System for producing methanol by using coke oven gas

A technology for the production of methanol and coke oven gas, which is applied in the preparation/separation of ammonia, the preparation of hydroxyl compounds, and the preparation of organic compounds. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

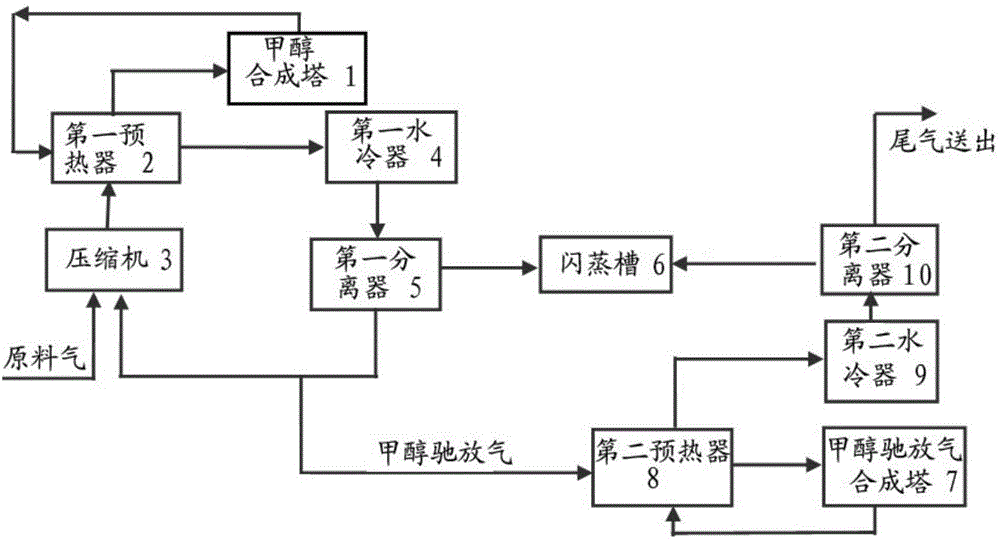

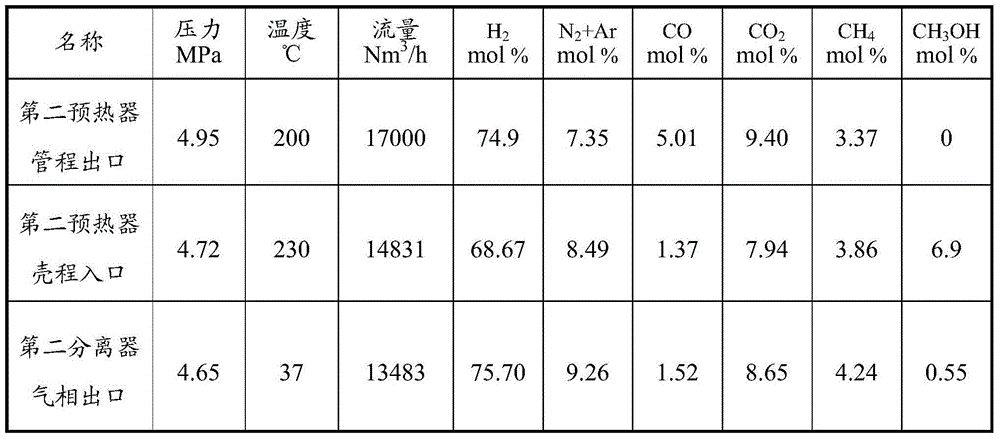

[0044] Purge methanol into figure 1 Methanol purge gas synthesis unit shown in. The methanol purge gas synthesis tower 7 selects a GC type water-cooled plate synthesis reactor produced by Nanjing Guochang Company, and the filling catalyst is a C-307 type catalyst of Nanhua Research Institute. In the second preheater 8, the methanol purge gas inlet pipe side, and the product gas from the methanol purge gas synthesis tower enters the shell side. The logistics parameters of each position in the system are shown in Table 1.

[0045] Table 1

[0046]

[0047] It can be seen from Table 1 that by adopting the method of the present invention, the total carbon conversion rate of coke oven gas can be increased from 92% to more than 98%, achieving the purpose of energy saving and emission reduction. At the same time, the invention provides a methanol purge gas synthesis system that can share the burden of the original coke oven gas to methanol system in the normal production of coke oven g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com