Catalyst for preparing vinyl acetylene and application method thereof

A vinyl acetylene and catalyst technology, which is applied in the preparation of vinyl acetylene catalysts and its application fields, and can solve the problems of low catalytic selectivity, low single-pass conversion rate of acetylene, and increased production costs of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

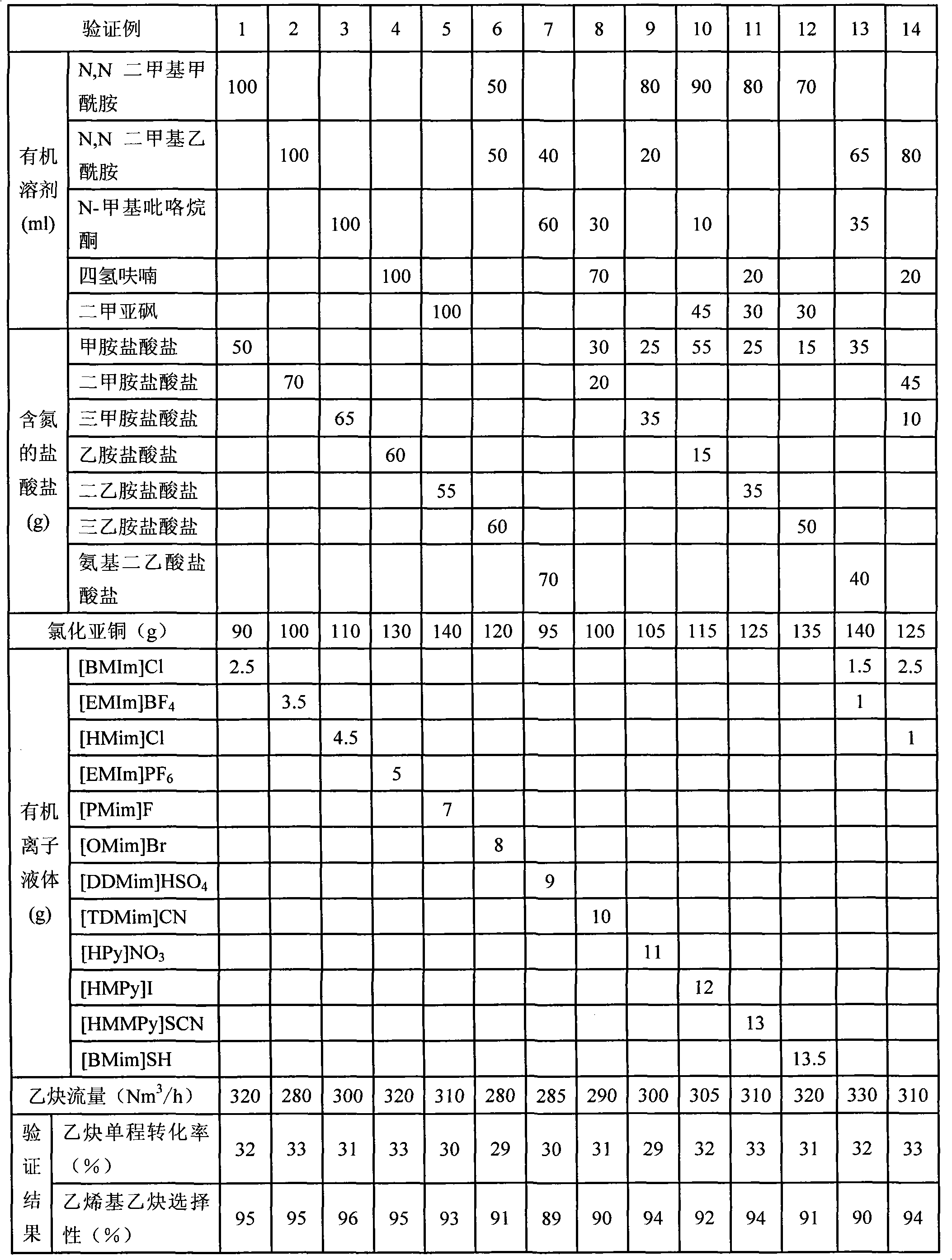

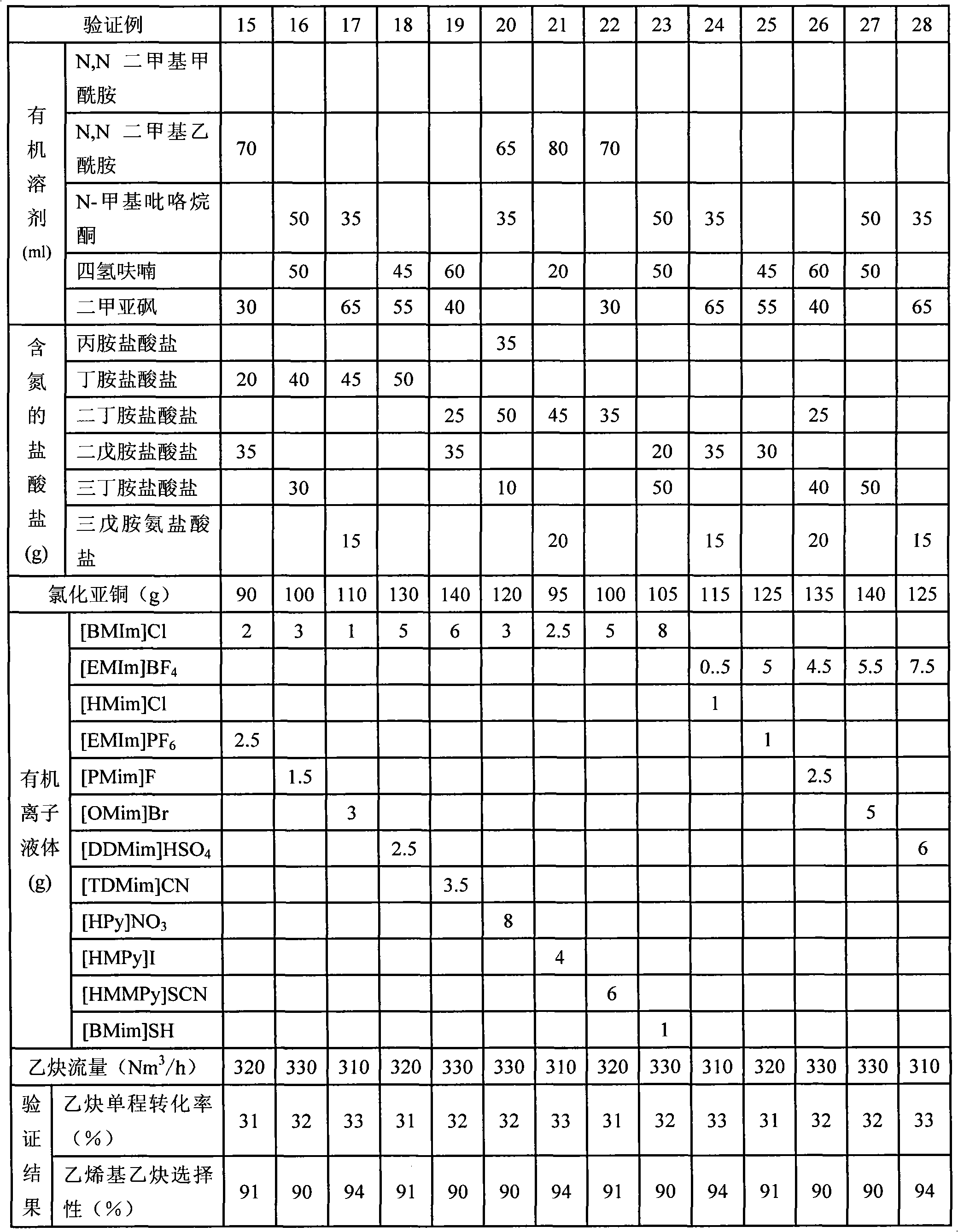

[0018] A catalyst for the preparation of vinyl acetylene includes cuprous chloride in its components. Also include in the catalyst of the present invention: organic solvent, nitrogen-containing hydrochloride and organic ionic liquid; Wherein, organic solvent: nitrogen-containing hydrochloride: cuprous chloride: organic ionic liquid=100mL: 50~70g: 90 ~140g: 2.5~13.5g;

[0019] The organic solvent used is one of N, N dimethylformamide, N, N dimethylacetamide, N-methylpyrrolidone, tetrahydrofuran, dimethyl sulfoxide, or a mixed solvent of two or more;

[0020] The nitrogen-containing hydrochloride used is one of the hydrochloride salts of primary amines, secondary amines and tertiary amines formed by alkyl, aryl or carboxylic acid alkyl directly connected to the central nitrogen atom, or a mixed mixture containing Nitrogen hydrochloride; Among them, primary amine hydrochloride is a compound formed by HCl after the hydrogen atom in the ammonia molecule is replaced by a hydrocarbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com