Integrated coal gasification fuel cell system with CO2 capture

A fuel cell system and integrated coal gasification technology, which can be used in fuel cells, fuel cell additives, fuel cell heat exchange, etc. To achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

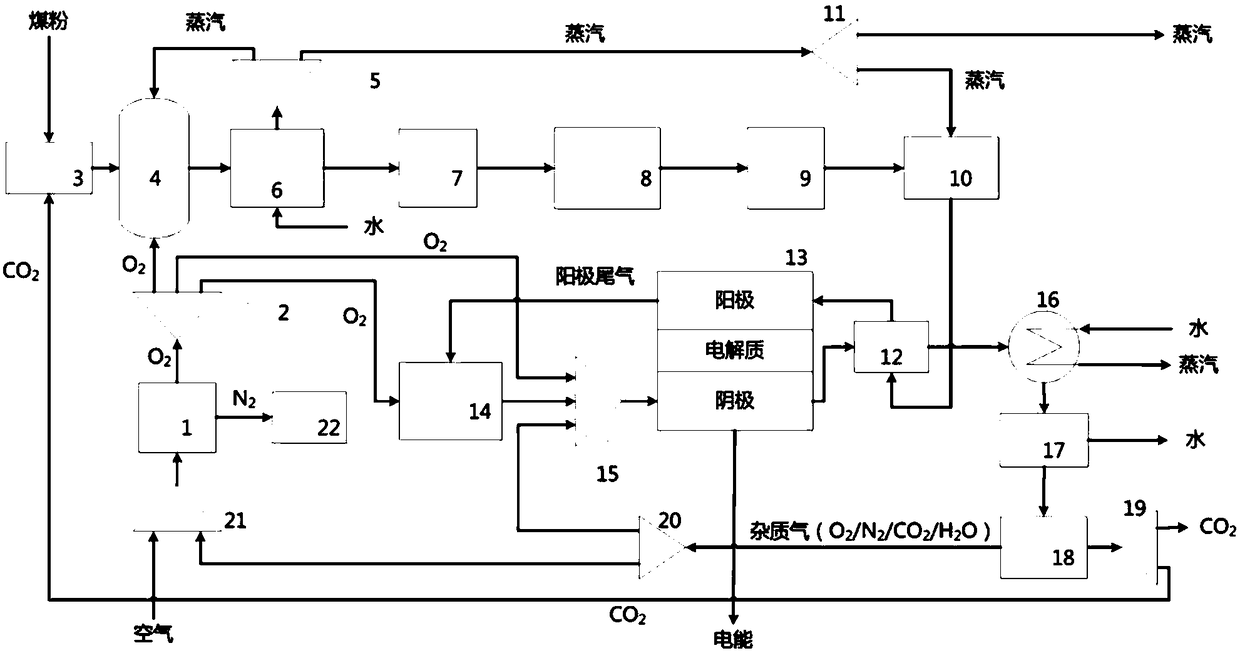

[0045] coal, steam, oxygen and CO 2 Pass it into the gasifier 4 to produce syngas, the temperature of which is 1200°C, and the composition is CO ≈ 67%, H 2 ≈25%, CO 2 ≈7%, the rest is N 2 、H 2 S, COS, CH 4 and other impurities. The synthesis gas first passes through the waste heat recovery device 6 for heat exchange, the temperature is lowered to below 200°C, and then passes into the dust removal device 7, so that the particulate matter content is lower than 10mg / Nm 3 ; then pass into the water vapor shift device 8, the concentration of CO in the gas is reduced to below 10%; then pass into the desulfurization device 9, so that the H 2 The concentrations of S and COS are lower than 1ppm; they are passed into the fuel humidifier 10, and part of the steam generated by the waste heat recovery device 6 is also passed into the fuel humidifier, so that the content of H2O in the syngas is greater than 10%. The syngas is heated to above 500°C through the heat exchanger 12, and th...

Embodiment example 2

[0047] coal, steam, oxygen and CO 2 Pass it into the gasifier 4 to produce syngas, the temperature of which is 1200°C, and the composition is CO ≈ 67%, H 2 ≈25%, CO 2 ≈7%, the rest is N 2 、H 2 S, COS, CH 4 and other impurities. The synthesis gas first passes through the waste heat recovery device 6 for heat exchange, the temperature is lowered to below 200°C, and then passes into the dust removal device 7, so that the particulate matter content is lower than 10mg / Nm 3 ; then pass into the water vapor shift device 8, the concentration of CO in the gas is reduced to below 10%; then pass into the desulfurization device 9, so that the H 2 The concentrations of S and COS are lower than 1ppm; they are passed into the fuel humidifier 10, and part of the steam generated by the waste heat recovery device 6 is also passed into the fuel humidifier, so that the content of H2O in the syngas is greater than 10%. The synthesis gas is heated to above 600°C through the heat exchanger 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com