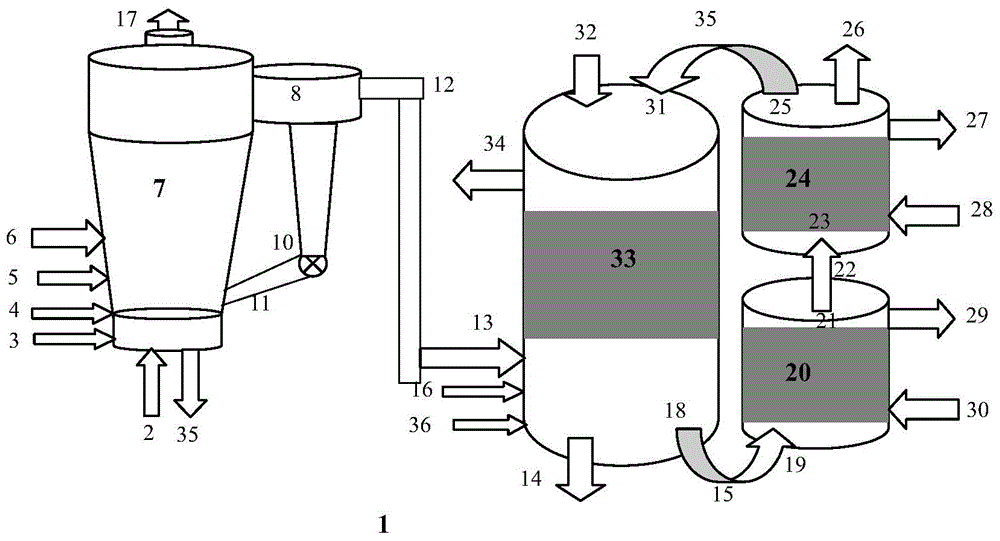

Process for preparing hydrogen from deoiled asphalt employing combustion gasification and CO2 in-situ adsorption-enhanced water-gas shift reaction in in-furnace calcium-spraying circulating fluidized bed

A circulating fluidized bed and water-vapor shift technology, applied in hydrogen, chemical recovery, inorganic chemistry, etc., can solve problems such as low conversion rate and inability to produce hydrogen from solid raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] According to the mass ratio of heavy oil residue primary feed and secondary feed of 1:6, the air used in the circulating fluidized bed is 1:1.2 according to the ratio of the number of oxygen moles in the air to the carbon moles in the primary feed of heavy oil residue, and the water vapor used According to the ratio of the moles of water vapor to the carbon moles in the heavy oil residue secondary feed is 5:1, the amount of limestone desulfurizer is 6% according to the mass ratio of its Ca content to the heavy oil residue secondary feed, the gasification agent The water vapor enters the circulating fluidized bed furnace at an angle of 25 degrees downwards and injects it into the nozzle to burn and gasify the heavy oil residue in the circulating fluidized bed, and the generated synthesis gas enters the water vapor shift reactor. Carbon, water vapor and nitrogen in the molar ratio C / H 2 O / N 2 It is 1.78 / 5.35 / 20.8, sent into the water vapor shift reactor, wherein the flow...

Embodiment 2

[0025] According to the mass ratio of heavy oil residue primary feed and secondary feed of 1:8, the air used in the circulating fluidized bed is 1:1.1 according to the ratio of the number of oxygen moles in the air to the carbon moles in the primary feed of heavy oil residue, and the water vapor used According to the ratio of moles of water vapor to carbon moles in the secondary feed of heavy oil residue is 6:1, the amount of limestone desulfurizer is 10% according to the mass ratio of its Ca content to the secondary feed of heavy oil residue, gasification agent The water vapor enters the circulating fluidized bed furnace at an angle of 30 degrees downwards and injects the nozzle to carry out the circulating fluidized bed combustion and gasification of the heavy oil residue, and the generated synthesis gas enters the water vapor shift reactor. Carbon, water vapor and nitrogen in the molar ratio C / H 2 O / N 2 It is 1.78 / 5.35 / 20.8, sent into the water vapor shift reactor, wherein...

Embodiment 3

[0027]According to the mass ratio of heavy oil residue primary feed and secondary feed of 1:7, the air used in the circulating fluidized bed is 1:1.2 according to the ratio of the number of oxygen moles in the air to the carbon moles in the primary feed of heavy oil residue, and the water vapor used According to the ratio of moles of water vapor to carbon moles in the secondary feed of heavy oil residue is 5:1, the amount of limestone desulfurizer is 8% according to the mass ratio of its Ca content to the secondary feed of heavy oil residue, gasification agent The water vapor enters the circulating fluidized bed furnace at an angle of 28 degrees downward and injects into the nozzle to burn and gasify the heavy oil residue in the circulating fluidized bed, and the generated synthesis gas enters the water vapor shift reactor. Carbon, water vapor and nitrogen in the molar ratio C / H 2 O / N 2 It is 1.78 / 5.35 / 20.8, sent to the water vapor shift reactor, wherein the flow rate of nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com