External heating water gas gasification method

A water gas and external heat technology, applied in the field of coal gas production, can solve the problems of complex process pipeline, low production efficiency, low production intensity, etc., and achieve the effects of high hydrogen content, improved production efficiency and reasonable ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

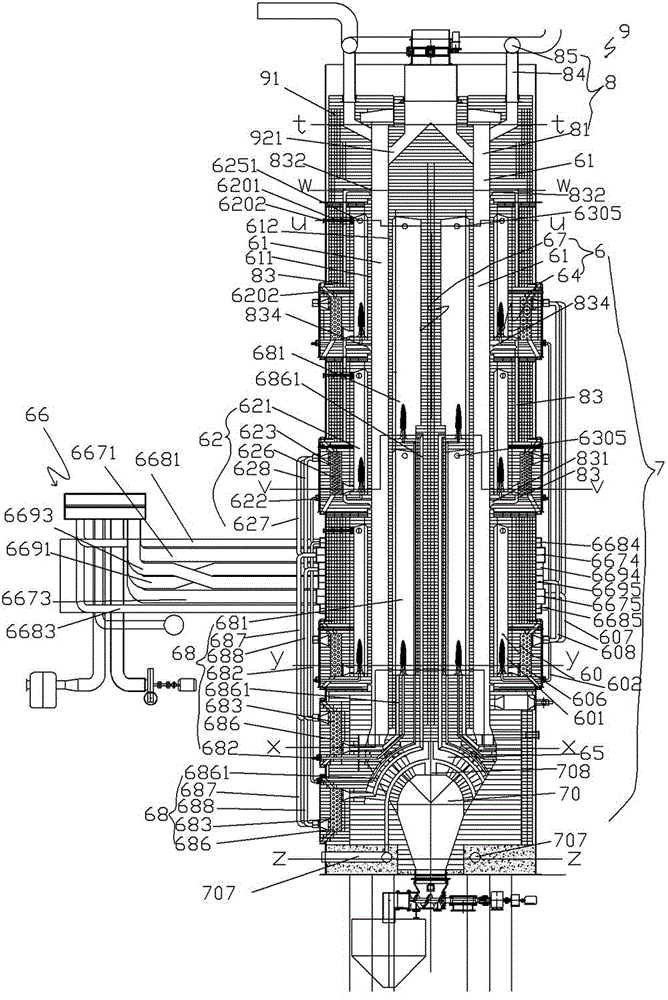

[0041] The specific embodiments of the continuous external heating type water gas gasification integrated process of the present invention are mainly described in detail below.

[0042] Part I Low-rank coal particle size control

[0043] The low-rank coal (lignite) is pyrolyzed to obtain smokeless, anhydrous, low ash, and highly active anthracite with a particle size of 10-50 mm as the raw material for water gas gasification. Within this particle size range, the anthracite raw material water gas reacts more Sufficient, but this does not constitute a restriction on the low-rank coal (lignite) required by the present invention. The present invention is also applicable to water-gas reaction with anthracite or coke.

[0044] The second part of preheating smokeless charcoal

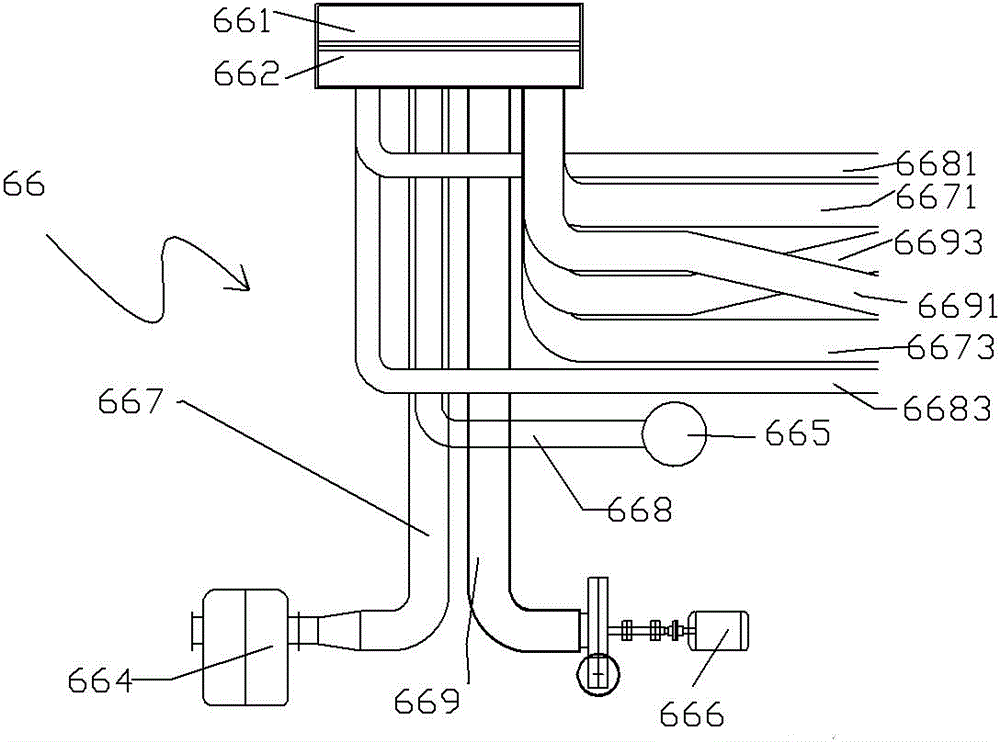

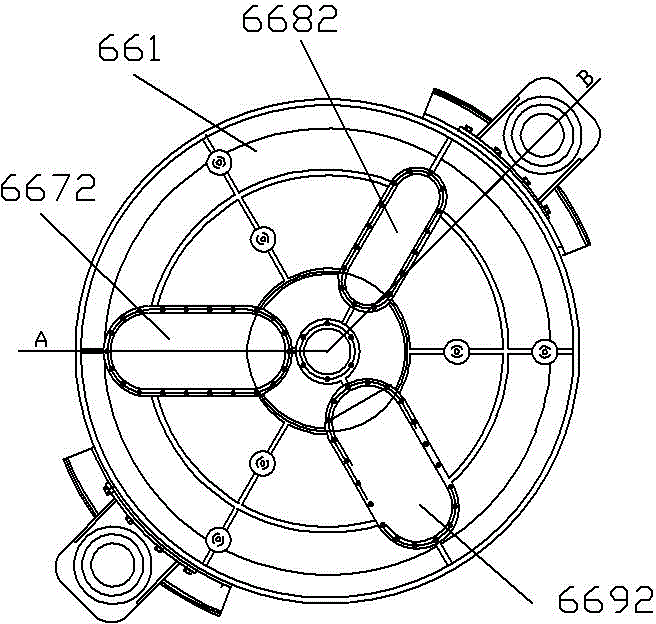

[0045] Such as Figure 19 , Figure 16 As shown: the preheating bin 1 includes a shell 11, a hot gas heat exchanger 13, and a lower silo 14; a silo 111 for preheating smokeless carbon is formed in the shell 11, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com