Patents

Literature

33 results about "Triethyl borate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triethyl borate is a colorless liquid with the formula B(OCH₂CH₃)₃. It is an ester of boric acid and ethanol. It has few applications. It is a weak Lewis acid (AN = 17, Gutmann-Beckett method). . It burns with a green flame and solutions of it in ethanol are therefore used in special effects and pyrotechnics.

Multiple metal corrosion inhibitor

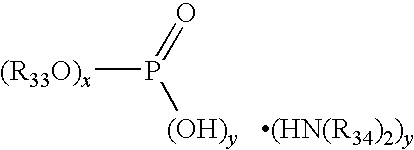

Disclosed is a lubricant composition comprising a) a lubricant, b) a triazole metal deactivator, c) a borate ester and optionally d) an amine phosphate. The lubricants, e.g. engine oils or functional fluids exhibit low corrosion of lead, copper, iron and zinc. The metal deactivators are 1,2,4-triazoles, for example 1-(di-isooctylaminomethyl)-1,2,4-triazole or 1-(di-(2-ethylhexyl)aminomethyl)-1,2,4-triazole, or are benzotriazoles, for example 1-(2-methoxyprop-2-yl)tolyltriazole, 1-(1-cyclohexyloxypropyl)tolyltriazole, 1-(1-cyclohexyloxyheptyl)tolyltriazole or 1-(1-cyclohexyloxybutyl)tolyltriazole or 1-[bis(2-ethylhexyl)aminomethyl-4-methylbenzotriazole. The borate esters are for example triethyl borate, tripropyl borate, triisopropyle borate, tributyl borate, tripentyl borate, trihexyl borate, tricyclohexyl borate, trioctyl borate, triisooctyl borate, tridecyl borate, tri(C8C10) borate, tri (C12-C15) borate or oleyl borate. The amine phosphate are for examplewherein R33 is n-hexyl and R34 is C11-C14 branched alkyl, and when x=1 then y=2; when x=2 then y=1.

Owner:CHASAN DAVID E +1

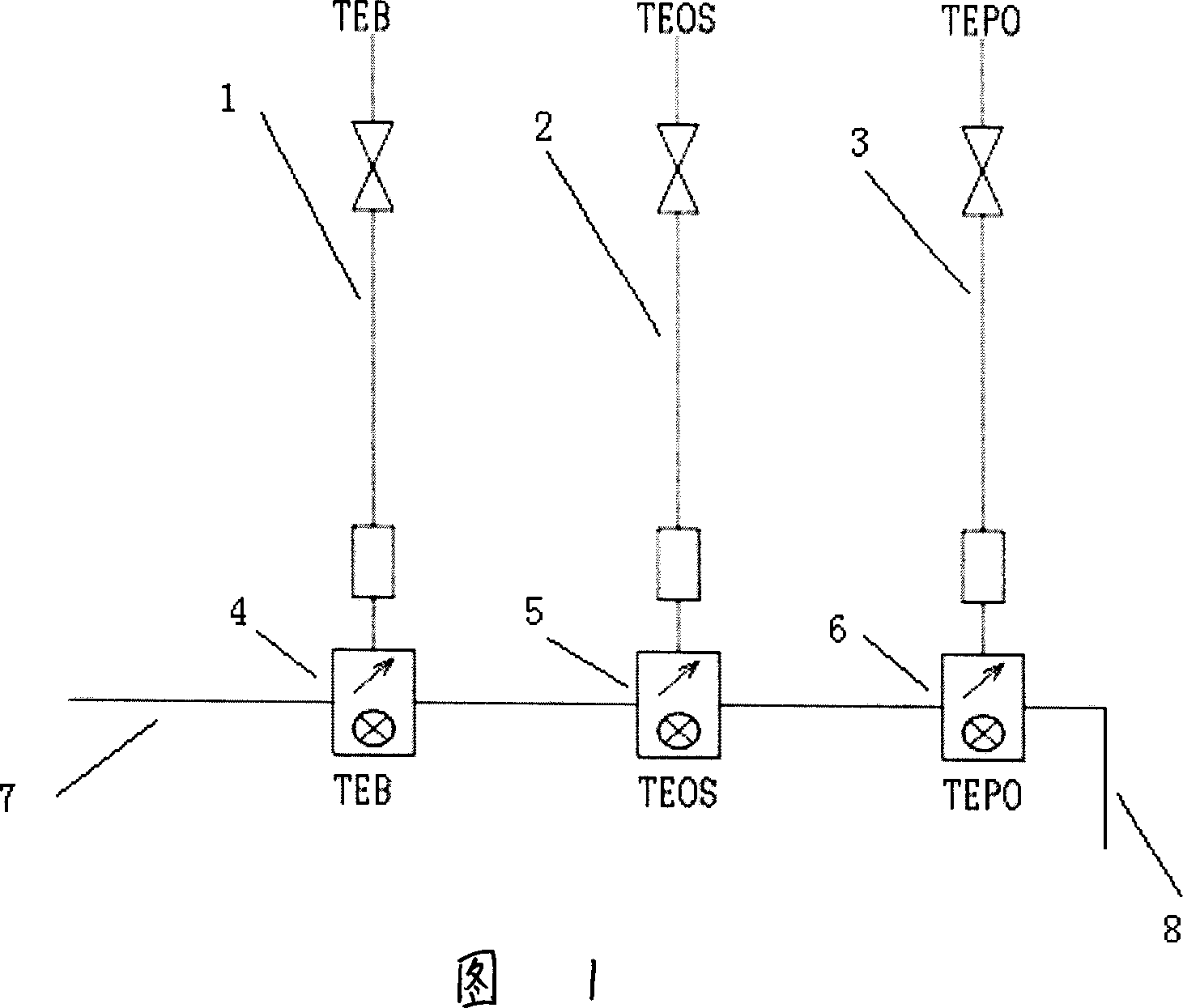

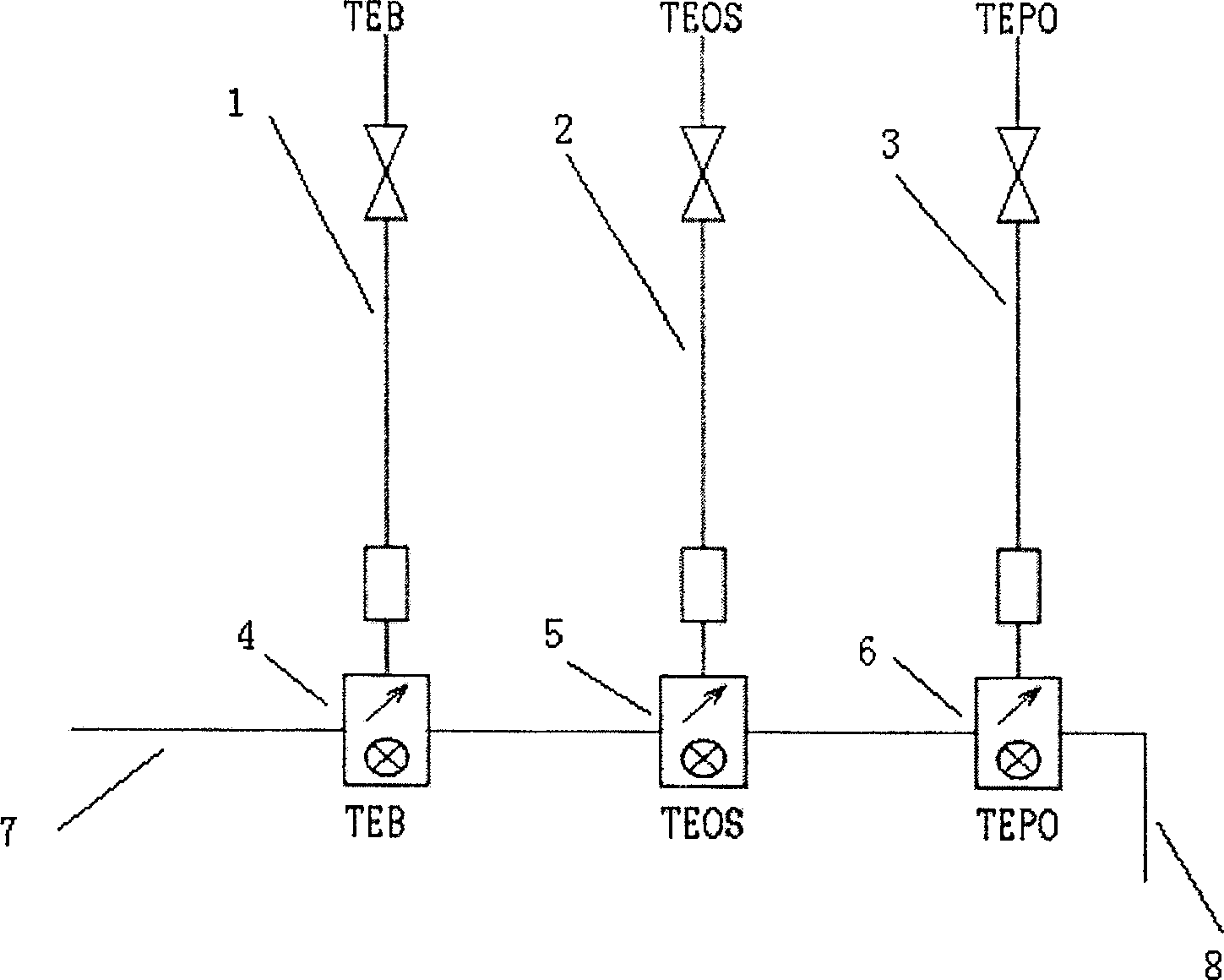

Multi-component mixtures for manufacturing of in situ doped borophosphosilicate

This invention concerns a stable composition useful in the manufacture of semiconductors, comprising a liquid mixture of: tetraethylorthosilicate ("TEOS"), triethylborate ("TEB"), and a triethylphosphorus compound such as triethylphosphate ("TEPO"). The composition may be advantageously used in a plasma enhanced chemical vapor deposition apparatus equipped with a liquid mass flow controller. The boron and phosphorus percentages in the resulting borophosphosilicate film may be varied to arrive at desired percentages. This invention also includes a method useful for the preparation of a high purity liquid mixture useful in the manufacture of semiconductors, comprising the steps of: obtaining high purity (a) tetraethylorthosilicate, (b) triethylborate, and (c) a triethylphosphorus compound; adding components (a), (b), and (c) to a sealed, stainless steel container; and mixing the components to form the liquid mixture.

Owner:ENTEGRIS INC

Method for synthesizing polyethylene glycol-12-hydroxy stearate by adopting boric acid ester exchange method

The invention discloses a method for synthesizing polyethylene glycol-12-hydroxy stearate by adopting a boric acid ester exchange method. The method concretely comprises the following steps: firstly, carrying out transesterification on triethyl borate and polyethylene glycol 400 under the condition of a basic catalyst, so as to obtain a boric acid polyglycol ester; carrying out transesterification on the boric acid polyglycol ester and 12-hydroxy stearate under an acid condition, so as to generate the polyethylene glycol-12-hydroxy stearate. The scheme disclosed by the invention has the advantages of mild process condition and short reaction time, and the product is free of ethylene oxide residues.

