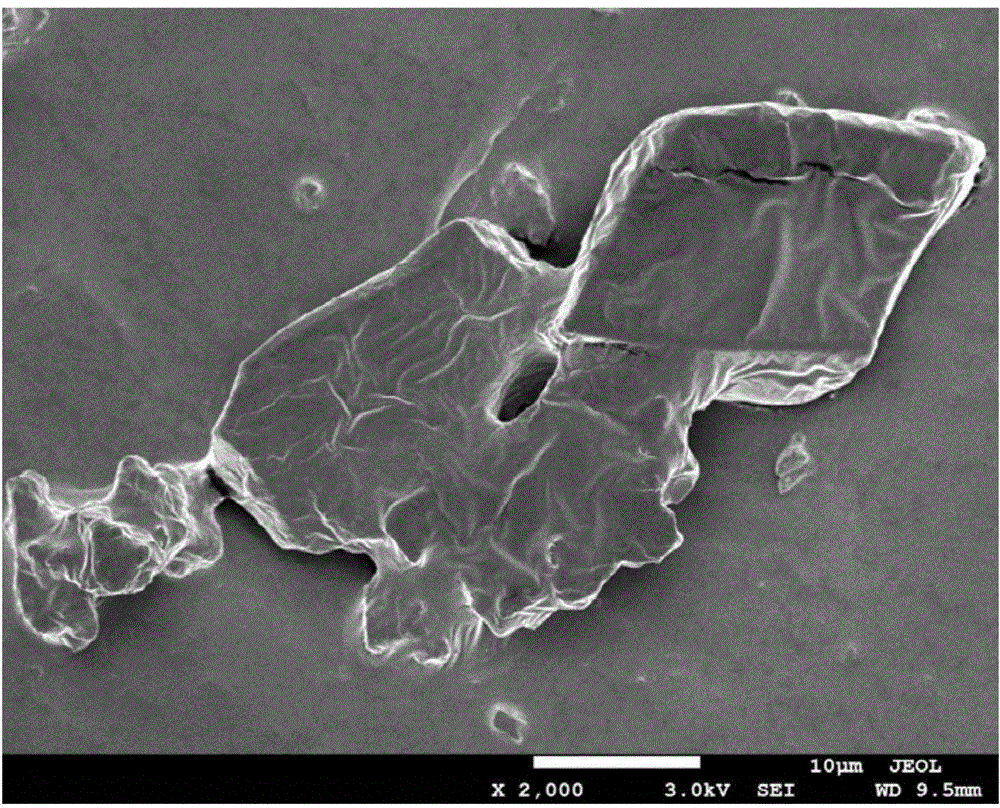

Method for preparing single-phase ZrB2 powder employing triethyl borate as boron source through sol-gel method

A technology of triethyl borate and gel method, applied in boron/boride, metal boride and other directions, can solve problems such as unfavorable preparation process and subsequent material processing and development, and achieves low production cost, simple equipment and reaction conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

