Method for preparing nano zirconium boride ceramic fibers from organic zirconium source, ceramic fibers and application

A nano-zirconium boride and ceramic fiber technology is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc. It can solve the problems of long preparation cycle, unstable ammonia cracking atmosphere, and long heat preservation time, and achieves low density and universal application. Sexuality and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

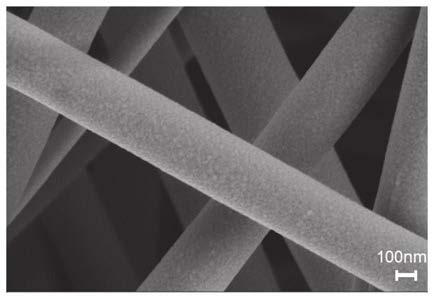

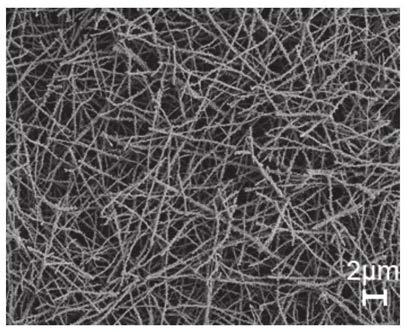

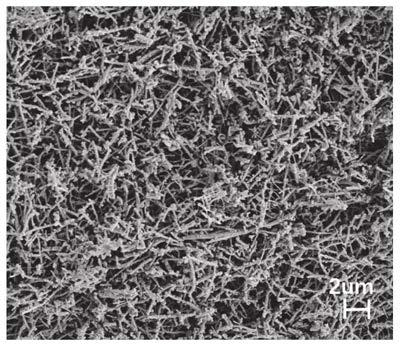

[0034] Add 1.289g sucrose to 10ml N`N dimethylformamide and heat until completely dissolved. After cooling to room temperature, add 5.55ml triethyl borate to the solution, mix well, then add 1.8g zirconium acetate to the solution, completely After dissolving, acetic acid was added to adjust the pH value of the solution to 4. After stirring for 1 hour, an appropriate amount of polyvinylpyrrolidone was added to the solution, and stirring was continued for 6 hours, followed by static defoaming to obtain a precursor electrospinning liquid. Inhale the spinning solution into a 5ml medical syringe and place it on the syringe pump to fix it, adjust the collection distance to 15cm, the drum speed to 240r / min, the injection speed to 0.8ml / h, and the high-voltage power supply to 18KV to determine the spinning room environment ( 25 ℃, relative humidity 45%), carry out electrospinning to obtain the precursor fiber (see figure 1 ). The precursor fibers were first placed in the corundum ark...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com