Owner:HUNAN ER KANG PHARMA

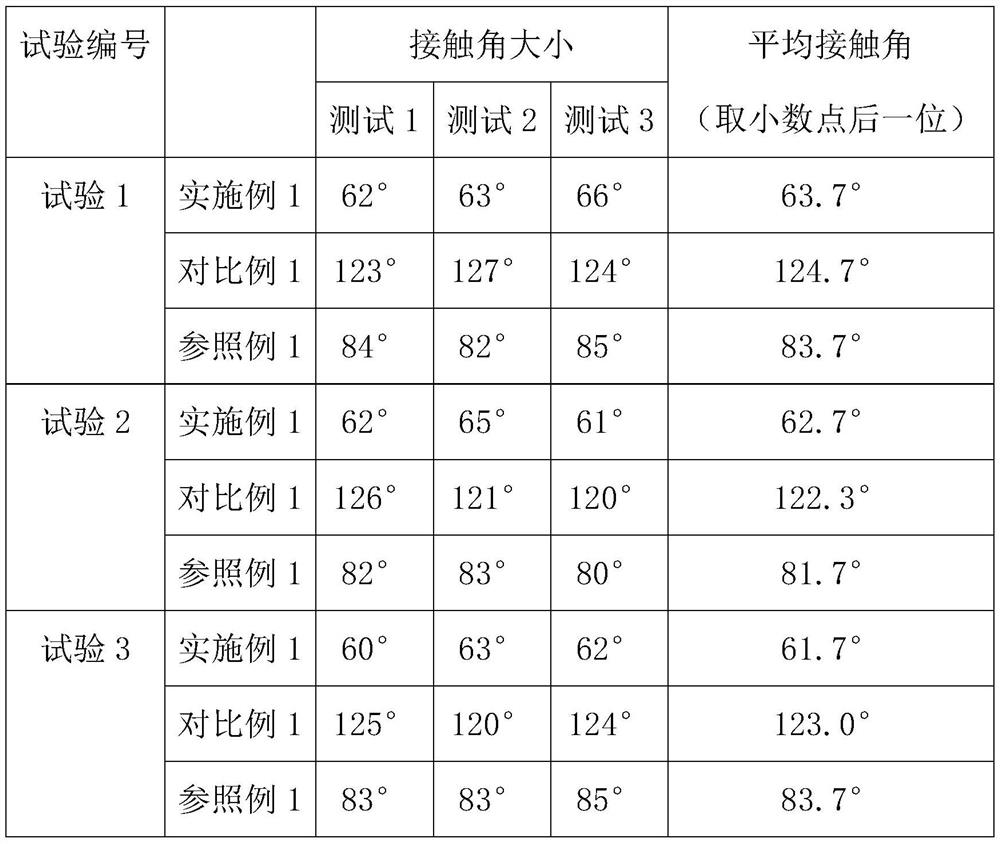

Polymerisation initiators, polymerisable compositions, and uses thereof for bonding low surface energy substrates

InactiveUS7189463B2Easy to peelIncrease resistanceSynthetic resin layered productsOrganic non-macromolecular adhesiveLithiumPolyolefin

Owner:HENKEL IP & HOLDING GMBH +1

Method for preparing tributyl borate by utilizing reactant n-butyl alcohol as water-carrying agent

InactiveCN102766152AImprove conversion rateSolve the disadvantages of high risk of operationGroup 3/13 element organic compoundsReaction temperatureTriethyl borate

The invention provides a method for preparing tributyl borate by utilizing a reactant n-butyl alcohol as a water-carrying agent. The method comprises the following preparation processes of: a: adding boric acid and the n-butyl alcohol which are taken as raw materials into a reactor; b: adding the n-butyl alcohol taken as the water-carrying agent into the reactor to react; in a reaction process, discharging water generated in the reaction out by a water distributor in time to obtain a rough product of the tributyl borate; and c: utilizing a fractional column to carry out decompression fraction to separate the tributyl borate, and recycling the n-butyl alcohol. The n-butyl alcohol disclosed by using the method is used as the raw material of esterification reaction and is also used as the water-carrying agent; the reaction temperature is increased so as to be good for carrying out the esterification reaction and the conversion rate of the reaction is improved; the defects that the toxin is great and the operation danger is great when benzene, toluene or carbon tetrachloride is used as the water-carrying agent can be overcome; the recycled n-butyl alcohol can be circularly utilized; and the tributyl borate with the content of being more than 99.0% can be obtained by utilizing the fractional column to carry out the decompression fraction.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

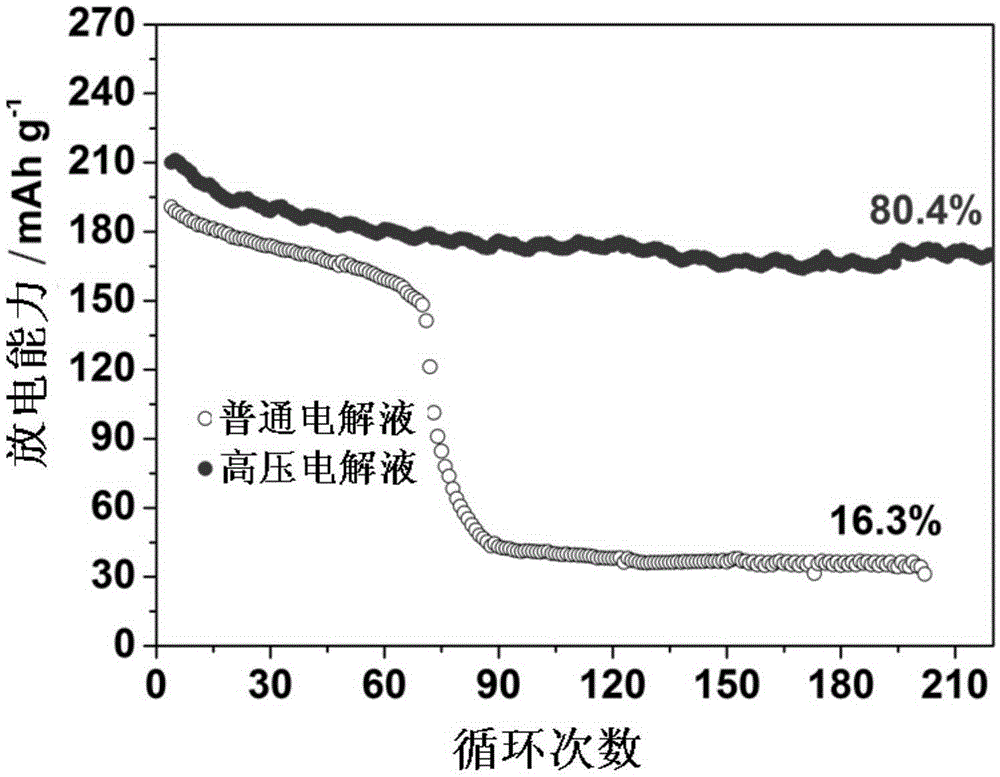

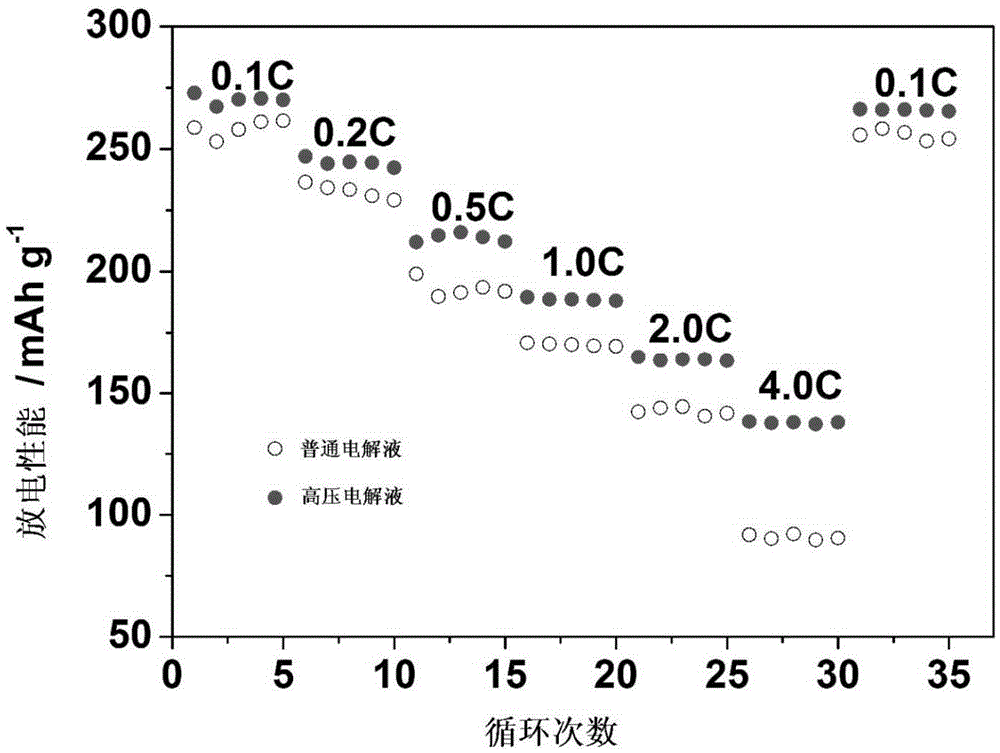

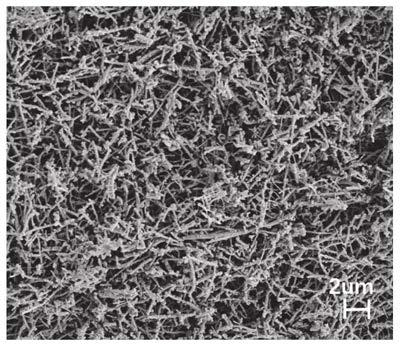

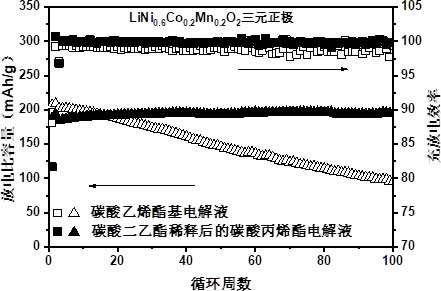

Electrolyte containing triethyl borate additive as well as preparation method and application thereof

InactiveCN105244540AInhibit surface activityAvoid contactSecondary cellsOrganic solventDecomposition

