Catalyst for preparing light aromatic hydrocarbon by synthetic gas one-step process, and preparation method and application thereof

A light aromatic hydrocarbon and catalyst technology, which is applied in the field of high-efficiency dual-functional integrated catalysts, can solve the problems of catalyst activity temperature mismatch, achieve excellent high-temperature activity and stability, excellent shape selectivity, and improve single-pass conversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

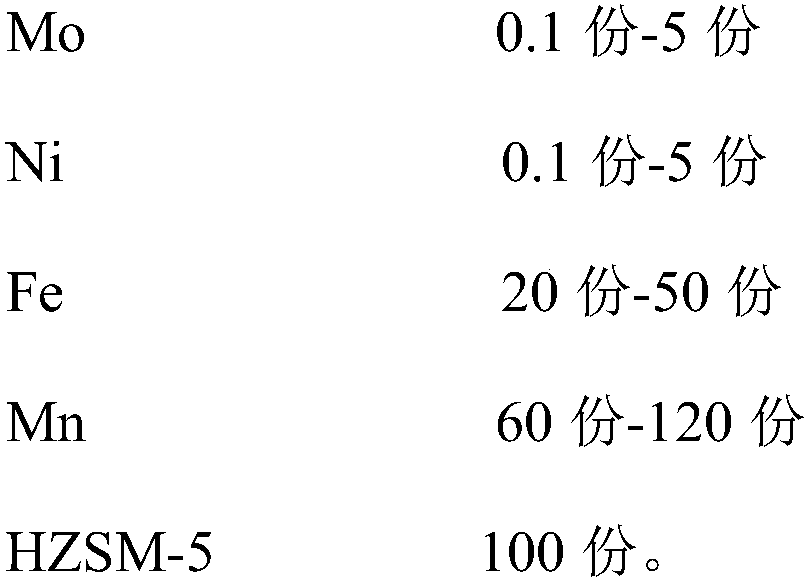

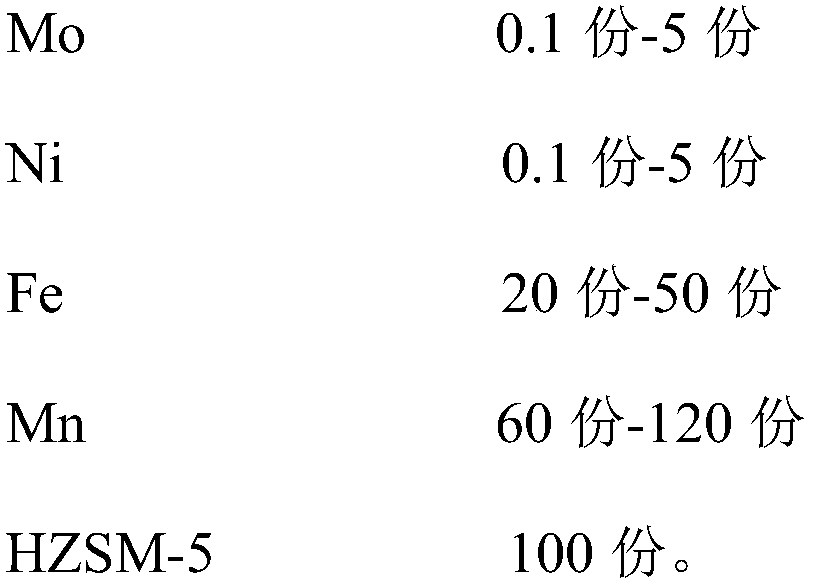

Method used

Image

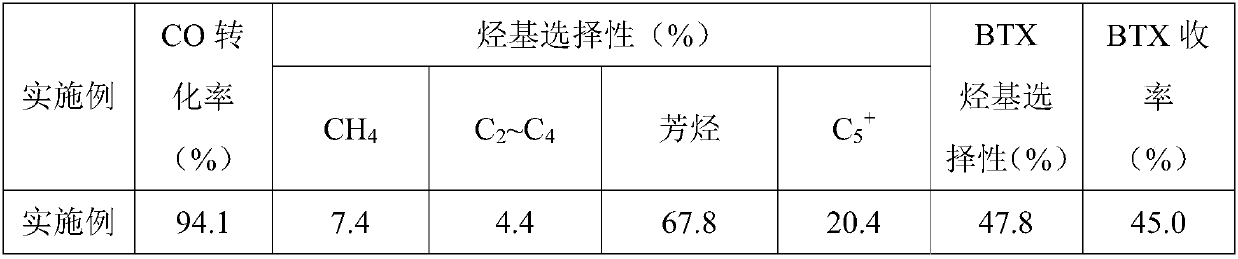

Examples

Embodiment 1

[0042] (1) Ferric nitrate and manganese nitrate are added to the distilled water that temperature is 65 ℃, be mixed with the mixed aqueous solution of metal nitrate, guarantee that the molar fraction of iron ion in the mixed aqueous solution of metal nitrate obtained is 1mol / L, the molar fraction of manganese ion 1.5mol / L;

[0043] (2) Mix 100mL ammonia water and 100mL deionized water to make an alkaline solution, add the alkaline solution and metal nitrate dropwise to 200ml deionized water, control the pH value to 8, and age for 2 hours. After suction filtration and washing, Dry at 120°C for 12h, finally move to a muffle furnace, calcinate at 350°C for 4h, and crush to below 200 mesh to obtain Fischer-Tropsch synthesis catalyst Fe 2 o 3 -MnO;

[0044] (3) Weigh a certain mass of (NH 4 ) 6 Mo 7 o 24 4H 2 O, prepare 25ml of ammonium molybdate solution, adopt the equal volume impregnation method, drop the ammonium molybdate solution onto the 5g ZSM-5 carrier, ensure that ...

Embodiment 2

[0049] (1) Ferric nitrate and manganese nitrate are added to the distilled water that temperature is 65 ℃, be mixed with the mixed aqueous solution of metal nitrate, guarantee that the molar fraction of iron ion in the mixed aqueous solution of metal nitrate obtained is 1mol / L, the molar fraction of manganese ion 1.5mol / L;

