Novel gas generator

A coal gasifier, a new type of technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of waste of high-quality gasification raw material coal, incomplete combustion of coal, low utilization rate of gasification coal, etc., and achieve the low safety evaluation level standard , Simple structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

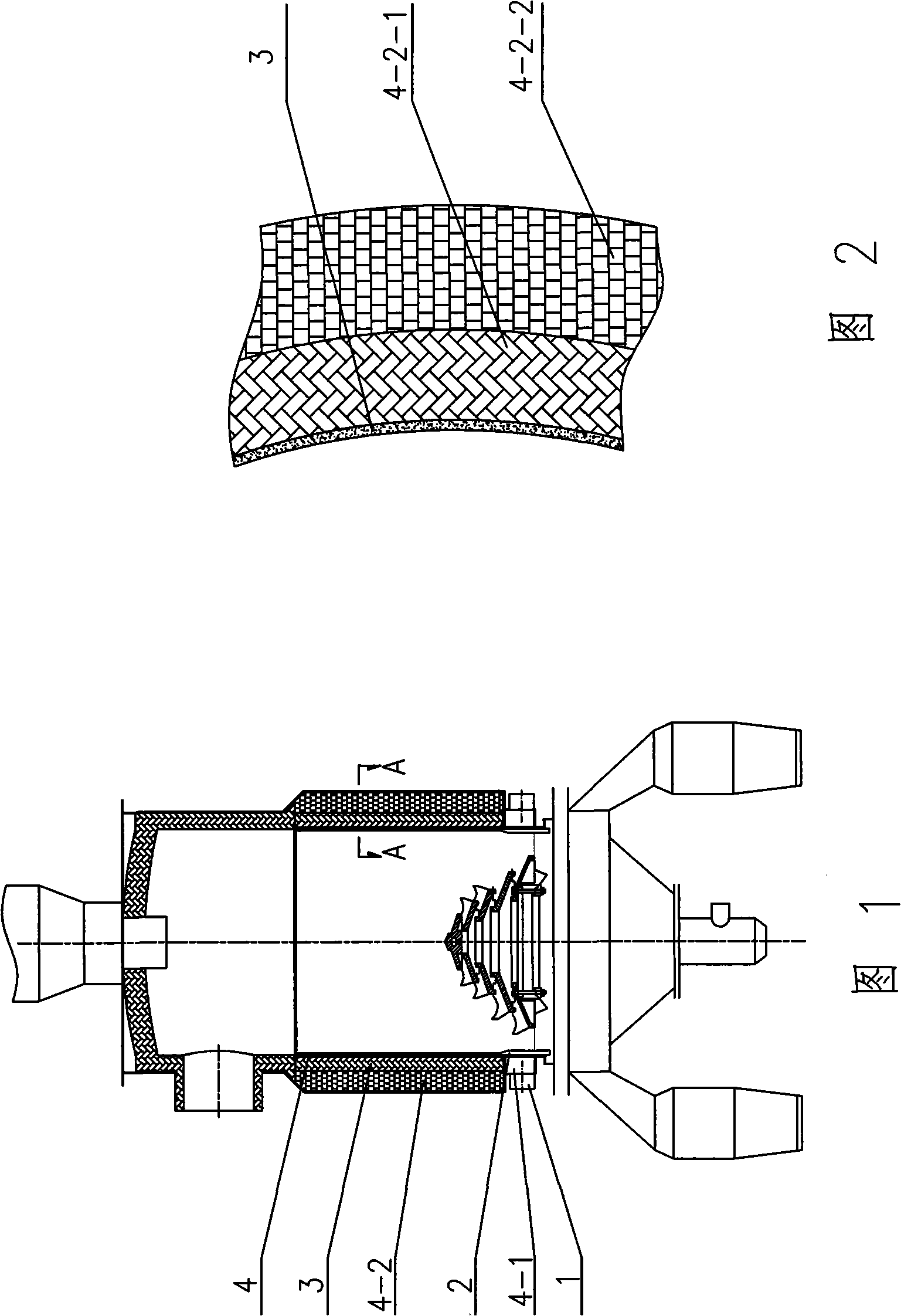

[0008] Embodiment 1: According to Fig. 1, shown in Fig. 2, among the figure 4 is a furnace body, the middle section 4-2 of the furnace body 4, the furnace wall is made of high temperature resistant, heat-insulating non-metallic material bricks, and there is no water jacket , the inner side of the furnace wall is sprayed with high-temperature resistant and wear-resistant ceramic sheets 3; the lower section 4-1 of the furnace body is a metal annular cylinder with an annular steam channel inside, and the slag strip 2 is welded on the lower section 4-1 of the furnace body. On the inner side of the cylinder body, there are water vapor passage holes on the inner side wall of the annular cylinder body, and an air inlet pipe joint 1 is arranged on the outer side wall.

Embodiment 2

[0009] Embodiment 2: according to embodiment 1, the inboard of wherein said furnace wall is spray-coated with high temperature resistant, wear-resistant paint layer 3.

Embodiment 3

[0010] Embodiment 3: According to Embodiment 1 or Embodiment 2, in order to ensure that the furnace body has sufficient supporting strength and excellent heat insulation performance, the furnace wall of the middle section 4-2 of the furnace body is divided into two layers, and the inner The layer 4-2-1 is a high-strength high-temperature-resistant, heat-insulating non-metal material brick, and the outer layer 4-2-2 is a high-temperature-resistant, heat-insulating non-metal material brick with high heat insulation performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com