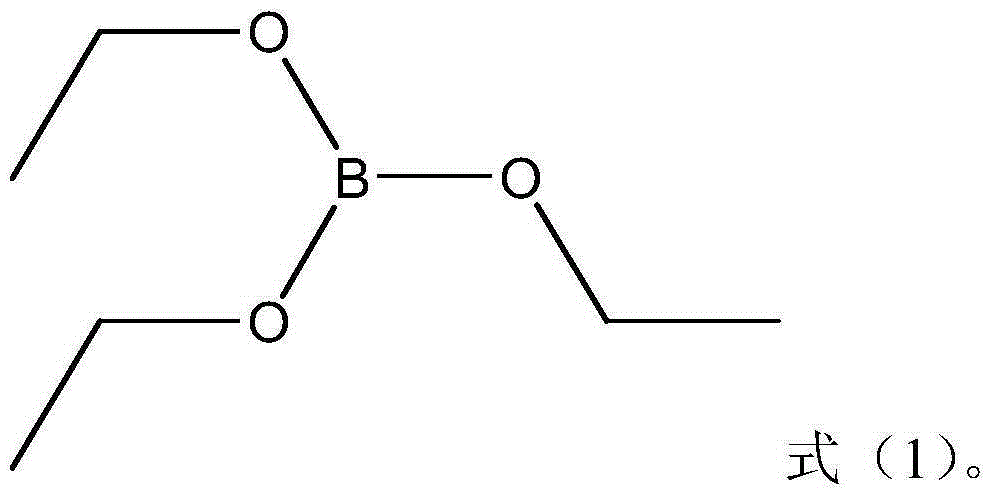

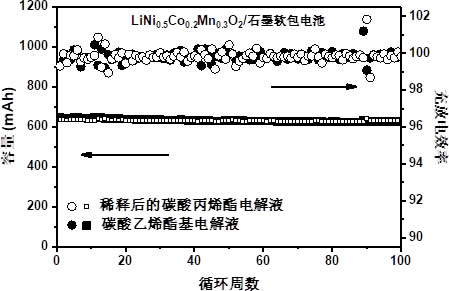

The invention belongs to the technical field of lithium ion batteries and discloses electrolyte containing a triethyl borate additive as well as a preparation method and application thereof. The electrolyte comprises a conductive lithium salt, an organic solvent and the triethyl borate additive. By using the triethyl borate additive, a positive electrode / electrolyte interface is optimized, the surface activity of a positive electrode is reduced and oxidative decomposition of the electrolyte is inhibited; and the cycling and rate performance of the lithium batteries which take high voltage (4.8V) rich lithium as a positive electrode material can be improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Polymerisation initiators, polymerisable compositions, and uses thereof for bonding low surface energy substrates

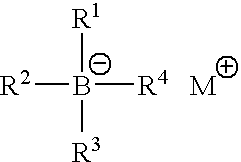

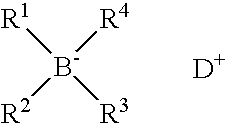

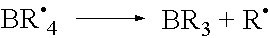

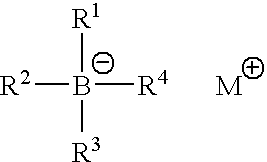

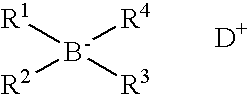

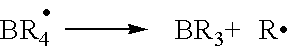

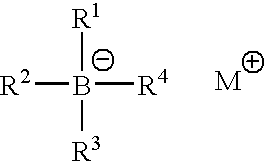

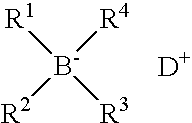

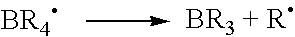

Quaternary boron salts are used as initiators of polymerisation in adhesive compositions for bonding low surface energy substrates such as polyolefins. The quaternary boron salts are of the formula Iwherein R1 is C1-C10 alkyl,R2, R3 and R4, which may be the same or different, are, C1-C10 alkyl or C3-C10 cycloalkyl, phenyl, or phenyl-substituted C1-C10 alkyl or C3-C10 cycloalkyl,provided that any two of R1-R4 may optionally be part of a carbocyclic ring, and M+ is a metal ion or a quaternary ammonium ion.When M+ is a quaternary ammonium ion, the initiator may be used in a two-part composition having a (meth)acrylate monomer in both parts and the initiator compound in one part, the two parts being in a weight ratio of about 1:1.Particular examples of initiator compounds include sodium tetraethyl borate, lithium tetraethyl borate, lithium phenyl triethyl borate, tetramethylammonium phenyl triethyl borate, and tetra methyl ammonium phenyl tri-n-butyl borate, the last-mentioned of which is a novel compound.

Owner:HENKEL IP & HOLDING GMBH

Method for preparing sub-atmosphere pressure film

ActiveCN1978700AIncrease temperatureExtend your lifeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTriethyl borateVaporization

The invention discloses a standard normal pressure film manufacturing method. It includes the following steps: inputting ethyl phosphate, triethoxy boron, and tetraethoxy silicane into respective corresponding tube; using carbureting valve to heat up to 137-143 degree centigrade to vaporize the ethyl phosphate; using it the vaporize the other two; adjusting the tube temperature to 105-110 degree centigrade; inducing the vaporized matter into the cavity to react and generate boron-phosphorosilicate glass and by-product. The invention can improve vaporization property by increasing gas tube temperature to 110 degree centigrade, ethyl phosphate to 140 degree centigrade which can not only prolong carbureting valve useful life, but also reduce production cost.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Polymerisation initiators, polymerisable compositions, and uses thereof for bonding low surface energy substrates

InactiveUS20050154160A1Easy to peelIncrease resistanceSynthetic resin layered productsOrganic non-macromolecular adhesiveLithiumPolyolefin

Quaternary boron salts are used as initiators of polymerisation in adhesive compositions for bonding low surface energy substrates such as polyolefins. The quaternary boron salts are of the formula I wherein R1 is C1-C10 alkyl, R2, R3 and R4, which may be the same or different, are, C1-C10 alkyl or C3-C10 cycloalkyl, phenyl, or phenyl-substituted C1-C10 alkyl or C3-C10 cycloalkyl, provided that any two of R1-R4 may optionally be part of a carbocyclic ring, and M+ is a metal ion or a quaternary ammonium ion. Particular examples of initiator compounds include sodium tetraethyl borate and lithium tetraethyl borate, lithium phenyl triethyl borate and tetraethylammonium phenyl triethyl borate.

Owner:HENKEL IP & HOLDING GMBH

Halogen-free flame-retardant composite material and preparation method thereof

The invention discloses a halogen-free flame-retardant composite material which comprises the following components in parts by weight: 25-40 parts of modified rice hull powder, 27-46 parts of modified bagasse, 10-20 parts of p-diacetylene-benzene, 5-10 parts of triethyl borate, 80-100 parts of organic silicone oxygen resin, 10-20 parts of magnesium hydrate, 10-20 parts of aluminum hydroxide, 1-4 parts of a coupling agent and the like. A preparation method comprises the following steps: (1) weighing p-diacetylene-benzene, triethyl borate and organic silicone oxygen resin according to the formula, and melting; (2) mixing a polyethynylbenzene polymer with magnesium hydrate, aluminum hydroxide, an antioxidant and the coupling agent, melting in a mixing mill, putting polytetrafluoroethylene into the mixing mill, and melting; and (3) putting a granular material and a lubricant into a press vulcanizer, and performing hot-pressing at 8-15MPa, thereby obtaining the halogen-free flame-retardant composite material. As the organic silicon oxygen resin is generated, the flame-retardant effect and mechanical properties of the composite material can be improved.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

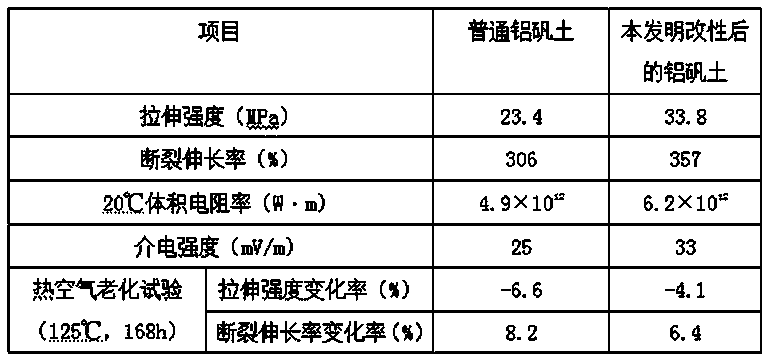

Modified bauxite for thermal ageing resistant polyurethane cable material and preparation method of modified bauxite

InactiveCN104194414AGood lipophilic and hydrophobic propertiesImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPhosphateBoronic acid

The invention discloses modified bauxite for a thermal ageing resistant polyurethane cable material and a preparation method of the modified bauxite. The modified bauxite is prepared from the following raw materials in parts by weight: 55-65 parts of bauxite, 7-13 parts of 4A molecular sieve powder, 5-10 parts of triethyl borate, 2-3 parts of peroxidized di(2-ethylhexyl) dicarbonate, 10-15 parts of calcined pottery clay powder, 8-14 parts of methyl MQ silicon resin, 1.5-2.5 parts of N-phenyl maleimide, 3-5 parts of trihydroxymethylpropyl trioleate, 4-7 parts of divinyl benzene, 5-10 parts of tung oil anhydride, 2-3 parts of cerous fluoride, 2.5-4.5 parts of 3, 3'- dichloro-4,4'- diaminodiphenyl methane, 4-6 parts of isodecyl salicylate, 5-10 parts of butoxytriethyl phosphate, 0.5-1.5 parts of 2-(4-morpholinyldithio) benzothiazole and 3-5 parts of auxiliaries. After being subjected to modified treatment, the bauxite has very good oleophylic and hydrophobic performances, is very easily dispersed in a polyurethane system, and is good in compatibility, high in filling performance, capable of improving performances such as chemical corrosion resistance and heat-proof aging performance while improving the mechanical performances of the polyurethane cable material and wide in application prospect.

