Process method for directly preparing olefin from synthesis gas

A process method and synthesis gas technology, applied in chemical instruments and methods, from carbon oxides to hydrocarbons, sustainable manufacturing/processing, etc., can solve the problem of low utilization rate of synthesis gas, achieve high selectivity, suppress selectivity , the effect of high one-way conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

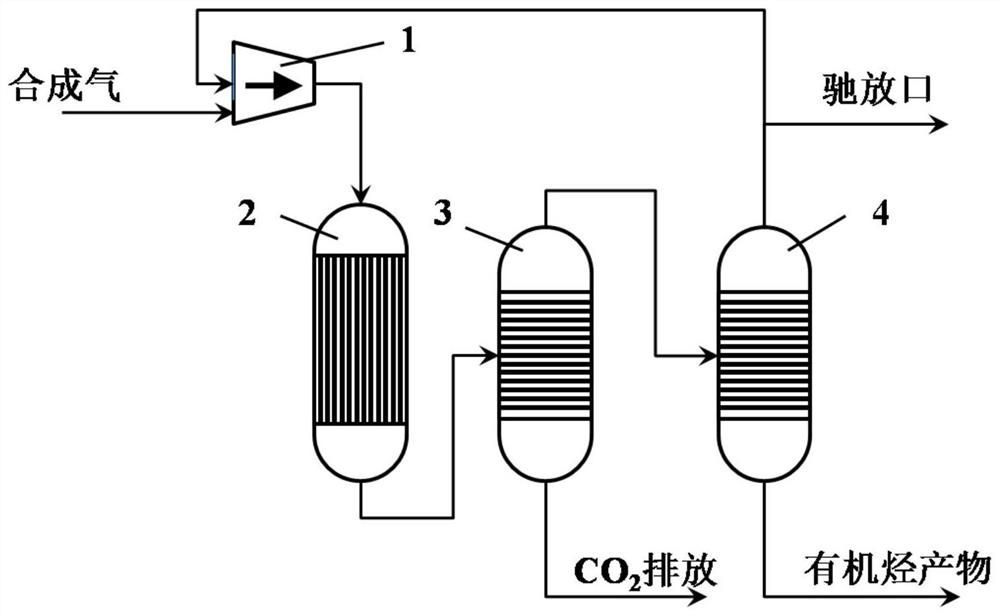

[0035] use as figure 1 In the process flow shown, the catalyst in the fixed bed is filled with oxide and molecular sieve at a ratio of 1:1, ZnCr oxide in the oxide; the molecular sieve is SAPO-34 molecular sieve, at 400°C, 4.0Mpa, 4800h -1 Under the condition of controlling H 2 :CO=1:1, methane content was 10%, reacted for 20 hours, and the reaction product was monitored online by gas chromatography. The reaction results are shown in Table 1.

Embodiment 2

[0037] Adopt the technological process and catalyst packing with embodiment 1; At 400 ℃, 4.0Mpa, 4800h -1 Under the condition of controlling H 2 :CO=1:1, methane content was 3%, reacted for 20 hours, and the reaction product was monitored online by gas chromatography. The reaction results are shown in Table 1.

Embodiment 3

[0039] Adopt the technological process and catalyst packing with embodiment 1; At 400 ℃, 4.0Mpa, 4800h -1 Under the condition of controlling H 2 :CO=1:1, methane content was 20%, reacted for 20 hours, and the reaction product was monitored online by gas chromatography. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com