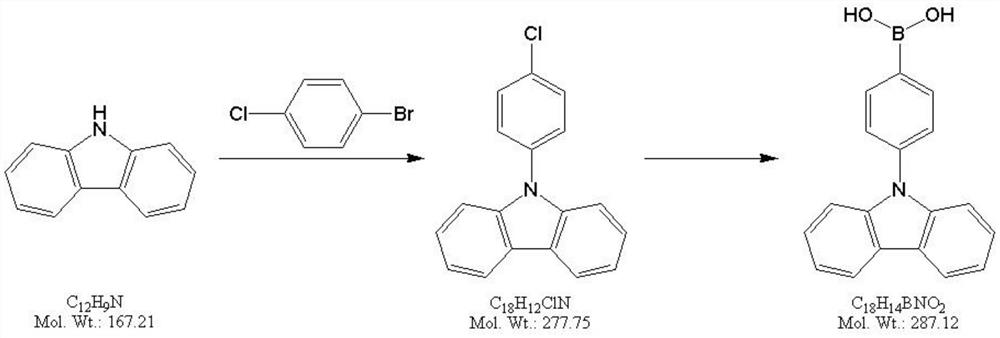

Preparation method of 4-(9H-carbazol-9-yl)phenylboronic acid

A technology of phenylboronic acid and carbazole, which is applied in the field of preparation of 4-phenylboronic acid, can solve problems such as not being suitable for industrial production, and achieve the effect of avoiding ultra-low temperature reaction and being suitable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of 9-(4-chlorophenyl)-9H-carbazole

[0023] Add 100g carbazole to a 1L three-necked flask, then add 500ml N,N-dimethylformamide, stir to dissolve; then add 137.4g 4-chlorobromobenzene, 206.6g potassium carbonate, 5.0g Pd(dppf) 2 Cl 2 , under the protection of nitrogen, the temperature was raised to 100°C for reaction, and after 8 hours TLC monitored the complete reaction of carbazole; after the reaction, the reaction solution was lowered to 25°C, filtered, and 500ml of water and 500ml of ethyl acetate were added to the filtrate to extract and separate the liquid; water The phase was extracted once more with 200ml ethyl acetate, and the organic phases were combined; the organic phase was washed 3 times with 500ml×3 saturated brine, dried over anhydrous sodium sulfate, and then evaporated to dryness to obtain a brown viscous substance; Add 800ml of toluene to the mixture, heat to reflux to dissolve, then evaporate 500ml of toluene under normal pressure, c...

Embodiment 2

[0030] (1) Preparation of 9-(4-chlorophenyl)-9H-carbazole

[0031] Add 2.00kg carbazole to a 20L glass kettle, then add 10L N,N-dimethylformamide, stir to dissolve; then add 3.43kg 4-chlorobromobenzene, 4.96g potassium carbonate, 100g Pd(dppf) 2 Cl 2 , under the protection of nitrogen, the temperature was raised to 100°C for reaction, and after 10 hours, TLC monitored the complete reaction of carbazole; after the reaction, the reaction solution was lowered to 25°C, filtered, and 10L of water and 10L of ethyl acetate were added to the filtrate for extraction and liquid separation; water The phase was extracted once more with 5L ethyl acetate, and the organic phases were combined; the organic phase was washed 3 times with 12L×3 saturated brine, dried over anhydrous sodium sulfate, and then evaporated to dryness to obtain a brown viscous substance; Add 11L of toluene to the mixture, heat to reflux to dissolve, then evaporate 4L of toluene under normal pressure, cool down to 0-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com