Owner:ANHUI MINGDU ELECTRIC WIRE

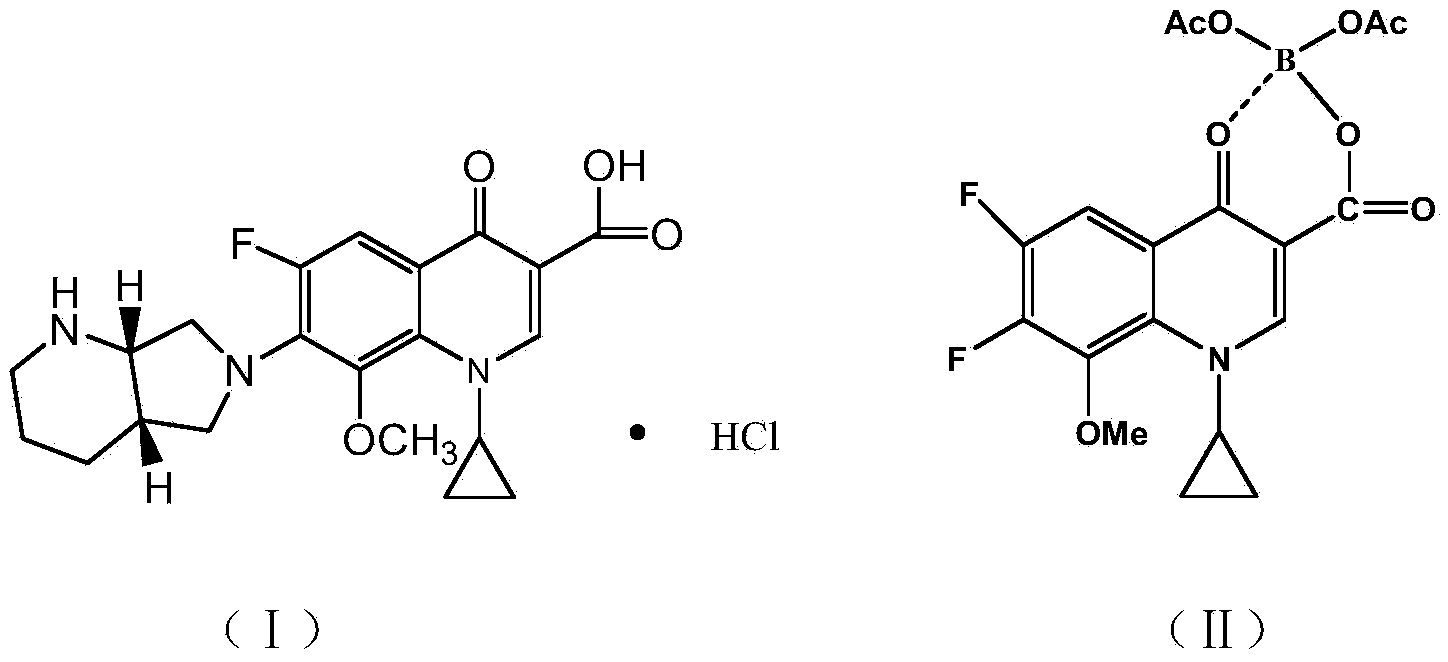

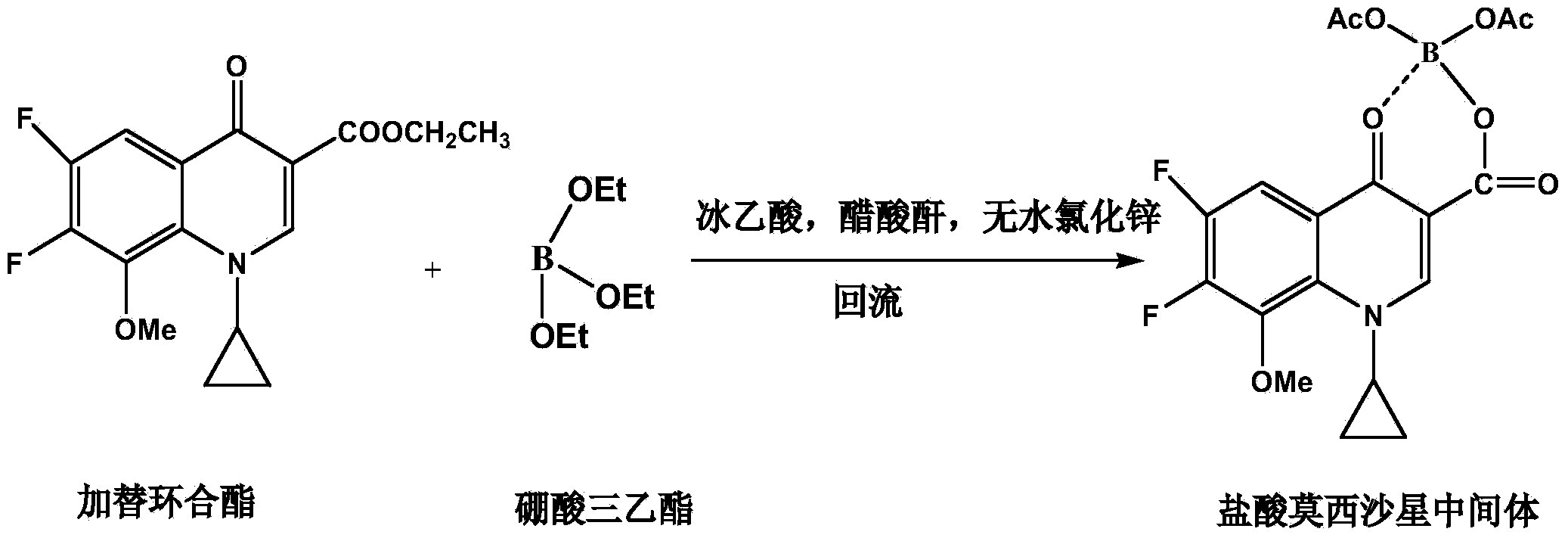

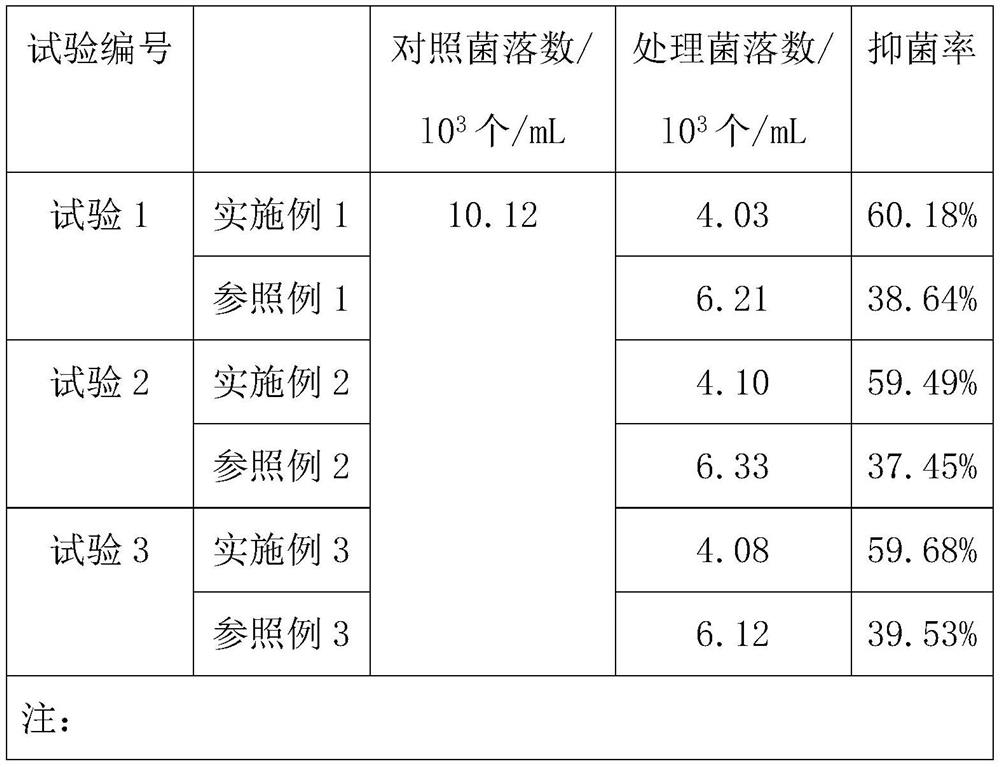

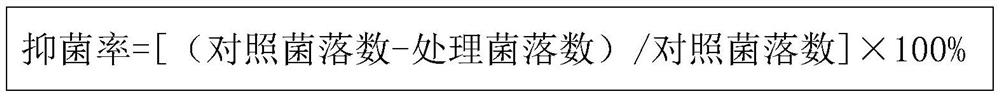

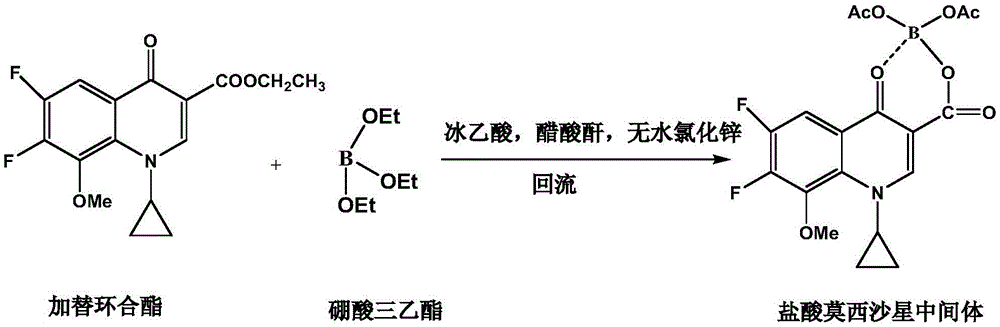

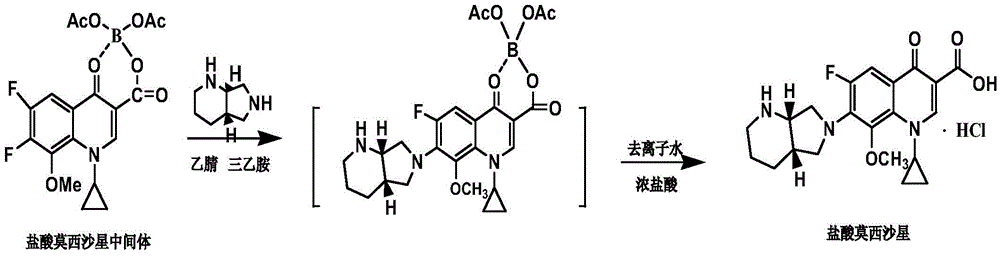

Synthesis method of moxifloxacin hydrochloride intermediate

InactiveCN104031078AEasy to operateGroup 3/13 element organic compoundsSynthesis methodsAcetic oxide

The invention discloses a synthesis method of a moxifloxacin hydrochloride intermediate, and belongs to the field of medical intermediate synthesis. The synthesis method comprises the following steps: S1, chelation reaction: sequentially adding acetic oxide and glacial acetic acid to a reaction kettle, agitating and adding anhydrous zinc chloride, dropwise adding triethyl borate, carrying out agitated reaction after dropwise adding is ended and then adding a gatifloxacin intermediate, and reacting at 70-100 DEG C until the gatifloxacin intermediate is completely transformed; and S2, post-treatment: cooling and crystallizing a liquid in the reaction kettle, centrifugally filtering, pulping the obtained solid by using purified water and ethanol respectively and then centrifugally filtering again, and preparing the moxifloxacin hydrochloride intermediate after drying the solid. The method disclosed by the invention has the advantages of being easy to operate, simple in synthesis and high in yield. The yield of the product prepared by adopting the method disclosed by the invention is over 85%, the purity can be up to over 99%, and the moisture is smaller than or equal to 2%.

