Gasification-flash pyrolysis graded utilization method for biomass and low-rank coal

A technology of biomass and coal gasification, which is applied in the direction of gasification process, manufacture of combustible gas, petroleum industry, etc., can solve the problems of increasing raw material cost, lower tar yield, long residence time, etc., to reduce production cost and improve carbon The effect of high conversion rate and energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

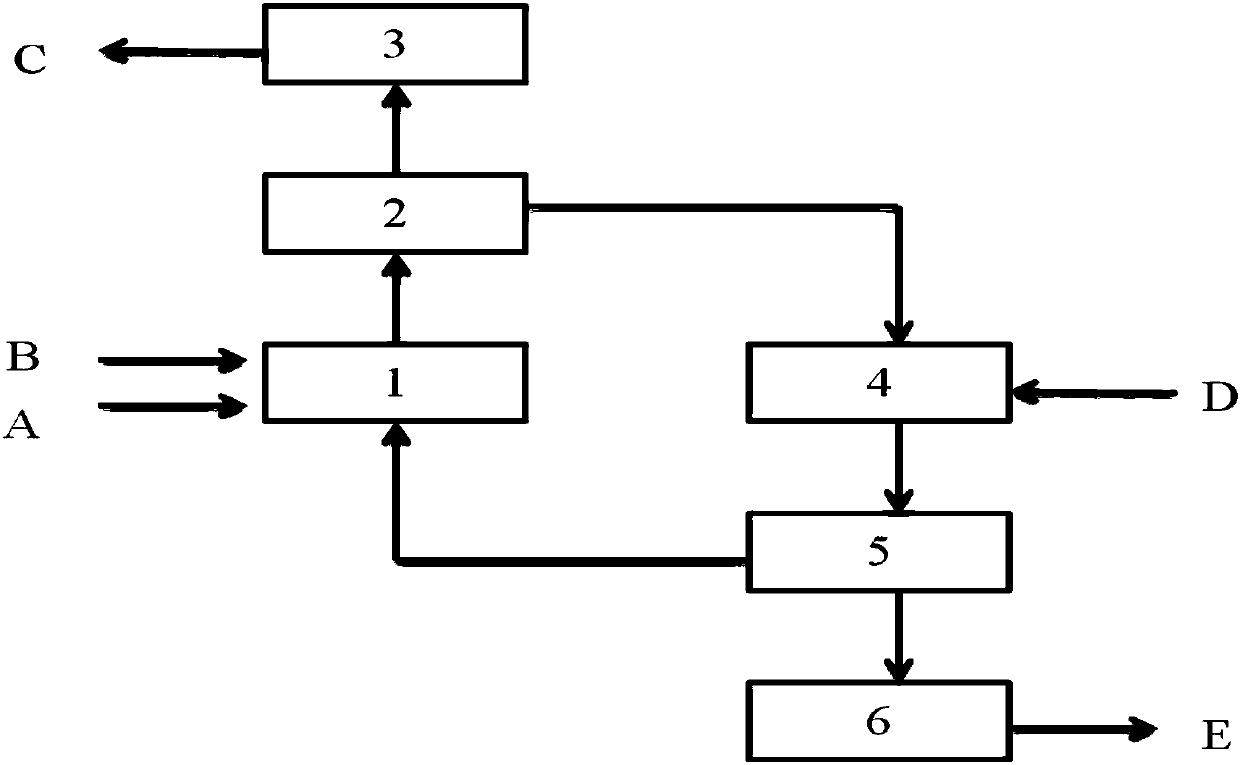

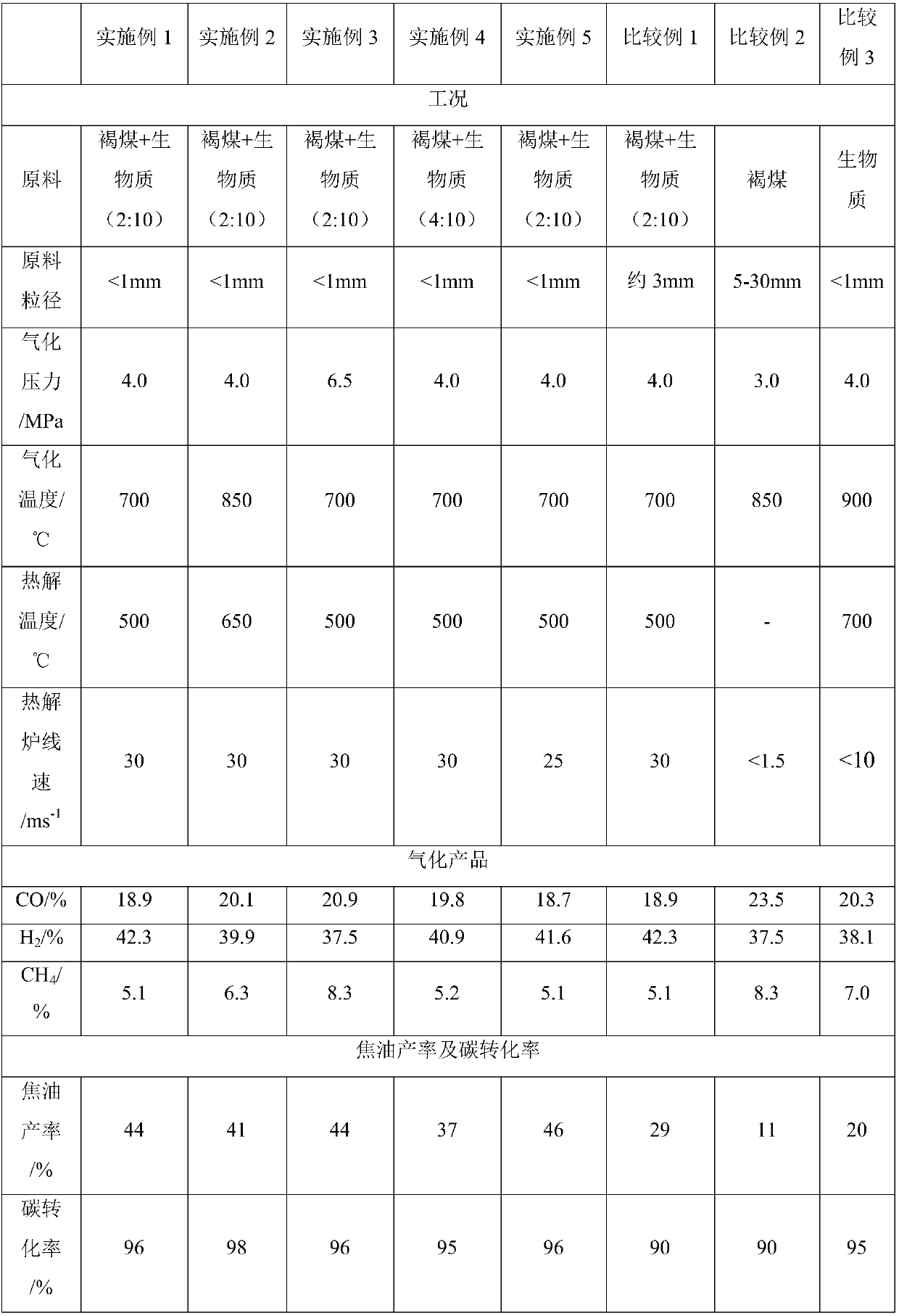

[0028] The mixture of biomass and lignite with a ratio of 10:2 is sent to the pyrolysis furnace 1 through the feeding device, and mixed with the high-temperature circulating semi-coke particles from the gasifier 4 and separated by the second gas-solid separation device 5 , the mixture of raw biomass and low-rank inferior coal (particle size 2 , CO and CH 4 The contents were 42.3%, 18.9% and 5.1%, respectively. The high-temperature circulating semi-coke is separated by the second gas-solid separation device 5 and then sent to the pyrolysis furnace 1 to continue the pyrolysis reaction with the mixture of raw biomass and coal. There are synergistic effects in the reactions, and the carbon conversion rate of the whole cyclic reaction system reaches 96%.

Embodiment 2

