Coke-containing solid particle two-stage gasification method and device

A technology of solid particles and gasification devices, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. The effect of continuous gasification

Inactive Publication Date: 2016-06-29

PETROCHINA CO LTD

View PDF12 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Single-bed gasification is commonly used in the above technologies. Gasification at lower severity requires a larger gasification reactor and a larg

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

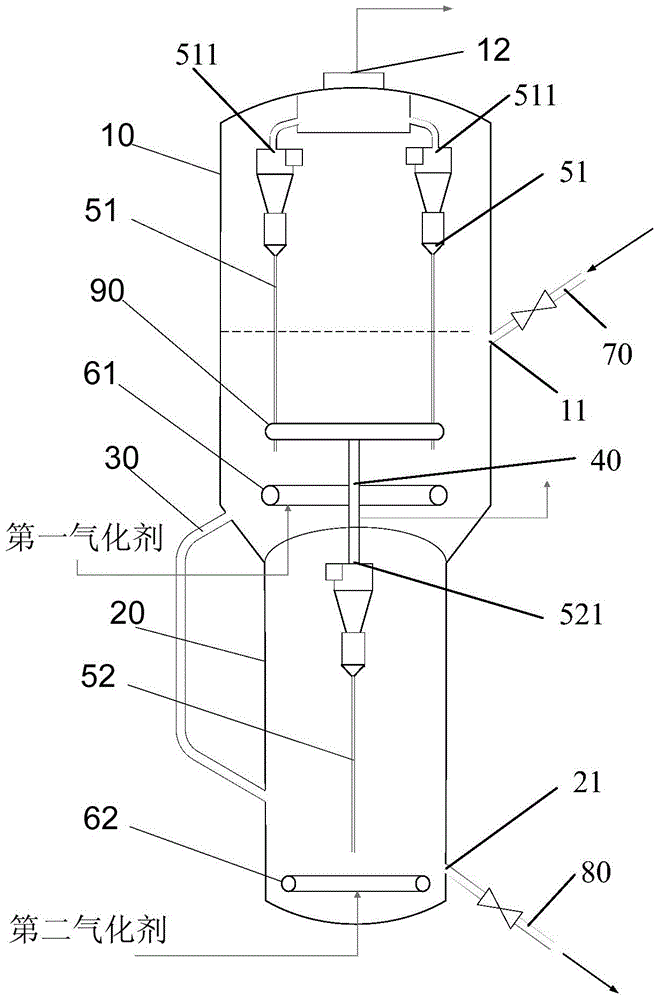

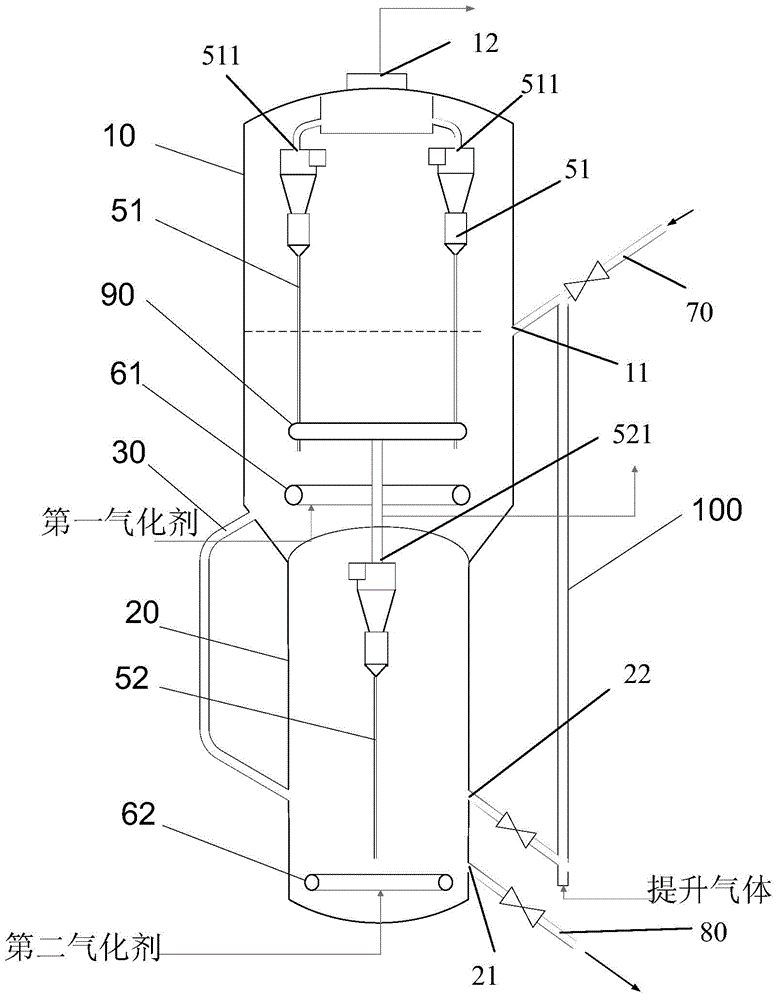

The invention relates to a two-stage gasification method and device for coke-containing solid particles, which adopts two-stage fluidized bed reactors connected in series to realize continuous gasification, including the first-stage gasification reaction at a temperature of 800-900°C; Solid separation to obtain the first synthesis gas product and the first separated solid particles; the separated first solid particles go down to the second fluidized bed reactor through external circulation to undergo the second stage gasification reaction at 900-1000°C; Solid separation to obtain the second synthesis gas product and separated second solid particles; when the second synthesis gas product is drawn out to the outside world, part of it is introduced into the first fluidized bed reactor, or all of it is drawn out to the outside world, and the separated second solid The particles are continuously removed from the second fluidized bed reactor. The implementation of the two-stage series gasification method proposed by the invention can reduce the size of the gasification reactor, reduce investment, and produce gas products with different calorific values to meet the different requirements of refineries.

Description

technical field [0001] The invention relates to a petrochemical process, in particular to a process method for producing synthesis gas by continuous gasification of coke-containing solid particles and a device for realizing the continuous gasification of coke-containing solid particles to produce synthesis gas. Background technique [0002] In the process of catalytic cracking and thermal conversion of heavy oil, the use of fluidized bed reactor is a very important direction, such as fluidized catalytic cracking, fluidized coking and so on. In this type of process, fluidized solid particles, that is, catalysts or heat carriers, will generate carbon deposits on the surface during the reaction. If there is a large amount of carbon deposits, the effect of solid particles may be affected, and the coke needs to be burned and removed. Combustion regeneration of coke-containing solid particles is not limited to oil refining process, and it is often involved in fluidized bed reactor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10J3/56C10J3/72C10J3/84

Inventor 张兆前白跃华周华群乔明彭博施梁川李超

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com