Device and method for directly preparing methane based on coal chemical chain gasification

A chemical chain and coal methane technology, applied in chemical instruments and methods, organic chemistry, carbon compound catalysts, etc., can solve the problems of complex catalyst recovery process, slow reaction speed, low carbon conversion rate, etc., and achieve low cost and high production volume Less carbon dioxide and high carbon utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

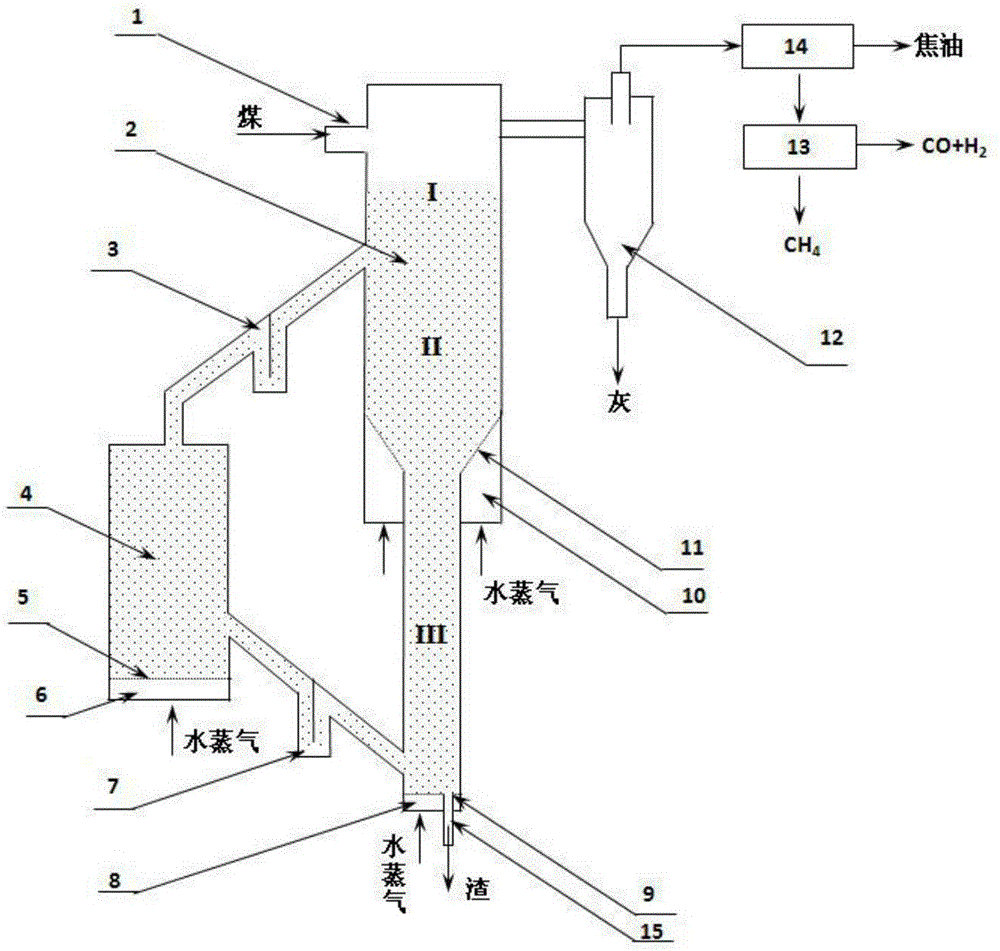

[0033] The main structure of the device for directly producing methane based on coal chemical looping gasification described in this embodiment includes a solid feeder 1, a chemical looping gasification reactor 2, a regeneration reactor 4, a first flow control device 3, and a second flow control device. Device 7, first gas pre-distribution chamber 6, second gas pre-distribution chamber 8, third gas pre-distribution chamber 10, first gas distribution plate 5, second gas distribution plate 9, third gas distribution plate 11, cyclone separation device 12, gas separation unit 13, gas purification unit 14, and slag outlet 15; the diameter ratio of the upper and lower parts of the chemical looping gasification reactor 2 is 1.2 to 5, and the lower part of the chemical looping gasification reactor 2 is the hydrogen generation section III , the flow pattern is a fast fluidized bed flow pattern, and the fluidized medium is water vapor or carbon dioxide; the upper part is respectively fro...

