Differential rotating bed continuous feeding biomass gasification furnace

A technology of rotating bed and biomass, applied in the field of energy science, can solve the problems of reduced gasification intensity, partial burn-through of gasifier, uneven blanking, etc. The effect of gasification intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

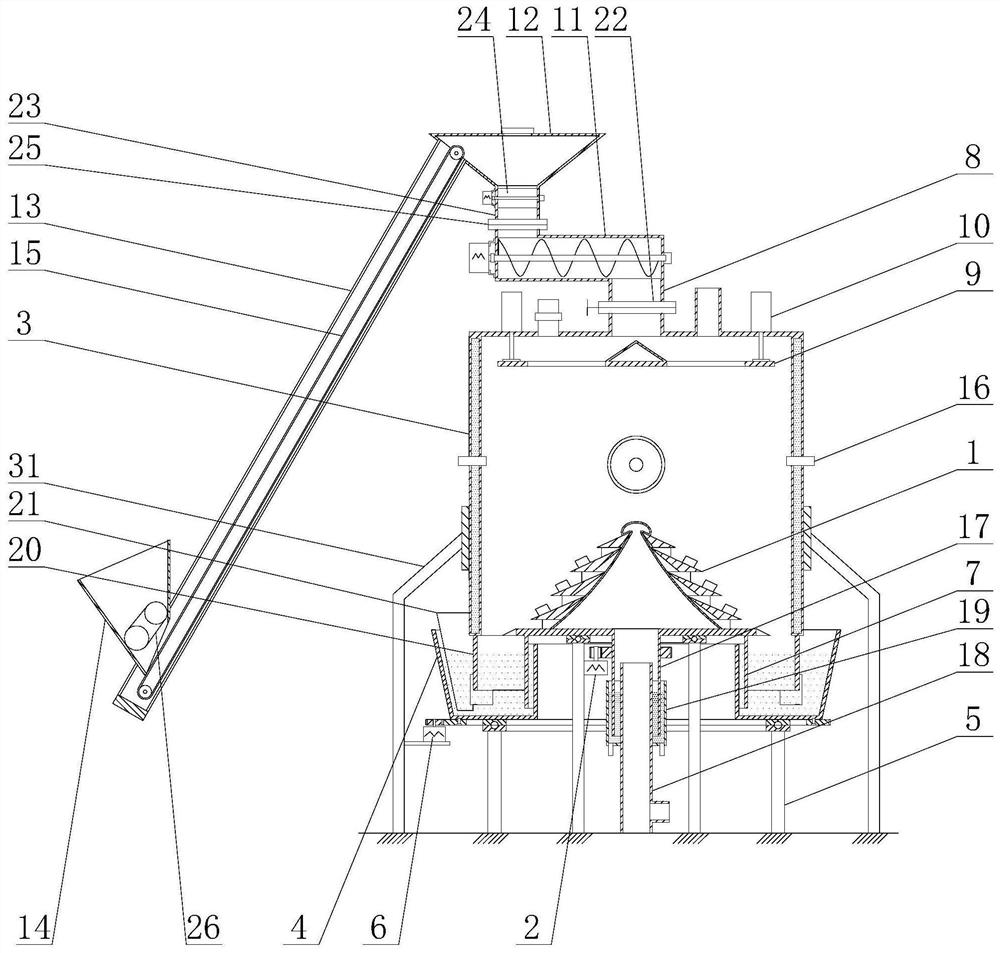

[0022] Example: as attached figure 1 As shown, the present invention is a differential rotary bed continuous feed biomass gasifier, including a furnace body, the furnace body is provided with a wind distribution pan 1, and a wind pan driving device 2 for driving the wind distribution pan 1 to rotate , the lower side of the air distribution plate 1 is provided with an air distribution plate support, and the top of the air distribution plate support is provided with a base for supporting the air distribution plate 1, and the base is rotatably connected with the air distribution plate support through a turntable bearing, and the air plate drive device 2 can be The electric motor is directly adopted, and the wind disk driving device 2 is installed on the air distribution disk support. Preferably, in order to ensure the airtightness of the air inlet of the air distribution panel, the middle part of the bottom of the air distribution panel 1 is provided with a second water seal 17, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com