Gasifying agent strongly-rotating pulverized coal gasifying device and gasifying method

A technology of gasification device and gasification agent, which is applied in the field of coal gasification, and can solve problems such as burning of the inner wall of the gasifier, uneven slag hanging on the wall of the gasifier, corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

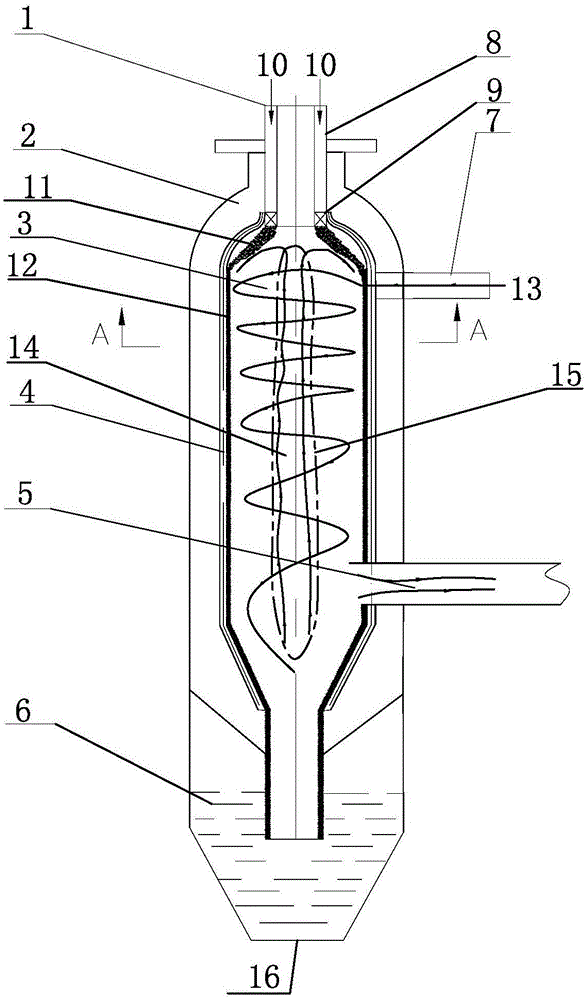

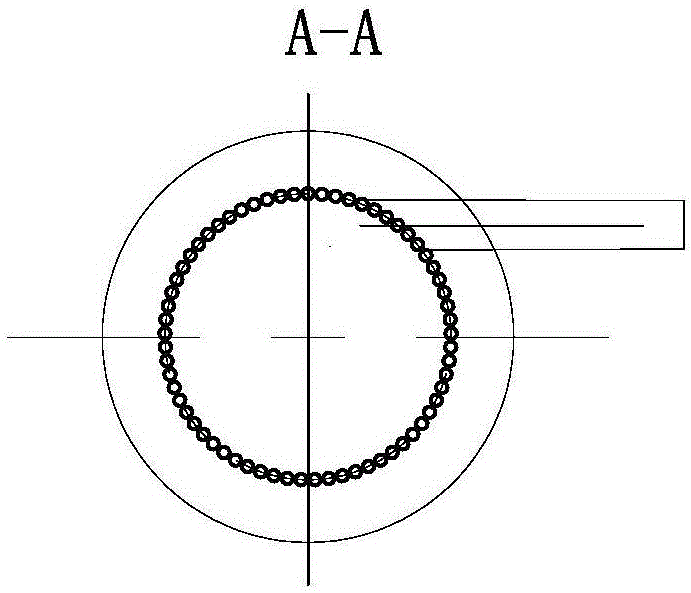

[0022] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment mode, a gasification agent strong rotary pulverized coal gasification device described in this embodiment includes a pulverized coal burner 1, a gasification furnace body 2, a water wall 4, a syngas channel 5 and a gasification agent nozzle 7, the gasification agent The gasification furnace body 2 is composed of a hemisphere and a cylinder. The water-cooled wall 4 is installed in the gasification furnace body 2. The water-cooled wall 4 is composed of a plurality of vertical circular tubes. The water-cooled wall 4 encloses a rotary gasification furnace 3. The bottom of the gasification furnace body 2 is provided with a slag pool 6, the syngas channel 5 is inserted in the lower part of the gasification furnace body 2, the gasification agent nozzle 7 is arranged on the upper part of the gasification furnace body 2, and the gasification agent nozzle 7 is arranged along the The tangen...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 with figure 2 To illustrate this embodiment, a swirl vane 9 is provided at the fire inlet end of a pulverized coal channel 8 of a gasification agent strong rotary pulverized coal gasification device in this embodiment. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 with figure 2 Describe this embodiment, this embodiment is the specific steps of described a kind of strong rotary pulverized coal gasification method of gasification agent as follows:

[0025] Step 1. Set the internal pressure of the gasification furnace 3 to 0.1-4 MPa, and the operating temperature of the gasification furnace 3 to be 1250-1600°C;

[0026] Step 2. The dry coal powder at a temperature of 25-100°C is carried by nitrogen or carbon dioxide and sent into the furnace 3 through the coal powder channel 8 on the coal powder burner 1 in a swirling flow, and the volume fraction of the coal powder is 1%. ~25%, forming a rotating and downward pulverized coal flow in the furnace top area;

[0027] Step 3: After the pulverized coal airflow comes into contact with the high-temperature synthesis gas entrained in the central recirculation zone, it is ignited by it, and burns at the top of the furnace 3 to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com