Sintering quicklime digestion device and method

A technology for quicklime and raw materials, applied in the field of sintering process, can solve the problems of easy blockage of the device, troublesome operation, difficult to implement, etc., and achieve the effect of uniform distribution of CaO and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

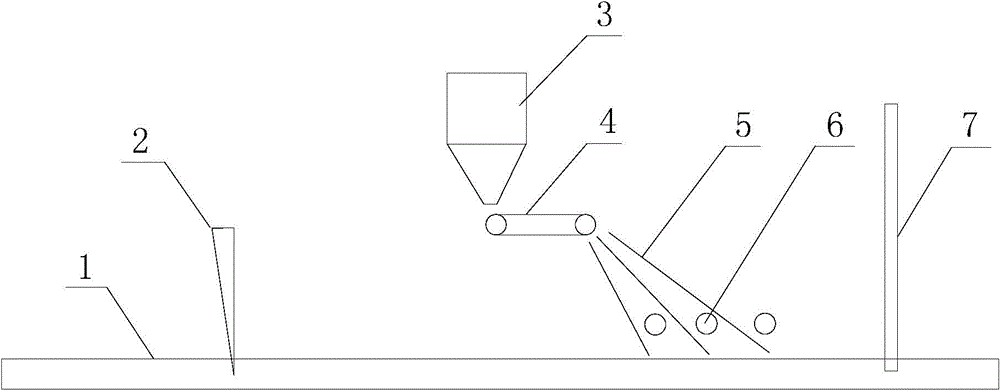

[0021] On the basis of the original quicklime digestion device, that is, the raw material belt 1, the scraping groove plate 2 above, the rear flat material plate 6, and the quicklime disc distributor 3 and the discharge belt 4 below it, a quicklime flow divider is added to separate the quicklime flow. The device is composed of 3 distribution plates 5, which are arranged in three layers. The lower part of each distribution plate 5 is provided with a digestive water pipe 7 with the water outlet facing upward. The 3 distribution plates 5 are all made of 800mm wide and 10mm thick steel plates are welded, and the width is the same as that of the discharge belt 4 .

[0022] Scrape the raw material on the raw material belt 1 with the groove scraping plate 2, and then fill it with the quicklime disc distributor 3 and the discharge belt 4, and the filled quicklime is evenly distributed on the raw material after scraping the groove through 3 distribution plates 5 On the surface, the dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com