[0030]The mixture of biomass and lignite with a ratio of 10:2 is sent to the pyrolysis furnace 1 through the feeding device, and mixed with the high-temperature circulating semi-coke particles from the gasifier 4 and separated by the second gas-solid separation device 5 , the mixture of raw biomass and low-rank inferior coal (particle size 2 , CO and CH 4 The contents were 39.9%, 20.1% and 6.3%, respectively. The high-temperature circulating semi-coke is separated by the second gas-solid separation device 5 and then sent to the pyrolysis furnace 1 to continue the pyrolysis reaction with the mixture of raw biomass and coal. There are synergistic effects in the reactions, and the carbon conversion rate of the whole cyclic reaction system reaches 98%.

Embodiment 3

[0032] The mixture of biomass and lignite with a ratio of 10:2 is sent to the pyrolysis furnace 1 through the feeding device, and mixed with the high-temperature circulating semi-coke particles from the gasifier 4 and separated by the second gas-solid separation device 5 , the mixture of raw biomass and low-rank inferior coal (particle size 2 , CO and CH 4 The contents were 37.5%, 20.9% and 8.3%, respectively. The high-temperature circulating semi-coke is separated by the second gas-solid separation device 5 and then sent to the pyrolysis furnace 1 to continue the pyrolysis reaction with the mixture of raw biomass and coal. There are synergistic effects in the reactions, and the carbon conversion rate of the whole cyclic reaction system reaches 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com