Owner:CHENGDU CLIMB PHARMA TECH

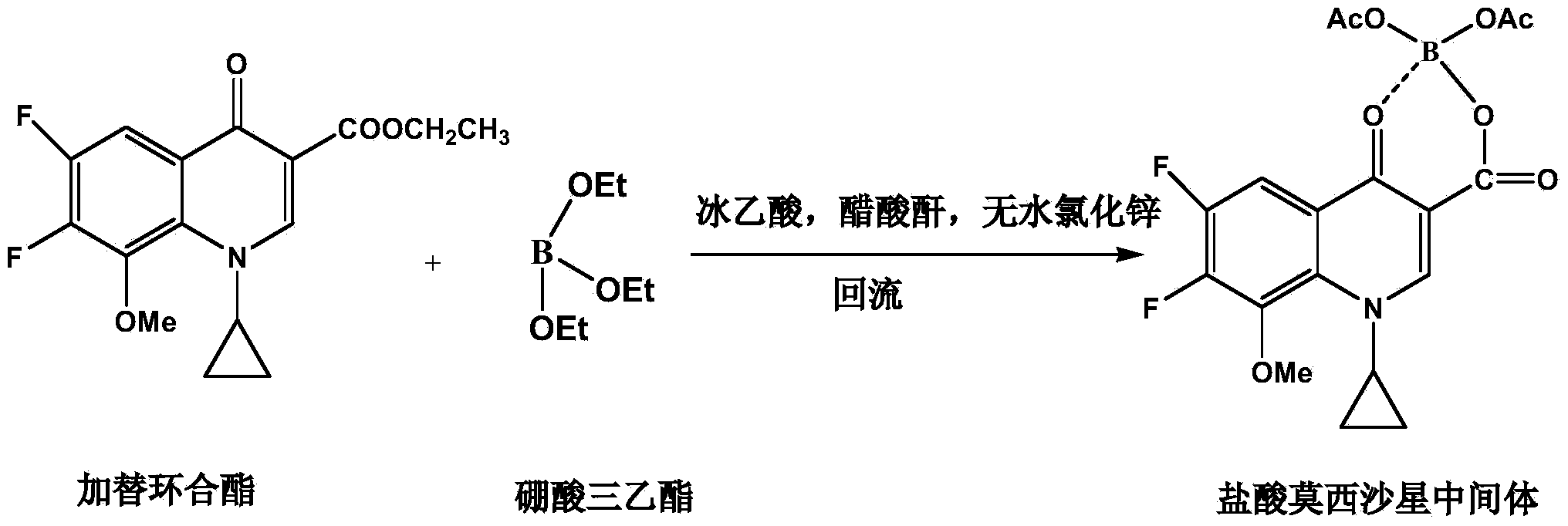

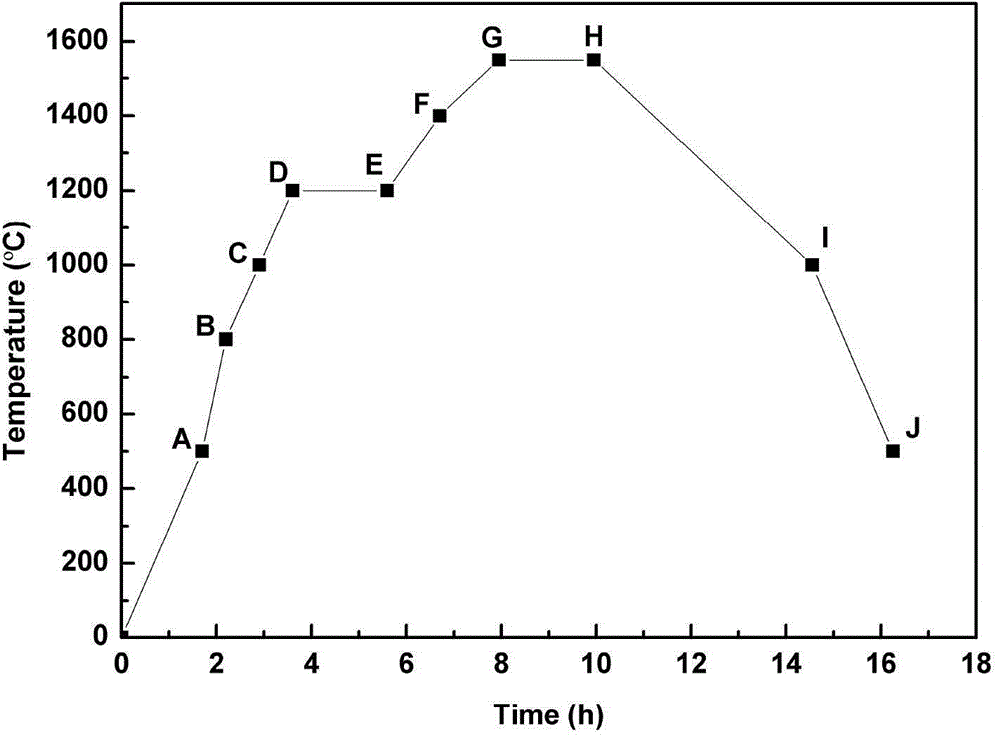

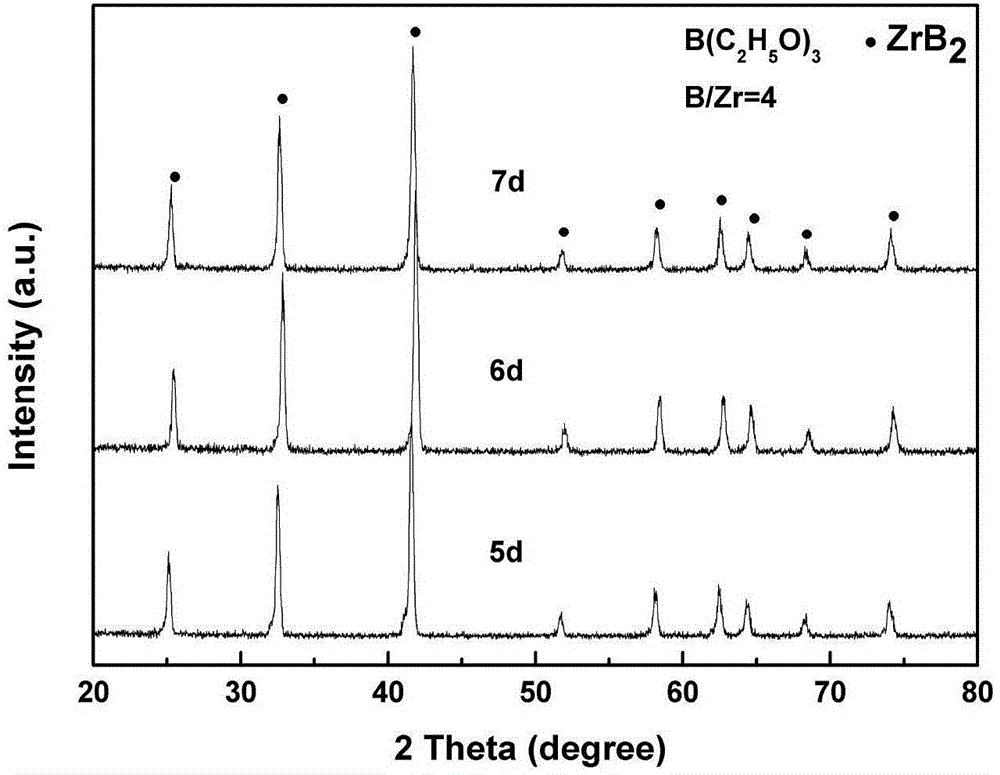

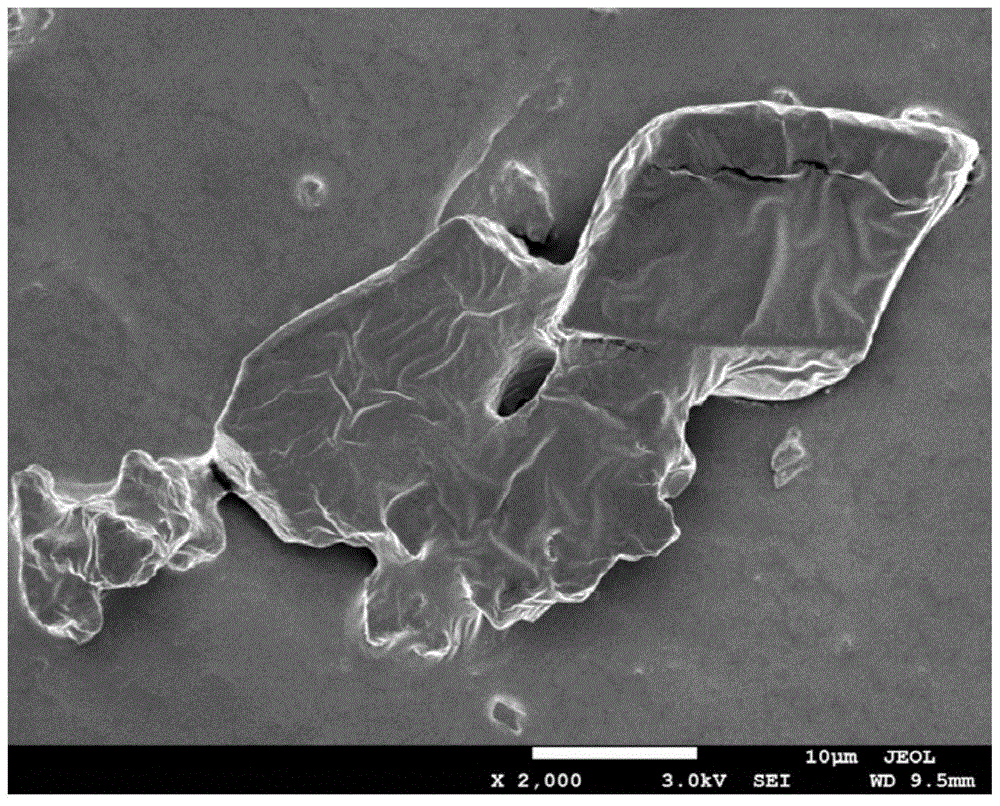

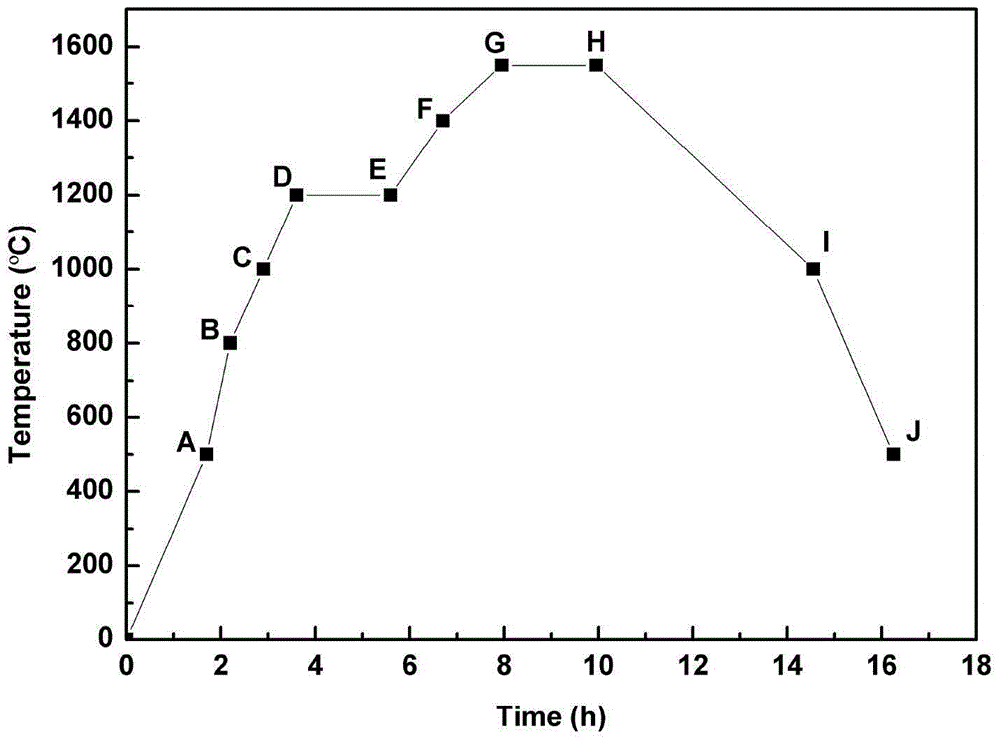

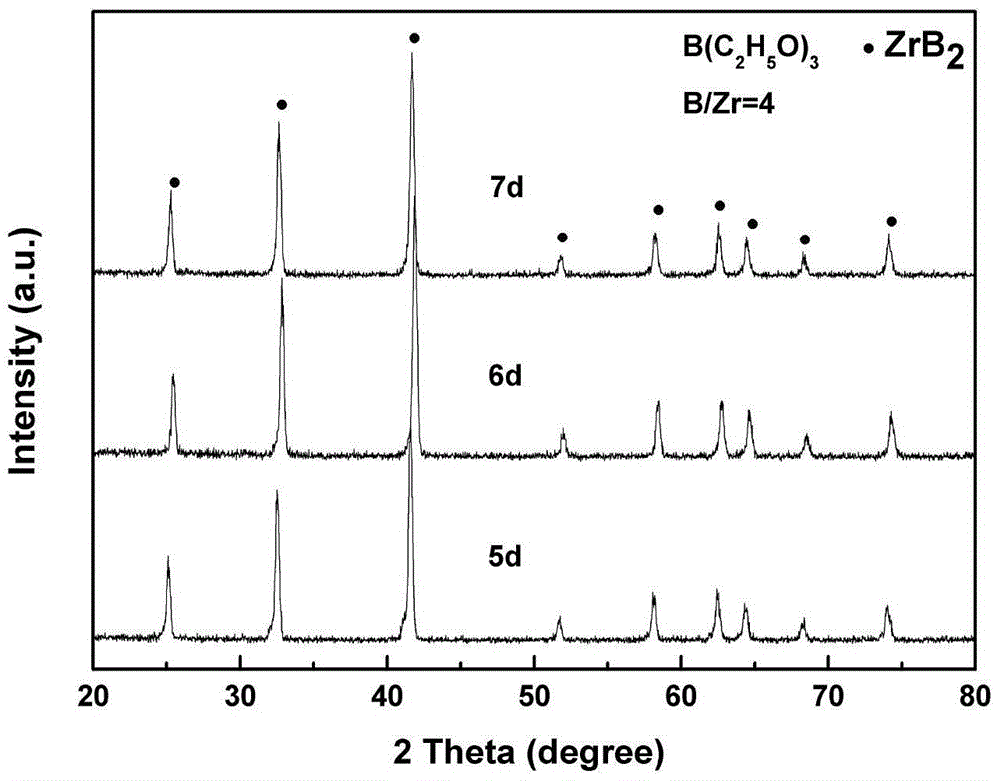

Method for preparing single-phase ZrB2 powder employing triethyl borate as boron source through sol-gel method

InactiveCN104876236ALow costPrecise control of the reaction processMetal boridesEthyl fumarateRaw material

The invention discloses a method for preparing single-phase ZrB2 powder employing triethyl borate as a boron source through a sol-gel method. The method comprises the following steps: by virtue of the sol-gel method, with D-fructose, triethyl borate and zirconium n-propoxide as raw materials, obtaining precursor gel powder of ZrB2 by adjusting the molar ratio of B to Zr; and carrying out preheating and burning at different heating and cooling rates under protection of argon and cooling along with a furnace, so as to obtain the single-phase pure ZrB2 powder. The precursor gel powder obtained by reaction can reach uniform atomic scale and molecular scale; and the components of a final synthetic material can be strictly controlled by calculating the components of reactants. In addition, through simple process and cheap equipment, the gel or powder with large specific surface area can be obtained; and the purity of the product is high.

Owner:BEIHANG UNIV

Coating material for protecting liquid gasification tank

InactiveCN107868501AImprove wear resistanceImprove corrosion resistanceCoatingsPigment physical treatmentIsooctyl acrylateWeather resistance

The invention discloses a coating material for protecting a liquid gasification tank. The coating material is prepared from the following substances: styrene resin, isooctyl acrylate, terpene resin, phenol-formaldehyde resin, methyl cellulose, triethyl borate, ethylene glycol dimethacrylate, konjak gum, modified mica powder and glycerine. According to the coating material, the ingredients of the coating material are optimized; under the jointly-matched action of all the ingredients, the coating material disclosed by the invention has the characteristics of very good wear resistance, decay resistance, weather resistance, strength and the like, a formed coating is uniform, is high in compactness, high in protective ability and long in service life, is not prone to cracked spalling, and thus,the coating material has a popularized use value.

Owner:安徽启东热能科技有限公司

Environment-friendly type anti-rust cutting fluid for numerical-control machine tool and preparation method thereof

The invention discloses environment-friendly type anti-rust cutting fluid for a numerical-control machine tool. The environment-friendly type anti-rust cutting fluid is prepared from the following rawmaterials in parts by weight: 32-38 parts of an anti-rust agent, 12-16 parts of amine phosphate triacetate, 10-12 parts of sodium dodecyl sulfate, 6-10 parts of amino triethyl borate, 8-12 parts of disodium lauriminodipropionate, 5-9 parts of fumed silica, 6-10 parts of oleoyl-N-sodium methyl taurate, 2-6 parts of a bactericide, 1-3 parts of a water-based de-foaming agent and 1-3 parts of a cleaning agent. The environment-friendly type anti-rust cutting fluid for the numerical-control machine tool is free of pollution, is green and environmentally friendly, has good antibacterial, lubricatingand anti-rust performance; and besides, the material cost is relatively low, raw materials are easily available, a using value is relatively high, and the application prospect is good.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