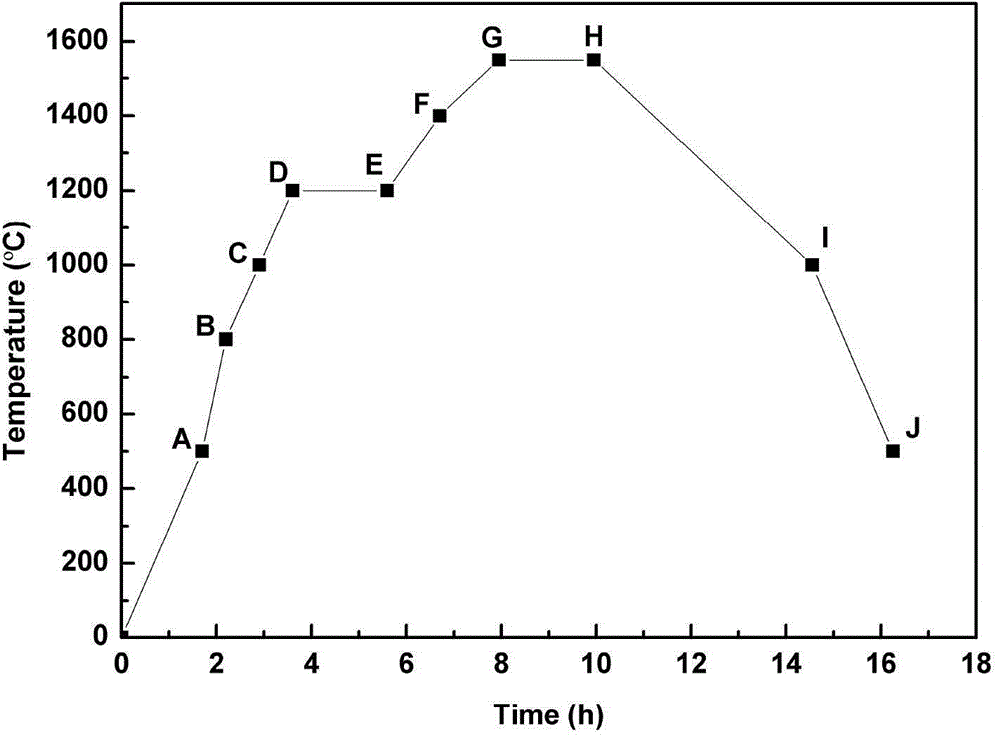

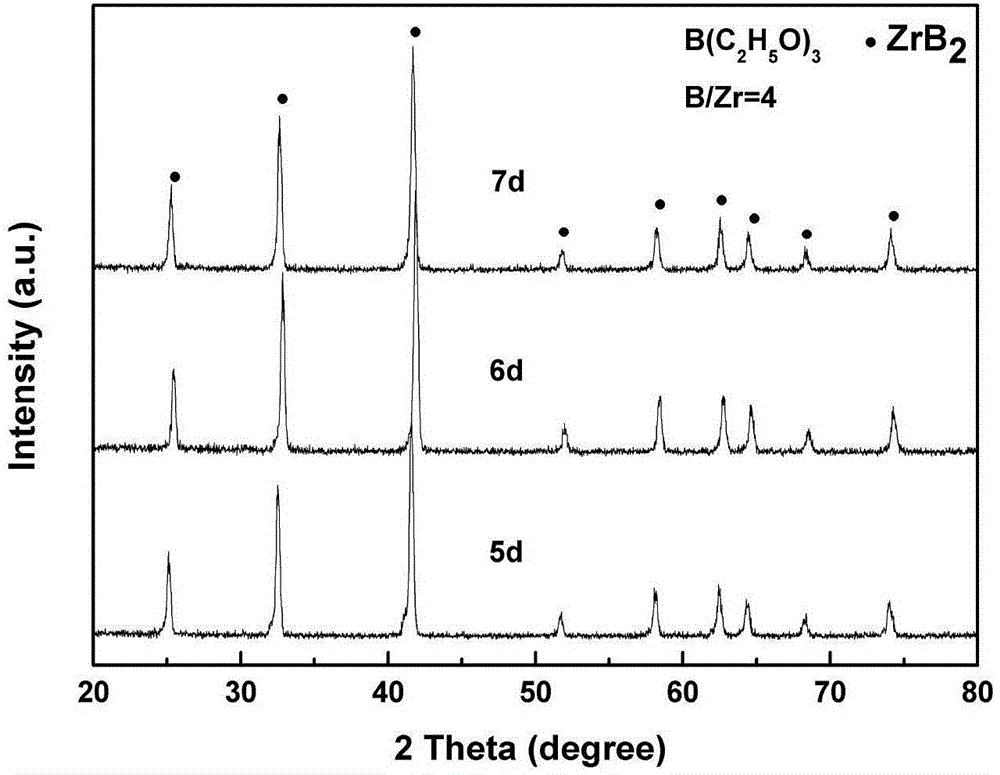

[0060] The present invention proposes a single-phase ZrB prepared by a sol-gel method using triethyl borate as a boron source 2 The method of powder, this method comprises the following steps:

[0061] Step 1: Dissolve D-fructose in acetic acid CH 3 In COOH (mass percentage concentration 99.9%), magnetically stir in a water bath at 80°C until the first solution is formed; the stirring speed is 200r / min;

[0062] Step 2: Place the first solution in cooling water, and cool it down to 60°C at a cooling rate of 3°C / min to form a second solution;

[0063] Step 3: Mix triethyl borate (97% by mass concentration) with zirconium n-propoxide (70% by mass percent) to form a third solution; the mixing conditions are: mixing temperature 20°C, stirring speed 200r / min ;

[0064] Step 4: at a stirring speed of 200r / min, the third solution is added to the second solution to form a homogeneous solution;

[0065] Dosage: Add 1.85g of D-fructose, 4.09g of zirconium n-propoxide, and 10ml of ac...

Embodiment 2

[0074] The present invention proposes a single-phase ZrB prepared by a sol-gel method using triethyl borate as a boron source 2 The method of powder, this method comprises the following steps:

[0075] Step 1: Dissolve D-fructose in acetic acid CH 3 In COOH (mass percentage concentration 99.9%), magnetically stir in a water bath at 75°C until the first solution is formed; the stirring speed is 400r / min;

[0076] Step 2: Place the first solution in cooling water, and cool it down to 60°C at a cooling rate of 6°C / min to form a second solution;

[0077] Step 3: triethyl borate (mass percentage concentration 97%) is mixed with n-propoxide zirconium (mass percentage concentration 70%) to form a third solution; the mixing conditions are: mixing temperature 25°C, stirring speed 400r / min ;

[0078] Step 4: at a stirring speed of 200r / min, the third solution is added to the second solution to form a homogeneous solution;

[0079] Dosage: Add 2.5g of D-fructose, 5.3g of zirconium n-...

Embodiment 3

[0088] The present invention proposes a single-phase ZrB prepared by a sol-gel method using triethyl borate as a boron source 2 The method of powder, this method comprises the following steps:

[0089] Step 1: Dissolve D-fructose in acetic acid CH 3 In COOH (mass percentage concentration 99.9%), magnetically stir in a water bath at 82°C until the first solution is formed; the stirring speed is 300r / min;

[0090] Step 2: Place the first solution in cooling water, and cool it down to 65°C at a cooling rate of 5°C / min to form a second solution;

[0091] Step 3: triethyl borate (mass percentage concentration 97%) is mixed with n-propoxide (mass percentage concentration 70%) to form a third solution; the mixing conditions are: mixing temperature 20°C, stirring speed 300r / min ;

[0092] Step 4: at a stirring speed of 200r / min, the third solution is added to the second solution to form a homogeneous solution;

[0093] Dosage: Add 1.4g of D-fructose, 3.2g of zirconium n-propoxide, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com