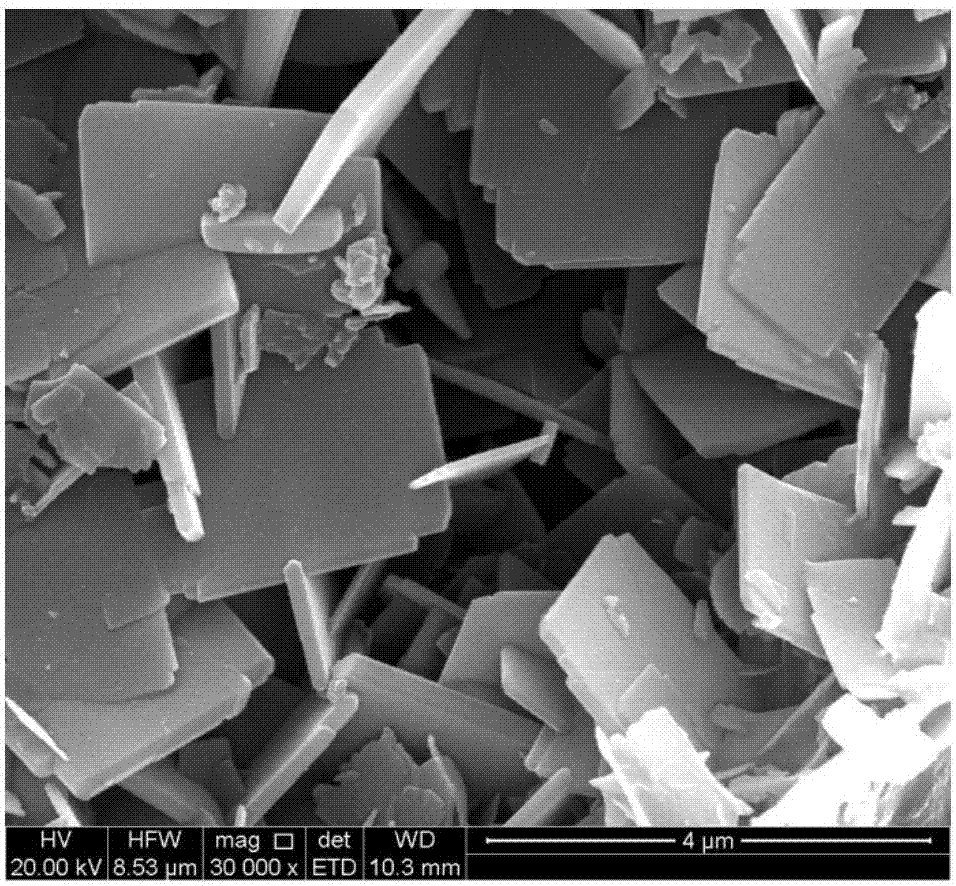

[0051] 0.31g of ZSM-35 molecular sieve seeds with a grain size of 2 to 5 microns (see the scanning electron microscope picture figure 1 ), 4.54g ethylenediamine and 41.27g acidic silica sol (25wt% SiO 2 Content) sequentially add to the above uniform solution, continue to stir at room temperature for 2 hours to ensure that the solution does not splash, and finally form a white uniform sol;

[0052] Transfer the above-mentioned sol solution into a hydrothermal crystallization kettle, crystallize at 180°C for 72 hours, filter and wash, dry at 80°C for 12 hours, and then heat up to 550°C at a heating rate of 2°C / min for roasting and roasting for 4 After hours, the original so...

Embodiment 2

[0056] This embodiment provides a boron-modified ferrierite molecular sieve catalyst, which is prepared by the following steps:

[0057] 3.18g sodium hydroxide, 1.44g triethyl borate and 2.93g aluminum sol (30wt% Al 2 O 3 Content) Add 97.0g of deionized water and stir at room temperature until a uniform solution is formed;

[0058] 0.72g of ZSM-35 molecular sieve seeds with a grain size of 2 to 5 microns, 4.54g of n-butylamine and 41.27g of neutral silica sol (25wt% SiO 2 Content) sequentially add to the above uniform solution, continue to stir at room temperature for 2 hours to ensure that the solution does not splash, and finally form a white uniform sol;

[0059] Transfer the above sol solution into a hydrothermal crystallization kettle, crystallize at 190°C for 50 hours, filter and wash, dry at 80°C for 20 hours, then heat up to 500°C at a heating rate of 2°C / min for roasting, and roast for 8 hours Then, the raw powder of sodium-type molecular sieve with a silicon-aluminum oxide ...

Embodiment 3

[0063] This embodiment provides a boron-modified ferrierite molecular sieve catalyst, which is prepared by the following steps:

[0064] Add 3.21g of sodium hydroxide, 1.24g of aluminum sulfate and 1.44g of ammonium borate into 107.3g of deionized water, and stir at room temperature until a uniform solution is formed;

[0065] 0.52g of ZSM-35 seed crystals with a grain size of 2 to 5 microns, 4.13g of pyrrolidone and 41.27g of alkaline silica sol (25wt% SiO 2 Content) sequentially add to the above uniform solution, continue to stir at room temperature for 6 hours to ensure that the solution does not splash, and finally form a white uniform sol;

[0066] Transfer the above-mentioned sol solution into a hydrothermal crystallization kettle, crystallize at 200°C for 68 hours, filter and wash, and dry at 120°C for 10 hours, and then heat up to 600°C at a heating rate of 2°C / min for roasting and roasting for 8 After hours, the raw powder of sodium molecular sieve with a silicon-aluminum ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com