A kind of halogen-free flame-retardant composite material and preparation method thereof

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

A kind of low-volatility environment-friendly pickling-free flux solution and its preparation method and application

ActiveCN111151924BWell mixedNo need to stirWelding/cutting media/materialsSoldering mediaPotassium fluoridePhysical chemistry

Owner:ZHEJIANG XINRUI WELDING MATERIAL

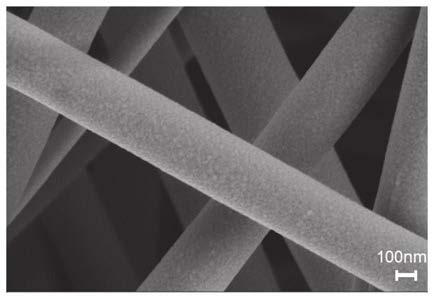

Method for preparing nano zirconium boride ceramic fibers from organic zirconium source, ceramic fibers and application

The invention relates to the field of nano ceramic fibers, and provides a method for preparing nano zirconium boride ceramic fibers from an organic zirconium source, the ceramic fibers and application. The method comprises the following steps of (1) adding cane sugar into a proper amount of organic solvent, heating to achieve dissolving, sequentially adding triethyl borate and zirconium acetate after cooling, adjusting the pH value of the solution to be acidic with acetic acid, adding a proper amount of a spinning aid after uniform mixing, and conducting stirring for 3-6 hours to obtain a precursor solution; (2) carrying out electrostatic spinning in a proper environment to obtain precursor fibers; and (3) carrying out high-temperature calcination on the precursor fibers in a tubular furnace in an argon atmosphere to obtain the nano zirconium boride ceramic fibers. According to the method, the zirconium acetate which is low in price and can be prepared in a laboratory serves as a zirconium source, the triethyl borate serves as a boron source, the diameter of the zirconium boride ceramic fibers prepared through an electrostatic spinning method is about 200 nm, and the fibers have the properties of being high in specific surface area, low in density, high in temperature resistance, good in thermal shock resistance and the like. The nano zirconium boride ceramic fibers can be usedin the fields of structural components, catalyst carriers, reinforcing materials and the like, and have wide application prospects.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

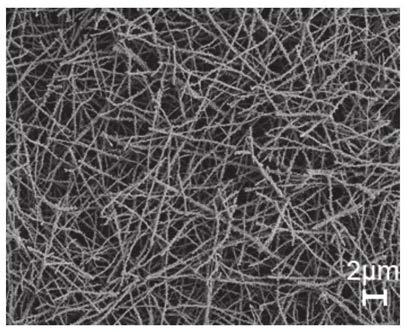

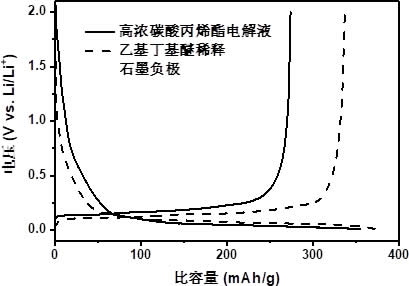

Propylene carbonate based electrolyte and lithium ion battery containing same

InactiveCN112909339AImprove electrochemical performanceGood low temperatureSecondary cellsOrganic electrolytesElectrolytic agentMethyl carbonate

The invention discloses a propylene carbonate based electrolyte and a lithium ion battery containing the same, the electrolyte comprises a propylene carbonate solvent, a lithium salt and a diluent, and the diluent is a chain solvent with weak polarity. The diluent is one or more of trimethyl borate, triethyl borate, tripropyl borate, dimethyl carbonate, diethyl carbonate, methyl ethyl carbonate, methyl butyl ether, ethyl butyl ether, propyl butyl ether, methyl ethyl ether and ethylene glycol dimethyl ether. The propylene carbonate based electrolyte and the lithium ion battery containing the propylene carbonate based electrolyte have the characteristics of high conductivity, excellent low-temperature performance and good high-voltage stability.