Embodiment 2

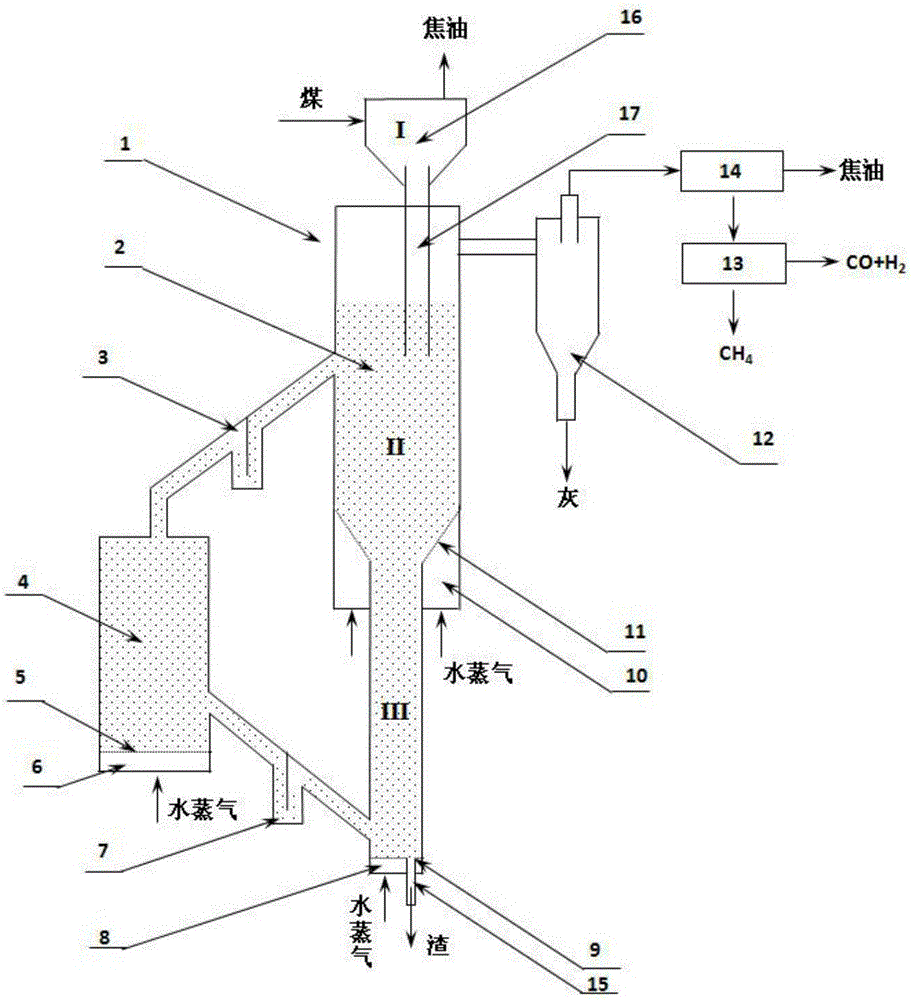

[0057] On the basis of Example 1, this embodiment adds a separate solid pyrolysis device 16 and dipleg 17, and the solid pyrolysis device 16 communicates with the chemical looping gasification reactor 2 through the dipleg 17. When preparing methane, first Send coal powder particles of 0.1 to 1mm into the solid pyrolysis device 16 for coal pyrolysis reaction to obtain coal tar, and the generated semi-coke enters the coal chemical looping gasification reactor 2 through the dipleg 17, and the remaining steps are the same as in Example 1 , the device and method can realize the graded utilization of coal and the graded utilization of heat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com