[0050] (2) Mix 100mL ammonia water and 100mL deionized water to make an alkaline solution, add the alkaline solution and metal nitrate dropwise to 200ml deionized water, control the pH value to 8, and age for 2 hours. After suction filtration and washing, Dry at 120°C for 12h, finally move to a muffle furnace, calcinate at 350°C for 4h, and crush to below 200 mesh to obtain Fischer-Tropsch synthesis catalyst Fe 2 o 3 -MnO;

[0051] (3) Weigh a certain mass of (NH 4 ) 6 Mo 7 o 24 4H 2 O, prepare 25ml of ammonium molybdate solution, adopt the equal volume impregnation method, drop the ammonium molybdate solution onto the 5g ZSM-5 carrier, ensure that ...

Embodiment 3

[0056] (1) Ferric nitrate and manganese nitrate are added to the distilled water that temperature is 65 ℃, be mixed with the mixed aqueous solution of metal nitrate, guarantee that the molar fraction of iron ion in the mixed aqueous solution of metal nitrate obtained is 1mol / L, the molar fraction of manganese ion 1.5mol / L;

[0057] (2) Mix 100mL ammonia water and 100mL deionized water to make an alkaline solution, add the alkaline solution and metal nitrate dropwise to 200ml deionized water, control the pH value to 9, and age for 2 hours. After suction filtration and washing, Dry at 120°C for 12h, finally move to a muffle furnace, calcinate at 350°C for 4h, and crush to below 200 mesh to obtain Fischer-Tropsch synthesis catalyst Fe 2 o 3 -MnO;

[0058] (3) Weigh a certain mass of (NH 4 )6Mo 7 o 24 4H 2 O, prepare 25ml of ammonium molybdate solution, adopt the equal volume impregnation method, drop the ammonium molybdate solution onto the 5g ZSM-5 carrier, ensure that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com