Three-layer gas supply heating self-conversion tar gasifier

A technology of tar gasification and gas supply, which is applied in the direction of gasification process, petroleum industry, and manufacture of combustible gas. It can solve the problems of gas utilization equipment damage, lower gasification efficiency, and easy generation of carbon black, so as to reduce tar capture. and separation device, optimized gasification process, good effect of gasification state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

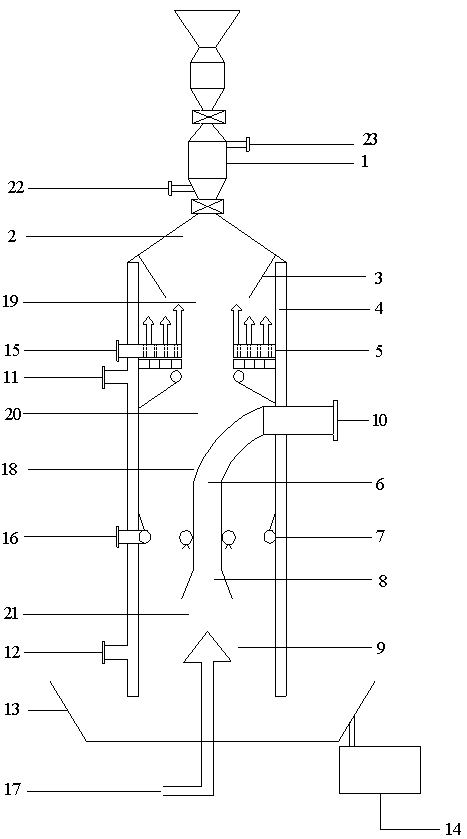

[0028] as attached figure 1 As shown, implement a kind of three-layer gas supply heating self-reforming tar gasifier provided above of the present invention, the structural design embodiment of this gasifier is as follows:

[0029]A three-layer gas-supply heating self-reforming tar gasification furnace is composed of a double-charging bell coal feeder, a furnace body, a gasification agent distributor, a slag discharge structure and a gas supply system.

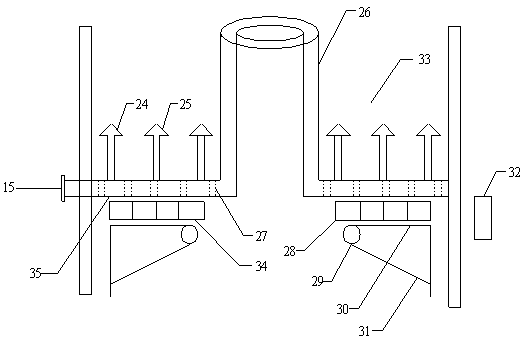

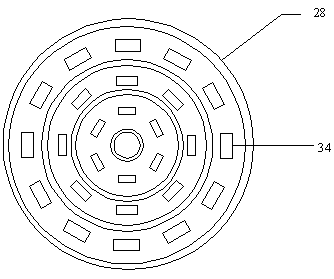

[0030] Double bell stoker 1 is a series-sealed double bell stoker located on the top of the furnace body. The lower part of the left side is provided with a cleaning air inlet 22, and the upper part of the right side is provided with an exhaust port 23; the furnace body 2 is a water-jacketed furnace body , the water jacket water inlet 11 is located at the upper part of the water jacket furnace body, the water jacket water outlet 12 is located at the lower part of the water jacket furnace body, and communicates with the steam d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com