Carbon brake disc negative pressure directional flow outward thermal gradient chemical gas phase penetration process and apparatus

A carbon brake disc, directional flow technology, applied in mechanical equipment, gaseous chemical plating, coating and other directions, can solve the problems of affecting the uniformity of density, low carbon deposition efficiency, easy crusting on the surface, etc., to reduce equipment power consumption, widening the dense belt of deposited carbon, and good friction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

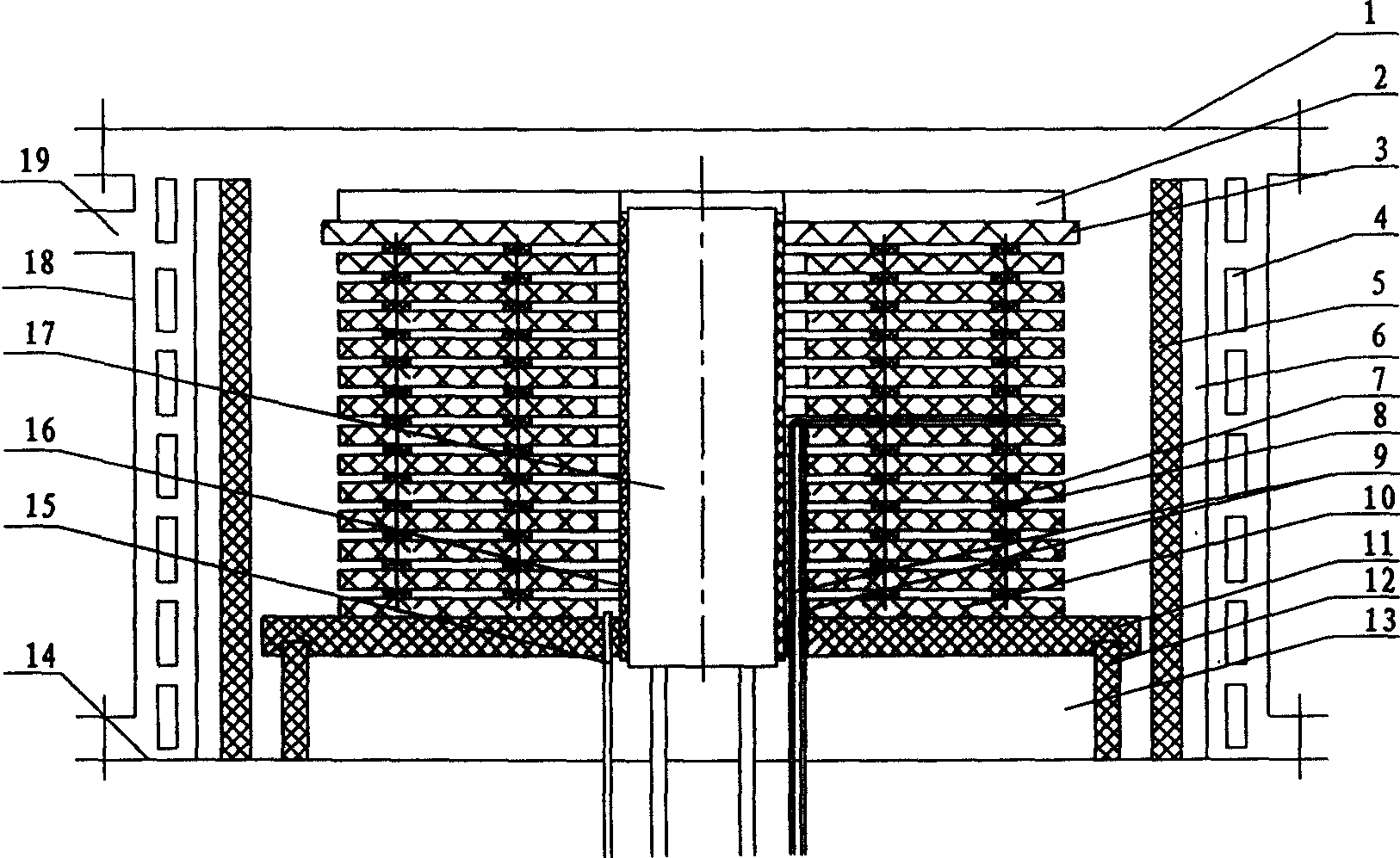

[0024] Such as figure 1 As shown, the directional flow external thermal gradient CVI equipment designed by the present invention consists of a furnace cover 1, a graphite cover plate 3 and an insulating felt 2 on it, a graphite heating element 5 and an insulating felt 6 located outside it, and a Copper induction coil 4, carbon plate prefabricated body 7, graphite gasket 8, thermocouple 9, insulation layer 10, graphite pallet 11, graphite bracket 12, insulation felt 13, furnace bottom 14, air intake pipe 15, insulation felt 16, The inner water cooling device 17, the outer furnace body 18, and the air extraction hole 19 are formed. The inner water cooling device 17 is arranged on the bottom of the furnace 14, and is inserted into the inner diameter of the charcoal disc prefabricated body 7, and is provided with a certain distance from the charcoal disc prefabricated body 7. The water cooling device 17 is a water pipe for internal cooling water, and the temperature difference bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com