Furnace body cooling device of coal gasifier

A cooling device and coal gasification technology, applied in the field of coal gasification, can solve problems such as rising temperature of the water jacket in the combustion zone, easy blockage of the gas outlet, serious slag accumulation on the furnace top and furnace wall, etc., so as to thicken the coal seam and reduce cleaning Slag workload and ignition operation are easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

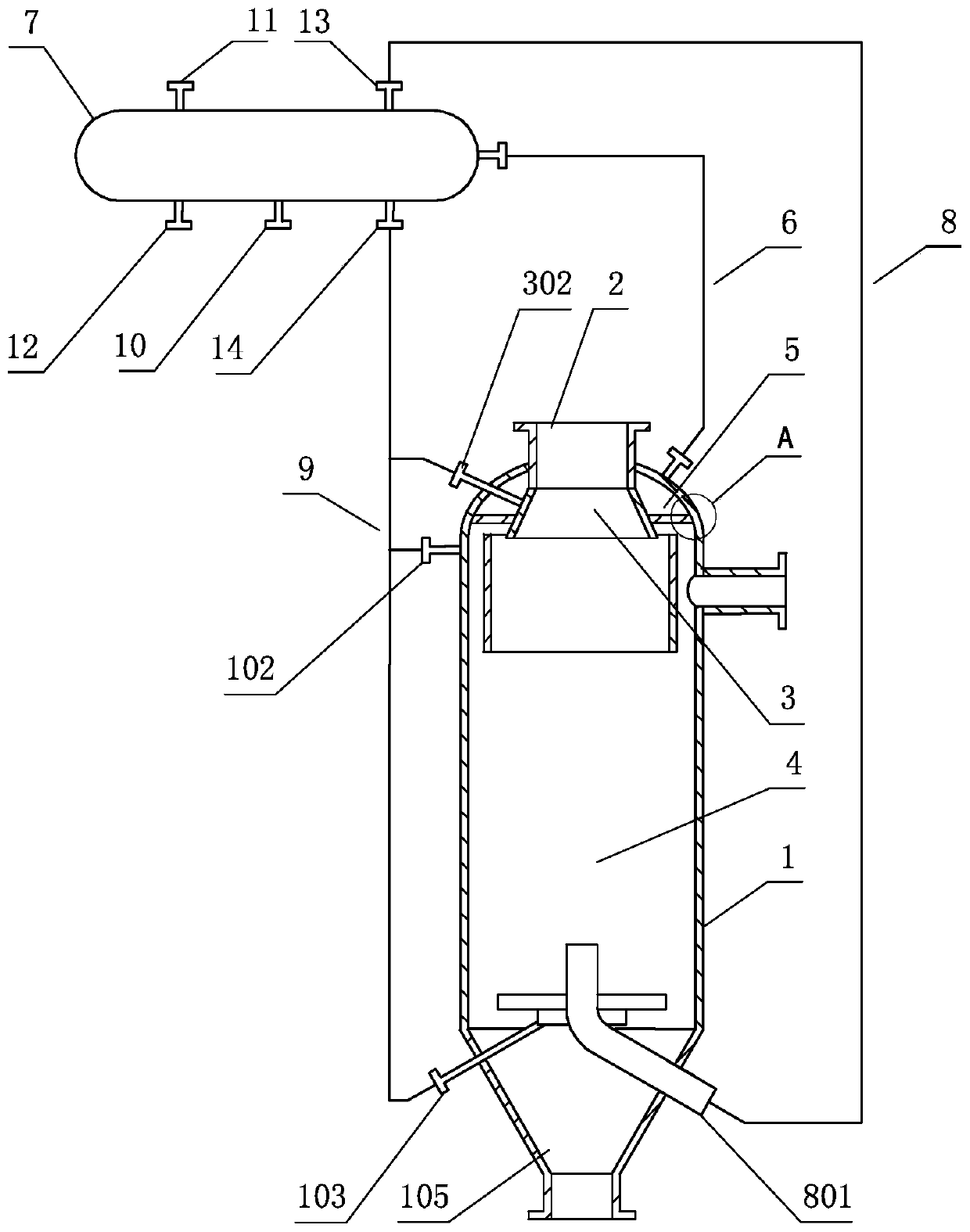

[0020] see figure 1 , the furnace body cooling device of the coal gasification furnace of the present invention comprises a furnace body 1 for gasifying raw coal, a raw coal inlet pipe section 2 is arranged on the top of the furnace body, and an ash outlet 105 is arranged at the bottom of the furnace body, and the The gasification reaction furnace 4 is arranged in the middle part of the furnace body; the bottom end of the raw coal inlet pipe section is connected to the conical tubular coal distribution section 3, and the coal distribution section cooling water jacket device is arranged on the conical tubular coal distribution section. The first water supply pipe joint 302 is arranged on one side of the coal section cooling water jacket device, and the steam outlet pipe of the coal distribution section is arranged on the other side; the furnace body cooling water jacket device is arranged on the outer wall of the furnace body, and the furnace body cooling water jacket device Th...

