Method for preparing sub-atmosphere pressure film

A thin-film, normal-pressure technology, applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve the problems of accelerated deposition, clogging of triethyl phosphate, and intensified reaction, so as to reduce production costs and reduce costs. The effect of easy precipitation and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

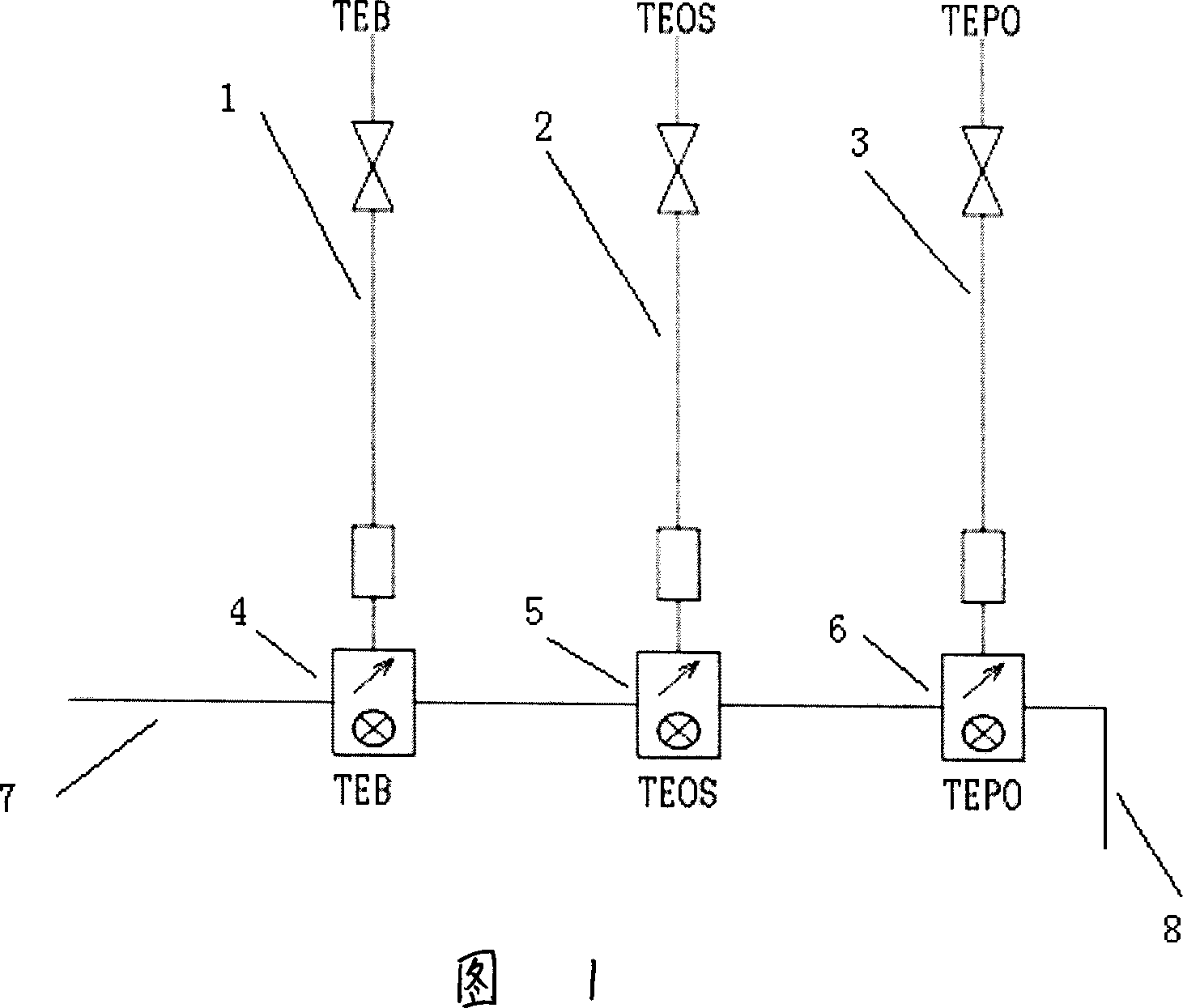

[0010] Fig. 1 is a schematic diagram of a device for preparing a quasi-atmospheric pressure film according to the present invention. As shown in Figure 1, a kind of preparation method of quasi-atmospheric pressure thin film of the present invention, at first pass into triethyl borate liquid in pipeline 1, pass into tetraethoxysilane liquid in pipeline 2, pass into in pipeline 3 Triethyl phosphate liquid; in the second step, the temperature of triethyl borate reaches 100°C and is vaporized through the vaporization valve 4, and the temperature of tetraethoxysilane reaches 100°C through the vaporization valve 5 and vaporized, and the triethyl borate is vaporized through the vaporization valve 6. The ethyl ester temperature reaches 140°C and is vaporized, and the temperature of triethyl phosphate can also be between 137°C-143°C; the third step is to adjust the temperature of the gas pipeline 7 to reach 110°C, and the vaporized triethyl phosphate and boric acid tris Ethyl ester and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com