Owner:SHENZHEN HONCELL ENERGY CO LTD +1

A preparation method of pitch-based carbon fiber with high modulus and high thermal conductivity

ActiveCN108456950BUniform and controllable introductionAvoid the problem of poor performance consistencyArtifical filament manufactureCarbon fibersCarbonization

The invention discloses a preparation method of high-modulus and high-heat-conducting asphalt-based carbon fibers. The preparation method comprises the following steps: firstly, preparing ethylene tarasphalt with the softening point of 80 to 90 DEG C through a common pressure nitrogen bubbling and purging method; then adding triethyl borate into the ethylene tar asphalt; them preparing boron-containing spinnable mesophase asphalt through a pressurization and thermal polymerization, and decompression and devolatilization method; then carrying out melting spinning, pre-oxidization, carbonization and graphitization to prepare a high-modulus and high-heat-conducting asphalt-based carbon fiber sample, wherein the tensile modulus is 800 to 900GPa and the heat conductivity is 800 to 1000W / m.K. According to the preparation method disclosed by the invention, a boron element is introduced into mesophase spinning asphalt through a chemical reaction method and uniform and controllable addition ofthe boron element is realized; the difficulty of a conventional method that the boron element is not uniformly added is solved; the boron element effectively has the effect of catalyzing the graphitization in a subsequent preparation process of the asphalt-based carbon fibers, so that the graphitization treatment temperature is reduced, the service life of a graphite furnace is prolonged and theproduction cost is reduced.

Owner:湖南东映碳材料科技股份有限公司

Bamboo fiber-modified melamine flame-retardation sound-absorbing foamed material used for crane and preparation method thereof

The invention relates to a bamboo fiber-modified melamine flame-retardation sound-absorbing foamed material used for a crane. The bamboo fiber-modified melamine flame-retardation sound-absorbing foamed material comprises the following raw materials in parts by weight: melamine, 37% of formaldehyde solution, paraformaldehyde, octadecylamine, bamboo fiber, triethyl borate, benzene, maleic anhydride, amino silicon oil, trimethylol propane, 1,1-bis(tert-butyldioxy)cyclohexane, iso-propyl xanthogen disulfide, vinyl acetate, toluene, ethanol, sodium ethoxide, propyl p-hydroxybenzoate, methyl ethyl ether, pentaerythritol phosphate ester, pentane, phosphoric acid, sodium hexametaphosphate, a proper amount of hexamethylene tetramine, and a proper amount of deionized water. The foamed material has excellent flame resistance and good sound-absorbing capability, and reduces noise by greater than 10 dB.

Owner:安徽恒源煤电股份有限公司

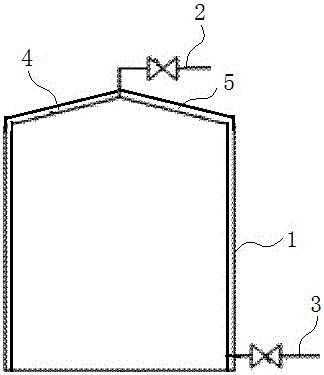

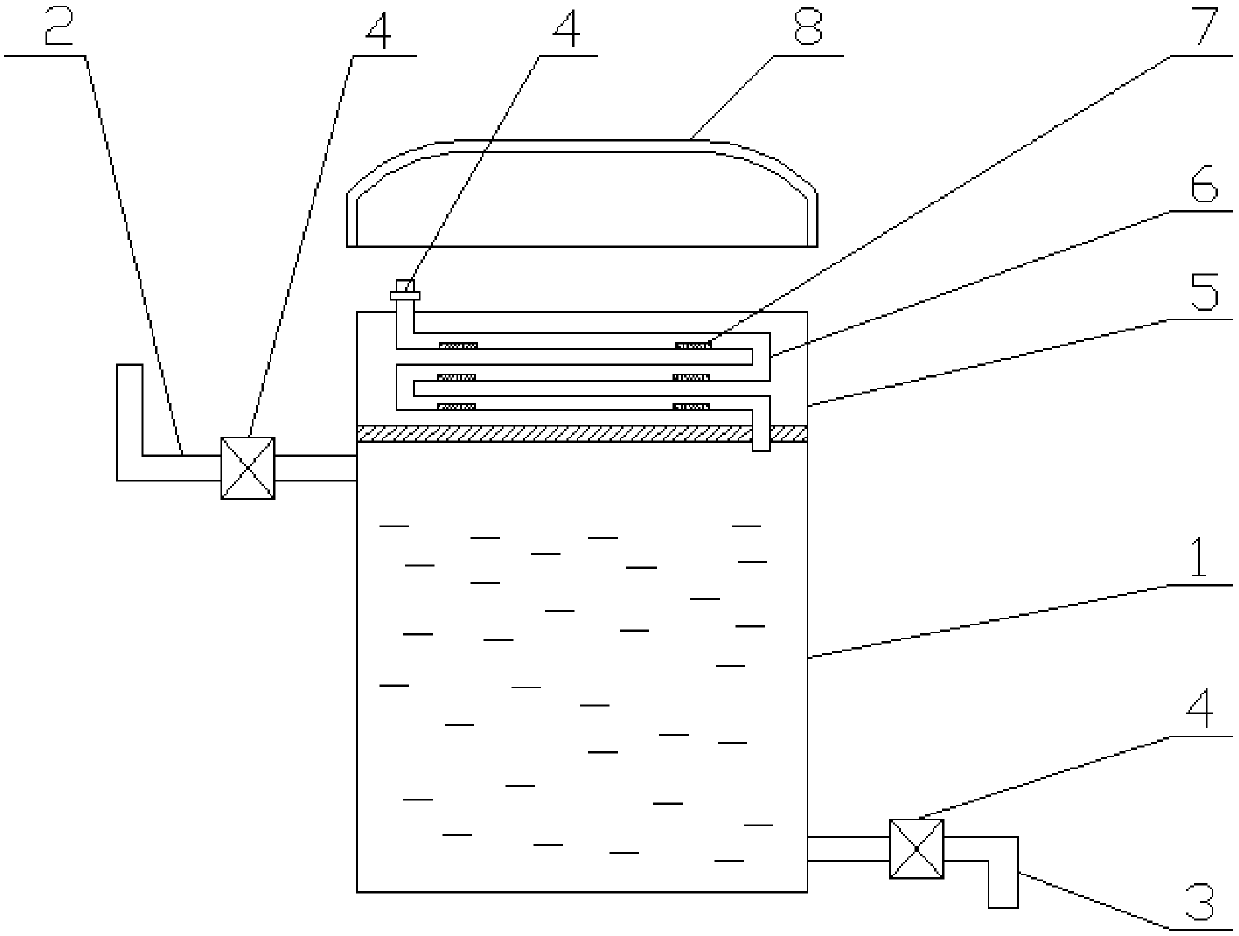

Storage container for triethyl borate

InactiveCN106697596AKeep dryImprove practicalityLarge containersContainers preventing decayTriethyl borateBoric acid

The invention discloses a storage container for triethyl borate. The storage container comprises a tank body which is of a cylinder structure with a conical top portion. Interlayer structures are arranged on the exterior of the conical top portion and the exterior of the cylinder, and drying agents are arranged in the interlayer structures. The storage container for triethyl borate can be used as drying degree indication and can also play a very good role in drying, the dryness of the triethyl borate storage environment is ensured, using is safe and stable, and the storage container has very good practicality.

Owner:NANTONG HONGZHI CHEM

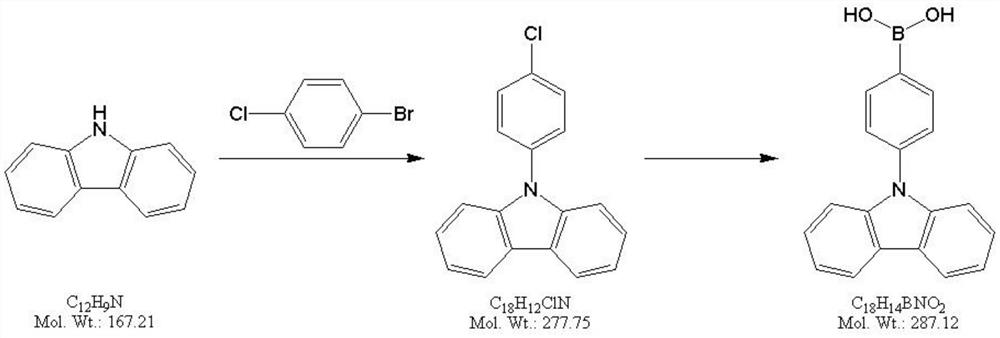

Preparation method of 4-(9H-carbazol-9-yl)phenylboronic acid

PendingCN113603714AAvoid ultra-low temperature reactionsSuitable for industrial productionGroup 3/13 element organic compoundsPhenylboronic acidChlorobenzene

Owner:山东瑞辰新材料有限公司

Heat-resistant silicone rubber material and preparation method thereof

The invention relates to the technical field of silicone rubber material preparation, in particular to a heat-resistant silicone rubber material and a preparation method thereof. Each part of the silicone rubber material is prepared from the following raw materials in parts by mass: 100 to 130 parts of raw rubber, 10 to 12 parts of white carbon black, 5 to 8 parts of a KH570 silane coupling agent, 3 to 7 parts of phenol formaldehyde resin, 30 to 45 parts of a reinforcing filler, 31.2 to 93.6 parts of a modified hydrophilic solution, 5 to 10 parts of zinc dialkyl dithiophosphate, 7 to 9 parts of polyimide, 7 to 9 parts of triethyl borate and 10 to 13 parts of tetraethoxysilane. The preparation method comprises the following steps: S1, weighing the raw materials according to the weight for later use; s2, fully stirring and mixing the raw rubber, the white carbon black, the KH570 silane coupling agent, the reinforcing filler, the zinc dialkyl dithiophosphate, the polyimide and the triethyl borate in a stirrer, and drying in a drying oven at 55 DEG C for 4-6 hours. The hydrophilic ability of the silicone rubber material is improved, and meanwhile, the friction between the silicone rubber material and a human skin contact interface is reduced, so that the effect of effectively inhibiting bacterium breeding is achieved.

Owner:万贤钧

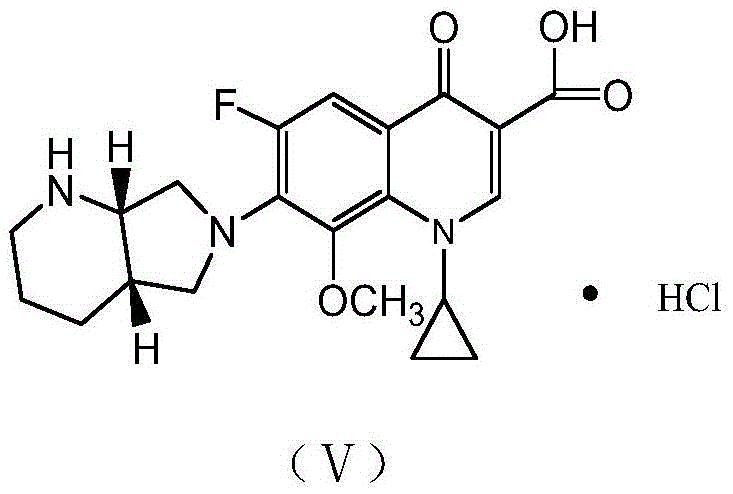

A kind of synthetic method of moxifloxacin hydrochloride

ActiveCN104031043BLow single impurity contentEasy to operateOrganic chemistryAcetic anhydrideSynthesis methods

The invention discloses a novel synthesis method of moxifloxacin hydrochloride, belonging to the field of pharmaceutical chemistry. The synthesis method comprises the following steps: sequentially adding acetic anhydride and glacial acetic acid into a reaction kettle, adding anhydrous zinc chloride while stirring, dropwisely adding triethyl borate, stirring to react after finishing the dropwise addition, adding gatifloxacin intermediate, and carrying out after-treatment on the obtained solid to obtain a moxifloxacin hydrochloride intermediate; and in the presence of an organic solvent, reacting the moxifloxacin hydrochloride intermediate with (S,S)-2,8-diazabicyclo[4.3.0]nonane, dropwisely adding concentrated hydrochloric acid, reacting to obtain a moxifloxacin hydrochloride crude product, and recrystallizing with ethanol to obtain the high-purity moxifloxacin hydrochloride. The single impurity content of the moxifloxacin hydrochloride is lower than 0.05%, and the total impurity content is lower than 0.1%; and the method is simple to operate, has the advantages of mild conditions and high yield, and is suitable for industrial production.