Embodiment 2

[0029] This embodiment is an improvement made on the basis of Embodiment 1. For the same parts in this embodiment as Embodiment 1, please refer to the content disclosed in Embodiment 1 for understanding, and no repeated description is made here; the disclosure in Embodiment 1 The content should also be taken as the content disclosed in this embodiment.

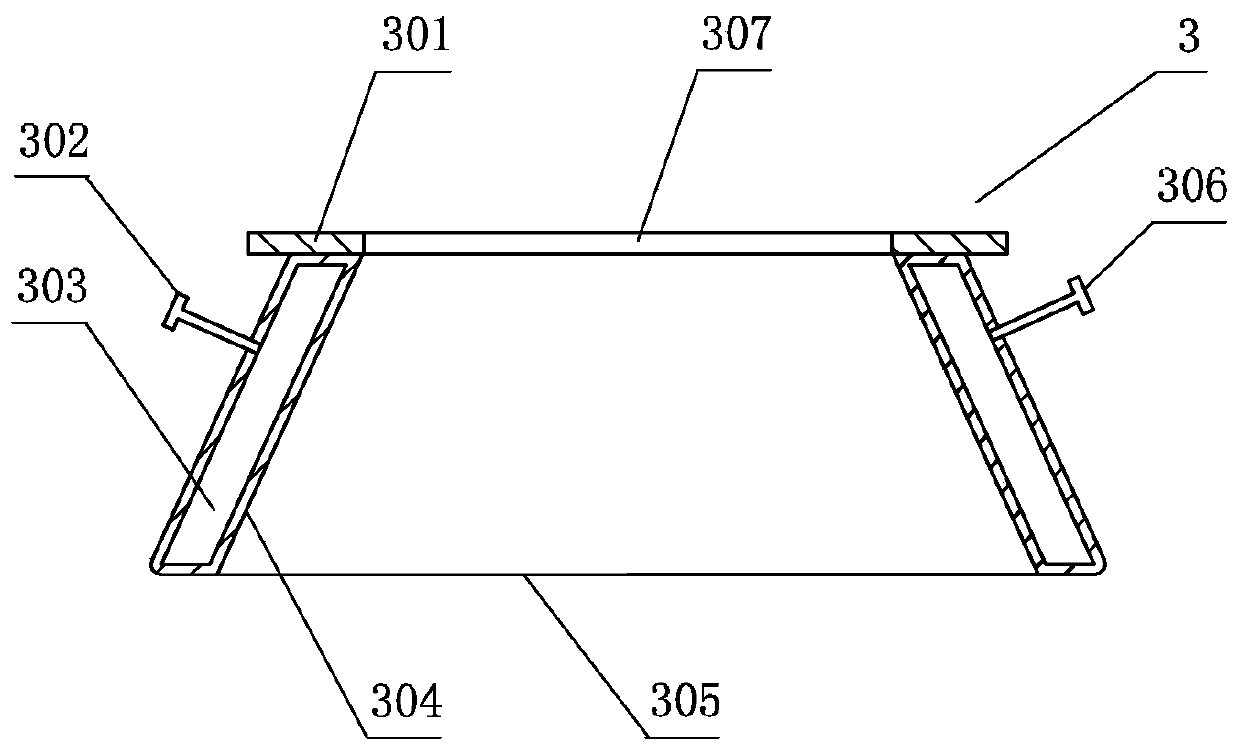

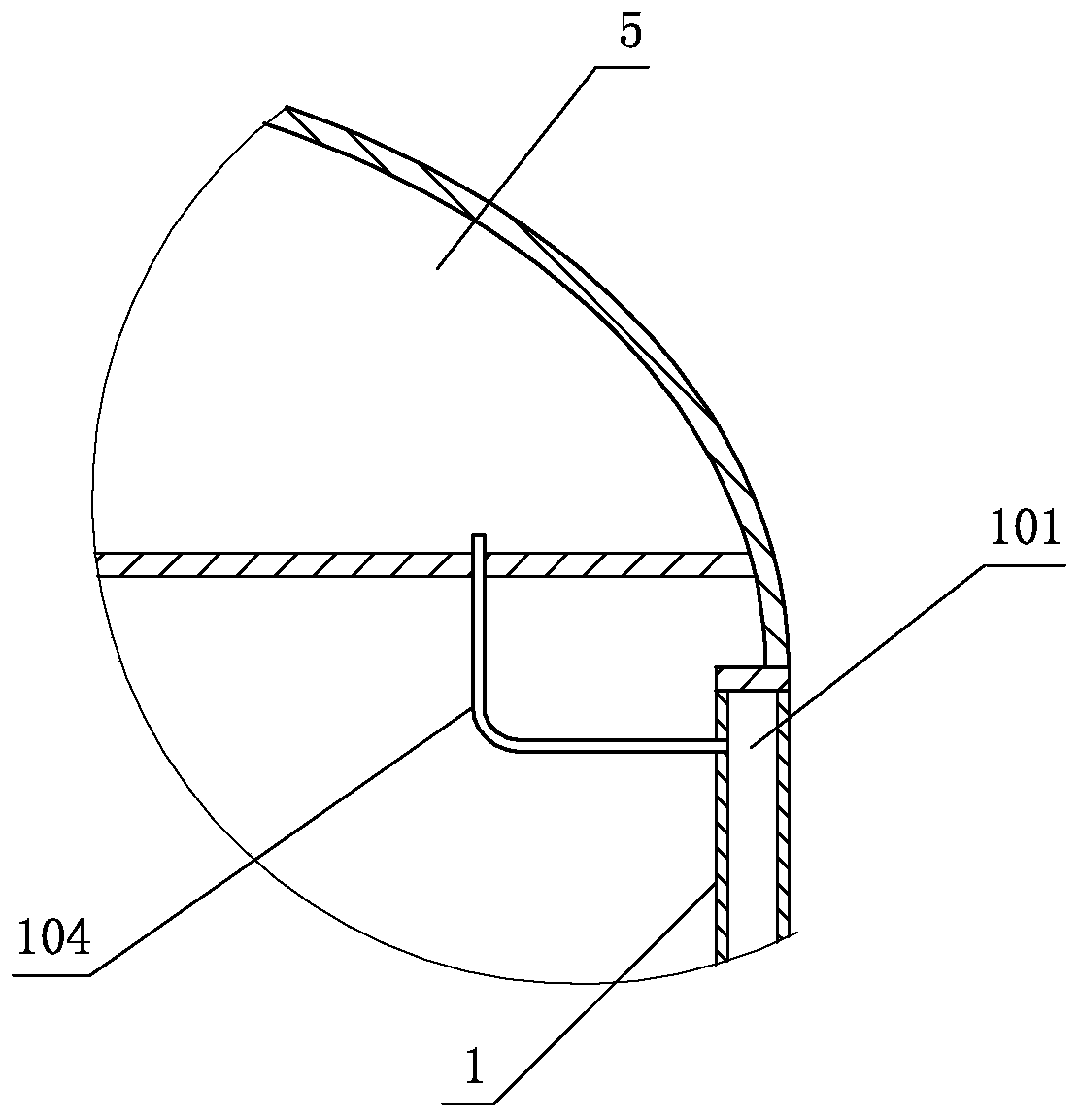

[0030] see Figure 4 , Figure 5 ( Figure 4 , Figure 5 It is a schematic diagram of the outer cylinder wall of the water jacket of the furnace body cooling water jacket device according to the circumference). In this embodiment, the furnace body cooling water jacket device includes the outer cylinder wall of the water jacket, the inner cylinder wall of the water jacket, and the water supply pipe joint (No. Two water supply pipe joints 102), steam outlet pipe (boiler steam outlet pipe 104); the inner cylinder wall of the water jacket is a part of the outer wall of the furnace; the outer cylinder wall of the water jacket an...

Embodiment 3

[0035] This embodiment is an improvement made on the basis of Embodiment 1 and Embodiment 2. For the same parts as Embodiment 1 and Embodiment 2 in this embodiment, please refer to the content disclosed in the previous embodiment for understanding, and no further description is made here. repeat description;

[0036] see Figure 6 ( Figure 6 It is a schematic diagram of the outer cylinder wall of the water jacket of the furnace cooling water jacket device according to the circumference). In this embodiment, the preferred swinging bubble sweeper includes a plurality of cylindrical floating bodies, and a plurality of defoaming needles are arranged on the cylindrical floating bodies. Each two cylindrical floating bodies are connected by cable chains in an up-and-down structure to form a cylindrical floating body chain, and the bottom end of the cylindrical floating body chain is fixed on the bottom of the furnace body cooling water jacket device. The cylindrical floating body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com