Owner:CHENGDU CLIMB PHARMA TECH

Film forming agent for coatings

InactiveCN107974115AIncreased complexityHigh strengthAnti-corrosive paintsIsooctyl acrylatePetroleum resin

The invention discloses a film forming agent for coatings. The film forming agent is prepared from the following substances of styrene resin, isooctyl acrylate, C9 petroleum resin, urea-formaldehyde resin, methyl cellulose, triethyl borate, ethylene glycol dimethacrylate and seaweed gel. The film forming agent disclosed by the invention has the beneficial effects that the spreadability, the smoothness and the adhesiveness are good, and the protective effect and the service life of the coating are effectively improved, so that the film forming agent has extremely high promotion and use values.

Owner:安徽启东热能科技有限公司

Triethyl borate storage using device

InactiveCN107792553AHigh humidityHigh water contentLarge containersTank wagonsTriethyl borateEthyl ester

The invention discloses a triethyl borate storage using device. The triethyl borate storage using device comprises a sealed tank. A liquid inlet pipe is arranged at the upper portion of the sealed tank, and a liquid outlet pipe is arranged at the lower portion of the sealed tank. The liquid inlet pipe and the liquid outlet pipe are provided with sealing valves. A sealed drying chamber is further arranged at the upper end of the sealed tank and internally provided with a ventilation pipe. The drying chamber is additionally arranged at the upper end of the sealed tank and internally provided with the ventilation pipe for ventilation, and when part of triethyl borate needs to be taken out to be used, the sealing valves of the liquid outlet pipe and an air inlet of the ventilation pipeline areopened, the triethyl borate flows into experiment or usage equipment from the liquid outlet pipe, at the time, part of air can enter from the ventilation pipe due to pressure intensity, the part of air flows in from the ventilation pipe, is subjected to drying and dehumidification through a drying agent in the ventilation pipe and enters the sealed tank, and the situation that the humidity and water content of part of air are large, and consequently triethyl borate hydrolysis is caused is prevented.

Owner:NANTONG HONGZHI CHEM

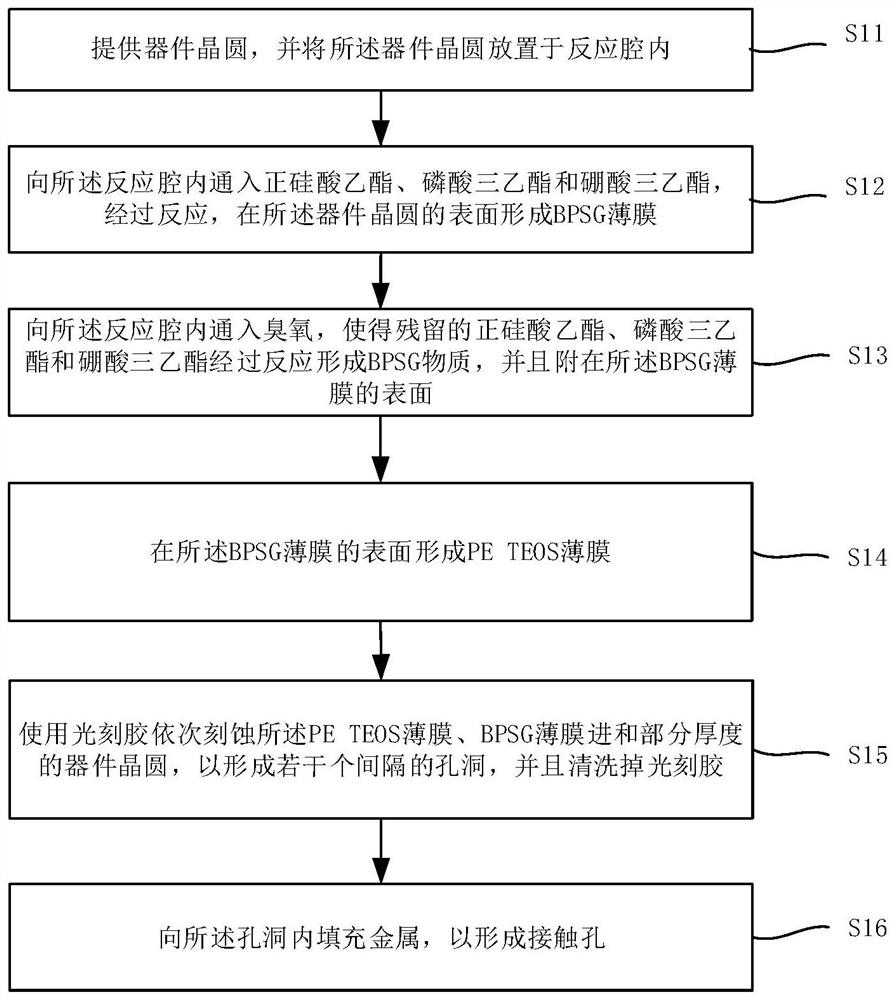

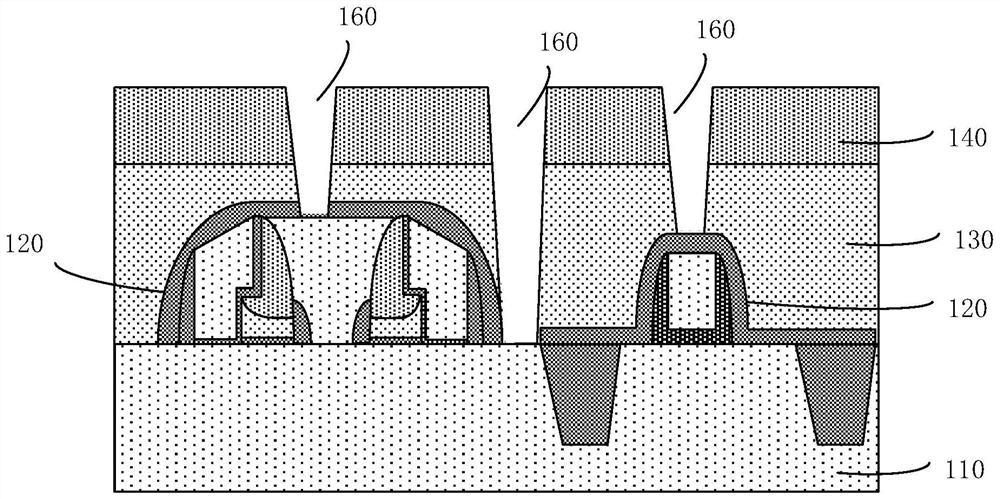

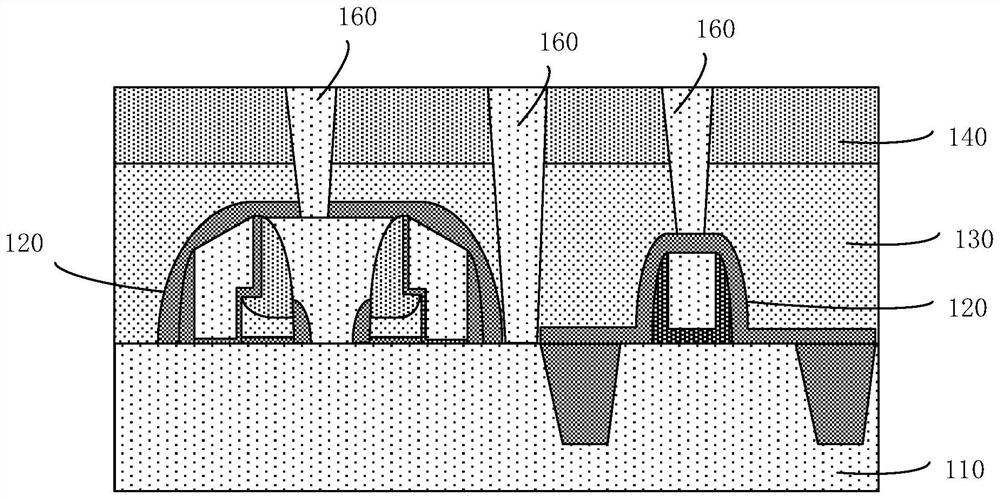

Formation method of semiconductor device

PendingCN114388445AQuality improvementImprove leakageSemiconductor/solid-state device manufacturingDevice materialWafer

The invention provides a method for forming a semiconductor device, which comprises the following steps of: providing a device wafer, and placing the device wafer in a reaction cavity; introducing tetraethoxysilane, triethyl phosphate and triethyl borate into the reaction cavity, and forming a BPSG film on the surface of the device wafer through reaction; ozone is introduced into the reaction cavity, so that the residual tetraethoxysilane, triethyl phosphate and triethyl borate react to form a BPSG substance, and the BPSG substance is attached to the surface of the BPSG film; forming a PE TEOS film on the surface of the BPSG film; cleaning the PE TEOS thin film; and sequentially etching the PE TEOS film, the BPSG film and a part of thickness of the device wafer to form a plurality of spaced holes, and filling metal into the holes to form contact holes. According to the method, the quality of the BPSG film is improved, the situation of electric leakage of the contact hole is further improved, and the product quality is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Method for preparing sub-atmosphere pressure film

ActiveCN100500933CIncrease temperatureExtend your lifeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTriethyl borateVaporization

The invention discloses a standard normal pressure film manufacturing method. It includes the following steps: inputting ethyl phosphate, triethoxy boron, and tetraethoxy silicane into respective corresponding tube; using carbureting valve to heat up to 137-143 degree centigrade to vaporize the ethyl phosphate; using it the vaporize the other two; adjusting the tube temperature to 105-110 degree centigrade; inducing the vaporized matter into the cavity to react and generate boron-phosphorosilicate glass and by-product. The invention can improve vaporization property by increasing gas tube temperature to 110 degree centigrade, ethyl phosphate to 140 degree centigrade which can not only prolong carbureting valve useful life, but also reduce production cost.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

A preparation of single-phase zrb by sol-gel method using triethyl borate as boron source 2 powder method

InactiveCN104876236BLow costPrecise control of the reaction processMetal boridesTriethyl borateD fructose

Owner:BEIHANG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com